Abstract

The present study provides an insight into the optimization of a glucose and sucrose mixture to enhance the denitrification process. Central Composite Design was applied to design the batch experiments with the factors of glucose and sucrose measured as carbon-to-nitrogen (C:N) ratio each and the response of percentage removal of nitrate–nitrogen (NO3 −–N). Results showed that the polynomial regression model of NO3 −–N removal had been successfully derived, capable of describing the interactive relationships of glucose and sucrose mixture that influenced the denitrification process. Furthermore, the presence of glucose was noticed to have more consequential effect on NO3 −–N removal as opposed to sucrose. The optimum carbon sources mixture to achieve complete removal of NO3 −–N required lesser glucose (C:N ratio of 1.0:1.0) than sucrose (C:N ratio of 2.4:1.0). At the optimum glucose and sucrose mixture, the activated sludge showed faster acclimation towards glucose used to perform the denitrification process. Later upon the acclimation with sucrose, the glucose uptake rate by the activated sludge abated. Therefore, it is vital to optimize the added carbon sources mixture to ensure the rapid and complete removal of NO3 −–N via the denitrification process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The Malaysian population had reached 30 million in 2014 and was anticipated to grow progressively for the next 30 years (Abdullah 2012). The rapid migration of Malaysian population towards urbanization and industrialization together with burgeoning of agricultural activities has brought about the indiscriminate introduction of large quantity of nitrate into the environment. The nitrate concentration in surface water is typically higher than groundwater. Nevertheless, nitrate–nitrogen (NO3 −–N) concentration exceeded the Department of Environment Malaysia groundwater standard in Pelarit, Perlis had been reported by Ismail et al. (2007). The Department of Environment Malaysia standard has set a limit of 10 mg/L for NO3 −–N in groundwater (Ismail et al. 2007) which was in commensurate with the maximum contaminant level (MCL) as decreed by US Environmental Protection Agency under the Drinking Water Regulations and Health Advisories 1996. In addition, as more than half of public water supply in Kelantan originates from groundwater, the NO3 −–N concentration of approximately 72% higher than the Malaysia standard had been measured in Kota Bharu, Kelantan at an average groundwater level of 5.65 m above the mean sea level (Mohamed Zawawi et al. 2010). In addition, about 35% of the regions close to the Kelantan River valley including of Kota Bharu, Bachok, Tumpat and Pasir Mas districts possessed NO3 −–N levels beyond the threshold limit with some parts of the area exceeding 45 mg/L (Mohamed Zawawi et al. 2010). Contamination of freshwater bodies with nitrate constitutes an alarming environmental concern not only in Malaysia, but worldwide. In China, groundwater in some rural and suburban areas used primarily as a drinking water source by both humans and livestock was contaminated with NO3 −–N at a concentration above 130 mg/L (Liu et al. 2009). The water resources in Basse Normandie area of France were polluted with nitrate discharged from industries and human activities as well as fertilizers utilization for the intensive agriculture (Garcia et al. 2006). Likewise in US, about 10–25% of the groundwater used as drinking water suffered from nitrate contamination above the maximum permissible contaminant level (Tong et al. 2014). Such occurrence can generally lead to eutrophication in receiving water bodies that severely affects the indigenous surrounding and aquatic organisms when the consequential hypoxia looms, degrading the intrinsic values of nature. As for the contamination of drinking water, the nitrate is potentially bio-reverted to toxic nitrite which can convert haemoglobin into methemoglobin, resulting in methemoglobinemia disorder to infants. Adults who consume prolonged excessive nitrate-bearing drinking water have been associated with gastric cancer resulted from the potential formation of nitrogen–nitroso, proven carcinogenic compounds (Tong et al. 2014).

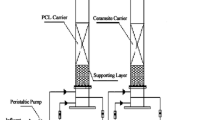

Numerous nitrate-treating technologies had been investigated and these included adsorption, filtration, ion exchange, anion-exchange membrane, electrocoagulation, electrodialysis, photocatalysis, etc. As price of treatment is a prime concern, biological denitrification-based technologies are traditionally extolled to be the most cost effective; besides being environmentally sound techniques with high stability and reliability whilst treating large volume of wastewater containing nitrate (Lim et al. 2014a, b; Tong et al. 2014). The main prerequisite to ensure the feasibility of the denitrification process is the availability of accessible biodegradable carbon sources that act as electron donors, in addition to anoxic conditions and suitable pH and temperature ranges (Lim et al. 2013; Mukkata et al. 2016). To this end, organic carbon sources are commonly exploited and their classifications had been thoroughly detailed by Lim et al. (2014a, b) as presented in Fig. 1. The organic carbon source originating from the wastewater itself is known as an internal carbon source, and it is initially used to sate the denitrification process. However, the major setback that usually foils the use of this carbon source is when treating low COD/N wastewaters, e.g. supernatants from sludge digesters and stabilization ponds as well as pretreated industrial wastewaters by anaerobic fermentation, in which external carbon source is frequently added to spur the denitrification activities. Based on their physical states, the external carbon source can be further subdivided into either liquid carbon source or solid carbon source. Of late, research into applying various solid carbon sources used for the denitrification process enhancement has been reported (Zhang et al. 2012; Shen et al. 2013; Lim et al. 2014a, b; Yang et al. 2015). As time is of the essence, solid carbon sources are generally less attractive since they induce slower rate of denitrification as compared with the use of liquid carbon source (Shen et al. 2013). Also demonstrated by Shen et al. (2013), the application of starch/polylactic acid as a solid carbon source undermined the denitrification rate due to the conspicuous difference of biodegradability between the two carbon-blended components. In the worst case, some of the solid carbon sources such as wheat straw and sawdust are potentially releasing nitrogen compounds via leaching, giving rise to the secondary pollution (Zhang et al. 2012).

Classification of carbon sources used for the denitrification process (Lim et al. 2014)

To date, the introduction of various liquid carbon sources that serves to promote the denitrification process has been exhaustively reported. Paul et al. (1989) confirmed that the denitrification capacity per mole of carbon differed in the order of sucrose < glucose < acetate < propionate < butyrate. The effectiveness of glucose synthetic wastewater in promoting denitrification had as well been compared with industrial wastewater and anaerobic-treated cassava stillage by Xie et al. (2012). Nevertheless, the optimization of liquid carbon mixtures via systematic study using statistical tools has not been reported in the literature. To the best of our knowledge, this paper reports for the first time on manipulating Design of Experiments (DOE) to isolate the best combination of glucose and sucrose mixtures in terms of carbon-to-nitrogen (C:N) ratio each in enhancing the denitrification process. Accordingly, the research output is anticipated to shed a brighter understanding on exploiting mixed liquid carbon sources, such as beverage industry wastewaters laden with high sucrose and glucose reducing agents, to eliminate nitrate pollutant via natural process of denitrification without having compromising the cost of treatment. The Central Composite Design (CCD) tool of DOE was chosen for statistical C:N ratio optimization of glucose and sucrose mixtures since it permits the extensions of low and high values of factors in computing the optimum point.

Materials and methods

Fresh wastewater from open fish farm

The fresh wastewater from open fish farm in Kelantan, Malaysia located at the coordinate latitude: 5.744491|longitude: 101.864224 was collected once a week from mid-February 2016 to May 2016. The collected wastewater samples were immediately ferried to the Environmental Laboratory and analysed for nitrogen species (ammonium, nitrite and nitrate) concentrations as well as chemical oxygen demand (COD) and biochemical oxygen demand (BOD5) values. The nitrogen species concentrations were determined based on HACH method using DR5000 spectrophotometer, whereas the COD and BOD5 values of the samples were measured based on standard methods (APHA 1998). The concentrations of NO3 −–N, COD and BOD5 were then found to fluctuate within the ranges of 43 ± 5, 22 ± 3 and 12 ± 6 mg/L, respectively, for all the collected wastewater samples. On another note, the concentrations of ammonium and nitrite ions in the samples appeared negligible.

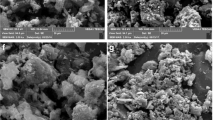

Batch bioreactor setup

An Erlenmeyer flask of 250 mL capacity was used as a batch bioreactor for the determination of optimum glucose and sucrose mixture used for the denitrification process. A 200 mL volume of fresh wastewater obtained from open fish farm was initially conditioned to attain a NO3 −–N concentration of 50 mg/L before introducing it into the batch bioreactor. This conditioned wastewater was inoculated with indigenous activated sludge at the concentration of approximately 800 mg/L of mixed liquor suspended solids (MLSS) with 72% volatile suspended solids (VSS). The sludge volume index (SVI) was measured at 63 mL/g, indicating good settleability due to the presence of dense sludge. The mixed liquor was then sparged using helium to displace dissolved oxygen in the mixed liquor. Nutrient broth of 1 mL containing 1.0 g/L of KH2PO4, K2HPO4, MgSO4, NaHCO3, FeCl3.6H2O and CaCl2 each was spiked into the batch bioreactor, giving slightly alkaline pH of 7.8 ± 0.2 upon homogenization, a preferable pH for denitrification (Simek et al. 2002). Finally, the stock glucose–carbon (glucose–C) and sucrose–carbon (sucrose–C) solutions (2000 mg/L each) used as a carbon source for the denitrification process were injected into the batch bioreactors according to the runs as specified in Table 1. The opening of batch bioreactor was immediately covered to minimize the intrusion of atmosphere oxygen and agitated at 250 rpm. The bioreactor was finally incubated at 28 ± 2 °C throughout the time course of experiment. Each run was concluded when the concentration of NO3 −–N in the mixed liquor reached fairly constant value measured from continuous sampling of mixed liquor via siphoning with pipette.

Experimental design by Central Composite Design

Design-Expert® Version 7.0 (Stat-Ease, Inc., Minneapolis, MN 55413, USA) software was used for the statistical DOE and analysis of data. The CCD tool of DOE was selected to design batch experiments, whereas response surface methodology (RSM) was subsequently employed to identify the optimum condition. The range of C:N from 0:1 to 1.5:1 for each glucose and sucrose in the mixture was acquired from preliminary experiments in concert with ancillary evidence from the literature (Tong et al. 2014). The coded values set for glucose (A) and sucrose (B) at three levels were −1 (0:1), 0 (0.75:1) and 1 (1.5:1), resulting in four factorial points (consisting of all possible combinations of the maximum and minimum levels), four axial points (one of the factors set at the midpoint) and five centre points (replicated experimental runs at the factors midpoint), all shown in Table 1. The dependent variable or response used to gauge the outcome of glucose and sucrose mixture was the percentage removal of NO3 −–N measured at the end of every run. The optimum mixture of glucose and sucrose was later predicted using quadratic equation model as expressed in the following equation (Myers et al. 2009; Leong et al. 2016):

where Y is the response, x i and x j are the process variables, β 0 is the constant coefficient, β i , β ii and β ij are the interaction coefficients of linear, quadratic and second order terms, respectively, k is the number of process variables and \( \varepsilon \) is the random error component. As only two factors were being involved in this study (k = 2), the following equation is derived (Tong et al. 2014):

Analysis of variance (ANOVA) was then used for graphical analyses of data to conceive the interactions between the process variables and the response. The quality of the fitted quadratic model was demonstrated by the coefficient of determination (R 2) and its statistical significance was verified by the F value (Fisher variation ratio) and Adequate Precision. The instantaneous consideration of response involved the initial creation of a suitable response surface model and later identification of optimum operational condition that targeted the response such in the most desired range.

Profile study at optimum condition

The optimum ratios of glucose and sucrose mixture in terms of C:N ratio each were then utilized for profile studies of nitrate–nitrogen (NO3 −–N), nitrite–nitrogen (NO2 −–N), glucose and sucrose indicated by their respective time courses. Similar experimental procedure as described in the section: batch bioreactor setup, was implemented with the injection of stock glucose-C and sucrose-C solutions into the batch bioreactor attaining optimum C:N ratios of glucose and sucrose in the mixture. Samplings were performed at every 2–3 h once until the concentrations of all monitored species reached steady state in which fairly constant values could be detected.

Results and discussion

Removal of NO3 −–N based on the design of CCD

The experimental removal efficiencies of NO3 −–N based on the CCD of DOE are tabulated in Table 1. The removals of NO3 −–N were recorded varying from 1 to 88% throughout the 13 runs with the mean value calculated to be approximately 60%. In general, the removal of NO3 −–N increased with the ascent of C:N ratios of glucose and sucrose in the mixture, indicating the proportionality between carbon source supply and denitrification intensity.

Significance of NO3 −–N removal model terms

The model terms of NO3 −–N removal were statistically analysed using ANOVA and the assessment results are concluded in Table 2. All the model terms, except for B 2, owned a high F value with Prob > F < 0.05, indicating model term significances. By ostracizing the insignificant model term, B 2 with Prob > F > 0.10, the final regression model of polynomial equation of NO3 −–N removal in terms of coded and actual factors could be presented as in Eqs. (3) and (4), respectively:

By either substituting the coded value into Eq. (3) or actual value into Eq. (4) from Table 1, the percentage removal of NO3 −–N could be calculated in verifying the equations. This model had F value 261.13 and Prob > F < 0.0001 signifying significance of model and lack of fit Prob > F = 0.6909 confirming the model lack of fit was insignificant. The quality of the fitted model was expressed by the R 2, adjusted R-squared (adj. R 2) and predicted R-squared (Pred. R 2) with the respective values of 0.9924, 0.9886 and 0.9768. Good fitted model should have a minimum R 2 = 0.8. The R 2 of approaching 1.0 shows good agreement between the calculated and observed results within the experimental range. The Adj. R 2 is R 2 adjusted for the number of terms in the model with respect to the number of points in the design. The model estimates the fraction of the overall variation in the data. The Pred. R 2 is R 2 of the predicted NO3 −–N removal model of actual factors (Eq. (4)). A reasonable agreement of Adj. R 2 with Pred. R 2 is accepted with the difference between them not greater than 0.2 or 20% (Tong et al. 2014). In this study, the difference was only 0.0118 or 1.18%, revealing reasonable agreement and the data fitted the model well. The Adequate Precision (AP) representing the error between the predicted values at the design points and the average prediction. The model AP should be greater than four to substantiate that the noise is not contributing any error to the response surface and the model can be employed to navigate in the design space (Tong et al. 2014). The NO3 −–N removal model acquired the AP of 55 in this study, verifying the absence of significant error due to the noise in the model. The coefficient of variance (CV) formulated as the ratio of the standard deviation of estimate (2.64% in this study) to the mean value of observed response (60% in this study) denotes the reproducibility of the model. The permissible upper fiducial limit of CV should not be greater than 10% to ensure the reproducibility of the model which was also fulfilled by the model in this study (CV 4.43%). Therefore, the statistical analysis demonstrated the adequacy of the model which could be used to navigate in the design space identified by CCD of DOE.

By employing the developed model, the distribution of NO3 −–N removal was noticed following the normal distribution as vindicated by the normal probability plot of internally studentized residuals as presented in Fig. 2. The studentized residual is the division of raw residual by its estimated standard deviation. The internally studentized residual was regarded by virtue of the estimation of standard deviation is of the same data used in model fitting. However, in many instances, little scattering is anticipated even with normal data. In addition, the developed model could precisely account the predicted values of NO3 −–N removal which were observed to be in good conformity with actual values (Fig. 3).

Optimization of glucose and sucrose mixture in enhancing the NO3 −–N removal

Based on the developed model, the three-dimensional (3D) response surface plot manifested the interactive relationships between glucose and sucrose mixture which impacted the NO3 −–N removal via denitrification process (Fig. 4). Generally, the rise of either carbon source concentrations would result in increasing of NO3 −–N removal with the peak of almost 90% attained at C:N ratios of glucose and sucrose mixture of 1.5:1.0 each. Deriving from Fig. 4, the perturbation plot (Fig. 5) explicitly illustrated the profound effect of glucose on NO3 −–N removal as opposed to sucrose. The sharp curvature of A underscored the dependent variable NO3 −–N removal was more responsive towards glucose carbon source. On the flipside, the NO3 −–N removal was less sensitive with respect to the change of sucrose C:N ratio, highlighted by semi-sharp curvature of B curve belonging to sucrose carbon source. Paul et al. (1989) had recorded that the denitrification capacity per mole of carbon was always lower for sucrose as compared with glucose. Sucrose was also labelled the least efficient carbon source for process yield in removing nitrate from contaminated groundwater by Gomez et al. (2000). The setback which foiled the substantial use of sucrose as a carbon source for denitrification process could be plausibly due to its disaccharide structure which was essentially needed to be hydrolyzed by the cells before it could serve as an electron donor.

The interactions of glucose and sucrose mixture were then manipulated by CCD to identify the value of response positioned at the maximum removal of NO3 −–N. The maximum NO3 −–N removal was recognized as a complete removal of NO3 −–N from the mixed liquor which is shaded with grey colour in Fig. 6 (area of interest). By narrowing the C:N ratios gap between the glucose and sucrose, the optimum combination of mixture of glucose and sucrose was achieved at C:N ratios of 1.0:1.0 and 2.4:1.0, respectively, as flagged in Fig. 6. The theoretical C:N ratio for a complete reduction of NO3 −–N to nitrogen gas was 1.07:1.0 for either glucose (Eq. (5)) or sucrose (Eq. (6)) as shown below:

However, higher C:N ratio was noted in this study with a total of 3.4:1.0 for the mixture of glucose and sucrose to attain the complete removal of NO3 −–N. According to Paul et al. (1989), simultaneous fermentation and denitrification could occur under anaerobic condition in a reaction mixture amended with glucose and nitrate, explaining the possible loss of carbon source not spent on denitrification process. Moreover, in tandem with the finding by Lorrain et al. (2004), the optimum mixture of carbon sources required larger portion of sucrose; again confirming the superiority of glucose used as a carbon source to enhance the denitrification process. To further justify, also reported by Her and Huang (1995), the minimum C:N ratio required to complete the denitrification process increased with the increase of organic carbon sources’ molecular weights.

Profile study at optimum glucose and sucrose mixture

The profile studies of nitrogen species and carbon sources in terms of time courses at the optimum C:N ratios of 1.0:1.0 and 2.4:1.0 for glucose and sucrose, respectively, are presented in Fig. 7. The removal of NO3 −–N required a lag period of almost 18 h as can be observed in Fig. 7a, before it was removed steadily at the rate of 5.35 mg/L h. The appearance of NO2 −–N albeit it was not added into the mixed liquor, unveiling the occurrence of denitrification process with the peak of NO2 −–N accumulation attained at the concentration of approximately 2.5 mg/L. The accumulated NO2 −–N was finally denitrified swiftly after the NO3 −–N concentration fell below the detection limit in the mixed liquor.

The consumption of glucose and sucrose concentration profiles (Fig. 7b) bore some semblance trend with NO3 −–N concentration profile (Fig. 7a). The lag periods as seen in Phase 1 of carbon source consumption profiles were plausibly due to the acclimation requirement by the indigenous activated sludge from the wastewater before it could extensively assimilate and oxidize glucose and sucrose in the mixed liquor. Cells that are not pre-adapted to the new substrate or growth condition usually experience a long lag phase and acclimation period (Wilson and Clarke 1994). To that end, also observed by Silva et al. (2014), the non-acclimated sludge showed lag phase of almost 11–15 times longer than the acclimated sludge while metabolizing long-chain fatty acids.

The Phases 2 and 3 in Fig. 7b show noticeable consumption of carbon sources predominantly due to the denitrification process, as evidenced by the plummet of NO3 −–N concentration at the same time period (Fig. 7a). By looking closely to these phases, the consumption of glucose (7.35 mg/L h) was faster than sucrose (3.30 mg/L h) in Phase 2 and the reverse took effect in Phase 3 [glucose (2.14 mg/L h) and sucrose (7.75 mg/L h)]. The results in Phase 2 concluded that the activated sludge could acclimate to glucose and use this carbon source for denitrification process faster than in the case of sucrose. Nevertheless, by lengthening the acclimation period to Phase 3, the activated sludge showed capability to boost sucrose consumption used for denitrification process. This activated sludge’s potential is important particularly when the primary carbon source is depleted from the reaction mixture and the activated sludge still can perform denitrification process using other types of carbon sources, eliminating the dependency to only one carbon source. Hence, to utilize the sugary wastewaters containing high concentration of sucrose, it must be initially conditioned to own the correct proportion of glucose for the fast attainment of acclimated activated sludge towards sucrose. In this regard, the rapid removal of NO3 −–N via the denitrification process can be achieved simultaneously with the treatment of sugary wastewaters with minimum cost entailed.

Phase 4 represented the end of denitrification process in which the decrease of glucose and sucrose concentrations became less intense because of the exhaustion of oxidized nitrogen (NO3 −–N and NO2 −–N) concentrations in the mixed liquor. However, a gradual consumption of these carbon sources was still transpiring in Phase 4 possibly due to sulphate-reducing bacteria activity which was retarded in the presence of NO3 −–N in the earlier phases (He et al. 2010). As the use of carbon sources for the denitrification process is of concern in this research, the profile studies of all species were terminated in Phase 4.

Conclusions

The polynomial regression model of NO3 −–N removal was successfully derived by the CCD of DOE after eliminating the insignificant model term. The derived model was able to explain the interactive effects of glucose and sucrose mixture which impinged on the removal of NO3 −–N via denitrification process. From the interaction study, the removal of NO3 −–N was noticed to be more sensitive on the presence of glucose as opposed to sucrose. Considering of the derived NO3 −–N removal model, the best combination of glucose and sucrose mixture was attained at C:N ratios of 1.0:1.0 and 2.4:1.0, respectively, leading to the complete removal of NO3 −–N. Using this optimum mixture of glucose and sucrose, the activated sludge could acclimate to glucose faster than sucrose in performing the denitrification process. Nevertheless, the consumption rate of glucose was abated once the activated sludge had acclimated to the presence of sucrose and used it for denitrification process.

References

Abdullah S (2012) Water resource users in Malaysia: issues and challenges, Malaysia Water Resources Management Forum 2012. “Time for Solutions”. Perbadanan Putrajaya, Putrajaya

APHA (1998) Standard methods for the examination of water and wastewater, 20th edn. APHA, AWWA, WPCF, American Public Health Association, Washington, DC

Garcia F, Ciceron D, Saboni A, Alexandrova S (2006) Nitrate ions elimination from drinking water by nanofiltration: membrane choice. Sep Purif Technol 52(1):196–200

Gomez MA, Gonzalez-Lopez J, Hontoria-Garcia E (2000) Influence of carbon source on nitrate removal of contaminated groundwater in a denitrifying submerged filter. J Hazard Mater 80(1–3):69–80

He Q, He Z, Joyner DC, Joachimiak M, Price MN, Yang ZK, Yen HCB, Hemme CL, Chen W, Fields MW, Stahl DA, Keasling JD, Keller M, Arkin AP, Hazen TC, Wall JD, Zhou J (2010) Impact of elevated nitrate on sulphate-reducing bacteria: a comparative study of Desulfovibrio vulgaris. ISME J 4(11):1386–1397

Her JJ, Huang JS (1995) Influences of carbon source and C/N ratio on nitrate/nitrite denitrification and carbon breakthrough. Bioresour Technol 54(1):45–51

Ismail WR, Sarju H, Mansor M (2007) Water quality of streams and wells of North Perlis: a comparative analysis. Malaysian J Environ Manage 8:69–85

Leong KY, See S, Lim JW, Bashir MJK, Ng CA, Tham L (2016) Effect of process variables interaction on simultaneous adsorption of phenol and 4-chlorophenol: statistical modeling and optimization using RSM. Appl Water Sci. doi:10.1007/s13201-016-0381-8

Lim JW, Lim PE, Seng CE, Adnan R (2013) Evaluation of aeration strategy in moving bed sequencing batch reactor performing simultaneous 4-chlorophenol and nitrogen removal. Appl Biochem Biotechnol 170(4):831–840

Lim JW, Lim PE, Seng CE, Adnan R (2014a) Alternative solid carbon source from dried attached-growth biomass for nitrogen removal enhancement in intermittently aerated moving bed sequencing batch reactor. Environ Sci Pollut Res 21(1):485–494

Lim JW, Bashir MJK, Ng CA, Guo X (2014b) Supplementation of novel solid carbon source prepared from dried attached-growth biomass for bioremediation of wastewater containing nitrogen. Wastewater engineering: advanced wastewater treatment systems. Int J Sci Res Books. doi:10.12983/1-2014-03-01

Liu H, Jiang W, Wan D, Qu J (2009) Study of a combined heterotrophic and sulfur autotrophic denitrification technology for removal of nitrate in water. J Hazard Mater 169(1–3):23–28

Lorrain MJ, Tartakovsky B, Peisajovich-Gilkstein A, Guiot SR (2004) Comparison of different carbon sources for ground water denitrification. Environ Technol 25(9):1041–1049

Mohamed Zawawi MA, Yusoff MK, Hussain H, Nasir S (2010) Nitrate-nitrogen concentration variation in groundwater flow in a paddy field. Inst Eng Malaysia 71(4):2–10

Mukkata K, Kantachote D, Wittayaweerasak B, Techkarnjanaruk S, Boonapatcharoen N (2016) Diversity of purple nonsulfur bacteria in shrimp ponds with varying mercury levels. Saud J Biol Sci 23(4):478–487

Myers RH, Montgomery DC, Anderson-Cook CM (2009) Response surface methodology, process and product optimization using designed experiments, 3rd edn. Wiley, Hoboken

Paul JW, Beauchamp EG, Trevors JT (1989) Acetate, propionate, butyrate, glucose, and sucrose as carbon sources for denitrifying bacteria in soil. Can J Microbiol 35(8):754–759

Shen Z, Zhou Y, Wang J (2013) Comparison of denitrification performance and microbial diversity using starch/polylactic acid blends and ethanol as electron donor for nitrate removal. Bioresour Technol 131:33–39

Silva SA, Cavaleiro AJ, Pereira MA, Stams AJM, Alves MM, Sousa DZ (2014) Long-term acclimation of anaerobic sludges for high-rate methanogenesis from LCFA. Biomass Bioenerg 67:297–303

Simek M, Jisova L, Hopkins DW (2002) What is the so-called optimum pH for denitrification in soil? Soil Biol Biochem 34(9):1227–1234

Tong S, Chen N, Wang H, Liu H, Tao C, Feng C, Zhang B, Hao C, Pu J, Zhao J (2014) Optimization of C/N and current density in a heterotrophic/biofilm-electrode autotrophic denitrification reactor (HAD-BER). Bioresour Technol 171:389–395

Wilson DJ, Clarke AN (1994) Hazardous waste site soil remediation: theory and application of innovative technologies. Marcel Dekker Inc, New York

Xie L, Chen J, Wang R, Zhou Q (2012) Effect of carbon source and COD/NO3 −–N ratio on anaerobic simultaneous denitrification and methanogenesis for high-strength wastewater treatment. J Biosci Bioeng 113(6):759–764

Yang XL, Jiang Q, Song HL, Gu TT, Xia MQ (2015) Selection and application of agricultural wastes as solid carbon sources and biofilm carriers in MBR. J Hazard Mater 283:186–192

Zhang J, Feng C, Hong S, Hao H, Yang Y (2012) Behavior of solid carbon sources for biological denitrification in groundwater remediation. Water Sci Technol 65(9):1696–1704

Acknowledgements

The financial support from the Universiti Teknologi PETRONAS through STIRF (0153AA-D80) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Lim, JW., Beh, HG., Ching, D.L.C. et al. Central Composite Design (CCD) applied for statistical optimization of glucose and sucrose binary carbon mixture in enhancing the denitrification process. Appl Water Sci 7, 3719–3727 (2017). https://doi.org/10.1007/s13201-016-0518-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-016-0518-9