Abstract

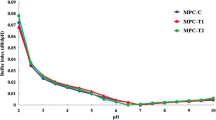

The demand of milk protein concentrate (MPC) powders is continuously increasing as high protein dairy ingredients. Presence of higher calcium and casein contents; heating, ultrafiltration (UF), diafiltration (DF) and spray drying of buffalo skim milk induces undesirable changes in milk proteins that causes problem of poor solubility in MPC powders. Therefore, this investigation was aimed to study the effect of change in pH (6.8-native, 7.0-neutral), heat treatments (74 ± 1 °C/15 s, 80 ± 1 °C/5 min, 85 ± 1 °C/5 min, 90 ± 1 °C/5 min) and DF on physicochemical, functional, reconstitution and rheological properties of medium protein buffalo milk protein concentrate (MP-BMPC) powder. Based on maximum ζ-potential and heat stability, UF retentate was selected, diafiltered and spray dried to obtain MP-BMPC powder. Despite having higher protein content, MP-BMPC powder exhibited markedly better functional (solubility, wettability, viscosity and emulsion stability) properties than buffalo milk protein concentrate 60. The interstitial air content, occluded air content, loose bulk density, packed bulk density, particle density and porosity values of MP-BMPC powder were 145.97 and 112.92 mL 100 g−1 of powder, 0.21 g mL−1, 0.30 g mL−1, 0.55 g mL−1 and 65.09%. Further, its specific surface area; particle size distribution (d10, d50, d90); Sauter (D32) and DeBroukere (D43) mean values were 97.93 m2 kg−1; 34.32, 104.42, 218.58 µm; 61.27 µm and 117.99 µm. The storage modulus (G′) and loss modulus (G″) crossover temperature of UF and DF retentates were ~ 57.16 °C and 55.10 °C, respectively. Rheological behaviour of UF, DF retentates and MP-BMPC solution were best explained by Herschel-Bulkley model. Fourier-transform infrared spectroscopy best described amide I, II and III regions in 1700–1400 cm−1 and 1350–1200 cm−1 wavenumber range.

Similar content being viewed by others

References

Agarwal S, Beausire RL, Patel S, Patel H (2015) Innovative uses of milk protein concentrates in product development. J Food Sci 80(S1):A23–A29

Alexander M, Nieh MP, Ferrer MA, Corredig M (2011) Changes in the calcium cluster distribution of ultrafiltered and diafiltered fresh skim milk as observed by small angle neutron scattering. J Dairy Res 78:349–356

Amaladhas PH, Emerald FME (2017) Physicochemical and Sensory properties of dried dairy products. In: Handbook of drying for dairy products, pp 203–228

Bhaskar GV, Singh H, Blazey ND (2003) Milk protein products and processes. US Patent US 2003/0096036

Bouvier JM, Collado M, Gardiner D, Scott M, Schuck P (2013) Physical and rehydration properties of milk protein concentrates: comparison of spray-dried and extrusion-porosified powders. Dairy Sci Technol 93(4–5):387–399

Carr RL (1965) Evaluating flow properties of solids. Chem Eng 72(2):163–169

Crowley SV, Gazi I, Kelly AL, Huppertz T, O’Mahony JA (2014) Influence of protein concentration on the physical characteristics and flow properties of milk protein concentrate powders. J Food Eng 135:31–38

Huppertz T, Gazi I (2015) Milk protein concentrate functionality through optimized product-process interactions. New Food 18(1):12–17

Ishwarya SP, Anandharamakrishnan C (2017) Spray drying. In: Handbook of drying for dairy products, p. 56

Keeney M, Bassette R (1959) Detection of intermediate compounds in the early stages of browning reaction in milk products1. J Dairy Sci 42(6):945–960

Khatkar SK, Gupta VK (2012) Physicochemical and functional quality attributes of dairy whitener prepared from ultrafiltration process. J Food Process Pres 38:1145–1154

Khatker SK, Gupta VK, Khatker AB (2014) Studies on preparation of medium fat liquid dairy whitener from buffalo milk employing ultrafiltration process. J Food Sci Technol 51(9):1956–1964

Kher A, Udabage P, McKinnon I, McNaughton D, Augustin MA (2007) FTIR investigation of spray-dried milk protein concentrate powders. Vib Spectrosc 44(2):375–381

Lagrange V, Whitsett D, Burris C (2015) Global market for dairy proteins. J Food Sci 8(S1):A16–A22

Liu DZ, Weeks MG, Dunstan DE, Martin GJ (2014) Alterations to the composition of casein micelles and retentate serum during ultrafiltration of skim milk at 10 and 40 °C. Int Dairy J 35(1):63–69

Mao XY, Tong PS, Gualco S, Vink S (2012) Effect of NaCl addition during diafiltration on the solubility, hydrophobicity, and disulfide bonds of 80% milk protein concentrate powder. J Dairy Sci 95:3481–3488

McKenna AB (2000) Effects of processing and storage on the reconstitution properties of whole milk and ultrafiltered skim milk powders, Ph.D. thesis, Massey University, Palmerston North, New Zealand

Meena GS, Singh AK, Borad S, Raju PN (2016) Effect of concentration, homogenization and stabilizing salts on heat stability and rheological properties of cow skim milk ultrafiltered retentate. J Food Sci Technol 53(11):3960–3968

Meena GS, Singh AK, Arora S, Borad S, Sharma R, Gupta VK (2017) Physico-chemical, functional and rheological properties of milk protein concentrate 60 as affected by disodium phosphate addition, diafiltration and homogenization. J Food Sci Technol 54(6):1678–1688

Meena GS, Singh AK, Gupta VK, Borad S, Arora S, Tomar SK (2018) Effect of pH adjustment, homogenization and diafiltration on physicochemical, reconstitution, functional and rheological properties of medium protein milk protein concentrates (MPC70). J Food Sci Technol 55(4):1376–1386

Patel RS, Mistry VV (1997) Physicochemical and structural properties of ultrafiltered buffalo milk and milk powder. J Dairy Sci 80:812–817

Patil AT, Meena GS, Upadhyay N, Khetra Y, Borad S, Singh AK (2018) Production and characterization of milk protein concentrates 60 (MPC60) from buffalo milk. LWT-Food Sci Technol 91:368–374

Schuck P (2013) Dairy protein powders. In: Smithers GW, Augustin MA (eds) Advances in dairy ingredients. Wiley and Institute of Food Technologists, Hoboken, pp 1–29

Schuck P, Le Floch-Fouere C, Jeantet R (2013) Changes in functional properties of milk protein powders: effects of vacuum concentration and drying. Dry Technol 31(13–14):1578–1591

Shilpashree BG, Arora S, Chawla P, Tomar SK (2015) Effect of succinylation on physicochemical and functional properties of milk protein concentrate. Food Res Int 72:223–230

Sikand V, Tong PS, Roy S, Saona LER, Murray BA (2011) Solubility of commercial milk protein concentrates and milk protein isolates. J Dairy Sci 94:6194–6202

Singh H (2011) Functional properties of milk proteins. In: Fuquay JW, Fuquay JW, Fox PF, McSweeney PLH (eds) Encyclopaedia of dairy science, vol 3, 2nd edn. Academic Press, San Diego, pp 887–893

Singh H, Newstead DF (1992) Aspects of proteins in milk powder manufacture. In: Fox PF (ed) Advanced dairy chemistry, vol 1, proteins, 2nd edn. Elsevier Applied Science, New York, pp 735–765

Udabage P, Puvanenthiran A, Yoo JA, Versteeg C, Augustin MA (2012) Modified water solubility of milk protein concentrate powders through the application of static high pressure treatment. J Dairy Res 79:76–83

Ye A (2011) Functional properties of milk protein concentrates: emulsifying properties, adsorption and stability of emulsions. Int Dairy J 21(1):14–20

Zayas JF (1997) Functionality of proteins in food. Springer, Berlin, pp 76–133

Acknowledgements

The first author is thankful to the Director of National Dairy Research Institute, Karnal, India, for providing financial assistance in the form of Institutional Fellowship for carrying out this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Patil, A.T., Meena, G.S., Upadhyay, N. et al. Effect of change in pH, heat treatment and diafiltration on properties of medium protein buffalo milk protein concentrate. J Food Sci Technol 56, 1462–1472 (2019). https://doi.org/10.1007/s13197-019-03630-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-03630-y