Abstract

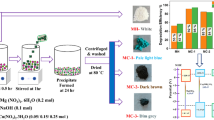

Cu2ZnSnS4 QDs (5–7 nm) were synthesized by chemical coprecipitation route. Using prepared Cu2ZnSnS4 QDs, a new type of BiOCl–Cu2ZnSnS4 heterostructures were prepared using bismuth nitrate as a precurssor and potassium chloride as a source of chlorine at 100 °C, 4 h. BiOCl–Cu2ZnSnS4 heterostructures were analyzed by XRD, TEM, UV–visible NIR, PL and surface area studies. The diffracted peaks of BiOCl–Cu2ZnSnS4 heterostructure show the presence of tetragonal BiOCl and did not show the intense peaks of Cu2ZnSnS4 QDs. TEM images of BiOCl–Cu2ZnSnS4 showed the deposition of Cu2ZnSnS4 QDs on the BiOCl microsphere surface. The surface area of BiOCl, Cu2ZnSnS4 and BiOCl–Cu2ZnSnS4-1 was of 1.91 m2/g, 3.06 m2/g and 13.39 m2/g, respectively. BiOCl–Cu2ZnSnS4-1 had a higher photodegradation rate for Congo red dye than BiOCl and Cu2ZnSnS4 QDs under sunlight, and that higher photoactivity was due to the heterostructure effect between BiOCl and Cu2ZnSnS4 QDs along with increased optical absorption in the visible region. Scavenger study endorses the involvement of superoxide and holes radicals in the degradation of Congo red.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Semiconductor photocatalysis is a useful, low-cost and environmentally benign technique for solving environmental pollution problems. The scientific community is focused on a very challenging and relevant research’s direction, for the synthesis of a better photocatalyst for hydrogen production, environmental pollution and many more. Bismuth oxychloride (BiOCl) is one of the good adsorbents and photocatalyst for the elimination of organic pollutants such as dyes, phenols, bacteria as it possesses a high chemical stability (Li et al. 2017). The good photocatalytic activity is attributed to layered structure consisting of alternate arrangement of [Bi2O2]2+ monolayer and dual Cl layers (Ao et al. 2016). BiOCl had better photodegradation performance than commercial TiO2 (P25) under UV light irradiation. However, due to its large band gap (3.17–3.54 eV) decreases BiOCl photoactivity (Liu et al. 2016). Thus, it is necessary to overcome these limitations and it can be performed by forming heterostructured composites through coupling of BiOCl with another semiconductor having narrow band gap. The designed BiOCl heterostructured composite will possess better visible light response and also facilitate the separation of photoinduced electron–hole pairs due to synergistic effect which eventually provides excellent photodegradation of contaminants.

Copper zinc tin sulfide (Cu2ZnSnS4) is a quaternary semiconducting compound of stannite structure. Cu2ZnSnS4 is an abundant, non-toxic component in the earth crust. The absorption coefficient of Cu2ZnSnS4 is 104 cm−1. Its band gap is about 1.4–1.7 eV (Malerba et al. 2014). Cu2ZnSnS4 has shown to be an excellent light energy-harvesting material for solar cells and good chemical stability in the photodegradation of organics (Arbouz et al. 2017; Hou et al. 2014; Barpuzary et al. 2015).

BiOCl-based constructed heterostructures revealed the enhanced photocatalytic activity, for example, BiOCl–La2Ti2O7 (Ao et al. 2016), Bi2S3–BiOCl (Xu et al. 2017), CdS–BiOCl (Pan et al. 2018), BiOCl–ZnFe2O4 (Sun et al. 2018), AgCl–BiOCl (Cheng et al. 2014), BiVO4–BiOCl (He et al. 2014), Co3O4–BiOCl (Tana et al. 2014), BiOCl–TiO2 (Li et al. 2016), Bi3O4Br/BiOCl (Gao et al. 2010), BiOCl/C3N4 (Huang et al. 2017), α-Fe2O3/BiOCl (Zheng et al. 2018), BiOCl–Ag3PO4 (Cao et al. 2013), BiOCl–Ag2CO3 (Fang et al. 2016), Ag-modified BiOCl (Yu et al. 2017), BiOCl–SnO2 (Sun et al. 2015), Bi2MoO6–BiOCl (Zuo et al. 2015), CdS/BiOCl (Lin et al. 2017), BiOCl–Ag8SnS6 (Shambharkar and Chowdhury 2018). This inspires us to fabricate a novel BiOCl–Cu2ZnSnS4 heterostructure with the hope of boosting visible light absorption capacity for better photocatalytic activity than their single component.

In the present study, chemical coprecipitation method was employed for synthesizing Cu2ZnSnS4QDs (5–7 nm). The prepared Cu2ZnSnS4 QDs were used for constructing BiOCl–Cu2ZnSnS4 heterostructure through deposition of Cu2ZnSnS4 particles on the surface of BiOCl with the help of coprecipitation method. BiOCl–Cu2ZnSnS4 heterostructure can extend the response of visible light and separate the photogenerated excitons very effectively and also increases the amount of reactive oxidative species under sunlight. As result, BiOCl–Cu2ZnSnS4 heterostructure had a better photocatalytic performance than bare BiOCl and Cu2ZnSnS4 QDs. Till date, no study has been conducted on the synthesis of BiOCl–Cu2ZnSnS4 heterostructured nanocomposites and evaluated its photocatalytic performance in the degradation of Congo red.

Experimental procedure

Materials

Cu(NO3)2·3H2O, ethylene glycol, Bi(NO3)3.5H2O were procured from Fisher Scientific Ltd. ZnCl2, SnCl2·2H2O, thiourea, potassium chloride were purchased from Merck. Congo red dye was procured from SRL. Distilled water was used to carry out the experiments.

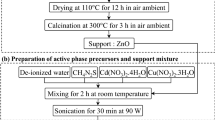

Production of Cu2ZnSnS4 QDs, BiOCl and BiOCl–Cu2ZnSnS4 heterostructures

Cu2ZnSnS4 QDs were prepared by chemical coprecipitation (Shambharkar and Chowdhury 2018; Shambharkar and Chowdhury 2016). 0.1 M Cu(NO3)3, (0.05 M) ZnCl2, (0.05 M) SnCl2 solutions were taken in a round-bottomed flask, and 50 ml of ethylene glycol (EG) and 10 g of thiourea were added into it and then heated it at 160 °C, 6 h. The black precipitate of Cu2ZnSnS4 QDs was acquired and washed with methanol to remove EG and dried.

At the initial stage of reaction, Sn2+, Cu+, Zn2+ ions combine with EG to form Sn–EG, Cu–EG, Zn–EG. When thiourea was added into the reaction system, Sn2+, Cu+ and Zn2+ ions form complex with thiourea and yielded Sn–thiourea, Cu–thiourea and Zn–thiourea complexes. These complexes undergo thermal decomposition at 160 °C to produce EG-capped Cu2ZnSnS4 QDs. The possible reactions occurred during the preparation of Cu2ZnSnS4 QDs were as follows:

BiOCl–Cu2ZnSnS4-1 heterostructured nanocomposite was obtained from coprecipitation method. 100 mg of Cu2ZnSnS4 QDs was mixed with bismuth nitrate solution (0.01 M), 20 ml of EG, and 1 g of KCl. The reaction mixture was stirred and heated at 100 °C, 4 h. Gray color precipitate of BiOCl–Cu2ZnSnS4 was formed. Subsequently, the final product was washed to remove EG with methanol and dried at 80 °C. Similar procedure was followed for preparing BiOCl–Cu2ZnSnS4-2 using 150 mg of Cu2ZnSnS4 QDs. BiOCl microspheres were obtained from our published procedure (Shambharkar and Chowdhury 2018).

Characterization techniques

Crystallinity and purity of Cu2ZnSnS4 QDs, BiOCl and BiOCl–Cu2ZnSnS4 were determined by conducting X-ray diffraction (XRD) on Bruker AXS D8 ADVANCE X-ray diffractometer. Transmission electron microscope was performed on JEOL Model JEM-2100 to assess the morphology of samples. Band gap energy was obtained from UV–visible diffuse reflectance spectra (Varian, Cary 5000 UV–Vis NIR spectrophotometer). Surface area of the samples was determined from N2 adsorption–desorption isotherms (Micromeritics ASAP 2020), and photoluminescence (PL) spectra were recorded by JY Fluorolog-3-11 fluorescence spectrofluorimeter with Xenon Lamp (450 W) as excitation source with excitation wavelength 310 nm.

Photocatalytic activity of BiOCl, Cu2ZnSnS4 QDs and BiOCl–Cu2ZnSnS4 was evaluated by conducting degradation studies using Congo red dye (20 mg/l) under direct sunlight irradiation. BiOCl–Cu2ZnSnS4 powder (100 mg) was added in 80 ml of Congo red solution and agitated in the dark to ensure adsorption–desorption equilibrium before light irradiation. A solution of 5 ml from the mixture was taken out after irradiation time was over and centrifuged. Absorbance the dye was measured at λmax = 497 nm on Cary 100 Bio UV–Vis spectrophotometer. The similar technique was accepted for BiOCl and Cu2ZnSnS4 nanoparticles, and the photodegradation performance of samples was studied.

Results and discussion

XRD, TEM, UV–visible NIR, PL and BET studies

XRD pattern of BiOCl, Cu2ZnSnS4 QDs and BiOCl–Cu2ZnSnS4 is shown in Fig. 1a–c. The diffracted peaks of the synthesized Cu2ZnSnS4 QDs were matched with JCPDS file 00-026-0575 (Kesterite, syn) with crystal system tetragonal. The crystallite size of Cu2ZnSnS4QDs was obtained from Debye Scherrer formula, D = 0.99λ/β cos θ, where β is full width at half maximum of the diffracted peak, λ is the X-ray wavelength and θ is the angle of diffraction and it was found to be 7 nm. BiOCl–Cu2ZnSnS4 heterostructure displayed the typical BiOCl signals (JCPDS file 01-085-0861). Characteristic peaks of Cu2ZnSnS4 QDs were not seen in the pattern of BiOCl–Cu2ZnSnS4 which may be due to low content of Cu2ZnSnS4 QDs in the composite (Fig. 1c). The surface morphology and the interaction of Cu2ZnSnS4 QDs with BiOCl were studied from TEM (Fig. 2a–f). From Fig. 2e–f, it was seen that Cu2ZnSnS4 nanoparticles (5–7 nm) were deposited on BiOCl microsphere surface to form interface linking between BiOCl and Cu2ZnSnS4 QDs. The EDX data (Fig. 3) of BiOCl–Cu2ZnSnS4 revealed the presence of elements O, S, Cl, Cu, Zn, Sn and Bi and were distributed homogenously in the composite.

UV–Vis NIR absorption spectra of BiOCl, Cu2ZnSnS4QDs and BiOCl–Cu2ZnSnS4 are shown in Fig. 4. Cu2ZnSnS4 QDs absorbed UV–visible light up to near infrared region, while UV radiation was absorbed by BiOCl and BiOCl–Cu2ZnSnS4 composites exhibited a mixed absorption (Fig. 4b). The band gap energy (Eg) for BiOCl microspheres, Cu2ZnSnS4 QDs and BiOCl–Cu2ZnSnS4 was obtained from Tauc equation (Xiao et al. 2018), and the plots are shown in Fig. 5a–d. The obtained Eg value of BiOCl microspheres was closed to 3.46 eV (Zang et al. 2006). The Eg value was decreased on loading of Cu2ZnSnS4 QDs in composites (Table 1) which may be aroused from synergistic effect between Cu2ZnSnS4 QDs and BiOCl in lowering the band gap.

To study the charge recombination over BiOCl–Cu2ZnSnS4 heterostructures, PL responses were taken and the plots were presented in Fig. 6. At excitation wavelength of 310 nm, BiOCl shows PL intensity with emission peaks at 313 nm, 360 nm and 625 nm. The emission intensity was decreased on incorporating Cu2ZnSnS4 QDs in the BiOCl–Cu2ZnSnS4-1. This was occurred due to the isolation of electrons and holes by coupling BiOCl with Cu2ZnSnS4. On further addition of Cu2ZnSnS4 in BiOCl–Cu2ZnSnS4-2, the PL intensity was increased because of the recombination of isolated electrons and holes. Thus, our findings have shown that BiOCl–Cu2ZnSnS4-1 heterostructure exhibited the best e−–h+ pair separation.

N2 adsorption–desorption isotherms of Cu2ZnSnS4 QDs, BiOCl and BiOCl–Cu2ZnSnS4 were of type III (Fig. 7), and the surface area of BiOCl–Cu2ZnSnS4 was increased after adding Cu2ZnSnS4 QDs in composite (Table 1). The pore volume of BiOCl–Cu2ZnSnS4 was of 0.076 cm3/g.

Photocatalytic performance

After sunlight irradiation, absorbance spectra of Congo red dye solution in the presence of BiOCl microspheres, Cu2ZnSnS4 QDs and BiOCl–Cu2ZnSnS4 were measured (Fig. 8a–d). The Congo red molecules were degraded completely in the presence of BiOCl–Cu2ZnSnS4-1 photocatalyst, and the degradation efficiency was represented in Fig. 9a. BiOCl–Cu2ZnSnS4-1 showed higher photodegradation and degraded 94.9% of Congo red dye after 90 min of sunlight irradiation. The photodegradation rate constant of Congo red was higher for heterostructure than for bare BiOCl and Cu2ZnSnS4 QDs (Fig. 9c). The improved photocatalytic activity of BiOCl–Cu2ZnSnS4 was endorsed to the formation of heterostructure between BiOCl and Cu2ZnSnS4 QDs that improved separation and transport of photogenerated charge carriers. The degradation behavior of BiOCl–Cu2ZnSnS4 was compared with commercial P25 TiO2 and it was observed that the degradation efficiency of BiOCl–Cu2ZnSnS4 was lesser than that of P25 TiO2 towards Congo red (Shambharkar and Chowdhury 2018).

The band edge positions of BiOCl and Cu2ZnSnS4 (Zheng et al. 2018; Cao et al. 2013) were determined (Table 1). The χ value for Cu2ZnSnS4 QDs was calculated to be 5.29, and χ value for BiOCl was calculated to be 6.36 (Sun et al. 2015). The CB of Cu2ZnSnS4 QDs was higher than CB of BiOCl. Therefore, the photoinduced electrons from the conduction band of Cu2ZnSnS4 QDs were inserted to the conduction band of BiOCl. Meanwhile, the photogenerated holes on the valence band of BiOCl were moved to valence band of Cu2ZnSnS4. This process resulted in heterojunction at the interface of the two compounds (Fig. 10). The holes react with H2O and generate ·OH radicals. The electrons combine with O2 to yield active superoxide radical anion of oxygen and decomposed the Congo red dye on the catalyst surface. The degradation experiment was repeated using the BiOCl–Cu2ZnSnS4. BiOCl–Cu2ZnSnS4 heterostructure had retained its stability up to four cycles.

Various scavengers like isopropanol (Pr) for •OH radicals, ammonium oxalate (AO) for h+, 1,4-benzoquinone (BQ) for O ∙−2 radicals were mixed with Congo red solution containing BiOCl–Cu2ZnSnS4 compound, and the photocatalytic activity was executed. From Fig. 9b, it was observed that AO and BQ were inhibited the photodegradation reaction. Therefore, the possible reactions happened over BiOCl–Cu2ZnSnS4 heterostructure in the degradation of the dye were given below.

Conclusions

Facile coprecipitation method was employed for constructing a new BiOCl–Cu2ZnSnS4 heterostructure. BiOCl–Cu2ZnSnS4-1 heterostructured composite showed superior photocatalytic activity in the degradation of Congo red than single phase BiOCl and Cu2ZnSnS4 QDs in the presence of sunlight. The degradation of Congo red was achieved 94.9% in 90 min of sunlight irradiation. The photoactivity of BiOCl–Cu2ZnSnS4-1 was due to the generation of heterostructure between BiOCl and Cu2ZnSnS4, which separates the photoexcited electron–hole pairs in the interface of BiOCl and Cu2ZnSnS4 on absorption of visible light radiation. The recombination of e− and h+ in BiOCl was removed by constructing BiOCl–Cu2ZnSnS4 heterostructure. The created BiOCl–Cu2ZnSnS4 heterostructure can be used as a promising photocatalyst for environmental cleanup.

References

Ao Y, Wang K, Wang P, Wang C, Hou J (2016) Fabrication of p-type BiOCl/n-type La2Ti2O7 facet coupling heterostructure with enhanced photocatalytic performance. RSC Adv 6:48599

Arbouz H, Aissat A, Vilco JP (2017) Simulation and optimization of CdS-n/Cu2ZnSnS4 structure for solar cell applications. Int J Hydrog Energy 42:8827–8832

Barpuzary D, Banik A, Gogoi G, Qureshi M (2015) Noble metal-free counter electrode utilizing Cu2ZnSnS4 loaded with MoS2 for efficient solar cells based on ZnO nanowires cosensitized with CuInS2–CdSe quantum dots. Mater Chem A3:14378–14388

Cao B, Dong P, Cao S, Wang Y (2013) BiOCl/Ag3PO4 composites with highly enhanced ultraviolet and visible light photocatalytic performances. J Am Ceram Soc 96:544–548

Cheng J, Wang C, Cui Y, Sun Y, Zuo Y, Wang T (2014) Large improvement of visible-light-driven photocatalytic property in AgCl nanoparticles modified black BiOCl microsphere. Mater Lett 127:28–31

Fang S, Ding C, Liang Q, Li Z, Xu S, Peng Y, Lu D (2016) In-situ precipitation synthesis of novel BiOCl/Ag2CO3 hybrids with highly efficient visible-light-driven photocatalytic activity. J Alloys Compd 684:230–236

Gao B, Chakraborty AK, Yang JM, Lee W (2010) Visible-light photocatalytic activity of BiOCl/Bi3O4Cl nanocomposites. Bull Korean Chem Soc 31:1941–1944

He Z, Shi Y, Gao C, Wen L, Chen J, Song S (2014) BiOCl/BiVO4 p–n heterojunction with enhanced photocatalytic activity under visible-light irradiation. J Phys Chem C 118:389–398

Hou X, Li Y, Yan J-J, Wang C-W (2014) Highly efficient photocatalysis of p-type Cu2ZnSnS4 under visible-light illumination. Mater Res Bull 60:628–633

Huang Y, Kang S, Gong W, Fang Y, Qin H, Liu S, Yang S, Li X (2017) BiOCl nanoplates decorated on g-C3N4 for enhanced photocatalytic activities. Int J Electrochem Sci 12:4351–4359

Li W, Tian Y, Li H, Zhao C, Zhang B, Zhang H, Geng W, Zhang Q (2016) Novel BiOCl/TiO2 hierarchical composites: synthesis, characterization and application on photocatalysis. Appl Catal A 516:81–89

Li K, Liang Y, Yang J, Gao Q, Zhu Y, Liu S, Xu R, Wu X (2017) Controllable synthesis of 001 facet dependent four square BiOCl nanosheets: a high efficiency photocatalyst for degradation of methyl orange. J Alloys Compd 695:238–249

Lin W, Yu X, Shen Y, Chen H, Zhu Y, Zhang Y, Meng H (2017) Carbon dots/BiOCl films with enhanced visible light photocatalytic performance. J Nanopart Res 56:1–11

Liu X, Su Y, Zhao Q, Du C, Liu Z (2016) Constructing Bi24O31Cl10/BiOCl heterojunction via a simple thermal annealing route for achieving enhanced photocatalytic activity and selectivity. Sci Rep, Sci. https://doi.org/10.1038/srep28689

Malerba C, Biccari F, Ricardo CLA, Valentini M, Chierchia R, Müller M, Santoni A, Esposito E, Mangiapane P, Scardi P, Mittiga A (2014) CZTS stoichiometry effects on the band gap energy. J Alloy Compd 582:528–534

Pan J, Liu J, Zuo S, Khan UA, Yu Y, Li B (2018) Synthesis of cuboid BiOCl nanosheets coupled with CdS quantum dots by region-selective deposition process with enhanced photocatalytic activity. Mater Lett 103:216–224

Shambharkar BH, Chowdhury AP (2016) Ethylene glycol mediated synthesis of Ag8SnS6 nanopartilces and their explotation in the degradation of eosin yellow and brilliant green. RSC Adv 6:10513–10519

Shambharkar BH, Chowdhury AP (2018) BiOCl–Ag8SnS6 heterostructure: facile preparation and photocatalytic applications. J Environ Chem Eng 6:2085–2094

Sun M, Zhao Q, Du C, Liu Z (2015) Enhanced visible light photocatalytic activity in BiOCl/SnO2: heterojunction of two wide band-gap semiconductors. RSC Adv 5:22740–22752

Sun Y, Shao C, Li X, Guo X, Zhou X, Li X, Liu Y (2018) Hierarchical heterostructures of p-type bismuth oxychloride nanosheets on n-type zinc ferrite electrospun nanofibers with enhanced visible-light photocatalytic activities and magnetic separation properties. J Colloid Interface Sci 516:110–120

Tana C, Zhua G, Hojamberdiev M, Okada K, Lianga J, Luo X, Liu P, Liu Y (2014) Co3O4 nanoparticles-loaded BiOCl nanoplates with the dominant 001 facets: efficient photodegradation of organic dyes under visible light. Appl Catal B Environ 152–153:425–436

Xiao P, Lou J, Zhang H, Song W, Wu X-L, Lin H, Chen J, Liu S, Wang X (2018) Enhanced visible-light-driven photocatalysis from WS2 quantum dots coupled to BiOCl nanosheets: synergistic effect and mechanism insight. Catal Sci Technol 8:201–209

Xu J-J, Yang J-W, Zhang P, Yuan Q, Zhu Y-H, Wang Y, Wu M-M, Wang Z-M, Chen M-D (2017) Preparation of 2D square-like Bi2S3–BiOCl heterostructures with enhanced visible light-driven photocatalytic performance for dye pollutant degradation. Water Sci Eng 10:334–339

Yu H, Cao C, Wang X, Yu J (2017) Ag-modified BiOCl single-crystal nanosheets: the dependence of photocatalytic performance on the region-selective deposition of Ag nanoparticles. J Phys Chem C 121:13191–13201

Zang K-L, Liu C-M, Huang F-Q, Zheng C, Wang W-D (2006) Study of the electronic structure and photocatalytic activity of the BiOCl photocatalyst. Appl Catal B 68:125–129

Zheng Y, Zhang X, Zhao J, Yang P (2018) Assembled fabrication of α-Fe2O3/BiOCl heterojunctions with enhanced photocatalytic performance. Appl Surf Sci 430:585–594

Zuo Y, Wang C, Sun Y, Cheng J (2015) Preparation and photocatalytic properties of BiOCl/Bi2MoO6 composite photocatalyst. Mater Lett 139:149–152

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Chowdhury, A.P., Shambharkar, B.H. Synthesis and characterization of BiOCl–Cu2ZnSnS4 heterostructure with enhanced photocatalytic activity. Appl Water Sci 8, 202 (2018). https://doi.org/10.1007/s13201-018-0853-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-018-0853-0