Abstract

In recent days the manufacturing process have become more precise and cost efficient due to advancement in the field of computer technology. Information technology has been integrated with manufacturing practice and has resulted in time reduction from concept of a product to marketing of the product. Cutting force generated is the main manufacturing issue raised among industries as it clearly affects quality and cost of the final product. Hence using extensive literature and data base knowledge optimum cutting parameters are selected. Therefore, this paper focuses on a response surface methodology (RSM) based expert system that has been developed using JAVA programming with the help of response surface second order model to automatically generate values of cutting force during machining of Ti–6Al–4V alloy under minimum quantity lubrication (MQL) for different process input parameters. From RSM it has been observed that calculated value of F (20.36) was greater than the F-table value (3.02) and hence the model developed can be effectively used for machining of Ti–6Al–4V alloy. Further the developed RSM based expert system model can be successfully used to predict the force generated during cutting process while machining Ti–6Al–4V alloy under MQL conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The automobile and aerospace sectors are well-known for working under extreme mechanical and temperature conditions. It is desirable that the mechanical and machinability qualities of the material be understood in order to provide efficient and long-term performance under these conditions (Tolga 2005). Titanium alloys have been regarded as difficult to machine materials due to their high hardness, high chemical reactivity, and low thermal conductivity during machining, despite their exceptional characteristics. When comparing alpha phase titanium alloy to beta phase titanium alloy, there is a noticeable increase in cutting force (Donachie 2000). There has been various research carried out on machining of Titanium alloys. Siekmann (1955) suggested that machining of titanium alloy will be a challenge to the manufacturing industry. The cutting forces which were generated during machining of titanium alloys were similar to those obtained while machining steels (Nagi et al. 2008). Arrazola et al. (2009) carried out research on machining of titanium alloy and suggested that chatter was the major problem during machining due to low modulus of elasticity of titanium alloy. CaR and Milwain (1968), Konig et al. (1980) revealed that high temperature and high stresses induced at the tool cutting edge is the major problem while machining of titanium alloys. Hence proper selection of a cutting fluid to minimise this problem is of primary importance. Kaymakci et al. (2012) developed a unique cutting force model for various conventional machining process. Yang and Liu (1999) and Ahmed et al. (2007) suggested that cryogenic cooling and minimum quantity lubrication (MQL) can be considered as cutting fluids to increase the tool life. Ibrahim et al. (2014) carried out research on study of surface roughness under different lubrication modes. Wyen and Wegener (2010) studied the effects of cutting speed, feed and cutting edge radius on cutting forces while turning orthogonally the Ti–6Al–4 V titanium alloy workpiece. Islam et al. (2013) studied the effects of various input parameters such as cutting speed, feed and coolants on dimensional accuracy of cylindrical titanium alloy and suggested that by proper selection of cutting parameters the spring back problem can be nullified. Raviraj et al. (2014) during turning of Ti–6Al–4 V under almost dry machining using RSM, had analyzed the surface roughness. They had concluded that with selecting proper parameters for machining, a better performance at less time and cost could be achieved. Mookherjee and Bhattacharyya (2001) an expert system, namely EXTOOL, has been developed by the author and this system is based on the customer requisite material and geometry, to select inserts for turning and milling processes automatically”. Sapuan et al. (2002) have developed the expert tool material selection system for machining of automobile components. Chee et al. (2012) have developed an expert system for selection of carbide cutting tools for computer numerical control (CNC) lathe machine. Chougule et al. (2014) had developed an expert system to optimally select carbide cutting tools for turning operation. However, in spite of these many research on machining of titanium alloy researchers are still facing some challenges to titanium alloy part manufacture (Ezugwu and Wang 1997). However, application of MQL during machining of Titanium alloy using Response Surface Methodology (RSM) approach has been proved to be most effective technique for identifying the process output parameters (Dixit et al. 2012).

Hence in this paper an RSM based expert system has been developed using JAVA programming with the help of RSM model to predict cutting forces enhancement during machining of Ti–6Al–4 V alloy under MQL conditions.

1.1 Methodology

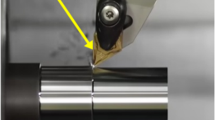

The cutting experiments have been carried out in “PSG A141 lathe (2.2 KW)” using “Cubic Boron Nitride tool” under Minimum Quantity Lubrication (MQL) Fig. 1.

In MQL, coconut oil is used as lubricant during machining. The cutting tool specification used to machine Ti–6Al–4V alloy are shown in Table 1. Table 2–Table 3 shows the Ti–6Al–4V chemical composition and mechanical properties at room temperature. The Ti–6Al–4V alloy specimen and its microstructure is shown in Fig. 2. The cutting forces generated during turning of Ti–6Al–4V alloy are measured by “9257BA KISTLER Dynamometer”.

1.2 Response surface methodology

Cutting force evolution during machining is challenging to analyse in the metal cutting industry. Evaluating cutting force has been the most effective way of determining the machining properties of any metal or alloy. As a result, an expert system based on RSM can anticipate cutting force as a function of cutting conditions in advance. RSM is a tool that uses a combination of mathematical and statistical techniques to develop a model, analyse the problem, and select the optimal cutting conditions (Montgomery 2005).

“In RSM the relationship between a process output variable of interest ‘y’ and a set of controllable variables {x1, x2.... xn} can be written in the form

where ε represents noise or error observed in the response y. If we denote the expected response be

then the surface represented by

is called response surface. The first step in RSM is to find a suitable approximation for the true functional relationship between y and set of independent variables employed. Usually a second order model is utilized in response surface methodology”.

Proposed by (Raviraj et al. 2008), the β coefficients, used in the above model can be calculated by means of least square method. However, a second-order model is normally used when the response function is unknown or nonlinear. “Face centred central composite design (FCCD)” is used while conducting the experiment in which α = 1, three controllable process factors (p = 3), region of interest coded {− 1, 1} whose levels are presented in Table 4 followed by 20 sets of experiments using “two-level full factorial with 8 factorial points, augmented with additional 6 centre and 6 axial points” as shown in Fig. 3.

A second-order model has been established for cutting force using response surface methodology. The selected levels and factors in machining of Ti–6Al–4V under MQL using response surface methodology are shown in Table 5.

1.3 Expert system

Because of the widespread use of Ti–6Al–4V in modern manufacturing industries, expert systems have evolved in process planning of machine tool, cutting conditions, and operating sequences. Because cutting conditions differ from material to material, appropriate instructions for selecting cutting condition must be provided. In the final section of the study, expert system-based software was developed utilizing JAVA programming to analyze the cutting force generated at various cutting parameters during Ti–6Al–4V machining under MQL. Figure 4 shows the general structure of the Expert system.

2 Results and discussion

2.1 Cutting force (RSM)

Response surface methodology is a popular technique for identifying the best process output variables with the fewest number of trials. This technique can be used to construct a second order mathematical model during metal cutting.

The relationship between the cutting parameters and cutting force has been expressed as follows:

From the analysis of Variance (ANOVA) (Table 6), it was observed that F calculated value (20.36) was greater than the F-table value (3.02) followed by P-table value less than 0.05 (95% confidence level) and hence the developed model was quiet adequate.

The contour and surface plots for each of the response surfaces at varied cutting conditions are plotted using the second order model (Figs. 5, 6 and 7). Cutting force can be predicted using response contours and surface plots in any zone of the machining domain. Scanning Electron Microscope (SEM) photographs of a machined surface at various cutting speeds are shown in Fig. 8. Figure 9 shows the mean cutting force profile at “101 m/min (Cutting Speed), 0.11 mm/rev (Feed) and 0.25 mm (Depth of cut)”.

2.2 Cutting force (RSM based expert system)

Cutting force during Ti–6Al–4V machining has a significant impact on manufacturing costs. As a result, a JAVA-based expert system model based on RSM has been created. NET BEANS was the software which has been used in this paper. Figure 10 shows the cutting force component representation file.

The RSM-based expert system calculates the cutting force generated during Ti–6Al–4V machining under various cutting circumstances first. The method for calculating cutting force is based on the response surface mathematical model generated in Eq. 1. Figure 11 shows the cutting parameter chosen using an RSM-based expert system under MQL lubrication conditions. “From RSM based expert system it is observed that at 101 m/min (Cutting Speed), 0.11 mm/rev (Feed) and 0.25 mm (Depth of cut) the cutting force generated was 134.565 N”.

2.3 Confirmatory experiments for cutting force

Cutting force generated during machining of Ti–6Al–4V is predicted and verified using MQL application verification tests. Figure 12 depicts the cutting force validation of experimental results and RSM-based Expert system results. Figure 12 shows that the experimental and predicted values for all of the tests in the experiment were fairly similar.

3 Conclusions

The following findings can be made from the study of RSM and RSM-based expert systems for machining Ti–6Al–4V under MQL:

-

The calculated F value (20.36) was found to be more than the F-table value (3.02) from RSM, indicating that the proposed model may be used successfully for machining Ti–6Al–4V.

-

It was discovered from the response contours and surface plot that increasing cutting speed resulted in a reduction in cutting force.

-

The developed RSM-based expert system allows the user to analyse the cutting force and select cutting parameters in order to get the desired result in a short amount of time and at a low cost.

-

During the validation of experimental data using an RSM-based expert system, it was discovered that the experimental and projected values for all of the selected tests of experiments were relatively similar.

4 Future work

To begin with, only few variables were selected for the RSM based expert system model. In order to investigate the effects of other variables, further study is required. Though the values and methods recommended in the literature were selected, some of the important factors such as lubricant pressure, nozzle diameter, lubricant impinging angle, nose radius, tool materials, rake angle, clearance angle and shank size were treated as constant input factors in the RSM based expert system model. An experiment aimed at determining the influence of these factors would be appropriate. Further, the RSM-based expert system model developed in this paper can be utilized to develop a mechanistic model, which will include other elements such as machine dynamics and tool geometry, and can forecast cutting force outputs for a larger variety of cutting situations.

References

Ahmed MI, Ismail AI, Abakr YAN, Amin AKM (2007) Effectiveness of cryogenic machining with modified tool holder. J Mater Process Technol 185:91–96

Arrazola PJ, Garay A, Iriarte LM, Armendia M, Marya S, le Maître F (2009) Machinability of titanium alloys (Ti6Al4V and Ti555.3). J Mater Process Technol 209:2223–2230

CaR EJ, Milwain D (1968) ISI Special Report 94. London, pp 143–150

Chee F, Ranjit S, Kher V (2012) An expert carbide cutting tools selection system for CNC lathe machine. Int Rev Mech Eng 6(7):1402–1405

Chougule PD, Kumar S, Raval HK (2014) An expert system for selection of carbide cutting tools for turning operations. In: 5th International and 26th All India manufacturing technology. Design and research conference, IIT Guwahati, Assam, India

Dixit US, Sarma DK, Davim JP (2012) Environmentally friendly machining. Springer, Berlin

Donachie JMJ (2000) Titanium—a technical guide, 2nd edn. ASM International, New York, pp 79–84

Ezugwu EO, Wang ZM (1997) Titanium alloys and their machinability—a review. J Mater Process Technol 68:262–272

Ibrahim D, Syed Waqar R, Salman P (2014) Analysis of lubrication strategies for sustainable machining during turning of titanium Ti–6Al–4V alloy. Procedia CIRP 17:766–771

Islam MN, Anggono JM, Pramanik A, Boswell B (2013) Effect of cooling methods on dimensional accuracy and surface finish of a turned titanium part. Int J Adv Manuf Technol 69(9–12):2711–2722

Kaymakci M, Kilic ZM, Altintas Y (2012) Unified cutting force model for turning, boring, drilling and milling operations. Int J Mach Tools Manuf 54(55):34–45

Konig W, Schroder B, Treffert H (1980) High speed grinding of any contour using CBN wheels, Friction and Lubrication in the fabrication of titanium and its alloys. Metal Inter Newslett 5(3):14–21

Montgomery DC (2005) Design and analysis of experiments, 6th edn. Wiley, New York

Mookherjee R, Bhattacharyya B (2001) Development of an expert system for turning and rotating tool selection in a dynamic environment. J Mater Process Technol 113(1–3):306–311

Nagi E, Che HCH, Jaharah AG, Shuaeib FM (2008) High speed milling of Ti–6Al–4V using coated carbide tools. Eur J Sci Res 22(2):153–162

Raviraj S, Tony KJ, Goutam DR, Srikanth SR, Diwakar S (2014) Surface roughness analysis during turning of Ti–6Al–4V under near dry machining using statistical tool. Int J Curr Eng Technol 4(3):2061–2067

Raviraj S, Raghuvir P, Kamath V, Rao SS (2008) Study on surface roughness minimization in turning of DRACs using surface roughness methodology and Taguchi under pressurized stream jet approach. ARPN J Eng Appl Sci 3(1):1819–6608

Sapuan SM, Jacob MSD, Mustapha F, Ismail N (2002) A prototype knowledge-based system for material selection of ceramic matrix composites of automotive engine components. Mater Des 23(8):701–708

Siekmann HJ (1955) How to machine titanium. The Tool Engineer 34:78–82

Tolga B (2005) On the mechanical surface enhancement techniques in aerospace industry—a review of technology. Aircraft engineering and aerospace technology. Int J 77(4):279–292

Wyen CF, Wegener K (2010) Influence of cutting edge radius on cutting forces in machining titanium. CIRP Ann Manuf Technol 59:93–96

Yang X, Liu CR (1999) Machining titanium and its alloys. Mach Sci Technol 3(1):107–139

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Research involving human participants and/or animals

The authors declare that this project does not involve Human Participants and/or animals in any capacity.

Informed consent

The authors declare that this research does not involve any surveys or participants in any capacity.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shetty, R., Kumar, C.R.S. & Ravindra, M.R. RSM based expert system development for cutting force prediction during machining of Ti–6Al–4V under minimum quantity lubrication. Int J Syst Assur Eng Manag 14 (Suppl 4), 938–945 (2023). https://doi.org/10.1007/s13198-021-01495-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-021-01495-z