Abstract

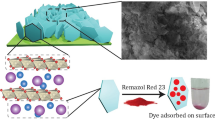

The paper presents the removal of Acid Green 1 (AG1) from aqueous solutions by [Zn–Al–Cl]-layered double hydroxides (LDHs). The LDH was prepared by coprecipitation at constant pH. The affinity of this material for AG1 was studied as a function of contact time, pH of the solution, LDH dose and AG1/LDH mass ratio. It was found that 32 h are enough to reach the equilibrium with a maximum retention at pH 8 for an LDH dose of 100 mg and with an AG1/LDH mass ratio higher than 2. The adsorption isotherm is of L-type, as described by the Langmuir model. The results demonstrate that AG1 retention on LDHs occurs by adsorption on external surface when AG1/LDH mass ratio is equal or lower than 2 and by both adsorption and interlayer ion exchange for ratios higher than 2. A mechanism for the AG1 removal has been confirmed by X-ray diffraction, Fourier transform infrared spectroscopy, thermogravimetric–differential thermal analyses and scanning electron microscopy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Freshwater resources are under threat due to activities from expanding population and increasing rate of overuse. The presence of effluents from industrial, agricultural and domestic sources is responsible for water pollution and harms the environment (Tan et al. 2007). The reduction of pollution by implementing environment-friendly technologies is currently a very high priority. Synthetic dyes are amongst these harming effluents and are used in many industries, including textile, leather tanning, printing, and food processing (Batzias and Sidiras 2007). These coloured contaminants are difficult to eliminate from water because of their high stability, poor biodegradability and the difficulty in treating them with conventional methods.

The textile and clothing industries use large amounts of water-soluble synthetic organic dyes in their processes. These colouring agents are sometimes very stable, even when exposed to light and heat, and some were found to be toxic to microorganisms. In addition, their presence in aquatic systems reduces light penetration and thus retards photosynthesis (Sumari et al. 2009).

The global import and export market for dispersed dyes and their preparations accounted for 570,000 metric tons in 2011 (Ghaly et al. 2014). The amounts of water have been estimated at 0.08–0.15 m3 per kg of fabrics depending on the type to be produced (Moustafa 2008). Since the dyeing process is not very efficient, large concentrations of dyestuffs are discharged in textile effluents. These were estimated at 15% worldwide (El Gaini et al. 2009).

The treatment of effluents from textile industries is usually carried out by physico-chemical techniques, such as flocculation, coagulation, advanced oxidation and ozonation, and biological methods to remove organic matters, nitrogen, phosphorus and metals. The traditional biological and chemical methods have proven to be inefficient given the low biodegradable nature of most of the dyes (Tabak et al. 2009; Fu and Viraraghavan 2001). Therefore, the removal of dyes by environment-friendly and economic technologies is currently high priority for the scientific community.

Adsorption has been found to be promising due to the ease in adsorbent management and the possibility of their recycling as well as the water purification outcome. Several studies have been conducted to evaluate various natural and synthetic sorbents, among which are activated carbons and clays (Javadian et al. 2014; Forgacs et al. 2004; Aydin and Yavuz 2004; Ayad and El-Nasr 2012).

Layered double hydroxides (LDHs) have proven to be good candidates for removing anionic dyes from aqueous solutions. These materials, which are endowed with high anionic exchange capacity and good adsorptive ability, have been able to retain and host several large organic anions (Lakraimi et al. 2000; Li et al. 2005) including dyestuffs (Dos Santos et al. 2013; Elkhattabi et al. 2013; Guo et al. 2013; Pereira et al. 2013; Alexandrica et al. 2015).

LDHs, also called hydrotalcite-like compounds and anionic clays, are based on the brucite, Mg(OH)2, layers with partial substitution of trivalent for divalent cations. The net positive charge is then balanced by exchangeable hydrated anions (Rives 2001). They are commonly represented by the general formula:

where MII and MIII are divalent and trivalent cations, An− is the interlayer anion and x the MII/(MII + MIII) ratio.

These materials offer a large spectrum of application opportunities because of their stability and their anion exchange properties, allowing for their intercalation and desintercalation. The importance of LDH compounds led to a very rich literature and several books and review articles have been devoted to their structure, properties and applications (Rives 2001; Evans and Slade 2006; Braterman et al. 2004; Duan and Evans 2006).

Metal complex dyes, like AG1, constitute a category of dyes used in several industries, including textile dyeing, leather finishing, inks, colouring for wood, metals and plastic. Their removal from industrial wastewaters has been given a lot of importance because of their toxicity and carcinogenic nature as well as their harm to the ecosystems (Hunger 2003). However, only a limited number of studies have been reported in the literature on this very important issue (Rizk and Hamed 2014).

The work presented in this paper focuses on the preparation and characterization of [Zn–Al–Cl]-LDHs and their evaluation as scavengers of AG1 dye from aqueous solutions. The aim is to understand the mechanism of interaction between adsorbent and adsorbate for an eventual use of the system to remove such organic pollutant from textile effluents.

Materials and methods

Adsorbent preparation and characterization

All experiments were carried out under a stream of N2 to avoid, or at least minimize contamination by atmospheric CO2. The [Zn–Al–Cl]-LDH, with a [Zn]/[Al] ratio of 2, was synthesized by coprecipitation at a constant pH of 9.0 and at room temperature. Mixtures of molar ZnCl2 (97% Loba Chemie) and AlCl3 (99% Loba Chemie) aqueous solutions were slowly introduced into the reactor at constant pH, maintained by simultaneous addition of a 0.1 M NaOH (98% Loba Chemie) solution. The resulting slurry was then stirred for 72 h at room temperature. It was then filtered, washed several times with decarbonated water and dried at room temperature (25 °C).

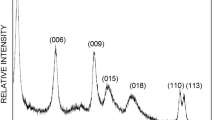

The material obtained is a pure LDH, as characterized by X-ray diffraction (XRD) (Fig. 1) (Miyata.1975) It consists of a well-crystallized single phase with large constituting crystallites. The experimental metal ratios and the lattice parameters, refined on the R‾3m space group, are given in Table 1.

Adsorbate

Acid Green 1 (DyStar Product-DA 40120) was used in its commercial form used in the textile industry. Some of its important properties are given in Table 2. A stock solution was prepared by dissolving 100 mg of AG1 in 1 L decarbonated water and was diluted in decarbonated water as needed. The maximum absorption wavelength of the dye was determined to be λmax = 650 nm, using an SP-3000 Plus UV/Vis spectrophotometer in the 200–800 nm range. The calibration curve was controlled on a weekly basis to check the stability of the stock solution.

Retention experiments

Retention experiments were carried out by the batch equilibrium technique at room temperature (25 °C), constant pH, maintained by addition of NaOH, and under a stream of N2. Amounts of [Zn–Al–Cl] were dispersed in 100 mL AG1 solutions. The initial concentration of AG1 was varied between 0.05 and 1 g L−1. After filtration, the solid products obtained were dried at room temperature. The quantity of AG1 retained by the LDH (Q) was calculated as the difference between initial and equilibrium concentrations of the dye (Ci and C, respectively) by mass of the adsorbent (m) in the volume of solution (V):

Analytical techniques

The XRD equipment used was a Siemens D 501 diffractometer. Samples of unoriented powder were exposed to copper Kα radiation (λ = 0.15415 nm). Measurement conditions were 2 h range, 5°–70°, step size: 0.08° 2θ, and step counting time: 4 s. Data acquisition was effected on a DACO-MP microcomputer. Unit cell constants were calculated using a least squares refinement.

Absorbance IR spectra were recorded on a Perkin-Elmer 16 PC spectrophotometer, at a resolution of 2 cm−1 and averaging over 100 scans, in the range 400–4000 cm−1. Samples were pressed into KBr discs.

TG and DTG studies were performed in air with a Setaram TG–DSC 92 instrument. Curves were recorded on 12 mg of the sample over a temperature range of up to 1200 °C at a heating rate of 5 °C min−1. The weights were corrected for the small effect of the gas flow as a function of temperature.

Scanning electron microscopy (SEM) analysis of the LDH surface was performed using a Philips device. The observations are carried out at a voltage of 5 kV.

Results and discussion

Preliminary adsorption experiments were conducted to determine the optimal conditions for the retention of AG1 on LDHs regarding the pH value, contact time (tc), initial adsorbate concentration (Ci) and the adsorbate/adsorbent mass ratio.

Effect of pH

Generally, pH is considered to be an important parameter that controls the retention at water–adsorbent interfaces (mLDH = 100 mg, Ci = 0.8 g L−1 and tc = 48 h). The retention of AG1 by [Zn–Al–Cl] was studied at different pH values ranging from 5 to 10 (Fig. 2). It is shown that the AG1 retention is at its maximum in the pH value around 8. The low retention observed at lower pH values (< 7) may be attributed to a partial dissolution of the basic mineral matrix by acidic hydrolysis, which becomes more pronounced when the pH decreases (El Gaini et al. 2008b; Elkhattabi et al. 2013). The low adsorption observed at pH 9 may be explained by a competition with the carbonate ions for which the LDH is known to have a great affinity.

The calibration of the medium (LDH + AG1) at relatively basic pH was carried out in air and is, therefore, susceptible to be contaminated by atmospheric CO2 (Legrouri et al. 2005). This phenomenon takes place despite the precautions taken during the preparation of the solid sample and the kinetics study at high pH values. Following these experiments, it was decided to carry out the retention experiments at pH 8.

Effect of contact time

The amount of AG1 retained by [Zn–Al–Cl] as a function of solid–solution contact time, using an adsorbent mass of 100 mg with adsorbate initial concentrations between 50 and 200 mg L−1, is shown in Fig. 3. The kinetic study shows that the retention equilibrium is reached after a contact time of 32 h for the highest concentration. This residence time was applied for the following retention experiments. A similar behaviour was obtained for other adsorbate with LDH materials (Elkhattabi et al. 2013; Legrouri et al. 2005; El Gaini et al. 2008a).

Kinetic models

Several models can be used to express the mechanism of solute adsorption onto an adsorbent. To design a fast and effective model, investigations were made on adsorption rates. Several kinetic models are used to test the experimental data for the examination of the controlling mechanisms of the adsorption process, such as chemical reaction, diffusion control and mass transfer. In this study, three kinetics models, namely the pseudo-first order, the pseudo-second order and the intra-particle diffusion were used to fit the experimental data from the adsorption of AG1 dye onto the LDH at pH 8 and initial dye concentrations of 50, 100 and 200 mg L−1.

Pseudo-first-order and pseudo-second-order models

Figure 4 presents the plots for the two models. For the pseudo-first-order model, a linear equation is obtained as follows:

where qe (mg g−1) and qt (mg g−1) are the sorption capacities at equilibrium and at time t, respectively, and k1 (min−1) is the rate constant.

The pseudo-second-order model is presented by the following equation:

where k2 is the pseudo-second-order rate constant of adsorption (g mg−1 min−1).

The analysis of the results reported in Table 3 shows that the AG1 retention kinetics by the LDH is in good agreement with the model of the pseudo-second order because the maximum amounts of experimental and theoretical adsorption data for the pseudo-first-order model are totally different. The experimental patterns are comparable with those of the pseudo-second order and the corresponding correlation coefficients are close to 1. The same result was obtained in a previous work (Elkhattabi et al. 2013).

Intra-particle diffusion model

To investigate the contribution of intra-particle behaviour on the adsorption process, the rate constant for intra-particle diffusion can be calculated from the following equation (Kang et al. 2013):

where kip is the intra-particle diffusion rate constant (mg g−1) and C is the vertical axis intercept. If the plot of Qt against t1/2 were linear, the adsorption process was deemed to have been determined by the intra-particle diffusion step.

Indeed, in this work, these lines correspond to the existence of the external diffusion process (external surface adsorption), followed by intra-particle diffusion and finally to a slow diffusion of the adsorbate to the micropores of the adsorbent (Yang et al. 2012).

The intra-particle diffusion model of AG1 adsorption onto LDH is shown in Fig. 5. For low concentrations (50 and 100 mg L−1), it can be said that the diffusion mechanism of the adsorption system is described by two distinct regions instead of a single linear over the whole domain, which shows that the process has more than one step.

On the other hand, for the high concentration (200 mg L−1), it is noted that the diffusion mechanism of the adsorption system is described by three distinct regions. The intermediate step is evident.

For the intra-particle diffusion, most curves show three linearities (Ofomaja 2010):

-

Area I: adsorption on the surface.

-

Area II: intra-particle diffusion (intercalation between the layers of the LDH phase).

-

Area III: saturation (steady state).

The constants for intra-particle diffusion are listed in Table 4.

Adsorption isotherms

Figure 6 displays the retention isotherms of AG1 onto 30, 50 and 75 mg of LDH. Several models, such as Freundlich, Elovich, and Dubinin–Radushkevich, were tried on our data but only the Langmuir model gave good results. Therefore, the isotherms were fitted by Langmuir equation and can clearly be considered as pure L-type. They indicate that the interaction sorbate–sorbent is much stronger than solvent–sorbent at the adsorption sites. Isotherms with this profile are typical of systems where the functional adsorbate is strongly attracted by the adsorbent, mostly by ion–ion interaction, which tends to reach a saturation value given by a nearly isotherm plateau. These results again suggest that AG1 anions are preferentially removed.

As may be seen, the AG1 retention is inversely proportional to the mass of LDH. The Qm value increases when the LDH mass decreases; this is somehow normal if we know that the retention of AG1 by the LDH can be done, in addition to adsorption, also by intercalation between the layers. This intercalation requires an increasing molar ratio (AG1/LDH) and, therefore, relatively small mass of LDH to allow maximum exchange of the chloride ions by the AG1 ions.

The data for the uptake of AG1 have been processed in accordance with the linear form of Langmuir isotherm equation:

where Q is the quantity of AG1 retained by the unit mass of LDH (mg g−1), Qm the maximum quantity of AG1 retained by the unit mass of LDH (mg g−1), Ce the equilibrium concentration of AG1 (mg L−1) and K is the affinity constant of AG1 for LDH (L mg−1).

A linear relationship was observed among the plotted parameters (Fig. 7), which indicates the applicability of the Langmuir’s equation. The sorption parameters obtained are summarized in Table 5.

This linearization was used to standardize the method of determining the maximum quantity Qm, which decreases when the mass of LDH is increased.

Effect of mass ratio AG1/LDH

The XRD of the solids obtained by ion exchange of chloride by AG1 corresponds to that of a hydrotalcite-type material. Figure 8 shows the XRD patterns for [Zn–Al–AG1]-LDHs prepared with different mass ratio AG1/LDH.

The layered structure of the material is preserved after intercalation. However, the crystallinity is lowered, as attested by the broadening of the lines and the decrease in their intensity. In addition, intercalation is observed to cause a displacement of the (003) line, denoting an increase in the interlayer space which is due to the exchange of the chloride by the larger AG1 ions. Furthermore, the adsorption on the surface does not affect this distance for low concentrations of the dye. By contrast, for relatively high concentrations, increased interlayer distance means that there is an exchange between chloride ions and the anions of AG1, which are larger and accompanied by the maximum occupancy of the available anionic sites.

The cell parameters for the best compound, in terms of crystallinity, were a = 0.306 nm, c = 2.934 nm and the interlayer distance d = 0.978 nm. The study of the effect of mass ratio AG1/LDH indicates the existence of two phases, in terms of crystallinity, for mAG1/mLDH = 2 (Fig. 8). The presence of the line at d = 0.778 nm indicates that the exchange is only partial in this case. In addition, the interlayer distance varies slightly with the mass ratio AG1/LDH.

The observation shows that the maximum AG1 removed decreases when the mass of LDH is increased, which may seem strange but can be considered as normal with regard to the ion-exchange ability of the LDH. In fact, the ion exchange was observed to be requiring a high mass ratio (mAG1/mLDH ≥ 2) and consequently a relatively low mass of the LDH allows for better ion exchange. It seems that this value corresponds to the optimum concentration of AG1 that is required to displace the chloride ions from within the LDH interlayer space. For mass ratios AG1/[Zn–Al–Cl] < 2 (Fig. 8), the interlayer distance remains equal to that of the initial matrix which means that retention is only done by adsorption to the surface. In contrast, when this ratio is higher than two, XRD patterns present another line at low 2θ values. This line corresponds to a distance of 0.978 nm, which proves the presence of a second phase intercalated by AG1 ions that are larger than chloride (d = 0.778 nm). This means that the increase in the concentration of AG1 and, therefore, the mass ratio (AG1/LDH) facilitates the exchange reactions with a large amount of chloride ions by the anions of dye.

Under these conditions, we can conclude that the elimination of the dye occurred according to two different processes:

-

AG1/[Zn–Al–Cl] < 2: retention by adsorption on the surface.

-

AG1/[Zn–Al–Cl] ≥ 2: both adsorption and intercalation between the layers.

The retention of AG1 by the LDH attained 100% for a mass ratio equal to 0.66 (485.4 mg g−1). This value is very good compared to results obtained by other researchers on the adsorption of some dyes by different materials (Table 6). This confirms the choice of LDH materials for the removal of such pollutants from water.

Infrared spectroscopy

The IR spectra of the phases, obtained following AG1–LDH interaction, are characteristic of LDH phases (Fig. 9). They are different from that of the parent material [Zn–Al–Cl] and present the bands reflecting the retention of AG1. The broad adsorption band around 3400 cm−1 is due to the stretching of O–H groups of the hydroxide layer and interlayer water. In the low-frequency region, the bands at 809, 601 and 451 cm−1 are ascribed to the lattice vibration modes attributed to the vibrations associated with the bonding of Zn and Al metals with oxygen—M–O and M–O–M (Hernandez-Moreno et al. 1985; Thorpe and Solin 1995; Legrouri et al. 2005). The asymmetric stretching vibration ν(SO32−) appears in the 1255 cm−1. The absorption band at 1500 cm−1 is assigned to the stretching vibration of C=C in an aromatic ring. The band at 1180 cm−1 is assigned to the bending vibration C–H out of the benzene’s cycle. Those at 1640, 1300 and 1188 cm−1 correspond to the C=O, C–O and C–N vibrations, respectively (Pouchert 1975; Pavia et al.1996).

TG and DTG analyses

TG and DTG curves obtained for pure AG1, [Zn–Al–AG1] and [Zn–Al–Cl] are reported in Fig. 10. The thermogram of [Zn–Al–AG1] is different from that of [Zn–Al–Cl], which confirms the retention of AG1. The thermal evolution under air takes place in six consecutive stages with weight losses for which the inflexion points coincide with temperatures corresponding to minima and maxima in the DTG trace. The first weight loss which begins as soon as heating is applied with a first effect at 85 °C is attributed to the loss of adsorbed water molecules. The second weight loss at 200 °C is assigned to the interlayer water. The third weight loss around 300 °C is attributed to the dehydroxylation of the brucite-like layers. This destruction takes place at the same temperature as that for the starting matrix [Zn–Al–Cl] (264 °C). This can be explained by the thickness of the interlayer gallery, d = 0.978 nm, which predicts an orientation for AG1 anions are parallel to sheets with a low rate of hydration. These three first stages are similar to those previously reported for hydrotalcite-like materials (Labajos and Rives 1996).

For the rest, there is a relative stabilization of the decomposition of the dye with a sharp variation of different weight percentages for each decomposition stage. It is noted that the different fragments from the encapsulated AG1 decompose at greater temperatures than those from free AG1. The LDH stabilizes AG1 and delays the combustion of adsorbed and intercalated molecules. In addition, the last loss takes place in two steps when the dye is intercalated between the layers. It probably corresponds to the elimination of a fragment, which contains sulphur in the form of SO2 because of its slow diffusion in the oxide matrix (Lakraimi et al. 2006).

The rest of the decomposition, which represents more than 30% of the total mass of [Zn–Al–AG1], leads to the formation of mixed oxides, ZnO, ZnAl2O4, Fe3O4 and Fe2O3, as shown in Fig. 11.

The thermal analyses confirm the retention of AG1 by the LDH via adsorption and intercalation, in agreement with the results obtained by the other characterization techniques [XDR and Fourier transform infrared spectroscopy (FTIR)].

Scanning electron microscopy

The SEM observation of the parent and the AG1-intercalated materials shows aggregates of crystallites formed perpendicular to the image plane (Fig. 12). The crystals present almost the same morphological features. They tend to result from the superposition of several leaflets with dimensions of the particles being about 2 μm for [Zn–Al–Cl] and lower than 2 μm for [Zn–Al–AG1]. The small morphological alteration of the layers, after exchange, can be due to the decrease in crystallinity observed by XRD in the samples.

Structural model

Before proposing an orientation of the AG1 anion between the layers, we determined the value of the length of the molecule AG1 by molecular orbital semi-empirical method with the Gaussian 03 software, the calculated value for a horizontal position is 0.22 nm. Figure 13 shows the orientation of AG1 dye intercalated between LDH sheets.

The interlayer distance determined experimentally, 0.978 nm, suggests a horizontal direction (parallel to the planes of the layers) of the anion in the interlayer space:

The adoption of a horizontal orientation for simple or large organic molecules has been proposed by other authors for porphyrins (d = 1.17 nm) (Bonnet et al. 1998), oxalates (d = 0.778 nm), aluminium oxalates (d = 0.99 nm) and hydroxyl terephthalates (d = 1.08 nm) (Prevot 1999).

Conclusions

The research activity focused on the removal of the textile dye AG1 by [Zn–Al–Cl]-LDHs from aqueous solutions. The LDH was prepared by coprecipitation and characterized by several physico-chemical techniques. Its retention of AG1 was observed to be important and occurs during the first hours of interaction. The equilibrium was reached after 2 h of contact and corresponds to an almost complete AG1 elimination for low concentrations.

The influence of various experimental parameters was studied to better understand and improve the retention process. These have resulted in the following satisfactory results:

-

A high AG1/LDH proportion leads to an improved retention performance.

-

The pH of the solution influences the ability of the LDH for the dye retention, with an optimal value of pH 8.

-

Several models, such as Freundlich, Elovich, and Dubinin–Radushkevich, were tried on our experimental data but our adsorption isotherms could only be described by the Langmuir equation.

-

The retention of the dye is due to adsorption for low AG1 concentrations. Both adsorption and intercalation in the interlayer space were observed for high concentrations.

-

The Cl–AG1 exchange is proven by an increase in the interlayer space observed by XRD and the presence of AG1 functional groups in IR spectra and thermograms.

-

Thermal analyses of the phase obtained after retention indicates that the LDH plays a stabilizing role and combustion retardant for AG1. The final product is a mixture of oxides that may be used as catalysts.

References

Alexandrica MC, Silion M, Hritcu D, Popa MI (2015) Layered double hydroxides as adsorbents for anionic dye removal from aqueous solutions. Environ Eng Manag J 14:381–388

Ayad MM, El-Nasr AA (2012) Anionic dye (acid green 25) adsorption from water by using polyaniline nanotubes salt/silica composite. J Nanostruct Chem 3:1–9

Aydin AH, Yavuz O (2004) Removal of acid red 183 from aqueous solution using clay and activated carbon. Ind J Chem Technol 11:89–94

Batzias FA, Sidiras DK (2007) Dye adsorption by prehydrolysed beech sawdust in batch and fixed-bed systems. Bioresour Technol 98:1208–1217

Bonnet S, Forano C, Besse JP (1998) Intercalation of tetracyanoquinodimethane in [Zn–Al] layered double hydroxide. Mater Res Bull 33:783–788

Boumchita S, Lahrichi A, Benjelloun Y, Lairini S, Nenov V, Zerrouq F (2016) Elimination d’un colorant cationique d’une solution aqueuse par un déchet alimentaire: epluchure de pomme de terre. J Mater Environ Sci 7(1):73–84

Braterman PS, Xu ZP, Yarberry F (2004) Chemistry of layered double hydroxides. In: Auerbach SM, Carrado KA, Dutta PK (eds) Handbook of layered materials. Marcel Dekker, New York

Dos Santos RMM, Gonçalves RGL, Constantino VRL, Da Costa LM, Da Silva LHM, Tronto J, Pinto FG (2013) Removal of Acid Green 68:1 from aqueous solutions by calcined and uncalcined layered double hydroxides. Appl Clay Sci 80–81:189–195

Duan X, Evans DG (eds) (2006) Layered double hydroxides. Springer, Berlin

El Gaini L, Lakraimi M, Sebbar E, Bakasse M (2008a) Removal of the methyl orange dye from water to zinc-aluminium-chloride layered double hydroxides. J Optoelectron Adv Mater 10:1415–1420

El Gaini L, Sebbar E, Boughaleb Y, Bakasse M, Lakraimi M, Meghea A (2008b) Removal of the herbicide 2,4-dichlorophenoxyacetate from water to calcined layered double hydroxides. Nonlinear Opt Quantum Opt 38(2):191–204

El Gaini L, Lakraimi M, Sebbar E, Meghea A, Bakasse M (2009) Removal of indigo carmine dye from water to Mg–Al–CO3-calcined layered double hydroxides. J Hazard Mater 161:627–632

Elkhattabi E, Lakraimi M, Badreddine M, Legrouri A, Cherkaoui O, Berraho M (2013) Removal of Remazol Blue 19 from wastewater by zinc-aluminium- chloride-layered double hydroxides. Appl Water Sci 3:431–438

Evans DG, Slade RCT (2006) Structural aspects of layered double hydroxides. Struct Bond 119:1–87

Forgacs E, Tibor C, Gyula O (2004) Removal of synthetic dyes from wastewaters. Environ Int 30:953–971

Fu Y, Viraraghavan T (2001) Fungal decolorization of dye wastewaters: a review. Bioresour Technol 79(3):251–262

Ghaly AE, Ananthashankar R, Alhattab M, Ramakrishnan VV (2014) Production, characterization and treatment of textile effluents: a critical review. J Chem Eng Process Technol 5:1–19

Guo Y, Zhu Z, Qiu Y, Zhao J (2013) Enhanced adsorption of acid brown 14 dye on calcined Mg–Fe layered double hydroxide with memory effect. Chem Eng J 219:69–77

Hernandez-Moreno MJ, Ulibarri MA, Rendon JL, Serna CJ (1985) IR characteristics of hydrotalcite-like compounds. Phys Chem Miner 12:34–38

Hunger K (2003) Industrial dyes-chemistry, properties, applications. VCH, New York

Javadian H, Angaji MT, Naushad M (2014) Synthesis and characterization of polyaniline/γ-alumina nanocomposite: a comparative study for the adsorption of three different anionic dyes. J Ind Eng Chem 20:3890–3900

Kang DJ, Yu XL, Tong SR, Ge MF, Zuo JC, Cao CY, Song WG (2013) Performance and mechanism of Mg/Fe layered double hydroxides for fluoride and arsenate removal from aqueous solution. Chem Eng J 228:731–740

Kefif F, Ezziane K, Sellami M, Labbaci A, Bettahar N (2011) Synthèse par coprécipitation et caractérisation des HDL [Cu–Al–CO3], [Co–Al–CO3]. Application dans la sorption d’un colorant industriel. Séminaire Eau et Environnement (SEE 2011), Chlef

Labajos FM, Rives V (1996) Thermal evolution of Cr(III) ions in hydrotalcite-like compounds. Inorg Chem 35:5313–5318

Lakraimi M, Legrouri A, Barroug A, De Roy A, Besse JP (2000) Preparation of a new stable hybrid material by chloride-2,4-dichlorophenoxyacetate ion exchange into the zinc-aluminium-chloride layered double hydroxide. J Mater Chem 10:1007–1011

Lakraimi M, Legrouri A, Barroug A, De Roy A, Besse JP (2006) Synthesis and characterization of a new stable organo-mineral hybrid nanomaterial: 4-chlorobenzenesulfonate in the zinc-aluminium layered double hydroxide. Mater Res Bull 41:1763–1774

Legrouri A, Lakraimi M, Barroug A, De Roy A, Besse JP (2005) Removal of herbicide 2,4-dichlorophenoxyacetate from water to zinc-aluminium-chloride layered double hydroxides. Water Res 39:3441–3448

Li F, Wang Y, Yang Q, Evans DG, Forano C, Duan X (2005) Study on adsorption of glyphosate (N-phosphonomethyl glycine) pesticide on Mg-Al-layered double hydroxides in aqueous solution. J Hazard Mater B 125:89–95

Mafra MR, Igarashi LM, Zuim D, Vasques EC, Ferreira MA (2013) Adsorption of remazol brilliant blue on an orange peel adsorbent. Braz J Chem Eng 30(3):657–665

Mahjoubi FZ, Khalidi A, Abdennouri A, Barka N (2016) Zn–Al layered double hydroxides intercalated with carbonate, nitrate, chloride and sulphate ions: Synthesis, characterisation and dye removal properties. J Taibah Univ Sci. http://www.sciencedirect.com/science/article/pii/S1658365515001533

Miyah Y, Lahrichi A, Idrissi M (2016) Removal of cationic dye –Methylene bleu– from aqueous solution by adsorption onto corn cob powder calcined. J Mater Environ Sci 7(1):96–104

Miyata S (1975) The syntheses of hydrotalcite-like compounds and their structures and physico-chemical properties: I. The systems Mg2+–Al3+–NO3 −, Mg2+–Al3+–Cl−, Mg2+–Al3+–ClO4 −, Ni2+–Al3+–Cl− and Zn2+–Al3+–Cl−. Clays Clay Miner 23:369–381

Moustafa S (2008) Environmental impacts of textile industries. Process analysis of textile manufacturing. UNESCO-IHE, Delft

Ofomaja AE (2010) Biosorption studies of Cu(II) onto Mansonia sawdust: process design to minimize biosorbent dose and contact time. React Funct Polym 70:879–889

Parimalam R, Raj V, Sivakumar P (2012) Removal of Acid Green 25 from aqueous solution by adsorption. E-J Chem 9(4):1683–1698

Pavia DL, Lampman GM, Kriz GS (1996) Introduction to spectroscopy Harcourt Brace. College Publisher, Orlando

Pereira de Sa F, Cunha BN, Nunes LM (2013) Effect of pH on the adsorption of Sunset Yellow FCF food dye into a layered double hydroxide (CaAl-LDHNO3). Chem Eng J 215–216:122–127

Pouchert CJ (1975) The Aldrich library of infrared spectra, 2nd edn. Aldrich Chemical Co, Milwaukee

Prevot V (1999) Etude d’hydroxydes doubles lamellaires Description de l’interfeuillet et réactions de greffage, Doctorat d’Université. Université Blaise Pascal, Clermont Ferrand

Rahmat NA, Ali AA, Hussain NS, Muhamad MS, Kristanti RA, Hadibarata T (2016) Removal of Remazol Brilliant Blue R from aqueous solution by adsorption using pineapple leaf powder and lime peel powder. Water Air Soil Pollut 227:105

Rives V (2001) Layered double hydroxides: present and future. Nova Science, New York

Rizk SE, Hamed MM (2014) Batch sorption of iron complex dye, naphthol green B, from wastewater on charcoal, kaolinite, and tafla. Desalination Water Treat, 1–11

Saravanan P, Sivakumar P, Geoprincy G, Nagendra Gandhi N (2012) Renganathan S, Biosorption of acid green 1 using dried Rhodoturula Glutinis biomass. Indian J Environ Protection 32:207–214

Sumari SM, Yasin Y, Hamzah Z (2009) Adsorption of anionic amido blank dye by layered double hydroxides ZnAlCO3-LDH. Malays J Anal Sci 13:120–128

Tabak A, Eren E, Afsin B (2009) Determination of adsorptive properties of a Turkish Sepiolite or removal of Reactive Blue 15 anionic dye from aqueous solutions. J Hazard Mater 161(2–3):1087–1094

Tan IAW, Hameed BH, Ahmed AL (2007) Equilibrium and kinetic studies on basic dye adsorption by oil palm fiber activated carbon. Chem Eng J 127:111–119

Thorpe MF, Solin SA (1995) Layer rigidity in intercalation compounds. In: Pinnavaia TJ, Thorpe MF (eds) Access in nanoporous materials. Plenum, New York, pp 59–72

Yang YQ, Gao NY, Chu WH, Zhang YJ, Ma Y (2012) Adsorption of perchlorate from aqueous solution by the calcination product of Mg/(Al–Fe) hydrotalcite-like compounds. J Hazard Mater 209–210:318–325

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Elkhattabi, E., Lakraimi, M., Berraho, M. et al. Acid Green 1 removal from wastewater by layered double hydroxides. Appl Water Sci 8, 45 (2018). https://doi.org/10.1007/s13201-018-0658-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-018-0658-1