Abstract

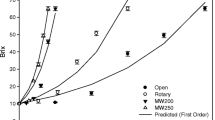

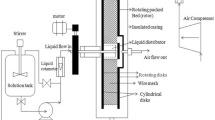

The preservation of the quality characteristics of fruit juices during the processing is one of the major challenges in the fruit juice industries. The high costs of fossil fuels and their environmental pollution increased the need to use of the renewable energies. In the present study, some quality characteristics of barberry juice were investigated during concentrating by the methods of liquid desiccant-assisted solar juice concentration system (LD-ASJCS) at the air flow rates of 0.006–0.014 kg/s, rotary vacuum evaporation system (RVES), and evaporation at atmospheric pressure (EAP). Although evaporation rate in LD-ASJCS increased by 25% with increasing of air flow rate from 0.006 to 0.014 kg/s, but it had negative effects on some quality properties of concentrated juices. The anthocyanins retention in the concentrated juices with different air flow rates of LD-ASJCS method were 16–28%. Reduction of the air flow rate resulted in a lower browning index and less variation of color indices (L*, a*, and b*). The a* values, browning index, and sensory attributes of the concentrated juices in the LD-ASJCS at the air flow rate of 0.006 kg/s were comparable to the concentrated juices by the RVES method. Although, RVES method compared to EAP and LD-ASJCS methods better improved the quality of barberry juice, but the LD-ASJCS method can be considered in fruit juice industries because of maintaining quality and sensory attributes, saving energy, and reducing environmental pollution. The mathematical modelling of physicochemical changes of LD-ASJCS concentrated juice showed that these variations are fitted with first-order and zero-order models.

Similar content being viewed by others

References

Aktaş M, Khanlari A, Aktekeli B, Amini A (2017) Analysis of a new drying chamber for heat pump mint leaves dryer. Int J Hydrogen Energy 42:18034–18044

Alemardan A, Asadi W, Rezaei M, Tabrizi L, Mohammadi S (2013) Cultivation of Iranian seedless barberry (Berberis integerrima ‘Bidaneh’): a medicinal shrub. Ind Crops Prod 50:276–287

Alighourchi H, Barzegar M (2009) Some physicochemical characteristics and degradation kinetic of anthocyanin of reconstituted pomegranate juice during storage. J Food Eng 90:179–185

Alizadeh HR, Mortezapour H, Akhavan HR, Balvardi M (2019) Performance of a liquid desiccant-assisted solar juice concentration system for barberry juice. Sol Energy 184:1–10

Alper N, Bahçeci KS, Acar J (2005) Influence of processing and pasteurization on color values and total phenolic compounds of pomegranate juice. J Food Process Preserv 29:357–368

Anonymous (2019) Iranian ministry of agriculture jahad yearbook. Available at: http://www.maj.ir/. [Accessed 22 December 2019].

Barta J, Balla C, Vatai G (2012) Dehydration preservation of fruits. In: Sinha NK, Sidhu JS, Barta J, Wu JSB, Cano MP (eds) Handbook of fruits and fruit processing, 2nd edn. Wiley-Blackwell, Iowa, pp 133–151

Berenji Ardestani S, Sahari MA, Barzegar M (2016) Effect of extraction and processing conditions on anthocyanins of barberry. J Food Process Preserv 40:1407–1420

Ceylan İ, Gürel AE (2016) Solar-assisted fluidized bed dryer integrated with a heat pump for mint leaves. Appl Therm Eng 106:899–905

Darvishi H, Mohammadi P, Fadavi A, Saba MK, Behroozi-Khazaei N (2019) Quality preservation of orange concentrate by using hybrid ohmic–Vacuum heating. Food Chem 289:292–298

Dorouzi M, Mortezapour H, Akhavan H-R, Ghazanfari Moghaddam A (2018) Tomato slices drying in a liquid desiccant-assisted solar dryer coupled with a photovoltaic-thermal regeneration system. Sol Energy 162:364–371

Elik A, Yanık DK, Maskan M, Göğüş F (2016) Influence of three different concentration techniques on evaporation rate, color and phenolics content of blueberry juice. J Food Sci Technol 53:2389–2395

Farjana SH, Huda N, Mahmud MP, Saidur R (2018) Solar process heat in industrial systems–a global review. Renew Sust Energ Rev 82:2270–2286

Fazaeli M, Hojjatpanah G, Emam-Djomeh Z (2013) Effects of heating method and conditions on the evaporation rate and quality attributes of black mulberry (Morus nigra) juice concentrate. J Food Sci Technol 50:35–43

Ferrari G, Maresca P, Ciccarone R (2010) The application of high hydrostatic pressure for the stabilization of functional foods: pomegranate juice. J Food Eng 100:245–253

Giusti MM, Wrolstad RE (2001) Characterization and measurement of anthocyanins by UV–visible spectroscopy. In: Wrolstad RE, Acree TE, An H, Decker EA, Penner MH, Reid DS, Schwartz SJ, Shoemaker CF, Sporns P (eds) Current protocols in food analytical chemistry. Wiley, New York

Hayaloglu A, Karabulut I, Alpaslan M, Kelbaliyev G (2007) Mathematical modeling of drying characteristics of strained yoghurt in a convective type tray-dryer. J Food Eng 78:109–117

Jiang T et al (2019) Degradation of anthocyanins and polymeric color formation during heat treatment of purple sweet potato extract at different pH. Food Chem 274:460–470

Khandetod Y, Mohod A, Shrirame H (2016) Bioethanol Production from fermented cashew apple juice by solar concentrator. In: Proceedings of the First International Conference on Recent Advances in Bioenergy Research, Springer, pp 63–79

Maillard M-N, Berset C (1995) Evolution of antioxidant activity during kilning: role of insoluble bound phenolic acids of barley and malt. J Agric Food Chem 43:1789–1793

Maskan M (2006) Production of pomegranate (Punica granatum L.) juice concentrate by various heating methods: colour degradation and kinetics. J Food Eng 72:218–224

Misha S, Mat S, Ruslan MH, Sopian K (2012) Review of solid/liquid desiccant in the drying applications and its regeneration methods. Renew Sust Energ Rev 16:4686–4707

Mortezapour H, Ghobadian B, Minaei S, Khoshtaghaza MH (2012) Saffron drying with a heat pump–assisted hybrid photovoltaic–thermal solar dryer. Drying Technol 30:560–566

Onsekizoglu P (2013) Production of high quality clarified pomegranate juice concentrate by membrane processes. J Membr Sci 442:264–271

Ouaabou R et al (2018) Valorization of solar drying process in the production of dried Moroccan sweet cherries. Sol Energy 172:158–164

Panchal H, Patel R, Chaudhary S, Patel DK, Sathyamurthy R, Arunkumar T (2018) Solar energy utilisation for milk pasteurisation: a comprehensive review. Renew Sust Energ Rev 92:1–8

Pathare PB, Opara UL, Al-Said FA-J (2013) Colour measurement and analysis in fresh and processed foods: a review. Food Bioprocess Technol 6:36–60

Patras A, Brunton NP, O’Donnell C, Tiwari B (2010) Effect of thermal processing on anthocyanin stability in foods; mechanisms and kinetics of degradation. Trends Food Sci Technol 21:3–11

Sabanci S, Icier F (2017) Applicability of ohmic heating assisted vacuum evaporation for concentration of sour cherry juice. J Food Eng 212:262–270

Sabanci S, Cevik M, Cokgezme OF, Yildiz H, Icier F (2019) Quality characteristics of pomegranate juice concentrates produced by ohmic heating assisted vacuum evaporation. J Sci Food Agric 99:2589–2595

Sinha N, Sidhu J, Barta J, Wu J, Cano MP (2012) Handbook of fruits and fruit processing. Wiley-Blackwell, Iowa

Tezcan F, Gültekin-Özgüven M, Diken T, Özçelik B, Erim FB (2009) Antioxidant activity and total phenolic, organic acid and sugar content in commercial pomegranate juices. Food Chem 115:873–877

Wang Z, Sun J, Chen F, Liao X, Hu X (2007) Mathematical modelling on thin layer microwave drying of apple pomace with and without hot air pre-drying. J Food Eng 80:536–544

Wrolstad RE, Durst RW, Lee J (2005) Tracking color and pigment changes in anthocyanin products. Trends Food Sci Technol 16:423–428

Yang Z, Han Y, Gu Z, Fan G, Chen Z (2008) Thermal degradation kinetics of aqueous anthocyanins and visual color of purple corn (Zea mays L.) cob. Innov Food Sci Emerg Technol 9:341–347

Yousefi S, Emam-Djomeh Z, Mousavi SMA, Askari GR (2012) Comparing the effects of microwave and conventional heating methods on the evaporation rate and quality attributes of pomegranate (Punica granatum L.) juice concentrate. Food Bioprocess Technol 5:1328–1339

Acknowledgments

The authors would like to acknowledge the Research Council of Shahid Bahonar University of Kerman for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alizadeh, HR., Mortezapour, H., Akhavan, HR. et al. Physicochemical changes of barberry juice concentrated by liquid desiccant-assisted solar system and conventional methods during the evaporation process. J Food Sci Technol 58, 4370–4381 (2021). https://doi.org/10.1007/s13197-020-04919-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04919-z