Abstract

Dalbergia sissoo pods, a lignocellulosic nitrogenous waste biomass, was evaluated for sequestering of Cr(VI) from synthetic wastewater. Dalbergia sissoo pods (DSP) were used in three different forms, viz. natural (DSPN), impregnated in the form of hydrated beads (DSPB), and in carbonized form (DSPC) for comparative studies. Batch experiments were performed for the removal of hexavalent chromium. Effects of pH adsorbent dose, initial metal-ion concentration, stirring speed, and contact time were investigated. The removal of metal ions was dependent on the physico-chemical characteristics of the adsorbent, adsorbate concentration, and other studied process parameters. Maximum metal removal for Cr(VI) was observed at pH 2.0. The experimental data were analyzed based on Freundlich and Langmuir adsorption isotherms. Kinetic studies indicated that the adsorption of metal ions followed a pseudo-second-order equation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Pollution of surface and ground water supplies with toxic Cr(VI) has been one of the major causes for the deterioration in water quality, as this metal is used in a number of industrial applications including steel production, electroplating, leather tanning, nuclear power plant, textile industries, wood preservation, anodizing of aluminum, water cooling, and chromate preparation (Altundogan 2005). Chromium exists in trivalent and hexavalent forms in aquatic systems. The trivalent form at very low concentration is an essential nutrient (Rojas et al. 2005), but the hexavalent form is toxic, carcinogenic, and mutagenic in nature. It is highly mobile in soil and aquatic systems and also is a strong oxidant capable of being absorbed by the skin (Singh and Singh 2002). The hexavalent form is 500 times more toxic than the trivalent form (Kowalski 1994). Human toxicity includes lung cancer, as well as kidney, liver, and gastric damage (Cieslak-Golonka 1995). The tanning process is one of the major sources of chromium pollution at global scale. In the chromium tanning process, the leather takes up only 60–80 % of the applied chromium, and the rest is usually discharged into wastewaters, causing serious environmental hazards. Chromium ion in liquid tanning wastes occurs mainly in the trivalent form, which gets further oxidized to the hexavalent form. The current drinking water guideline value for Cr(VI) recommended by the world health organization is 0.05 mg/L (Acar and Malkoc 2004). Compliance with this strict standard is expected to be very costly and therefore, treatment efficiency is one of the major concerns for risk management when treating water containing Cr(VI). Numerous treatment methods, such as ion exchange, chemical reduction, chemical precipitation (Acar and Malkoc 2004), membrane separations (Patterson 1977 and Tiravanti et al. 1997), electrochemical precipitation (Dahbi et al. 1999), photo-catalytic reduction (Kapoor et al. 1999), adsorption (Aksu 2001; Zhang et al. 1998; Demirbas 2005) and biosorption (Goel et al. 2005 and Mohanty et al. 2006) have been tested to remove Cr(VI) from effluents to the permissible level. However, due to prohibitive cost, their use is limited in developing countries like India. Hence, there is a need to develop low-cost and easily available adsorbents for the removal of heavy metal ions from the aqueous environment. An abundant source of potentially metal-sorbing biomass is lingo-cellulosic agricultural waste materials. These materials could be an inexpensive substitute for the treatment of heavy-metal laden wastewater (Sud et al. 2008). Biomass is widely available, inexhaustible, and inexpensive material that exhibits significant specificity for the heavy metal ions. Dalbergia sissoo pods, an agricultural waste material, are generated in large quantities in India. These pods are put in no use and are burned in the open field, dumped in forest areas, or blown into huge piles and left to naturally deteriorate. These pods are very rich in cellulose and hemicelluloses and comprise 80 % of organic matter. They contain many polymeric materials that possess functional moieties that may help for the binding of metal ions. The removal of metal ions from aqueous streams using agricultural materials is based upon metal biosorption (Volesky and Holan 1995). The basic components of the agricultural waste materials biomass include hemicellulose, lignin, extractives, lipids, proteins, simple sugars, water hydrocarbons, starch containing variety of functional groups that facilitates metal complexation which helps for the sequestering of heavy metals (Bailey et al. 1999; Hashem et al. 2005, 2006). The process of biosorption involves a solid phase (sorbent) and a liquid phase (solvent) containing a dissolved species to be sorbed. Due to high affinity of the sorbent for the metal-ion species, the latter is attracted and bound by rather complex process affected by several mechanisms involving chemisorption, complexation, adsorption on surface and pores, ion exchange, chelation, adsorption by physical forces, entrapment in inter and intrafibrillar capillaries and spaces of the structural polysaccharides network as a result of the concentration gradient and diffusion through cell wall and membrane (Bassco et al. 2002; Sarkanen and Ludwig 1971; Qaiser et al. 2007) (Fig. 1) Agricultural waste materials are usually composed of lignin and cellulose as the main constituents. Other components are hemicellulose, extractives, lipids, proteins, simple sugars, starches, water, hydrocarbons, ash and many more compounds that contain a variety of functional groups present in the binding process. Cellulose is a crystalline homo-polymer of glucose with β1 → 4 glycosidic linkage and intramolecular and intermolecular hydrogen bonds (Demirbas 2000a, b). Hemicellulose is a hetropolymer of mainly xylose with β1 → 4 glycosidic linkage with other substances of acetyl feruoyl and glycouronyl groups (Hashem et al. 2007). Lignin is three-dimensional polymer of aromatic compounds covalently linked with xylans in hardwoods and galactoglucomannans in softwoods (Garg et al. 2007; Sjötröm 1981) The functional groups present in biomass molecules acetamido groups, carbonyl, phenolic, structural polysaccharides, amido, amino, sulphydryl carboxyl groups alcohols and esters (Beveridge and Murray 1980; Gupta et al. 1999). These groups have the affinity for metal complexation. Some biosorbents are non-selective and bind to a wide range of heavy metals with no specific priority, whereas others are specific for certain types of metals depending on their chemical composition. The presence of various functional groups and their complexation with heavy metals during biosorption process has been reported by different research workers using spectroscopic techniques (Ahluwalia and Goyal 2005; Garg et al. 2007; Tarley and Arruda 2004). Various agricultural waste materials have been used, such as rice bran, rice husk, wheat bran, wheat husk, saw dust of various plants, bark of the trees, groundnut shells, coconut shells, black gram husk, hazelnut shells, walnut shells, cotton seed hulls, waste tea leaves, cassia fistula leaves, maize corn cob, jatropha de-oiled cakes, sugarcane bagasse, apple, banana, orange peels, soybean hulls, grapes stalks, water hyacinth, sugar beet pulp, sunflower stalks, coffee beans, arjun nuts, and cotton stalks, etc.(Annadurai et al. 2002; Cimino et al. 2000; Hashem et al. 2005; Macchi et al. 1986; Mohanty et al. 2005; Orhan and Bujukgungor 1993; Reddad et al. 2002; Tee and Khan 1988; Hamadi et al. 2001) A comparison of their adsorption capacities has been given in (Table 1). The present study explores the use of Dalbergia sissoo pods as sustainable adsorbent for chromium removal from aqueous systems under different experimental conditions. Experiments were performed in batch mode. Dalbergia sissoo pods were taken in three different forms, viz. natural, impregnated in form of hydrated beads, and carbonized forms. The results showed the potential removal of the Cr(VI) metal ion by biomass in matrix mode and carbon form as compared to the natural form under optimized conditions. Equilibrium and kinetic models were investigated and applied to the data to describe the overall adsorption process.

Materials and methods

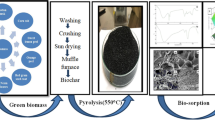

Preparation of adsorbent

The selected agricultural waste material Dalbergia sissoo pods (DSP) was collected from the local area. Hot water treatment was given to them for 1 h to remove the soluble organic components and debris, and the material was dried at 120 °C in hot air oven for 24 h. The material was then ground and sieved (150 MICS). Immobilization of biomass in the form of beads was prepared by mixing sodium alginate (polymer) and biomass in different ratios of 1:1, 1:3, 1:5, 1:7, 1:9, and 1:11 in a pre-calculated amount of de-ionized water and dropped into a 2 % solution of calcium chloride. The beads thus prepared were stirred in the CaC12 solution for 24 h for hardening. Beads were then washed three times with de-ionized water and maintained in 2 % CaC12 solution at 4 °C. The surface area of the beads was found to be 50.2 × 10−3 μm. The carbonized form of the biomass was prepared by heating the powder of biomass in a muffle furnace at 800 °C for 2 h.

Preparation of adsorbate

A stock solution of chromium (VI) (1,000 mg/L) was prepared by dissolving potassium dichromate in double-distilled water. The stock solution was diluted with distilled water to obtain Cr(VI) solutions of the desired concentration range. The pH of the solutions was adjusted using 0.01 M NaOH/0.01 M HCl using an Orion 420A pH meter. The Cr(VI) concentration was determined spectrophotometrically [Double Array UV–Vis Spectrophotometer, Agilent 8453] by the diphenyl-carbazide method (Zhang et al. 1998).

Experimental setup

Adsorption experiments were carried out using 100 mL of chromium solution of the desired concentration (50 mg/L) at an initial pH of 2.0 and with 1.5 g of adsorbent in a 250 mL Erlenmeyer flask at 25 ± 1 °C (stirring speed 250 rpm). At predetermined time intervals (60 min), samples were separated by centrifugation at 4,000 rpm for 10 min. The residual chromium concentration in the supernatant was determined as given earlier. All experiments were replicated three times for all the forms of adsorbents. The removal percentage (R %), defined as the ratio of difference in metal concentration before and after adsorption (Ci − Ce) to the initial concentration of chromium in the aqueous solution (Ci), was calculated using Eq. 1:

Results and discussion

Structural composition

In terms of their structure, Dalbergia sissoo pods (DSP) can be regarded as a lingo-cellulosic agricultural waste material containing high amount of proteins and crude fibers (Table 2). The pods are extremely rich in the nitrogenous substances containing various functional moieties for sequestering of heavy metal ions. The mechanism of Cr(VI) removal by lingo-cellulosic biomass is attributed to anionic adsorption or by reduction of Cr(VI) to Cr(III) by ligno-cellulosic biomass. The contributing functional groups such as phenolic methoxyl and hydroxyl groups of lignin are responsible for Cr(VI) reduction and the oxidation of these functional groups gives rise to the formation of carbonyl and carboxyl groups of lingo-cellulosic material. In addition to forming surface complexes, a portion of Cr(III) bound to ligno-cellulosic materials also formed a hydroxide precipitate. FT-IR analysis of the adsorbent before and after sorption of metal ions was performed to determine the vibrational frequency changes in the functional groups of the adsorbent in various forms. The spectra of adsorbents were measured in the range of 500–4,000 cm−1 wave number. The FT-IR spectra showed a number of adsorption peaks, indicating the complex nature of the studied adsorbent. In Dalbergia sissoo pods (DSP), the sorption peak at 3,083.6 cm−1 indicates the existence of free and intermolecular-bonded hydroxyl groups. The peaks observed at 2,922.3 cm−1 can be assigned to the stretching vibration of the C–H group. The peaks around 1,739.2 cm−1 correspond to the –C=O group. The strong C–O band at 1,055.7 cm−1 due to –OCH3 groups also confirms the presence of lignin structures in Dalbergia sissoo pods. The C–O absorption peak was observed to shift to 1,154.2 cm−1 when DSP was loaded with chromium. It seems that this functional group participates in metal binding. Table 3 presents the fundamental peaks of the adsorbent before and after use. The spectra display a number of absorption peaks indicating the complex nature of the examined adsorbent.

Effect of polymer and biomass ratio

For the formation of beads, biomass was bonded with sodium alginate in the ratio 1:9 of binding agent to biomass. This particular ratio was selected after a series of trials with different ratios of 1:1, 1:3, 1:5, 1:7, 1:9 and 1:11. The adsorption increased with increase in the ratio of biomass to binding agent. Maximum adsorption was achieved with a ratio of 1:9, as compared to 1:11, which was attributed to a lack of stability in the latter; hence, the adsorption experiments were further performed with beads prepared by using the ratio 1:9 (Fig. 2).

Effect of pH

pH is an important controlling parameter in the adsorption process due to its influence on the surface properties of the adsorbent and the ionic form of the metal ion in solution. Adsorption experiments were carried out in the pH range 2–10 (Although it was found that after pH 7, solution gets precipitated, thus studies were limited up to 7 pH only.), while keeping all other parameters constant (chromium concentration = 50 mg/L; stirring speed = 250 rpm; contact time = 60 min, adsorbent dose = 15 g/L, temp. = 25 °C). The pH of the chromium solution was adjusted after adding the adsorbent. The maximum adsorption of chromium was 99, 98, and 92 % for DSPC, DSPB, and DSPN, respectively at pH 2 (Fig. 3). There was a sharp decline in percent adsorption with increase in pH of the aqueous solution. Chromium adsorption by DSPN was decreased from 92 to 25 % as the pH was increased from 2 to 5. Chromium adsorption by DSPB was decreased from 98 to 28 % as pH was increased from 2 to 5. Similarly, chromium adsorption by DSPC was decreased from 99 to 45 % as pH was increased from 2 to 5. Maximum adsorption was observed at pH 2.0, and hence it was taken as the optimal pH value for further adsorption experiments. Our results are consistent with those of other workers (Kapoor et al. 1999; Aksu 2001; Zhang et al. 1998; Goel et al. 2005; Mohanty et al. 2005; Hamadi et al. 2001; Garg et al. 2004) who observed that the removal of Cr(VI) decreases with the increase of pH. The pH dependence of metal adsorption can largely be related to the type and ionic state of the functional groups present on the adsorbent and the metal chemistry in solution (Mohanty et al. 2006). In the pH range of 1.0–6.0, chromium ions co-exist in different forms, such as Cr2O7−, HCrO4−, Cr3O102−, and Cr4O132−, of which HCrO4− predominates. As the pH of the solution increases, the predominant species become CrO42− and Cr2O72−. More adsorption at acidic pH suggests that the lower pH results in an increase in H+ ions associated with the adsorbent surface, resulting in sufficiently strong electrostatic attraction between a positively charged adsorbent surface and negatively charged chromate ions. Lesser adsorption of Cr(VI) at pH values greater than 6.0 may be due to the dual competition of both the anions CrO42− and OH− to be adsorbed on the surface of the adsorbent, noting that OH− adsorption is favored by higher pH. This is in accordance with the earlier studies that have reported the removal of Cr(VI) by different adsorbents (Mohanty et al. 2005).

Adsorption kinetics

Studies comparing the three forms of biosorbents were conducted by varying the contact time from 5 to 120 min at a fixed initial chromium concentration (50 mg/L), stirring speed (250 rpm), temperature (25 °C), and pH (2.0). Maximum chromium was sequestered from the solution within 60 min by the different forms of adsorbent (Fig. 4). The chromium removal was 99 % by DSPC, 98 % by DSPB, and 92 % by DSPN within 60 min of contact time. In the case of DSPC, there was very fast adsorption, so keeping these observations in view, 30 min contact time was chosen for DSPC and 60 min for the DSPB and DSPN forms for further experiments.

Effect of adsorbent dose

The percent adsorption of Cr(VI) on different forms of adsorbent was studied at different adsorbent doses (250,500, 1,000, 1,500 and 2,000 mg/100 mL, respectively), keeping chromium concentration (50 mg/L), stirring speed (250 rpm), pH (2.0), temperature (25 °C), and contact time (30 and 60 min as obtained by kinetic studies) constant. The results showed that with increase in the adsorbent dose, the percentage adsorption of chromium was increased, and the maximum removal was observed with adsorbent dose of 5.0 g/L of DSPC, 12 g/L of DSPB, and 15 g/L of DSPN (Fig. 5). Increase in the percentage adsorption with adsorbent dose may be due to the increase in adsorbent surface area and availability of more adsorption sites (Mohanty et al. 2005). However, unit adsorption was decreased with increase in adsorbent dosage. As the adsorbent dose was increased from 2.5 to 20.0 g/L, the unit adsorption for DSPC, DSPB, and DSPN was decreased significantly. In the case of DSPN, it decreased from 1.74 to 0.30. This may be due to overlapping of adsorption sites as a result of overcrowding of adsorbent particles (Namasivayam et al. 1998). The order of percentage removal of chromium by studied adsorbent forms was: DSPC > DSPB > DSPN.

Effect of initial concentration

The percent adsorption of Cr(VI) with different adsorbents was studied by varying the chromium concentration (5,10, 25, 50, 75, 100, 250, and 500 mg/L), while keeping the adsorbent dose (15 g/L of DSPN, 12 g/L of DSPB, 5 g/L of DSPC), stirring speed (250 rpm), pH (2.0), temperature (25 °C), and contact time (60 and 30 min) constant. Higher concentrations of metal ions were used to study the maximum adsorption capacity of the adsorbents (Mohanty et al. 2006; Karthikeyan et al. 2005; Garg et al. 2007, 2008). The percent chromium adsorption was decreased with increase in initial chromium concentration (Fig. 6). However, the actual amount of chromium adsorbed per unit mass of the adsorbent was increased with increase in chromium concentration in the test solution (Fig. 7). As the chromium concentration in the test solution was increased from 5.0 to 500 mg/L, the unit adsorption of chromium on DSPC, DSPB, and DSPN increased from 12.00 to 912, 0.417 to 19.10, and 0.412 to 32.42 mg g−1, respectively (Table 4). The adsorption capacity of an adsorbent, which is obtained from the mass balance on the sorbate in a system with solution volume V, is often used to acquire the experimental adsorption isotherms. Under the experimental conditions, the adsorption capacities of all the adsorbents for each concentration of chromium (VI) ions at equilibrium were calculated from the following equation (Goel et al. 2005)

where Ci is the initial concentration in at equilibrium, V is the volume of solution (in L), and M is the mass of the adsorbent. The order of percentage removal of chromium for different metal-ion concentration was DSPC > DSPB > DSPN.

Adsorption isotherms

The analysis of equilibrium data is important for developing an equation that can be used for design purposes. The simplest adsorption isotherm is based on the assumptions that every adsorption site is equivalent and the ability of a particle to bind is independent of whether or not adjacent sites are occupied. Classical adsorption models, such as the Langmuir and Freundlich models, have been extensively used to describe the equilibrium established between adsorbed metal ions on the biomass (qe) and metal ions remaining in solution (Ce) at a constant temperature. The experimental results obtained for the adsorption of chromium on DSPC, DSPB, and DSPN at constant temperature (25 ± 1 °C) under pre-defined conditions of pH, adsorbent dose, and stirring speed obeyed the Freundlich adsorption isotherm. The Freundlich isotherm represents the relationship between the amount of metal adsorbed per unit mass of the adsorbent (x/m) and concentration of the metal ion in solution at equilibrium (Ce),

where Kf (L g−1) is an indicator of adsorption capacity and n (dimensionless) indicates the effect of concentration on the adsorption capacity and represents the adsorption intensity (dimensionless). The plot of log(x/m) versus log Ce for various initial concentrations was linear (figures not given), indicating the applicability of the classical adsorption isotherm to the DSPC-Cr(VI), DSPB-Cr(VI), and DSPN-Cr(VI) systems. The adsorption capacities (Kf) and the Freundlich constant (n) are given in Table 5.

The Langmuir isotherm is valid for monolayer adsorption onto a surface containing a finite number of identical sites. The model assumes uniform energies of adsorption on to the surface and no transmigration of adsorbate in the plane of the surface. The Langmuir isotherm is represented by the following equation,

where Ce is the equilibrium concentration (mg/L), qe the amount adsorbed at equilibrium time (mg g−1) and Qo and b are the maximum quantity of metal ions per unit weight of biomass to form a complete monolayer on the surface (mg g−1), whereas b is a constant related to the affinity of binding sites with the metal ions (l mg−1). The plots of Ce/(x/m) versus Ce are linear, which shows that the adsorption of Cr(VI) follows a Langmuir isotherm model. The correlation coefficient (r) values were very high for all the adsorbents (Table 5) which indicates that the data fitted reasonably well to the Langmuir isotherm in the present adsorption studies. Value of slope found to be lesser than unity implied that significant adsorption took place at low metal-ion concentration.

Adsorption kinetics

Pseudo first- and second-order equations

The kinetics of adsorption is important, as it controls the process efficiency. For evaluating the adsorption kinetics of heavy metals, the pseudo-first order equation of Lagergren has been used to test experimental data,

where Qe (mg/g) and Qt (mg/g) are the amount adsorbed of heavy metal ions at equilibrium and at time t, respectively, and K1 (min−1) is the rate constant of pseudo first-order adsorption. The application of this equation to the data of selected biosorbent (data not shown) indicated the inapplicability of the model.

The pseudo second-order kinetic model is linearly expressed as Ho and Mckay (1998).

where K2 (g/mg min) is the pseudo second-order rate constant, which can be calculated from the intercept of the straight line obtained from plotting t/QtVst. In addition, the initial sorption rate can be calculated using the relation (Koynucu 2008):

The perfect fit of the experimental data of DSP indicates the applicability of model for the adsorption of heavy metal ions on the selected biosorbent.

Film diffusion studies

Mass transfer plays an important role in sequestering of heavy metal from aqueous solution by the sorption process on the solid materials. In the present study, the mass transfer has been studied according to the model (Eq. 8) suggested by Mckay et al. assuming diffusion resistance within the particle to be negligible.

where Ct and C0 (both in mg g−1) are the respective concentrations of Cr(VI) ions at any time t and t = 0; k (1 g−1) is the product of Q0 and b and is known as Langmuir’s constant; m (g l−1) is the mass of adsorbent particles per unit volume, and Ss (cm−1) is the outer area of the adsorbent per unit volume. The mass of m and Ss were calculated using Eqs. (9) and (10).

and

where W (g) is the weight of the adsorbent, V is the volume of the particle-free solution; dp (cm) is the particle diameter, ρp is the density of the adsorbent and εp is the porosity of the particles. The value of k (1 g−1) in Eq. (8) was calculated using Eq. (11).

where Q0 and b are the same terms as those used in Langmuir’s model; k is also regarded as Langmuir’s constant. The curve was found linear up to 60 min; this implies that throughout the process film diffusion plays a significant role in the adsorption of Cr(VI) from aqueous solution onto the studied adsorbents. The mass transfer coefficient βL was calculated by multiplying the slope and intercept of the plot. The βL at 30 °C was found 0.235 cm s−1, respectively. The values indicate that the velocity of the mass transfer in the system is significant; hence, this process is recommended for industrial application.

Desorption efficiency and reusability

The regeneration of the biosorbent is one of the key factors in assessing of its potential for commercial applications. Two different desorption agents (1 M HCl and 1 M HNO3) were used to desorbe the Cr(VI) from the biosorbent. The desorption efficiency of Cr(VI) was found to be 98 and 65 % using 1 M HCl and 1 M HNO3 respectively. Therefore, 1 M HCl solution was selected as desorption agent. The reusability of the biosorbent was also tested in 10 consecutive sorption–desorption cycles. The results showed that the biosorbent offers potential to be used repeatedly in Cr(VI) sequestering process (Fig. 8).

Conclusions

The potential use of Dalbergia sissoo pods in its various forms as a biosorbent for sequestering of chromium (VI) was studied. This new biosorbent is able to remove the Cr(VI) ions from aqueous solutions, and the sorption capacity was strongly dependent on the adsorbent nature, the amount used, the initial metal-ion concentration, and the initial pH. The experimental data fitted well to the Freundlich and Langmuir equations, with good correlation coefficients. The experimental data also showed that the process followed a pseudo-second-order equation and both adsorbate and adsorbent were significant in the sorption rate determination. Chromium is adsorbed due to the strong interactions with the active sites of the adsorbent. Further, the utilization of biosorbent impregnated in the form of hydrated beads will also overcome the problem of release of soluble organic materials, while utilizing biomass in its natural form. Moreover, the natural form is not mechanically strong and has a wide size distribution, which can lead to the problems in the operations of reactors by blocking flow lines and clogging filters, while separation of biomass and effluent can be difficult and expensive. Thus, these results can be helpful in designing a wastewater system for the removal of such toxic heavy metal ions. Further work is in progress, in which modifications in the natural form of the biosorbent can lead to the enhanced removal and recovery of the metal ions from aqueous solutions.

References

Acar FN, Malkoc E (2004) The removal of chromium (VI) from aqueous solutions by Fagusorientalis. Bioresour Techno 94:13–15

Ahluwalia SS, Goyal D (2005a) Removal of heavy metals from waste tea leaves from aqueous solution. Eng Life Sci 5:158–162

Ahluwalia SS, Goyal D (2005b) Microbial and plant derived biomass for removal of heavy metals from waste water. Biores. Technol. 98:2243–2257

Aksu Z (2001) Equilibrium and kinetic modelling of cadmium (II) biosorption by C. vulgarisin a batch system: effect of temperature. Sep Purif Technol 21:285–294

Altundogan HS (2005) Cr(VI) removal from aqueous solution by iron (III) hydroxide-loaded sugar beet pulp. Process Biochem 40:1443–1452

Annadurai G, Juang RS, Lee DL (2002) Adsorption of heavy metals from water using banana and orange peels. Water Sci Technol 47:185–190

Bailey SE, Olin TJ, Bricka RM, Adrian DD (1999) A review of potentially low-cost sorbents for heavy metals. Water Res 33:2469–2479

Bassco MC, Cerrella EG, Cukierman AL (2002) Lignocellulosic materials as potential biosorbents of trace toxic metals from wastewater. Chem Res 41:3580–3585

Beveridge TJ, Murray RGE (1980) Sites of metal deposition in the cell wall of Bacillus subtilis. J Biotechnol 141:876–887

Bishnoi NR, Bajaj M, Sharma N, Gupta A (2004) Adsorption of chromium (VI) on activated rice husk carbon and activated alumina. Bioresour Technol 91:305–307

Cieslak-Golonka M (1995) Toxic and mutagenic effects of chromium (VI): a review. Polyhedron 15:3667–3689

Cimino G, Passerini A, Toscano G (2000) Removal of toxic cations and Cr(VI) from aqueous solution by hazelnut shell. Water Res 34:2955–2962

Dahbi S, Azzi M, Guardia M (1999) Removal of hexavalent chromium from wastewaters by bone charcoal. Fresenius J Anal Chem 363:404–407

Demirbas A (2000a) Biomass resources for energy and chemical industry. Energy Edu Sci Technol 5:21–45

Demirbas A (2000b) Recent advances in biomass conversion technologies. Energy Edu Sci Technol 6:19–40

Demirbas A (2005) Estimating of structural composition of wood non-wood biomass samples. Energy Sources 27:761–767

Fahim NF, Barsoum BN, Eid AE, Khalil MS (2006) Removal of Cr(III) from tannery wastewater using activated carbon from sugar industrial waste. J Hazard Mater 136:303–309

Farajzadeh MA, Monji AB (2004) Adsorption characteristics of wheat bran towards heavy metal cations. Sep Purifi Technol 38:197–207

Gardea-Torresdey JL, Tiemann KJ, Armendariz V, Bess-Oberto L, Chianelli RR, Rios J, Parsons JG, Gamez G (2000) Characterization of chromium (VI) binding and reduction to chromium (III) by the agricultural byproduct of Avena monida (oat) biomass. J Hazard Mater B 80:175–188

Garg VK, Gupta R, Kumar R, Gupta RK (2004a) Adsorption of chromium from aqueous solution on treated sawdust. Bioresour Technol 92:79–81

Garg VK, Gupta R, Kumar R, Gupta RK (2004b) Adsorption of chromium from aqueous solution on treated sawdust. Biores. Technol. 92:79–81

Garg UK, Kaur MP, Garg VK, Sud D (2007) Removal of hexavalent chromium from aqueous solution by agricultural waste biomass. J Hazard Mater 140:60–68

Garg UK, Kaur MP, Garg VK, Sud D (2008) Removal of Ni (II) from aqueous solution by adsorption on agricultural waste biomass using a response surface methodological approach. Bioresour Technol 99:1325–1331

Goel J, Kadirvelu K, Rajagopal C, Garg VK (2005) Removal of lead (II) by adsorption using treated granular activated carbon: batch and column studies. J Hazard Mater B125:211–220

Gupta VK, Ali I (2004) Removal of lead and chromium from wastewater using bagasse fly ash—a sugar industry waste. J Colloid Interface Sci 271:321–328

Gupta VK, Mohan D, Sharma S, Park KT (1999) Removal of Cr VI from electroplating industry wastewater using bagasse fly ash. Environmentalist 19:129–136

Hamadi ND, Chen XD, Farid MM, Lu MGQ (2001) Adsorption kinetics for the removal of chromium (VI) from aqueous solution by adsorbents derived from used tyres and sawdust. Chem Eng J 84:95–105

Hashem A, Abdel-Halim ES, El-Tahlawy KF, Hebeish A (2005) Enhancement of adsorption of Co(II) and Ni(II) ions onto peanut hulls though esterification using citric acid. Adsorp Sci Technol 23:367–380

Hashem A, Abou-Okeil A, El-Shafie A, El-Sakhawy M (2006) Grafting of high ά-cellulose pulp extracted from sunflower stalks for removal of Hg(II) from aqueous solution. Polymer-Plastics Technol Eng 45:135–141

Ho YS, Mckay G (1998) Kinetic models for the adsorption of dye from aqueous solution by wood. J Environ Sci Health 76:183–187

Kapoor A, Viraraghavan T, Cullimore DR (1999) Removal of heavy metals using the fungus Aspergillus niger. Bioresour Technol 70:95–104

Karthikeyan T, Rajgopal S, Miranda LR (2005) Chromium (VI) adsorption from aqueous solution by Heveabrasilinesis sawdust activated carbon. J Hazard Mater B124:192–199

Kowalski Z (1994) Treatment of chromic tannery wastes. J Hazard Mater 37:137–144

Koynucu H (2008) Adsorption kinetics of 3-hydroxy benzaldehyde on native and activated bentonite. Appl Clay Sci 38:279–282

Krishanani KK, Parmila V, Meng X (2004) Detoxification of chromium (VI) in coastal water using lignocellulosic agricultural waste. Water SA 30:541–545

Macchi G, Marani D, Tirivanti G (1986) Uptake of mercury by exhausted coffee grounds. Environ Technol Lett 7:431–444

Mohan D, Singh KP, Singh VK (2006) Trivalent Cr removal from wastewater using low cost activated carbon derived from agricultural waste material and activated carbon fabric cloth. J Hazard Mater B 135:280–295

Mohanty K, Jha M, Biswas MN, Meikap BC (2005) Removal of chromium (VI) from dilute aqueous solutions by activated carbon developed from Terminalia arjuna nuts activated with zinc chloride. Chem Eng Sci 60:3049–3059

Mohanty K, Jha M, Meikap BC, Biswas MN (2006) Biosorption of Cr(VI) from aqueous solutions by Eichhornia crassipes. J Chem Eng 117:71–77

Namasivayam C, Kadirvelu K, Kumuthu M (1998) Removal of direct red and acid brilliant blue by adsorption on to banana pith. Bioresour Technol 64:77–79

Oliveira EA, Montanher SF, Andnade AD, Nobrega JA, Rollemberg MC (2005) Equilibrium studies for the sorption of chromium and nickel from aqueous solutions using raw rice bran. Process Biochem 40:3485–3490

Orhan Y, Bujukgungor H (1993) The removal of heavy metals by using agricultural wastes. Water Sci Technol 28:247–255

Patterson JW (1977) Waste water treatment. Science Publishers, New York

Qaiser S, Saleemi AR, Ahmad MM (2007) Heavy metal uptake by agro based waste materials. Environ Biotechnol 10:409–416

Rao M, Parwate AV, Bhole AG (2002) Removal of Cr and Ni from aqueous solution using Bagasse and fly ash. Waste Manage 22:821–830

Reddad Z, Gerente C, Andres Y, Ralet MC, Thibault JF, Cloirec PL (2002) Ni(II) and Cd (II) binding properties of native and modified sugar beet pulp. Carbohydrate Polym 49:23–31

Rojas G, Silva J, Flores JA, Rodriguez A, Maldonado H (2005) Adsorption of chromium onto cross-linked chitosan. Sep Purif Technol 44:31–36

Sarin V, Pant KK (2006) Removal of chromium from industrial waste by using eucalyptus bark. Bioresour Technol 97:15–20

Sarkanen KV, Ludwig CH (1971) Lignins-occurance, formation, structure and reactions. Wiley-Interscience, New York

Singh IB, Singh DR (2002) Cr(VI) removal in acidic aqueous solution using iron-bearing industrial solid wastes and their stabilization with cement. Environ Technol 23:85–95

Sjötröm E (1981) Wood chemistry fundamentals and applications. Academic Press, New York

Sud D, Mahajan G, Kaur MP (2008) Agricultural waste material as potential adsorbent for sequestering heavy metal ions from aqueous solutions: a review. Bioresour Technol 99:6017–6027

Tarley CRT, Arruda MAZ (2004) Biosorption of heavy metals using rice milling byproducts. Characterization and application for removal of metals from aqueous effluents. Chemosphere 54:987–995

Tee TW, Khan RM (1988) Removal of lead, cadmium and zinc by waste tea leaves. Environ Technol Lett 9:1223–1232

Tiravanti G, Petrluzzelli D, Passino R (1997) Pretreatment of tannery wastewaters by an ion exchange process for Cr(III) removal and recovery. Water Sci Technol 36:197–207

Valix M, Cheung WH, Zhang K (2006) Role of heteroatom in activated carbon for the removal of hexavalent Cr from wastewater. J Hazard Mater 135:395–405

Venkateswarlu P, Ratnam MV, Rao DS, Rao MV (2007) Removal of chromium from aqueous solution using Azadirachta indica (neem) leaf powder as an adsorbent. Int J Phys Sci 2:188–195

Zhang L, Zhao L, Yu Y, Chen C (1998) Removal of lead from aqueous solution by non-living Rhizopus nigrican. Water Res 32:1437–1444

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Mahajan, G., Sud, D. Modified agricultural waste biomass with enhanced responsive properties for metal-ion remediation: a green approach. Appl Water Sci 2, 299–308 (2012). https://doi.org/10.1007/s13201-012-0050-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13201-012-0050-5