Abstract

Biodegradable films based on starches from different botanical sources exhibited physicochemical and functional properties which were related with the starch characteristics. However, had inadequate mechanical properties and were hard and brittle. In this research, jackfruit seed starch plasticized with glycerol were developed and characterized. The starch and glycerol concentrations ranged from 2 to 6% w/w and 20 to 60 g/100 g starch, respectively. Bioplastics were obtained by the casting method and characterized in terms of color, mechanical properties, solubility, water vapor permeability (WVP), morphology and free energy of the hydrophobic interaction. Electronic micrographics showed the presence of some intact starch granules. The bioplastics were hydrophilic and those of 6% starch and 40% glycerol were the most hydrophilic (\( \Delta G_{sas}^{tot} \) = 41.35 mJ m−1). The solubility of the films presented a direct relationship with the starch concentration ranging from 16.42 to 23.26%. Increased opacity and color difference were observed with increasing starch concentration. The WVP ranged from 1.374 × 10−3 to 3.07 × 10−4 g m/day m2 which was positively related with the concentration of starch and glycerol. Tensile strength, percent elongation and Young’s Modulus indicated that the jackfruit starch and glycerol provided a film with good mechanical properties. The results replaced that jackfruit starch can be used to develop films, with low opacity, moderate WVP and relatively high mechanical stability, by using glycerol in the gelatinized starch dispersions.

Similar content being viewed by others

References

AACC (1975) A time for self-reliance: A.A.C.C. 1975–1978. In: All Africa conference of churches

Association of Official Agricultural (1996) Official methods of analysis of AOAC international. AOAC International, Gaithersburg

ASTM-D882 (2012) In: ASTM international, West Conshohocken

Awadhiya A, Tyeb S, Rathore K, Verma V (2017) Agarose bioplastic-based drug delivery system for surgical and wound dressings. Eng Life Sci 17:204–214

Basiak E, Lenart A, Debeaufort F (2017) Effect of starch type on the physico-chemical properties of edible films. In Int J Biol Macromol 98:348–356

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Phys 37:911–917

Cereda MP, Daiuto ER, Vilpoux O (2004) Metodologia de determinação de amido digestão ácida em microondas. ABAM: Associação Brasileira dos Produtores de Amido de Mandioca 2:1–29

Chen L, Zhang Z, Zhao Z, Wang X, Chen X (2014) Polyoxometalates acid treatment for preparing starch nanoparticles. Carbohyd Polym 112:520–524

Debet MR, Gidley MJ (2007) Why do gelatinized starch granules not dissolve completely? Roles for amylose, protein, and lipid in granule “ghost” integrity. J Agr Food Chem 55:4752–4760

Fakhoury FM, Maria Martelli S, Canhadas Bertan L, Yamashita F, Innocentini Mei LH, Collares Queiroz FP (2012) Edible films made from blends of manioc starch and gelatin—Influence of different types of plasticizer and different levels of macromolecules on their properties. LWT Food Sci Technol 49:149–154

Faradilla RHF, Lee G, Arns J-Y, Roberts J, Martens P, Stenzel MH, Arcot J (2017) Characteristics of a free-standing film from banana pseudostem nanocellulose generated from TEMPO-mediated oxidation. Carbohyd Polym 174:1156–1163

Garcia-Hernandez A, Vernon-Carter EJ, Alvarez-Ramirez J (2017) Impact of ghosts on the mechanical, optical, and barrier properties of corn starch films. Starch Starke 69:1–7

Gontard N, Guilbert S, Cuq J-L (1992) Edible wheat gluten films: influence of the main process variables on film properties using response surface methodology. J Food Sci 57:190–195

Jerez A, Partal P, Martínez I, Gallegos C, Guerrero A (2007) Protein-based bioplastics: effect of thermo-mechanical processing. Rheol Acta 46:711–720

Joshi M, Aldred P, McKnight S, Panozzo JF, Kasapis S, Adhikari R, Adhikari B (2013) Physicochemical and functional characteristics of lentil starch. Carbohyd Polym 92:1484–1496

Laohakunjit N, Noomhorm A (2004) Effect of plasticizers on mechanical and barrier properties of rice starch film. Starch Stärke 56:348–356

López OV, García MA (2012) Starch films from a novel (Pachyrhizus ahipa) and conventional sources: development and characterization. In Mater Sci Eng C 32:1931–1940

Martínez C, Cuevas F (1989) Evaluación de la Calidad Culinaria y Molinera del Arroz, ed. C. I. d. A. Tropical. Luz María Medina, Cali, p 73

Mbey JA, Hoppe S, Thomas F (2012) Cassava starch–kaolinite composite film. Effect of clay content and clay modification on film properties. Carbohyd Polym 88:213–222

Ramaraj BJ (2007) Crosslinked poly(vinyl alcohol) and starch composite films. II. Physicomechanical, thermal properties and swelling studies. J Appl Polym Sci 103:909–916

Rengsutthi K, Charoenrein S (2011) Physico-chemical properties of jackfruit seed starch (Artocarpus heterophyllus) and its application as a thickener and stabilizer in chilli sauce. LWT Food Sci Technol 44:1309–1313

Santos LS, Bonomo RCF, Fontan RCI, Santos WO, Silva AAL (2009) Gelatinization temperature and acid resistance of jackfruit seed starch Temperatura de gelatinización y resistencia ácida de almidón de semilla de jaca. CyTA J Food 7:1–5

Schoch TJ, Maywald EC (1968) Preparation and properties of various legume starches. Cereal Chem 45:564–573

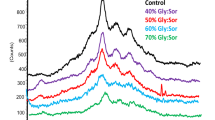

Shimazu AA, Mali S, Grossmann MVE (2007) Plasticizing and antiplasticizing effects of glycerol and sorbitol on biodegradable cassava starch films. Semin Cienc Agr 28:70–88

Singh AV, Nath LK (2013) Evaluation of chemically modified hydrophobic sago starch as a carrier for controlled drug delivery. Saudi Pharm J 21:193–200

Singh N, Belton PS, Georget DMR (2009) The effects of iodine on kidney bean starch: films and pasting properties. Int J Biol Macromol 45:116–119

Suryadevara V, Lankapalli SR, Danda LH, Pendyala P, Katta V (2017) Studies on jackfruit seed starch as a novel natural superdisintegrant for the design and evaluation of irbesartan fast dissolving tablets. Integr Med Res 6:280–291

Telles MR, Saran LM, Unêda-Trevisolli SH (2011) Produção, propriedades e aplicações de bioplástico obtido a partir da cana-de-açúcar. Ciência Tecnol FATEC-JB 2:52–63

Thakur R, Saberi B, Pristijono P, Stathopoulos CE, Golding JB, Scarlett Bowyer M, Voung QV (2017) Use of response surface methodology (RSM) to optimize pea starche-chitosan novel edible film formulation. J Food Sci Technol 54:2270–2278

Van Oss CJ, Giese RF (1995) The hydrophilicity and hydrophobicity of cly minerals. Clay Clay Miner 42:474–477

Wu H, Liu C, Chen J, Chang PR, Chen Y, Anderson DP (2009) Structure and properties of starch/α-zirconium phosphate nanocomposite films. Carbohyd Polym 77:358–364

Xie F, Halley PJ, Avérous L (2012) Rheology to understand and optimize processibility structures and properties of starch polymeric materials. Prog Polym Sci 37:95–623

Yoshida CMP, Antunes AJ (2009) Application of whey protein films. Food Sci Tech Braz Camp 29:420–430

Zanela J, Olivato JB, Dias AP, Grossmann MVE, Yamashita F (2015) Mixture design applied for the development of films based on starch, polyvinyl alcohol, and glycerol. J Appl Polym. doi:10.1002/app.42697

Zavareze EDR, Pinto VZ, Klein B, El Halal SLM, Elias MC, Prentice-Hemández C, Dias ARG (2012) Development of oxidised and heat–moisture treated potato starch film. Food Chem 132:344–350

Acknowledgements

We thank Foundation for Research Support of the Bahia State (FAPESB) and National Council for Scientific and Technological Development (CNPq) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Santana, R.F., Bonomo, R.C.F., Gandolfi, O.R.R. et al. Characterization of starch-based bioplastics from jackfruit seed plasticized with glycerol. J Food Sci Technol 55, 278–286 (2018). https://doi.org/10.1007/s13197-017-2936-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2936-6