Abstract

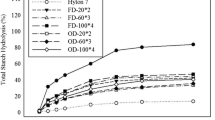

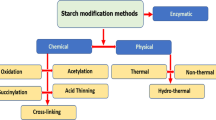

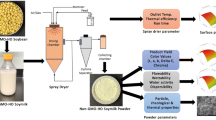

Plant-based milk products are gaining attention since it has been demonstrated that the consumption of animal-derived foods had to be reduced to combat global climate change. The production of plant-based milk includes a starch hydrolysis step for raw materials with high starch content such as cereals and pulses, since the gelatinized starch forms a thick slurry which causes an unsuitable consistency for a drinkable product. The objectives of this work were to investigate the effects of slurry concentration (solid to solvent ratio), enzyme including temperature, enzyme amount and mixing (rotation) speed on the pasting properties especially final viscosity of a crude chickpea milk and also to investigate the potential use of Micro Visco Amylo-Graph for monitoring starch hydrolysis. Response surface methodology, based on Box Behnken Design, was used to assess the parameters and to optimize the hydrolysis conditions for the minimum final viscosity. In conclusion, it was observed that slurry concentration and enzyme including temperature were the most critical factors that affect either the pasting properties or the final viscosity of the crude chickpea milk. Briefly, lower final viscosities were obtained from samples which were prepared at lower beginning concentrations and treated with higher enzyme amounts at lower temperatures.

Similar content being viewed by others

Availability of data and materials

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Abbreviations

- MVAG:

-

Micro visco-amylo-graph

- BU:

-

Brabender unit

- ANOVA:

-

Analysis of variance

- RAU:

-

Reference amylase unit

- cP:

-

Centipoise (mPa s)

References

Cabanillas B, Jappe U, Novak N (2018) Allergy to peanut, soybean, and other legumes: Recent advances in allergen characterization, stability to processing and IgE cross-reactivity. Mol Nutr Food Res 62(1):1700446. https://doi.org/10.1002/mnfr.201700446

Colonna P, Leloup V, Buléon A (1992) Limiting factors of starch hydrolysis. Eur J Clin Nutr 46(2):17–32

Corzo O, Gomez ER (2004) Optimization of osmotic dehydration of cantaloupe using desired function methodology. J Food Eng 64:213–219. https://doi.org/10.1016/j.jfoodeng.2003.09.035

Deswal A, Deora NS, Mishra HN (2014) Optimization of enzymatic production process of oat milk using response surface methodology. Food Bioproc Tech 7:610–618. https://doi.org/10.1007/s11947-013-1144-2

Fu Z, Chen J, Luo SJ, Liu CM, Liu W (2015) Effect of food additives on starch retrogradation: a review. Starch/staerke 67(1–2):69–78. https://doi.org/10.1002/star.201300278

Gong WJ, Zhang YP, Xu GR, Wei XJ, Lee KP (2007) Optimization strategies for separation of sulfadiazines using BoxBehnken design by liquid chromatography and capillary electrophoresis. J Cent South Univ Technol 14(2):196–201

Gugger ET, Galuska P, Tremaine A (2016) United states patent application US20160309732A1: Legume-based dairy substitute and consumable food products incorporating same. General Mills, Inc. USA

Haaland PD (1989) Statistical problem solving. In: Deeker M (ed) Experimental design in biotechnology. CRC Press, New York, pp 1–18

Haas R, Schnepps A, Pichler A, Meixner O (2019) Cow milk versus plant-based milk substitutes: a comparison of product image and motivational structure of consumption. Sustainability 11(18):5046. https://doi.org/10.3390/su11185046

Lahlali R, Massart S, Serrhini MN, Jijakli MH (2008) A Box-Behnken design for predicting the combined effects of relative humidity and temperature on antagonistic yeast population density at the surface of apples. Int J Food Microbiol 122(1–2):100–108. https://doi.org/10.1016/j.ijfoodmicro.2007.11.053

Lindahl L, Ahlden I, Öste R, Sjöholm I (1997) US 5(686):123

Mäkinen OE, Wanhalinna V, Zannini E, Arendt EK (2016) Foods for special dietary needs: non-dairy plant-based milk substitutes and fermented dairy-type products. Crit Rev Food Sci Nutr 56(3):339–349. https://doi.org/10.1080/10408398.2012.761950

Paul AA, Kumar S, Kumar V, Sharma R (2020) Milk analog: plant based alternatives to conventional milk, production, potential and health concerns. Crit Rev Food Sci Nutr 60(18):3005–3023. https://doi.org/10.1080/10408398.2019.1674243

Rincon L, Botelho RBA, de Alencar ER (2020) Development of novel plant-based milk based on chickpea and coconut. LWT—Food Sci Technol 128:109479. https://doi.org/10.1016/j.lwt.2020.109479

Sethi S, Tyagi SK, Anurag RK (2016) Plant-based milk alternatives an emerging segment of functional beverages: a review. J Food Sci Technol 53(9):3408–3423. https://doi.org/10.1007/s13197-016-2328-3

Silva ARA, Silva MMN, Ribeiro BD (2020) Health issues and technological aspects of plant-based alternative milk. Food Res Int 131:108972. https://doi.org/10.1016/j.foodres.2019.108972

StateEase (2021) https://www.statease.com/software/design-expert/. Accessed 20 June 2021

Suh D, Jane J (2003) Comparison of starch pasting p roperties at various cooking conditions using the micro visco-amylo-graph and the rapid visco analyser. Cereal Chem 80:745–749

Tester RF, Qi X, Karkalas J (2006) Hydrolysis of native starches with amylases. Anim Feed Sci Technol 130(1–2):39–54. https://doi.org/10.1016/j.anifeedsci.2006.01.016

Triantafyllou AÖ (2002) United states patent application US6451369B1: Non-dairy, ready-to-use milk substitute, and products made therewith. Oatly AB

Vykhodtsev SV (2010) United states patent application US 2010/0098805 A1: Probiotic oat-based food product and process for making the same

Wang S, Li C, Copeland L, Niu Q, Wang S (2015) Starch retrogradation: a comprehensive review. Compr Rev Food Sci Food Saf 14(5):568–585. https://doi.org/10.1111/1541-4337.12143

Acknowledgements

The authors would like to thank to Brabender/Anamed & Analytic Group and to Melek Malkoç for their technical assistance.

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

NYT contributed to conception and design, acquisition of data, analysis and interpretation of data; FK carried out the experiments and contributed to the first draft of the manuscript, HP contributed to statistical analysis and NBT was second reader of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yılmaz Tuncel, N., Korkmaz, F., Polat, H. et al. Monitoring starch hydrolysis with micro visco-amylo-graph for the production of chickpea milk and optimization of the parameters with response surface methodology. J Food Sci Technol 59, 3448–3457 (2022). https://doi.org/10.1007/s13197-021-05332-w

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-021-05332-w