Abstract

Alginate–calcium carbonate composite material was prepared in the form of beads and characterized using Fourier transform infra red (FT-IR) spectroscopy and scanning electron microscope (SEM) techniques. The adsorption of Cd2+ ions was studied through batch experiments. The adsorption parameters such as contact time (120 min), adsorbent dose (1.5 g), initial metal ion concentration(10 mg/L), pH (6) and agitation speed (150 rpm) were optimized at room temperature. Langmuir and Freundlich isotherms were applied to the data and it was noted that the adsorption of Cd2+ ions is better explained by Freundlich model. The kinetic studies showed that the adsorption of Cd2+ ions followed pseudo-first order kinetics. Thermodynamic parameters like ∆G 0, ∆H 0 and ∆S 0 were calculated and on the basis of these values it was established that the adsorption process is feasible and endothermic in nature. It was concluded from the study that the composite material of alginate and calcium carbonate can effectively be used to recover Cd2+ ions from wastewater.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The presence of heavy metals in the environment is of major concern because of their toxicity, bio-accumulating tendency and threat to human and animal life (Igwe et al. 2005). A majority of metals are persistent and toxic especially when accumulated above the level of permissible limits. Almost 2.3 billion people all over the world are suffering from waterborne diseases (UNESCO 2003). In developing countries over 2.2 million people die each year by drinking polluted water (WHO/UNICEF 2000).

Alginate is a family of linear non-branched polysaccharides and is extracted from brown seaweed. It can make a gel in the presence of divalent and trivalent cations. It has many applications in drug delivery systems, cell encapsulation and food indu stry (Gombotz and Wee 2012). In water treatment, it possibly will play an important role in removing heavy metal ions due to its advantages such as biodegradability, biocompatibility, being economical and environmentally friendly. In the adsorption process, the heavy metal ions appear to exchange with sodium or calcium ions by ion exchange process (Negm and Ali 2010). Utilization of alginate sorbents is limited as its mechanical strength and durability are relatively low. Mechanical properties of alginates have been improved by combining it with other materials like activated carbon (Kim et al. 2009), chitosan (Gotoha and Matsushima 2004), polyvinyl alcohol (Han et al. 2012), cellulose (Tiwari and Dewangana 2008) and humic acid (Pandey et al. 2003). The author (Mahmood et al. 2015) modified alginate with calcium carbonate to develop a composite material and used it as an adsorbent for phosphate ions confiscation. This recent study was aimed at learning the use of environmentally friendly cost effective material to recover metallic pollutants from waste water. The adsorption of Cd2+ ions was studied as potential pollutant as it is carcinogenic in nature.

Materials and methods

Preparation of the adsorbent

Well grounded calcium carbonate was impregnated on sodium alginate gel to prepare composite material in the form of beads in aqueous calcium chloride solution. In order to develop on laboratory scale dissolved 5 g sodium alginate in 200 mL distilled water with continuous stirring at 40 °C until a gel is obtained. Calcium carbonate powder (20 g) was mixed carefully under constant stirring with mechanical stirrer until the mixture became homogeneous. The suspension was injected dropwise into a 1-M solution of calcium chloride with the help of injection syringe. Fine complex beads of alginate–calcium carbonate were formed. The beads were separated from the solution by filtration on Whatman filter paper No. 41 and dried for overnight in electrical oven maintained at (70 ± 2) °C. Dried mass of the beads was used as an adsorbent for cadmium ion removal. Schematic diagram of the overall process is shown in Fig. 1.

Characterization of the adsorbent

Characterization of adsorbent material was made by Fourier transform infra red spectroscopy (FT-IR) and scanning electron microscope (SEM) techniques.

Preparation of synthetic wastewater

Stock solution of cadmium ions (1000 ppm) was prepared by dissolving calculated amount of cadmium chloride in distilled water and working standards of required strength were prepared by diluting the reserve solution.

Batch experiments

In order to optimize the operational parameters such as adsorbent dose, time of contact, pH of the medium and initial concentration, agitation speed batch mode experiments were conducted. The effects of batch parameters were investigated by changing adsorbent dosage (0.2, 0.5, 1, 1.5, 2 g), contact time (30, 60, 90, 120, 150, 180 min),pH (2–10),initial concentration (5, 10, 15, 20, 25 mg/L) and agitation speed (50, 100, 150, 200, 250 rpm).

In each experiment weighed quantity of adsorbent was added to a specific volume of standard solution and after adjusting the desired pH, the mixture was agitated at room temperature for specific time. The solution thus obtained was filtered through Whatman filter paper No. 41. Residual concentrations of the analyte ions were measured by Hitachi, Z-8000 Atomic Absorption Spectrometer on air-acetylene flame.

Removal efficiency calculations

The percentage removal efficiency and was calculated after each batch experiment using following relation:

where R is the removal efficiency, C i is the initial and C f is the final concentration in mg/L.

The metal uptake Q was calculated for each experiment in mg/g according to the following formula:

where V is the volume of the solution and M is dry mass of the adsorbent.

Results and discussion

Characterization of the adsorbent

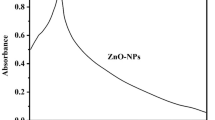

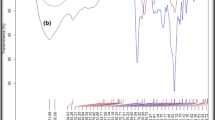

FT-IR spectra of alginate–calcium carbonate composite was recorded at 4000–400 cm−1 (Fig. 2). Diversity of peaks merged together in the range between 3200 and 3600 cm−1 are associated with the presence of free or bonded hydroxyl groups of alginate species along with the presence of inter and intra molecular hydrogen bonding within hydroxyl groups (Bojic et al. 2013). The distorted peaks of medium intensity correspond to asymmetric stretching vibrations of alkyl chains. The indistinct peaks at 1634, 1465, 1109 and 874 cm−1 are linked to stretching vibrations of C=O–COOH and –RCH groups (Kirova et al. 2012). It can be inferred from FT-IR spectra that strong bonding has occurred between alginate and host material, i.e. calcium carbonate.

The morphology of the adsorbent was noted by SEM images. The images were taken at different spots with 15 kV resolutions. The results showed the formation of composite material with some specific sites which may be responsible for adsorption of analyte ions at the adsorbate-adsorbent interface (Fig. 3).

Parameter optimization

Factors affecting adsorption of Cd2+ on alginate–calcium carbonate complex beads were optimized through batch experiments at room temperature (298.15 K).

Effect of contact time

Figure 4a indicates the graphical representation of contact time studies. Each experiment was conducted with increase of 30-min increment while keeping other parameters unchanged. The equilibrium point for cadmium ion adsorption was established after 120 min and it was noted that the rate of metal ion uptake was high during the initial phases of experiments and became almost constant after the equilibrium point was reached.

Effect of adsorbent dose

Different doses of the adsorbent (0.2, 0.5, 1, 1.5 and 2 g) were used to find the optimum dose required to adsorb maximum adsorbate ions. The results of effect of adsorbent dosage have been presented in Fig. 4b. It was observed that sorption process speeds up with increase in adsorbent dose and become uniform after attaining optimum dose, i.e. 1.5 g.

Effect of pH

The effects of pH change on adsorption of Cd2+ ions were investigated in the range 2–10 and presented in the Fig. 4c. The study showed that the maximum adsorption occurred at pH 6. The plot of pH vs. removal efficiency showed a decreasing trend towards adsorption of Cd2+ ions after pH 6. At low pH the surface has stronger positive charge similar to those of adsorbate ions; therefore, repulsion may occur between adsorbent surface and incoming metal ions, thus lowering the rate of adsorption (Ahmed et al. 1998).

Effect of agitation speed

The agitation speed was varied from 50 rpm to 250 rpm to monitor the effect of shaking speed on adsorption of cadmium ions. The results of the experiment are shown in Fig. 4d. It was noted that at 150 rpm shaking speed 94.9 % Cd2+ ions are removed.

Effect of initial concentration of metal ion

The effect of metal ion concentration was studied at varying initial concentration (5–25 mg/L) while keeping all the other parameters unchanged. Figure 4e indicates the effect of initial concentration on adsorption of Cd2+ ions. It can be noted that adsorption was higher at lower concentrations and vice versa. Maximum adsorption was noted at 5 mg/L with gradual decrease in sorption capacity up to 25 mg/L. Optimized conditions derived through batch mode experiments are summarized in Table 1.

Adsorption models

Adsorption models play an important role in understanding the nature of an adsorption process as a unit operation (Sawyer et al. 2003). For modelling of cadmium ion adsorption from wastewater commonly used Langmuir and Freundlich models were applied to the data.

Langmuir model

The Langmuir isotherm (Fig. 5) was constructed by plotting the data between functions Ce (equilibrium concentration in mg/L) and q (metal uptake in mg/g). A straight line having correlation coefficient (0.956) is obtained which is an indicator of the favorability of the adsorption process (Ho 2003). The Langmuir constants, i.e. q max (maximum sorption capacity) and b (affinity of adsorption) were calculated from slope and intercept of the isotherm. The values are shown in Table 2.

Freundlich model

The adsorption both physisorption and chemisorption is better explained by the Freundlich model (Ho and Wang 2008). The required isotherm was constructed by plotting logq vs. logC f (Fig. 6). The coefficient of linearity (R 2 = 0.985) almost approaches to unity which is an indicator of favourable adsorption. Table 3 gives values of K f (sorption capacity) and n (sorption intensity) calculated from slope and intercept of the isotherm. Values of the constants “n (4.274)” and “K f (0.698)” indicate that the sorption process is complimentary and type of sorption is physico-chemical in nature (Song et al. 1994; Schwarzenbach et al. 2003). Freundlich isotherm for cadmium ion removal can be represented by the equation described below.

Adsorption kinetics

Kinetics of the process was determined using data of the contact time and change in concentration of the analyte ions (Table 4).

Kinetic equations for pseudo-first order and second order are described as under:

(Pseudo-first order equation);

(Pseudo-second order equation), where q e and q are the analytes adsorbed in mg/g at equilibrium and at time t, respectively, and K 1 and K 2 are the rate constants (g mg−1 min−1). Pseudo-first order rate kinetics was determined by plotting log (q e − q t) against time t and the values of K1 and qe were calculated from the slope and intercepts of the plot. Figure 7 shows the plot of pseudo-first order rate kinetics for Cd2+ ions and the rate constant parameters are shown in Table 5. From the table the experimental as well as calculated qe values seem to be quite closer to each other thus indicating that the adsorption processes follow pseudo-first order reaction kinetics. Pseudo-second order rate curve was plotted between t/q and t (Fig. 7). The correlation coefficient is 0.652 which is far away from unity (Table 5). These results suggest that the adsorption process does not follow pseudo-second order kinetics since the values of correlation coefficients are significantly less than 1 and also the experimental and calculated q e values are not in good agreement with each other (Abdel-Ghani and El-Chaghaby 2014).

Thermodynamic parameters

Thermodynamic parameters, the standard enthalpy change (ΔH 0), standard entropy change (ΔS 0) and standard Gibbs free energy (ΔG 0) of adsorption, were determined at room temperature (298.15 K). The values of thermodynamic constants are listed in Table 6. The values of ΔS 0 (kj/mol K) and ΔH 0 (kj/mol) were calculated from the slope and intercept of the graph (Fig. 8). Values of thermodynamic parameters show that the adsorption process is feasible and endothermic in nature with minor randomness at the adsorbent-adsorbate interface (Vadivelan and Kumar 2005).

Conclusions

The adsorption of cadmium ions from aqueous solution on to alginate–calcium carbonate composite material was investigated in batch mode. The results showed that sorption of Cd2+ ions is a viable process with very encouraging recovery of the pollutant under study. It can be inferred from the study that the alginates modified with calcium carbonate may be a cost-effective alternative for waste water treatment.

References

Abdel-Ghani NT, El-Chaghaby GA (2014) Biosorption for metal ions removal from aqueous solutions: a review of recent studies. Int J Latest Res Sci Technol 3:24–42

Ahmed S, Chughtai S, Keane MA (1998) The removal of cadmium and lead from aqueous solution by ion exchange with Na- Zeolite. Separ Purif Technol 19:57–64

Bojić DV, Ranđelović MS, Zarubica AR, Mitrović JZ, Radović MD, Purenović MM, Bojić AL (2013) Comparison of new biosorbents based on chemically modified Lagenaria vulgaris shell. Desalin Water Treat doi:10.1080/19443994.2013.771287, 1–11

Gombotz WR, Wee SF (2012) Protein release from alginate matercis. Adv Drug Deliv Rev 64:194–205

Gotoha T, Matsushima Kikuchia KI (2004) Preparation of alginate chitosan hybrid gel beads and adsorption of divalent metal ions. Chemosphere 55(13):5–140

Han LCU, Park YU, Kim JA, Kang SB, Lee JK (2012) Immobilization of layered double hydroxide onto polyvinyl alcohol/alginate hydrogel beads for phosphate removal. Environ Eng Res 17:133–138

Ho YS (2003) Removal of copper ions from aqueous solution by tree fern. Wat Res 37:2323–2330

Ho YS, Wang CC (2008) Sorption equilibrium of mercury onto ground-up tree fern. J Hazard Mater 156:398–404

Igwe JC, Ogunewed DN, Abia AA (2005) Competitive adsorption of Zn (II), Cd (II) and Pb(II) from aqueous and non aqueous solution by maize cob and husk. Afr J Biotechnol 4:1113–1116

Kim DJ, Choi JW, Yang KS, Lee CE (2009) Adsorption of zinc and toluene by alginate complex impregnated with zeolite and activated carbon. Curr Appl Phys 9:694–697

Kirova G, Velkova Z, Gochev V (2012) Copper (II) removal by heat inactivated Streptomyces fradiae biomass: Surface chemistry characterization of the biosorbent. J Bio Sci Biotech. SE/ONLINE, 77–82

Mahmood Z, Nasir S, Jamil N, Sheikh A, Akram A (2015) Adsorption studies of phosphate ions on alginate-calcium carbonate composite beads. Afr J Env Sci Tech 9:274–281

Negm NA, Ali HE (2010) Modification of heavy metals uptake efficiency by modified chitosan/anionic surfactant system. Eng Life Sci 10:218–224

Pandey AK, Pandey SD, Mishra V, Devi S (2003) Role of humic acid entrapped calcium alginate beads in the removal of heavy metals. J Hazard Mater 98:177–181

Sawyer CN, McCarty PL, Parkin GF (2003) Chemistry for Environmental Engineering and Science, Fifth edition edn. Tata McGraw-Hill, New Delhi

Schwarzenbach RP, Gschwend PM, Imboden DM (2003) Environmental Organic Chemistry. Second edition, Amazon

Song L, Johnson PL, Elimelech M (1994) Kinetics of colloid deposition on to heterogeneously charged surfaces in porous media. Environ Sci Technol 28:1164–1171

Tiwari A, Dewangana T, Bajpai AK (2008) Removal of toxic as (V) ions by adsorption onto alginate and carboxymethyl cellulose beads. Chinese J Chem 55:952–961

UNESCO.2003.WWDR1 :Water for people water for life. The United Nations world water report.WWW.org/new/en/natural-science/environment/water/wwap/wwdr/wwdr1-2003/

Vadivelan V, Kumar KV (2005) Equilibrium kinetics, mechanism and process design for sorption of methylene blue onto rice husk. J Colloid Interf Sci 286:90–100

WHO/UNICEF.2000.Global water supply and sanitation assessment report. WWW.who.int/water_sanitation_health/monitoring/jmp2000.pdf

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors did not claim any conflict of interests.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mahmood, Z., Amin, A., Zafar, U. et al. Adsorption studies of cadmium ions on alginate–calcium carbonate composite beads. Appl Water Sci 7, 915–921 (2017). https://doi.org/10.1007/s13201-015-0302-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-015-0302-2