Abstract

Heavy metals are usually released into water bodies from industrial/domestic effluents such as metal plating industries, mining and tanneries. Adsorption is a fundamental process in the physiochemical treatment of wastewaters because of its low cost. Great efforts have been made to use the economically efficient and unconventional adsorbents to adsorb heavy metals from aqueous solutions, such as plant wastes and agricultural waste. Biochar mixed with chitosan after crosslinking can be casted into membranes, beads and solutions which can be effectively utilized as an adsorbent for metal ion uptake. Keeping these facts into consideration, the present study was undertaken with the objective to determine the effect of various proportions of biochar-modified chitosan membranes on the sorption characteristics of different heavy metals like Cu, Pb, As and Cd along with comparison of sorption characteristics between industrial waste water samples containing multi-metals and standard synthetic stock solution containing a particular metal. It is apparent from the results that the bioadsorbent prepared from biochar and chitosan are low-cost efficacious resource due to its easy availability. It is also eco-friendly material for making adsorbent for abstraction of heavy metals from aqueous solution. This adsorbent can be best utilized for adsorption of heavy metals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The pollution of surface and underground water has gradually increased and it is a worldwide concern for the last few decades due to disposal of wastes containing heavy metals. Heavy metals are usually released into water bodies from industrial/domestic effluents such as metal plating industries, mining and tanneries. Heavy metals from polluted water bodies can then diffuse into the surrounding soil, surface water and groundwater. When the polluted water is consumed by living organisms, the toxic heavy metals can accumulate and become harmful. The human health and ecological systems are threatened to get worse. Harmful heavy metals are abundant in the water bodies due to the rapid industrial development and wrong practices of agriculture, together with the pollution growth.

Water pollution has already rendered many ground water resources useless for humans and wildlife. It has been suggested that it is ecumenical the leading cause of deaths and diseases, and it accounts for the deaths of more than 14,000 people daily, while 580 people in India die due to water pollution-related illness every day (WHO 2006). Some of the common contaminants removal processes are chemical precipitation, ion exchange, adsorption, membrane filtration, electrochemical filtration, etc. Most of these processes are difficult to implement on large scale due to expensiveness and ineffectiveness at low concentration and production of toxic sludge and other waste products that also needs disposal. The disadvantages have increased the need of developing alternative and low-cost water treatment technologies for treatment of heavy metals. Among the cumbersomely heavy metal treatment technologies, adsorption is considered as simple, user friendly technique and efficient method. Adsorption is a fundamental process in the physiochemical treatment of wastewaters because of its low cost. Great efforts have been made to use the economically efficient and unconventional adsorbents to adsorb heavy metals from aqueous solutions, such as plant wastes and agricultural waste.

India produced 1.2 billion tons of potatoes in 2013–14 crop year (July–June), ranked 2nd after China, of which 50–60% was converted to daily potato products. The process to make these potato products generates 6–10% potato peel waste (PPW) depending on the final product, and this waste stream is a significant waste management issue. However, this waste is also a promising resource for large-scale production of biochar.

Biochar is pyrogenic black carbon derived from the pyrolysis of biomass, such as wood and grass under N2- or oxygen-limited conditions. Because of its special surface properties, biochar has been suggested to be a low-cost option for soil remediation and water treatment adsorbent. With the widespread production of carbohydrates, their utilization has been incremented to many times as compared to the utilization in the past decade.

Polysaccharides like chitosan, chitin, cellulose, xanthate, pectin, starch, amylase, dextrin and cyclodextrin are utilized for the membrane filtration of the toxic metal ions. Chitosan has free amino and hydroxyl sites which enhance chelating and crosslinking competency. Crosslinked chitosan retains the advantages of chitin and chitosan which include biocompatibility, antibacterial activity, nontoxicity, adsorptive capacity. New grafting materials like heparin, succinic anhydride, carboxy methyl, histidine, glutaraldehyde and epichlorohydrin are useful for modifying chitosan.

In view of this, the present study made an attempt to develop biochar-modified chitosan membranes for separation of Cu2+, Pb2+, As5+ and Cd2+. Biochar modified chitosan membrane networks were crosslinked with oxalic acid. A comparative account of Cu2+, Pb2+, As5+ and Cd2+ adsorption and efficiency of membranes have been carried out by considering different proportions of biochar and chitosan in membranes and then finally the results of all four have been compared.

Because of the solubility of chitosan in formic or acetic acid, it is suitable for the preparation of membrane. The chitosan membrane was first produced from a solution of chitosan in formic acid. The solution was poured on a glass plate and kept horizontally on the water bath, when the formic acid got completely evaporated, the glass plate was exposed to cold air so that the membrane could be easily abstracted from the glass plate. The chitosan membrane is resistant to alkaline solutions and many organic solvents have analyzed the structure of chitosan membranes which were chemically modified with aldehydes, such as glutaraldehyde and n-butyl aldehyde and their characteristics in terms of permeation and the separation of aqueous ethanol solutions. Lehmann et al. (2006) developed an application of chitosan membranes for the removal of heavy metal ions. The metal ions Cu(II), Cd(II), Co(II), Zn(II) and Ni(II) are virtually separated by the membranes while Cr(VI) and Mn(II) ions are separated depending on pH and process conditions.

In a study conducted by Radovic et al. (2000) reported that liquid industrial waste is a quandary in the management of industrial discharge; because the materials in it are often toxic in small quantities, accumulate in sediments and living organisms and can even be incorporated into natural and biological cycles. With regard categorically to the handling of wastes in the phase liquid that contain metal ions, techniques for treating wastewater are utilized according to the physicochemical characteristics, the type and the concentration of metal ions (Bansal et al. 1988). A study conducted by Zhou et al. (2013) on synthesized chitosan-modified biochar to produce a low-cost adsorbent for heavy metal remediation. The characterization results showed that the coating of chitosan on biochar surfaces could amend its performance as an adsorbent or as a soil amendment. The chitosan-modified biochars showed enhanced removal of three metals (i.e., Pb, Cu, and Cd) from the solution. Sorption of lead on chitosan-modified biochar also reduced its metal toxicity.

Wang et al. (2015a) conducted a study to compare the ability to sorb arsenic and lead by biochars made at different temperature (300, 450 and 600 °C). He investigated that both feedstock type and pyrolysis temperature affected biochars production rate (28–50%) and their ability to sorb the two metals in aqueous solutions with stock solutions made of sodium arsenate dibasic heptahydrate and lead nitrate. Another study being conducted by Wang et al. (2015b) demonstrated two modification methods to improve biochars ability to sorb As and Pb. In one, pine wood feedstock was pyrolyzed in the presence of MnCl2∙4H2O (MPB) and the other one was impregnated with birnessite via precipitation following pyrolysis (BPB). It was observed that As(V) and Pb(II) sorption capacities of MPB (0.59 and 4.91 g/kg) and BPB (0.91 and 47.05 g/kg) were higher than that of unmodified biochar (0.20 and 2.35 g/kg).

Reiad et al. (2012) conducted a study and prepared micro porous chitosan (CS) membranes by extraction of poly(ethylene glycol) (PEG) from CS/PEG blend membrane and examined it for iron and manganese ions abstraction from aqueous solutions. The affinity of CS/PEG blend membrane to adsorb Fe(II) ions has been reported to be higher than that of Mn(II) ions, with adsorption equilibrium achieved after 60 min. By increasing the CS/PEG ratio in the coalescence membrane the adsorption capacity of metal ions increased. It is also reported that pH has the most paramount effect on the adsorption capacity, concretely in the range of 2.9–5.9.

A study being carried out by Twu et al. (2003) and prepared the chitosan microspheres by spray-drying process with a spherical geometry and a smooth surface morphology. Deodorizing properties of these beads against trimethylamine (TMA) was investigated. He examined the metal ion sorption properties against Cu(II), Fe(III) and Ni(II) ions and inferred that the chitosan/cellulose blend beads have potential applications of odor treatment as well as metal ion adsorption. Similarly Liu and Bai (2006) reported that highly porous adsorptive hollow fiber membranes prepared from chitosan (CS) and cellulose acetate (CA) blend solutions has a good adsorption capacity (up to 35.3–48.2 mg/g), expeditious adsorption rates. Also at short adsorption equilibrium times (less than 20–70 min) for copper ions and can work efficaciously at low copper ion concentrations (<6.5 mg/L) to reduce the residual level to as low as 0.1–0.6 mg/L in the solution.

Cao et al. (2012) investigated the effect of biochar on soil nutrients. This has implicative situations both to the availability of nutrients to plants or microbes, as well as to the question of whether biochar soil amendment may enhance or reduce the leaching of nutrients. In his work, a range of laboratory experiments were conducted to determine the effect of biochar amendment on sorption and leaching of nitrate, ammonium, and phosphate in a sandy soil. The prepared biochar efficaciously reduced the total amount of nitrate, ammonium, and phosphate in the leachates by 34.0, 34.7, and 20.6%, respectively, relative to the soil alone.

Many such studies have been conducted to understand the various properties of Chitosan and Biochar. It has been found that crosslinking of Chitosan increases the chelating property. Biochar mixed with chitosan after crosslinking can be casted into membranes, beads and solutions which can be effectively utilized for metal ion uptake and various other industrial applications. Keeping these facts in consideration, the present study was undertaken with the objective to determine the effect of various proportions of biochar-modified chitosan membranes on the sorption characteristics of different heavy metals like Cu, Pb, As and Cd. Also, to compare the sorption characteristics in industrial waste water sample containing multi-metals.

Materials and methods

Methodology mainly includes preparation of bio-adsorbent from Biochar modified Chitosan, synthetic solutions of Copper, Lead, Arsenic and Cadmium and analysis of samples by Atomic Absorption Spectrophotometer. The chemicals and reagents used in the study were of analytical grade supplied by HIMEDIA Laboratories Pvt. Ltd. Industrial waste water sample was collected from a metal plating industry located in Gurugram, India. Potato peelings were collected and air dried for 24 h. Then after the peelings were oven dried for 2 h at 50 °C and then crushed. The crushed peelings were fed into the pyrolyzer and pyrolysis was conducted at 0.5 kg/h feed rate (K-Tron weight loss feeder) in an auger reactor (5 cm ϕ × 90 cm) at 450 °C with N2 purge (6 L/min) and the transfer tube set at 400 °C. The auger speed was adjusted to 1 rpm. Biochar was collected at the end of reactor. The resultant potato peeling waste biochar having 8.4% ash content, 75.1% of volatile matter, 16.5% of fixed carbon and had a calorific value of 19.2 MJ/kg (Fig. 1).

Each biodegradable biochar-modified chitosan membranes were prepared by solution casting technique and were crosslinked with 4 mL of oxalic acid solution. In a typical synthetic procedure, biochar and chitosan powder were added in ratios of 10:0, 9:1, 7:3, 5:5, 3:7, 1:9 and 0:10 to formulate a total 2 g amount to mix the same in 100 mL of 2% acetic acid. The polymer solution was prepared by mechanical stirring for 24 h and then poured on an immaculate glass plate. It was allowed to dry at room temperature for 48 h and then peeled off from the plate carefully. In total 5 films (i.e., blends of ratios 7:3, 5:5, 3:7, 1:9 and 0:10) were prepared and other 2 blends (i.e., blends of 10:0 and 9:1) were used in powdered form (Fig. 2).

The prepared biochar dose was being optimized by performing adsorption of heavy metals Cu, Pb, As and Cd. The synthetic stock solution of 20 mL of each metal was taken in separate conical flasks along with 0.05 g of prepared blend of biochar and chitosan of various proportions and was mixed thoroughly. The solutions were allowed to be adsorbed onto the membranes for 4 h and then the membranes were removed from the solutions.

The solutions were filtered through filter paper (Watman No. 22) to remove any suspended particles and the filtrate was taken for digestion. The clear filtrates were analyzed for heavy metal (Cu, Pb, As and Cd) concentration using Atomic Adsorption Spectrophotometer (AAS). Similarly Industrial wastewater sample was also analyzed on AAS, so as to obtain initial desired heavy metal concentration. Thereafter, 0.25 g of each biochar modified chitosan membranes were dipped in Industrial wastewater sample for 4 h and taken for heavy metal analysis. All the analysis was carried out as per the procedure prescribed by American Public Health Association (APHA 1998) Manual.

Heavy metals removal efficiency

The quantity of heavy metal that is adsorbed by the adsorbent has been calculated using the following equations (Eq. 1):

where E is the adsorption efficiency in terms of % removal of heavy metals, C 0 is the initial concentration of the metallic ion, C e is the final or equilibrium concentration of the metallic ion, in aqueous solution.

Adsorption isotherm

The two mostly accepted equations to determine the amount of heavy metals capacity of adsorption onto the adsorbent used in water and wastewater treatment are Langmuir and Freundlich isotherms. The capacity can be determined through the following mass balance equation (Eq. 2):

where Q e represents the adsorbent concentration after equilibrium (mg absorbent/g absorbent), V represents the total volume of the solute solution (L), C 0 represents the initial concentration of the solute (mg/L), C e is the residual equilibrium concentration of the solute after adsorption (mg/L), and M represents the weight of the adsorbent used (g).

Langmuir adsorption isotherm

Langmuir’s adsorption isotherm may be used for monolayer adsorption onto a surface containing a finite number of identical sites, and assumes uniform energies of adsorption on the surface, in addition to no transmigration of the adsorbate in the plane of the surface. The Langmuir isotherm model determines the maximum capacity of the adsorbent from complete monolayer coverage of the adsorbent surface. Langmuir’s isotherm non-linear equation is illustrated as below (Eq. 3):

where, Q e is the amount adsorbed (mg/g), C e is the equilibrium concentration of metal ion (mg/L), Q max is maximum amount of adsorbed metal ion/unit mass of adsorbent corresponding to complete coverage of the adsorption sites and b is the Langmuir constant (L/mg) which is adsorption equilibrium constant that relates to the energy of adsorption. Graph is plotted between \(\frac{1}{{Q_{\text{e}} }}\) vs \(\frac{1}{{C_{\text{e}} }}\).

Freundlich adsorption isotherm

Freundlich adsorption isotherm is used for heterogeneous surface energies and is commonly used to compare powder carbon in the treatment of water. The isotherm portrays that the ratio of the quantity of the solute adsorbed on a known mass of adsorbent to the concentration of the solute in the solution differs at different concentrations. The Freundlich equation is as follows (Eq. 4):

where C e is the equilibrium concentration of metal ion (mg/L), Q e is amount of metal ion/unit mass of the adsorbent (mg/g), K f is Freundlich constant (L/g) defining the adsorption coefficient that indicates the relative adsorption capacity of the adsorbent of the bonding energy, n is Freundlich equation exponential that represent quasi-Gaussian energetic heterogeneity of the adsorption surface. The values can be calculated by drawing the graph of log Q e v/s log C e where 1/n is the slope of the graph and K f is intercept of the graph.

Results and discussion

Heavy metals adsorption and adsorption capacity using chitosan-modified biochars in synthetic solutions and industrial wastewater

The adsorption studies were carried out using the chitosan-modified biochar membranes in synthetic stock solutions prepared to adsorb the desired heavy metals. The initial physical and chemical characteristics of industrial waste water and standard synthetic solution are given in Table 1. The concentration of remaining heavy metals has been assessed and the result for the same is summarized in Table 2. The B:C ratio indicates the blend being prepared using biochar and chitosan and has been varied from 10:0 to 0:10 in the present study. The remaining concentration of all the heavy metals is found to be maximum in case of B:C ratio of 10:0. However, the concentration of remaining heavy metals is found to be minimum at ratio of 3:7 in terms of Cu and Pb removal and at ratio of 5:5 in terms of As while at 7:3 in terms of Cd removal. The minimum values thus obtained indicating these blend ratios to be optimum in terms of heavy metals removal.

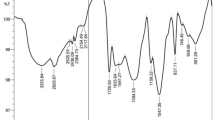

The adsorption capacity in terms of Q e has also been evaluated by determining the initial concentration of heavy metals before adsorption using chitosan-modified biochar membranes and the residual equilibrium concentration of the solute after adsorption. The results for the same is tabulated in Table 3. Perusal from the data summarized in Table 3 and Fig. 1 indicates that the adsorption capacity value of 1.15 and 1.646 mM/g is found to be maximum at B:C ration of 3:7 for Cu and Pb, respectively. The adsorption capacity maximum value of 0.832 mM/g has been observed for Asat B:C ratio of 7:3 while for Cd the maximum value of 0.263 mM/g has been observed at B:C ratio of 7:3 thus indicating the adsorption capacity to be highest. The adsorption capacity minimum values for all the heavy metals is observed at B:C ratio of 10:0 thus indicating the Biochar alone is not a good adsorbent (Fig. 3).

The adsorption studies using chitosan-modified biochar membranes were carried out for industrial wastewater samples. The initial and remaining concentration of heavy metals has been assessed and the result for the same is summarized in Table 3. The initial concentration of heavy metals Cu, Pb,As and Cd in industrial wastewater was found to be 88.26, 2.52, 15.47 and 0.149 mg/L, respectively. The B:C ratio indicates the blend being prepared using biochar:chitosan and has been varied from 10:0 to 0:10 in the present study. The adsorption process was carried out for of 4 h duration and thereafter the remaining concentration of all the heavy metals in all the samples was determined. The remaining concentration of 83.48, 2.12 and 0.144 mg/L is observed to be maximum at blend ratio of 10:0 in case of Cu, Pb and Cd, respectively.

In case of As the remaining concentration of 14.60 mg/L is observed to be maximum at blend ratio B:C ratio of 1:9. However, the remaining heavy metals concentration of 50.03 mg/L is found to be minimum at a blend ratio of 3:7 in case of Cu and 1.15 mg/L in case of Pb at a blend ratio of 5:5. In case of As, the minimum concentration is observed to be 12.16 mg/L at a blend ratio of 9:1 while for Cd the minimum concentration of 0.136 is observed at blend ratio of 3:7 and at 7:3.

However, no significant change has been observed in Cd concentration under different blend ratios. The minimum values thus obtained indicating these blend ratios to be optimum in terms of heavy metals removal. The adsorption capacity in terms of Q e has also been evaluated by determining the initial concentration of heavy metals before adsorption using chitosan-modified biochar membranes and the residual equilibrium concentration of the solute after adsorption. The adsorption study was carried out using industrial wastewater samples for 4 h duration and the results for the same are presented in Table 3.

Perusal from the data summarized in Table 3 and Fig. 4 indicate that the adsorption capacity value of 15.6 mg/g is found to be maximum for Cu at a blend of 3:7 and 0.548 mg/g for Pb at a blend ratio of 5:5. However, the adsorption capacity maximum value of 1.323 mg/g has been observed for As at blend ratio of 9:1 while for Cd the maximum value of 0.0052 mg/g has been observed at blend ratio of 7:3 and 3:7 thus indicating the adsorption capacity to be highest. The adsorption capacity minimum values of 1.912, 0.16 and 0.002 mg/g has been observed for Cu, Pb and Cd, respectively, at a blend ratio of 10:0 while for As the minimum value of 0.348 mg/g has been observed at blend ratio of 1:9.

Heavy metals removal from synthetic solution and Industrial Wastewater

The experimental study was being carried out using prepared chitosan and biochar membranes at different blend ratios in terms of heavy metals removal. The heavy metals removal efficiency has been determined in each set of experiments and the obtained results are summarized in Table 4. The variation in heavy metals removal efficiency using different types of blends under different conditions are shown through Figs. 5a, b and 6a–d. Perusal of the data summarized in Table 4 indicates that maximum removal efficiency of Cu is observed to be 57.5% for synthetic solution and 43.3% for industrial wastewater, respectively, at a blend ratio of 3:7.

The maximum removal efficiency for Pb is observed to be 82.32% for synthetic solution at a blend ratio of 3:7 and 54.3% for industrial wastewater, respectively, at a blend ratio of 5:5. However, in case of As maximum removal efficiency of 41.58% is assessed at a blend ratio of 3:7 for synthetic solution while in case of industrial waste water the removal efficiency of As is observed to be 54.3% at a blend ratio of 5:5. The maximum removal efficiency of Cd is found to be 13.16 and 8.56% for synthetic solution and industrial wastewater, respectively, at a blend ratio of 7:3.

Perusal of the data shown in Fig. 5a, b indicates that the Pb removal efficiency is observed to be highest in case of synthetic solution as well as in case of industrial wastewater also. However, no significant change in removal efficiency has been observed in Pb at a blend ratio of 5:5–0:10. The lowest removal efficiency of Cd is observed in both synthetic as well as industrial wastewater. In case of Cu the removal efficiency is observed to be increased sharply at a blend ratio of 5:5–0:10 in case of synthetic solution as well as industrial wastewater also.

The results obtained from present study on adsorption of heavy metals using chitosan–biochar membrane in synthetic solution and industrial wastewater is shown through Fig. 6a–d. The results indicate that maximum adsorption of Cu, Pb, As and Cd has taken place in case of synthetic solution as compared to industrial wastewater. The maximum adsorption of Cu, Pb has been observed at a blend ratio of 3:7, this is due to the chelation between metallic ions of Cu and Pb and amino groups of chitosan while in case of As and Cd the maximum adsorption is assessed at bend ratio of 7:3, this can be attributed from the fact that these metallic ions have high affinity towards biochar than amino group of chitosan.

Adsorption isotherms

Adsorption is customarily described through an isotherm. The adsorption isotherm designates how the adsorbed molecules distribute between the liquid phase and the solid phase when the adsorption process reaches an equilibrium state.

The coefficient of correlation (R 2 value) obtained denotes that Langmuir and Freundlich provided a better fit for adsorption of Pb on activated carbon. The values of both models obtained in this study are presented in Table 5. Langmuir parameters have been obtained from linear correlation between the values of 1/C e and 1/Q e and Freundlich values between log C e and log Q e. The data shown through Figs. 7a–d, 8a–d, 9a–d and 10a–d reveals that the adsorption equilibrium data for lead was in good acquiescent when calculated by both Freundlich and Langmuir models and it was fitted well in both models but best fit was observed in Langmuir’s model and it may be due to homogenous distribution of active sites on adsorbent surface. The applicability of the isotherm model was evaluated by the coefficient of correlation value (R 2).

Table 5 depicts the adsorption extent and degree of favorability of adsorption by Langmuir and Freundlich models. The Langmuir isotherm parameter Q max which quantifies monolayer adsorption capacity of the adsorbent and Freundlich isotherm adsorption coefficient, denotes the extent of adsorption, and were good measure of the adsorption capacity of activated carbon prepared at different temperatures.

For synthetic solutions, the adsorption isotherms for all chitosan-modified biochar membranes are summarized in Table 5. Among the tested synthetic solutions, Pb has the highest monolayer adsorption capacity (Q max), i.e., 0.7117 mM/g followed by As with 0.2562 mM/g followed by Cu with 0.2516 mM/g and low Q max value was obtained for Cd, i.e., 0.0114 mM/g besides this correlation coefficient (R 2) was 0.8835, 0.9820, 0.8979 and 0.9326 for Pb, As, Cu and Cd, respectively.

It is ostensible from these values that Pb sorption in synthetic solution is more propitious than others. The parameter of Freundlich equation depicting adsorption capacity as shown in Fig. 8a–d is found to be 5.6598, 4.2354, 3.4443 and 1.2965/g for As, Cu, Cd and Pb, respectively. The value is observed to be higher in case of As, whereby ‘n’ value designates poor sorption of 0.6077, 0.5608 and 0.0906 for Cu, As and Cd, respectively, as the value lies below 1. The ‘n’ value of Freundlich equation could correspond the favorability of sorption.

For industrial wastewater, the adsorption isotherms is shown though Figs. 9a–d and 10a–d for all chitosan-modified biochar membranes. Among all the industrial wastewater samples, Cuhas the highest monolayer adsorption capacity (Q max) of 1.1174 mg/g followed by Pb with a value of 0.0981 mg/g followed by As with a value of 0.0867 mg/g. The lowest Q max value of 0.0002 mg/g was obtained for Cd. However, the correlation coefficient (R 2) value has been obtained as 0.7827, 0.8716, 0.8868 and 0.9648 for Cu, Pb, As, and Cd, respectively. It is ostensible from these values that Cu sorption in synthetic solution is more propitious than others.

The parameters of Freundlich equation depicting adsorption capacity as observed from the obtained results are 0.5061/g, 0.2738/g, 0.1516/g and 0.0773/g for Pb, Cu, As, and Cd, respectively. The highest value of 0.5061/g is observed for Pb whereby ‘n’ value designates very good sorption of all heavy metals as the value lies above 1.

Conclusion

Result from present study indicates that the maximum removal percentage and adsorption capacity in terms of Q e has been found for Cu in synthetic solution as well as in industrial waste water sample. The data fitted well in Langmuir in case of synthetic solution and also fitted well in Freundlich in case of industrial waste water sample. The highest Q max achieved under Langmuir model was 0.7117 mM/L and R 2 was 0.89 for Pb in synthetic solution and 1.1174 mg/L and R 2 was 0.79 for Cu in industrial waste water exhibiting chitosan-modified biochar membrane as a good bio-adsorbent for abstraction of Cu and Pb from aqueous solution. The highest K f achieved under Freundlich model was 0.5061 mg/L and R 2 was 0.97 for Pb in industrial waste water sample and for the same 1 > n > 2 which confirms moderately good sorption of the metal ion. It is apparent from the results that the bioadsorbent prepared from biochar and chitosan were a low-cost efficacious resource due to its easy availability and eco-friendly material for making adsorbent for abstraction of heavy metals from aqueous solution. Thus, this adsorbent can be best utilized for adsorption of heavy metals.

References

APHA (1998) Standard methods for the examination of water and wastewater, 20th edn. American Public Health Association, Washington, DC

Bansal RC, Donnet JB, Stoeckli HF (1988) Active carbon. Marcel Dekker, New York, pp 27–118

Cao R, Lou L, Xu T, Duan D, Ying C (2012) Effect of bamboo biochar on pentachlorophenol leachability and bioavailability in agricultural soil. Sci Total Environ 414(1):727–731

Lehmann J, Gaunt J, Rondon M (2006) Bio-char sequestration in terrestrial ecosystems – a review. Mitig Adapt Strategies Glob Chang 11(2):403–427

Liu C, Bai R (2006) Adsorptive removal of copper ions with highly porous chitosan/cellulose acetate blend hollow fiber membranes. J Membr Sci 284:313–332

Radovic LR, Moreno C, Rivera UJ (2000) Carbon materials as adsorbents in aqueous solutions, en chemistry and physics of carbon. A series of advances, Ed Marcel Dekker, New York, pp 293–297

Reiad NA, Abdel Salam OE, Abadir EF, Harraz FA (2012) Adsorptive removal of iron and manganese ions from aqueous solutions with microporous chitosan/polythene glycol blend membrane. J Environ Sci 24(8):1425–1432

Twu Y-K, Huang H-I, Chang S-Y, Wang S-L (2003) Preparation and sorption activity of chitosan/cellulose blend beads. Sci Direct Carbohydr Polymer 54:425–430

Wang S, Gao B, Li Y, Mosa A, Zimmerman AR, Ma LQ, Harris WG, Mi KW (2015a) Manganese oxide-modified biochars: preparation, characterization, and sorption of arsenate and lead. Biores Technol 181:13–15

Wang S, Gao B, Mosa A, Zimmerman AR, Li Y, Ma L, Harris WG, Migliaccio KW (2015b) Physicochemical and sorptive properties of biochars derived from woody and herbaceous biomass. Chemosphere 134:257–262

World Health Organization (2006) A report on preventing disease through healthy environment. WHO press, Geneva, Switzerland

Zhou Y, Gao B, Zimmerman AR, Fang J, Sun Y, Cao X (2013) Sorption of heavy metals on chitosan-modified biochars and its biological effects. Chem Eng J 231:512–518

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Hussain, A., Maitra, J. & Khan, K.A. Development of biochar and chitosan blend for heavy metals uptake from synthetic and industrial wastewater. Appl Water Sci 7, 4525–4537 (2017). https://doi.org/10.1007/s13201-017-0604-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-017-0604-7