Abstract

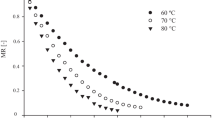

In this present study, solid desiccant-based pressure-swing adsorption (PSA) dehumidifier was developed and the process parameters were optimized to deliver the air continuously at 0.1% relative humidity. Mint (Mentha arvensis) leaves are tested to study the drying characteristics at varied flow rates of dehumidified air in the drying chamber. The initial moisture content of 5.059 g water/g dry matter have been reduced to a safe storage level in 360 min at 0.160 m3/min volume low rate. The effective moisture diffusivity of the mint leaves was found in the range of 2.07534 × 10−11m2/s to 3.45817 × 10−11m2/s. The percentage of retention of ascorbic acid in dried mint leaves is increased by an increase in the volume flow rate of dry air and a maximum of 70.11% is achieved by 0.160 m3/min. The colour measurement and chlorophyll content of the dried samples indicated that the desiccant dehumidified air dryers are suitable for heat sensitive green leafy vegetables.

Similar content being viewed by others

Abbreviations

- Adj SS:

-

Adjusted sum of squares

- m3/min:

-

Cubic metre per minute

- °C:

-

Degree celsius

- Deff :

-

Effective moisture diffusivity (m2/s)

- DBT:

-

Dry bulb temperature

- DR:

-

Drying rate (g water/g dry matter.min)

- g:

-

Gram

- hp:

-

Horse power

- kg:

-

Kilogram

- lpm:

-

Litre per minute

- m/s:

-

Meter per second

- m:

-

Metre

- md :

-

Moisture content on dry basis (g water/g dry matter)

- mt :

-

Moisture content at any time ‘t’

- MR:

-

Moisture ratio

- ppmv:

-

Parts per million volume basis

- %:

-

Percent

- R1:

-

Replication 1

- R2:

-

Replication 2

- R3:

-

Replication 3

- R2 :

-

Regression

- rh:

-

Relative humidity

- s:

-

Second

- t:

-

Drying time (sec)

- wo :

-

Initial weight of the product (g)

- wd :

-

Weight of the dry matter (g)

References

Abasi S, Minaei S, Khoshtaghaza MH (2017) Effect of desiccant system on thin layer drying kinetics of corn. J Food Sci Technol 54(13):4397–4404

Akpinar EK (2010) Drying of mint leaves in a solar dryer and under open sun: modelling, performance analyses. Energy Convers Manage 51(12):2407–2418

Alwazeer D, Örs B (2019) Reducing atmosphere drying as a novel drying technique for preserving the sensorial and nutritional notes of foods. J Food Sci Technol 56(8):3790–3800

Arulraj M, Palani PK, Venkatesh L (2017) Optimization of process parameters in stir casting of hybrid metal matrix (LM25/SiC/B4C) composite using taguchi method. J Adv Chem 13(9):6475–6479

Arulraj M, Palani PK (2018) Parametric optimization for improving impact strength of squeeze cast of hybrid metal matrix (LM24–SiC p–coconut shell ash) composite. J Braz Soc Mech Sci Eng 40(1):2

Djaeni M, van Boxtel AJB (2009) PhD Thesis summary: energy efficient multistage zeolite drying for heat-sensitive products. Dry Technol 27(5):721–722

El-Sebaii AA, Shalaby SM (2013) Experimental investigation of an indirect-mode forced convection solar dryer for drying thymus and mint. Energy Convers Manag 74:109–116

Gurtas Seyhan F, Evranuz Ö (2000) Low temperature mushroom (A. bisporus) drying with desiccant dehumidifiers. Drying Technol 18(1–2):433–445

Gichau AW, Okoth JK, Makokha A (2020) Moisture sorption isotherm and shelf life prediction of complementary food based on amaranth–sorghum grains. J Food Sci Technol 57(3):962–970

Hanif S, Sultan M, Miyazaki T, Koyama S (2019) Investigation of energy-efficient solid desiccant system for wheat drying. Int J Agric Biol Eng 12(1):221–228

Hodali R, Bougard J (2001) Integration of a desiccant unit in crops solar drying installation: optimization by numerical simulation. Energy Convers Manag 42(13):1543–1558

Kannan S, Arjunan T (2019) Optimization of process parameters of adsorption process in solid desiccant dehumidification system using genetic algorithm. J Chin Soc Mech Eng 40(4):437–443

Kannan VS, Arjunan TV, Vijayan S (2020) Experimental investigation of temperature swing adsorption system for air dehumidification. Heat Mass Transf: 1–13

Kaur A, Kaur D, Oberoi DPS, Gill BS, Sogi DS (2008) Effect of dehydration on physicochemical properties of mustard, mint and spinach. J Food Process Preserv 32(1):103–116

Kesavan S, Arjunan TV, Vijayan S (2019) Thermodynamic analysis of a triple-pass solar dryer for drying potato slices. J Thermal Anal Calorim 136(1):159–171

Kumar SS, Manoj P, Shetty NP, Giridhar P (2015) Effect of different drying methods on chlorophyll, ascorbic acid and antioxidant compounds retention of leaves of Hibiscus sabdariffa L. J Sci Food Agric 95(9):1812–1820

Lakshmi B, Vimala V (2000) Nutritive value of dehydrated green leafy vegetable powders. J Food Sci Technol 37(5):465–471

Misha S, Mat S, Ruslan MH, Salleh E, Sopian K (2016) Performance of a solar-assisted solid desiccant dryer for oil palm fronds drying. Sol Energy 132:415–429

Muthukumar A, Venkatesh A (2014) Biological inductions of systemic resistance to collar rot of peppermint caused by Sclerotium rolfsii. Acta Physiol Plant 36(6):1421–1431

Özbek B, Dadali G (2007) Thin-layer drying characteristics and modelling of mint leaves undergoing microwave treatment. J Food Eng 83(4):541–549

Ramachandra CT, Rao PS (2013) Shelf-life and colour change kinetics of Aloe vera gel powder under accelerated storage in three different packaging materials. J Food Sci Technol 50(4):747–754

Ranganna S (1986) Handbook of analysis and quality control for fruit and vegetable products. Tata McGraw-Hill Education, New York

Sallam YI, Aly MH, Nassar AF, Mohamed EA (2015) Solar drying of whole mint plant under natural and forced convection. J Adv Res 6(2):171–178

Seshachalam K, Thottipalayam VA, Selvaraj V (2017) Drying of carrot slices in a triple pass solar dryer. Thermal Sci 21(suppl. 2):389–398

Sowrirajan M, Mathews PK, Vijayan S (2017) Investigation and optimization of process variables on clad angle in 316L stainless steel cladding using genetic algorithm. In: High temperature material processes: an international quarterly of high-technology plasma processes, vol 21, no. 2. ASTFE, pp 109–125. https://doi.org/10.1615/HighTempMatProc.2017021841

Sugar VR, Suresh KP (2010) Recent advances in drying and dehydration of fruits and vegetables: a review. J Food Sci Technol 47(1):15–20

Sowrirajan M, Mathews PK, Vijayan S (2018) Simultaneous multi-objective optimization of stainless-steel clad layer on pressure vessels using genetic algorithm. J Mech Sci Technol 32(6):2559–2568

Venkatachalam SK, Thottipalayam Vellingri A, Selvaraj V (2020) Low-temperature drying characteristics of mint leaves in a continuous-dehumidified air drying system. J Food Process Eng 43(4):e13384

Vijayan S, Arjunan TV, Kumar A (2016) Mathematical modeling and performance analysis of thin layer drying of bitter gourd in sensible storage based indirect solar dryer. Innov Food Sci Emerg Technol 36:59–67

Vijayan S, Thottipalayam VA, Kumar A (2017a) Thin layer drying characteristics of curry leaves (Murraya koenigii) in an indirect solar dryer. Therm Sci 21(suppl. 2):359–367.h

Vijayan S, Arjunan TV, Kumar A (2017b) Fundamental concepts of drying. In: Solar drying technology. Springer, Singapore, pp 3–38

Vijayan S, Arjunan TV, Kumar A (2020) Exergo-environmental analysis of an indirect forced convection solar dryer for drying bitter gourd slices. Renew Energy 146:2210–2223

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kannan, V.S., Arjunan, T.V. & Vijayan, S. Drying characteristics of mint leaves (Mentha arvensis) dried in a solid desiccant dehumidifier system. J Food Sci Technol 58, 777–786 (2021). https://doi.org/10.1007/s13197-020-04595-z

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-020-04595-z