Abstract

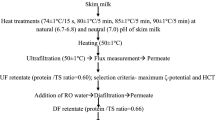

Milk protein concentrate (MPC) powders are high-protein, innovative dairy ingredients. Buffalo milk naturally contains higher concentrations of casein and calcium, which have adverse effect on solubility of MPC powders. Therefore, this study was undertaken to investigate the effect of Sodium triphosphate (STP) and Sodium hexametaphosphate (SHMP) addition in ultrafiltered retentate on physicochemical, functional and reconstitution properties, morphological characteristics and rheological behaviour of the resultant powder. Pasteurized buffalo skim milk (PBSM) was concentrated by ultrafiltration (UF) process to obtain 2.53 × UF retentate (2.53 × UFR) with 0.61 protein to total solids (TS) ratio. Compared to PBSM, ultrafiltration significantly increased (p < 0.05) calcium, protein and TS contents of 2.53 × UFR, but significantly decreased (p < 0.05) its heat stability. Addition of STP–SHMP mixture in 2.53 × UFR noticeably improved the solubility, flowability, water binding, oil binding, foaming capacity, foam and thermal stability and, viscosity of treated MPC60 powder over control powder. The DeBroukere (D43) mean, d50, specific surface area, span and water activity values of treated MPC60 powder were 94.96 ± 0.05, 78.33 ± 0.04 µm, 715.93 ± 0.29 m2 kg−1, 1.97 ± 0.01 and, 0.26 ± 0.01, respectively. Scanning electron micrograph showed the presence of different size powder particles without clustering. Rheological modelling of the reconstituted solution of treated MPC60 was very well described by Herschel–Bulkley model. Overall, this study established that addition of STP–SHMP salts mixer in 2.53 × UFR could improve the solubility of resultant buffalo milk based MPC60 powder.

Similar content being viewed by others

References

Agarwal S, Beausire RL, Patel S, Patel H (2015) Innovative uses of milk protein concentrates in product development. J Food Sci 80(S1):A23–A29

Amaladhas PH, Emerald FME (2017) Physicochemical and Sensory properties of dried dairy products. In: Anandharamakrishnan C (ed) Handbook of drying for dairy products. Wiley, pp 203–228. https://doi.org/10.1002/9781118930526

American Dry Milk Institute (1965) Standards for grades of dry milk including methods of analysis. Bull. 915 ADMI, USA

AOAC (1998) Official methods of analysis, 16th edn. Association of Official Analytical Chemists, Washington, D.C

Bouvier JM, Collado M, Gardiner D, Scott M, Schuck P (2013) Physical and rehydration properties of milk protein concentrates: comparison of spray-dried and extrusion-porosified powders. Dairy Sci Technol 93(4–5):387–399

Carr RL (1965) Evaluating flow properties of solids. Chem Eng 72(2):163–169

De Kort E, Minor M, Snoeren T, Van HT, Van DLE (2012) Effect of calcium chelators on heat coagulation and heat-induced changes of concentrated micellar casein solutions: the role of calcium-ion activity and micellar integrity. Int Dairy J 26(2):112–119

Early R (1998) Technology of dairy products. Blackie Academic and Professional, London

Huppertz T, Gazi I (2015) Milk protein concentrate functionality through optimized product-process interactions. New Food 18(1):12–17

Ishwarya SP, Anandharamakrishnan C (2017) Spray drying. In: Anandharamakrishnan C (ed) Handbook of drying for dairy products. Wiley, pp 57–94. https://doi.org/10.1002/9781118930526

Keeney M, Bassette R (1959) Detection of intermediate compound in early stages of browning reaction in milk products. J Dairy Sci 42:945–960

Meena GS, Singh AK, Arora S, Borad S, Sharma R, Gupta VK (2017a) Physico-chemical, functional and rheological properties of milk protein concentrate 60 as affected by disodium phosphate addition, diafiltration and homogenization. J Food Sci Technol 54(6):1678–1688

Meena GS, Singh AK, Panjagari NR, Arora S (2017b) Milk protein concentrates: opportunities and challenges. J Food Sci Technol 54(10):3010–3024

Muers MM, House TU (1962) A simple method for comparing wettability of instant spray dried separated milk powder. In: XVI international dairy congress, vol 8. Copenhagen, p 299

Patel RS, Mistry VV (1997) Physicochemical and structural properties of ultrafiltered buffalo milk and milk powder. J Dairy Sci 80:812–817

Patil AT, Meena GS, Upadhyay N, Khetra Y, Borad S, Singh AK (2018) Production and characterization of milk protein concentrates 60 (MPC60) from buffalo milk. LWT-Food Sci Technol 91:368–374

Patil AT, Meena GS, Upadhyay N, Khetra Y, Borad SG, Singh AK (2019) Effect of change in pH, heat treatment and diafiltration on properties of medium protein buffalo milk protein concentrate. J Food Sci Technol 56(3):1462–1472

Salaun F, Mietton B, Gaucheron F (2005) Buffering capacity of dairy products. Int Dairy J 15:95–109

Schuck P (2011) Milk powder: physical and functional properties of milk powders. In: Fuquay JW, Fox PF, McSweeney PLH (eds) Encyclopedia of dairy sciences, vol 2, 2nd edn. Elsevier, London, pp 117–124

Schuck P (2013) Dairy protein powders. In: Smithers GW, Augustin MA (eds) Advances in dairy ingredients. Wiley and Institute of Food Technologists, Hoboken, pp 1–29

Shilpashree BG, Arora S, Chawla P, Tomar SK (2015) Effect of succinylation on physicochemical and functional properties of milk protein concentrate. Food Res Int 72:223–230

Shinde AP (2018) Solubility enhancement in buffalo milk protein concentrate 60 using different salt solutions Master Thesis. National Dairy Research Institute, Karnal

Singh H (2011) Functional properties of milk proteins. In: Fuquay JW, Fox PF, McSweeney PLH (eds) Encyclopaedia of dairy science, vol 3, 2nd edn. Academic Press, San Diego, pp 887–893

Sjollema A (1963) Some investigation on the free flowing properties and porosity of milk powders. Neth Milk Dairy J 17:245–253

Uttamrao HJ, Meena GS, Borad SG, Punjaram SA, Khetra Y, Upadhyay N, Singh AK (2019) Effect of disodium phosphate and homogenization on physico-chemical and rheological properties of buffalo skim milk based ultrafiltered retentate. J Food Sci Technol 56(5):2426–2435

Zayas JF (1997) Functionality of proteins in food. Springer, Berlin, pp 76–133

Acknowledgement

All authors thankfully acknowledge the support provided by the Director, ICAR-National Dairy Research Institute, Karnal, Haryana, India to conduct this investigation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shinde, A.P., Meena, G.S. & Handge, J.U. Effect of sodium triphosphate and sodium hexametaphosphate on properties of buffalo milk protein concentrate 60 (BMPC60) powder. J Food Sci Technol 58, 1996–2006 (2021). https://doi.org/10.1007/s13197-020-04712-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04712-y