Abstract

we present a printed lens for radar applications. The structure of the presented lens consists of an array of modified micro-strip lines, which is positioned in the antenna’s aperture on the same planar substrate. Simulations show that the gain and directivity increase with the proposed lens in a wide band frequency band. The proposed design is insensitive to rotation of the antenna. This paper focuses on real industrial applications and problems. Further, we show that the lens can be used to improve the object detection ability of an ultrawide band radar system, which is used in industrial applications such as non-destructive monitoring of built-structures and for use in the renovation process. The signal to noise ratio is improved. Furthermore, we show how the microwave lens can also be used to reduce the clutter in applications where the complex refractive index of objects is determined. Further, different simulated results (for different cases) are compared, presented and concluded.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Different methods are being implemented to improve the performance of an of ultrawide band (UWB) radar systems, based on the modification of the geometries of the antennas, the use of meta-materials, and the use of lenses (Jenssen et al. 2019; Choudhary et al. 2020). These methods have found applications in ground-based non-destructive testing. (Choudhary et al. 2020; Zhang et al. 2019).

Since several years researchers have shown interest in Vivaldi antennas for radar applications; the Vivaldi antenna was introduced for the first time in 1979, (Gibson 1979). To improve the antenna characteristics (such as wide operating frequency range, etc.) further a modified structure known as antipodal Vivaldi antenna was introduced in (Gazit 1988). To improve the limitations faced by this antenna (Langley et al. 1993) proposed another type of Vivaldi antenna known as the balanced antipodal Vivaldi antenna. Further different types of loads and slots of different length on the arms of the antenna (Bai et al. 2011) have been used to improve the band width, directivity, and characteristics of the radiation patterns.

An extended dielectric director or lens was used by researcher in the antenna’s aperture to improve the bandwidth and gain (Juan et al. 2013; Keskin et al. 2020) . The half circular shaped lens was used in an exponentially tapered corrugated slot edge on the radiator and ground plane for gain enhancement (Moosazadeh et al. 2017). Various other methods based on lenses and slots have been used to improve the bandwidth, directivity, front-to-back ratio, and reduction of co-polarization and cross-polarization of antennas (Avdushin et al. 2014).

In this work, a printed lens (which is printed in the antenna’s aperture on the same planar substrate) is proposed to improve the performance of UWB radar systems in ground-based applications. UWB radar has the ability to penetrate concrete structures and good resolution in time domain, making it suitable for non-destructive testing (Choudhary et al. 2019). One such example of a non-destructive testing is health monitoring of bridges. In the long term, bridges require maintenance that may include ground-based non-destructive testing methods. Moreover, due to thick lossy concrete, electrically small reinforced iron joists size, unwanted noise and measurement errors, and the measured radar echoes fail to provide sufficient object information. Therefore, to overcome this problem, the printed lens can be used to focus the electromagnetic (EM) radiation of the radar’s antenna, which allows the detection of electrically small objects and also compensating for phase distortion. Further, the printed lens causes suppression of the clutter from unwanted objects, in an application where the determination of complex refractive index was performed.

To our knowledge, this is the first time a printed board lens is proposed for an antipodal Vivaldi antenna. The electromagnetic simulations and analysis of the antipodal-antenna design and system simulations for radar performance, are carried out using time-domain method in ANSYS high frequency simulator for electronics.

The article is structured as follows: Sect. 2 describes the design and results of the antipodal-Vivaldi antenna with printed lens. The radar performance simulations are presented in Sect. 3; Sect. 4 presents the conclusions.

2 Design

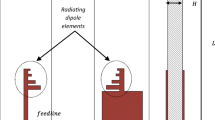

An antipodal-Vivaldi antenna with printed lens design is shown in Fig. 1(right). Figure 1(left) shows a zoomed view of the lens located in the antenna’s aperture. The lens was designed according to the design of the Antipodal-Vivaldi antenna, which has vertical symmetry (see Fig. 1). The design parameters are mentioned in Table 1 (see table 1). The structure consists of three layers: (1) a quarter elliptical design as a top metallic layer, (2) a low profile FR-4 epoxy substrate (\( \epsilon _{r}\) = 4.38, tan\( \delta \) = 0.003, with thickness t) as a dielectric substrate layer, and (3) a vertical mirror image of the top layer as a ground metallic layer. The top and bottom metallic layers are copper sheets with thickness (and conductivity of 5.8 \(\times \) 10\( ^{13} \) S/\( \mu \)m). All the three layers are sandwiched together in the z-plane.

On-board printed aperture lenses are insensitive to antenna rotation and misalignment, unlike bulky and separate metasurface microwave lenses as for example reported in (Azad et al. 2017), which may have misalignment issues. The Vivladi antenna (see Fig. 2) is used as the base-design to study the printed lens in the antenna’s aperture. The antenna is a tapered leaf shaped antipodal-designed structure. The antenna is feed along the height of the substrate in yz plane. The antenna is capable of operating in the frequency range 1–3 GHz. Initially, an aperture lens was reported in (Avdushin et al. 2014). It was tested and analysed, and the results were not as expected since the antipodal antenna device would require and antipodal-lens to achieve favorable results. Hence, we introduced the antipodal lens as shown in Fig. 1. We applied the optimization algorithm available in the electromagnetic simulator to optimize the printed lens’ parameters. The optimization aim is to maximize the gain and directivity without degrading the impedance matching to free space. Table 1 shows the optimized design paramters for the printed lens in aperture, (see zoomed view in Fig. 1). The frequency dependence of the S-parameters, i.e \( \mid S_{11} \mid \), of the antipodal-Vivaldi antenna with and without printed lens is shown in Fig. 2.

Magnitude of simulated \( S_{11} \) vs. frequency for the design shown in Fig. 1

The proposed lens increases the gain of the antipodal-Vivaldi antenna (up to two decibel or more) as shown in Fig. 3. The figure also shows the dependence of gain versus frequency.

Simulated gain vs. frequency for the design shown in Fig. 1

Further, Fig. 4 shows the 3D radiation pattern in xyz coordinates at a frequency of 1 GHz. As in the figure, the presence of the lens in the antenna’s aperture contributes to lowering the level of side lobes and focusing the EM radiation in the main beam lobe direction. The corresponding observation is made also for the increase in the antenna’s gain as shown in Fig. 3.

3D radiation pattern of the design shown in Fig.1, a without printed lens and b with printed lens in the antenna’s aperture

Table 2 provides a comparison between the presented lenses with other different types of lenses proposed in the literature. We can compare lenses in terms of design, materials used, construction and performance as shown in the table (see Table 2). It can be seen that the design of the present lens is planar (see Fig. 1), which makes it cost-effective and simplifies the manufacturing process. Moreover, 3D lenses require a complex printing technology and complex artifical materials, which make fabrication difficult and expensive. Although the increase in gain is better observed in 3D lenses as compared to planar lenses, moreover problems like misalignment issues, design of complex artifical materials, bulky in size, costly manufaturing etc. make them challenging for researchers.

3 Radar performance simulation and analysis

The electromagnetic simulations of the antipodal Vivaldi antenna with printed lens and radar performance simulations were carried out using time domain methods in an electromagnetic simulator.

3.1 Object detection

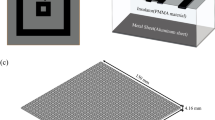

The radar system contains two presented antipodal-Vivaldi antennas with print lenses, which are collocated as a transmitter and a receiver as shown in Fig. 5. The system operates in a wide frequency range as mentioned above (i.e. the wavelength is 0.3–0.1 m). Simulations of the radar performance were made for an electrically small object in a lossy dielectric medium, which corresponds to a bridge of concrete with reinforcement iron joists, as shown in Fig. 5.

In through-the-medium or through the wall non destructive testing, the medium’s high complex refractive index affects the radar echoes and results in high attenuation of received echoes (Juan et al. 2013). The electrically small metallic object (10 cm \(\times \) 5 cm ) is submerged in the dielectric medium (see Fig. 5). An electrically small object means that the size of the object is smaller than the operating wavelength. The distance between the air-concrete interface and the radar system is 30 cm to avoid near field effects as discussed in Juan et al. (2013). In our case, the dielectric properties of the medium (or concrete) is \( n= 4 \) and \( k=0.25 \), where n is the refractive index and k is the absorption of the medium. The simulated radar echoes without lens and with the lens are shown in Fig. 6a, b respectively. It is observed that the metallic object, replicating the radar cross section of a reinforced iron joist, is undetected in the radar echo without printed lens. In the case when the proposed lens is used, it is clearly detected. In addition, the noise level is reduced (see Fig. 6a, b).

3.2 Radar imaging

Radar C-scan images are created by using frequency domain back projection imaging technique (Choudhary et al. 2019). To create the C-scan images the simulated radar echoes of different radar positions \( x_{i},y_{i} \) are processed together. For each \( x_{i},y_{i} \) positions of the antennas, the radar echo \( A(x_{i},y_{i}, \omega _{n}) \) is simulated. These received echoes are then combined in phase,

where \( d_{i} \) is the distance between radar position (\( x_{i},y_{i} \)) and image-pixel postion (\( \overline{x},\overline{y},\overline{z} \)).

The simulations were performed for different radar positions in a square pattern. The purpose of these simulations is to create the radar images (which are commonly used to visualize buried objects to a radar operator in industrial applications) and compare the results of radar images for the cases with and without lens. In Fig. 7a and b show the C-scan images of the metallic object. As expected, the metallic object is not clearly visible in the radar image, in which the printed lens was not used. However, in the case with the lens, the metallic object is clearly visible and easily distinguishable from the noise in the radar image.

3.3 Clutter reduction in determination of complex refractive index

The two metallic objects and a dielectric object (with known dielectric properties) were used for simulations. One bigger metallic object (30 \( \times \) 30 cm\( ^{2} \)) used as a reference object (RO) whereas another metallic object (10 \( \times \) 10\( \hbox {cm}^{2} \)) used as a unintended object (UO). The geometry of the simulation is shown in Fig. 8, wherein the object under test is placed (at 40cm away from the radar) between the radar system and RO. RO and UO are positioned at distance of \( d_{1}= \) 1 m and \( d_{2} \) = 1.2 m from the radar system, respectively. UO is replicating the radar cross section of unintended objects such as metallic conveyor-belt housing, metallic joists, metallic small-structures, etc.(often present in industrial environments). We used a conventional method to determine the complex refractive index, \(\tilde{n}=n+jk\), as in (Choudhary and Rönnow 2020), in which the real part, n of the refractive index can determined from time delays of the reflected pulses from different interfaces. We do not consider multiple reflections; such pulses are small in amplitude and seen at longer times than three initial pulses from three interfaces (interfaces shown in Fig. 8). For the method to work properly, the reflected pulses from different interfaces must be separable in time domain. Reflected pulses are received in the recorded time series in the following steps:

-

1.

Find the maximum peak value and the corresponding time instants of the time series. Define a time interval around this time instant; this is now one pulse.

-

2.

Find the maximum value and the corresponding time instant of the time series, without the time interval from Step 1.

-

3.

Continue until three maximum peak values from three pulses have been detected.

-

4.

Sort the simulated pulses in adjacent order in time such that \( \tau _{1}, \tau _{2},\) and \( \tau _{3} \) are obtained.

-

5.

Simiarly, \( \tau _{r} \) is obtained from the simulated reference pulse (without object under test).

Further, real part, n of the refractive index can determined as, (Choudhary and Rönnow 2020),

where \( \tau _{r} \) and \( \tau _{1} \) are the time delay of reference pulse (without object under test) and pulse from interface 1, etc., and the imagnary part, k, can be obtained from the slope of the ratio of the Fourier transforms of pulses, (Choudhary and Rönnow 2020),

where \( M_{3r} \) is slope of the ratio of the Fourier transforms of pulse from interface 3 to reference pulse vs. frequency, \( c_{0} \) is the speed of light in vacuum, and d is the distance between radar and reflecting interface 2.

An example of slopes obtained from simulated data from setup (see Fig. 8) vs. frequency is shown in Fig. 9. It can be clearly seen in Fig. 9 that, in the presence of UO the ratio exhibits some frequency dependence, which results in a change in the slope (see black line and dashed line with \( \times \) marker). For the cases without and with lens, it can also be clearly seen in the figure that the slopes of the ratios in the different cases (i.e, UO is absent, wherein the lens is not used in the aperture of antenna and UO is present, wherein the lens is printed in the aperture of antenna) are in good agreement (see black line and \( \mathbf{o} \) markers), which means that focused EM radiation can avoid clutter from UO. Also, the slope of the ratio from the case, in which the UO is present (wherein lens is not used in the aperture of the antenna) shows relatively higher slope (see dashed line with \( \times \) marker) as discussed above. The effect may vary with the size of the UO as object, as experimentally investigated in (Choudhary and Rönnow 2020). Objects of different size results in different frequency dependence. We conclude omni- or wide EM radiation of the antenna may can introduce clutter from unintended objects.

Table 3 shows the true complex refractive index, \(\tilde{n}=n+jk\), of objects under test. Also, the real and imaginary parts of refractive index, which were determined for the two different cases (i.e, UO is present, wherein lens is not used and UO is present, wherein lens is printed in the aperture of the antenna). It also shows that the microwave lenses may can be used to reduce the clutter in determination of the complex refractive index of objects.

4 Conclusions

We have presented the design of a printed lens for an antipodal-Vivaldi antenna, the purpose of which is to improve the performance of UWB radar systems at ground range. The presented lens works very well in the 1–3 GHz frequency band and furthermore an increase in gain can be seen up to 5.5 GHz (see Fig. 3). The lens is a modified micro-strips based structure printed in the antenna’s aperture. The antenna, intended for UWB radar applications is based on microstrip technology and is, hence, easy to fabricate. We can also conclude that the presented lens design contributes to lowering the level of side lobes and focusing EM radiation in the main beam lobe direction as well as ably compensate phase-distortion. Therefore, the gain is significantly increased for the antipodal-Vivaldi antenna. The lens design for the antenna is on the same substrate, so it is insensitive to rotation of the antenna. The 2-D printing technology can be used for lens fabrication, unlike 3-D lenses which require a complex printing technology. The results show that is suitable for non-destructive testing in ground-range (as shown in Sect. 3). The results also show that the microwave lens can be used to reduce the clutter in determination of the complex refractive index of objects in industrial applications.

The presented lens is limited to mentioned frequency range. It could be modified or improved for specific frequency range. Complex clutters could be measured and analysed. Other types of unintended-objects such as non-metallic objects (with differnet shapes) could be studied. The lens is also limited to antipodal antenna devices. The printed lens can be used for antipodal-antenna arrays and for beam-shaping applications.

References

Anwar MS, Abufanas H, Bangert A (2020) 3d printed dielectric lens for the gain enhancement of a broadband antenna. Int J RF Microw Comput Aided Eng 30(4):e22115

Avdushin A, Ashikhmin A, Negrobov V, Pasternak YG, Fedorov S (2014) Vivaldi antenna with printed lens in aperture. Microw Opt Technol Lett 56(2):369–371

Azad AK, Efimov AV, Ghosh S, Singleton J, Taylor AJ, Chen HT (2017) Ultra-thin metasurface microwave flat lens for broadband applications. Appl Phys Lett 110(22):224101

Bai J, Shi S, Prather DW (2011) Modified compact antipodal vivaldi antenna for 4–50-ghz uwb application. IEEE Trans Microw Theory Tech 59(4):1051–1057

Choudhary V, Rönnow D (2020) A nondestructive testing method for the determination of the complex refractive index using ultra wideband radar in industrial applications. Sensors 20(11):3161

Choudhary V, Rönnow D, Jansson M (2019) A singular value decomposition based approach for classifying concealed objects in short range polarimetric radar imaging. In: 2019 PhotonIcs & electromagnetics research symposium-spring (PIERS-Spring), pp 4109–4115

Choudhary V, et al. (2020) Metamaterial-based-absorber to improve the performance of s and x band radar systems. In: 7th International conference on signal processing and integrated networks, pp 126–129

Gazit E (1988) Improved design of the vivaldi antenna. In: IEE Proceedings H (microwaves, antennas and propagation), IET, vol 135, pp 89–92

Gibson P (1979) The vivaldi aerial. In: 9th European microwave conference. IEEE, pp 101–105

Jenssen ROR, Eckerstorfer M, Jacobsen S (2019) Drone-mounted ultrawideband radar for retrieval of snowpack properties. IEEE Trans Instrum Measure 69(1):221–230

Juan L, Guang F, Lin Y, Demin F (2013) A modified balanced antipodal vivaldi antenna with improved radiation characteristics. Microw Opt Technol Lett 55(6):1321–1325

Keskin N, Aksimsek S, Tokan NT (2020) Wide-band gain enhancement of a pyramidal horn antenna with a 3d-printed epsilon-positive and epsilon-near-zero metamaterial lens. Int J Microw Wirel Technol 1–9

Langley J, Hall P, Newham P (1993) Novel ultrawide-bandwidth vivaldi antenna with low crosspolarisation. Electron Lett 29(23):2004–2005

Moosazadeh M, Kharkovsky S, Case JT, Samali B (2017) Improved radiation characteristics of small antipodal vivaldi antenna for microwave and millimeter-wave imaging applications. IEEE Anten Wirel Propag Lett 16:1961–1964

Zhang B, Wu L, Zhou Y, Yang Y, Zhu H, Cheng F, Chen Q, Huang K (2019) A two-dimensional multibeam lens antenna for hydrologic radar application. IEEE Anten Wirel Propag Lett 18(12):2488–2492

Acknowledgements

The initial research work of this article was presented at the 13th international virtual conference of Antenna Tests and Measurements (ATMS-2021). The authors would like to thank the participants for their comments.

Funding

Open access funding provided by University of Gävle.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Funding

This work was supported by the European Commission within the European Regional Development Fund, through the Swedish Agency for Economics and Regional Growth, and in part by Region Gävleborg.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Choudhary, V., Rönnow, D. & Tripathy, M.R. A printed lens in antenna’s aperture to improve the performance of UWB-radar system. Int J Syst Assur Eng Manag 14 (Suppl 2), 603–609 (2023). https://doi.org/10.1007/s13198-021-01341-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-021-01341-2