Abstract

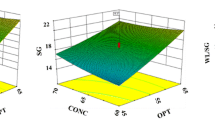

The aim of this study was to investigate the mass transfer and quality properties changes during the osmotic dehydration (OD) step of the candying process in pumpkins. The goal was to obtain nutritious, low calorie candied pumpkins improving the time-consuming and inconsistent traditional technique. The osmotic agents were sucrose, oligofructose and mixture of sucrose–oligofructose (1:1), while the concentration of each solution was constant (70° Brix). The process temperature varied in three levels (75, 85 and 95 °C) and the duration was 180 min for sucrose and 240 min for the other osmotic agents. The determined parameters during OD include solid gain, water loss, water activity, chroma, hardness and compression work. An empirical model based on a first-order kinetic equation was developed to predict the products’ properties, in which the rate constant is a function of the process temperature. The process temperature (T osm ) had a significant effect on the water loss and solid gain as well as on the physiochemical characteristics of processed pumpkins. The chroma of osmo-dehydrated pumpkins was affected significantly by process parameters. Both hardness and compression work decreased until an equilibrium value was reached as time and temperature of the process increased, regardless the osmotic agent used.

Similar content being viewed by others

Abbreviations

- A :

-

Compression work (N·s)

- A 0 :

-

Initial value of compression work (N·s)

- A 0e :

-

Compression work model parameter (N·s)

- A e :

-

Equilibrium value of compression work (N·s)

- A T :

-

Temperature effect exponent in compression work model (−)

- a* :

-

Color parameter (−)

- a w :

-

Water activity (−)

- b* :

-

Color parameter (−)

- C * :

-

Chroma (−)

- C *0 :

-

Initial chroma value (−)

- C *0e :

-

Chroma model parameter (−)

- C * e :

-

Equilibrium chroma value (−)

- C * T :

-

Temperature effect exponent in chroma model (−)

- F :

-

Hardness of material (N)

- F 0 :

-

Initial value of hardness (N)

- F 0e :

-

Hardness model parameter (N)

- F e :

-

Equilibrium value of hardness (N)

- F T :

-

Temperature effect exponent in hardness model (−)

- K 0 :

-

Water loss model parameter for rate constant (min−1)

- k A :

-

Rate constant of compression work model (min−1)

- k 0 :

-

Solids gain model parameter for rate constant (min−1)

- k 0A :

-

Compression work model parameter (min−1)

- k 0C* :

-

Chroma model parameter (min−1)

- k C* :

-

Rate constant of colour parameter (min−1)

- k 0F :

-

Hardness model parameter (min−1)

- k F :

-

Rate constant of hardness parameter (min−1)

- K SG :

-

Rate constant of solid gain during the osmotic process (min−1)

- K T :

-

Temperature effect exponent for rate constant in water loss model (−)

- k T :

-

Temperature effect exponent for rate constant in solids gain model (−)

- k TA :

-

Temperature effect exponent for rate constant in compression work model (−)

- k TC* :

-

Temperature effect exponent for rate constant in chroma model (−)

- k TF :

-

Temperature effect exponent for rate constant in hardness model (−)

- K WL :

-

Rate constant of water loss during the osmotic process (min−1)

- M :

-

Mass of material after time t of osmotic treatment (kg)

- M 0 :

-

Initial mass of fresh material (kg)

- m :

-

Dry mass of material after time t of osmotic treatment (kg)

- m 0 :

-

Dry mass of fresh material (kg)

- OD :

-

Osmotic dehydration (−)

- R 2 :

-

Coefficient of determination (−)

- SG :

-

Solids gain (kg/kg)

- SGe :

-

Solid gain at infinite process time (kg/kg)

- T osm :

-

Temperature of osmotic dehydration (°C)

- t :

-

Processing time (s)

- WL :

-

Water loss (kg/kg)

- WL e :

-

Water loss at infinite process time (kg/kg)

- Y e0 :

-

Water loss model parameter (kg/kg)

- y eo :

-

Solids gain model parameter (kg/kg)

- Y eT :

-

Temperature effect exponent in water loss model (−)

- y eT :

-

Temperature effect exponent in solids gain model (−)

- A :

-

Compression work index

- C :

-

Chroma index

- e :

-

Equilibrium

- F :

-

Hardness index

- o :

-

Initial

- osm :

-

Osmotic dehydration

- T :

-

Temperature

References

Abraão AS, Lemos AM, Vilela A, Sousa JM, Nunes FM (2013) Influence of osmotic dehydration process parameters on the quality of candied pumpkins. Food Bioprod Process 91:481–494. doi:10.1016/j.fbp.2013.04.006

Ahmed I, Qazi IM, Jamal S (2016) Developments in osmotic dehydration technique for the preservation of fruits and vegetables. Innov Food Sci Emerg Technol 34:29–43. doi:10.1016/j.ifset.2016.01.003

AOAC (1990) Official methods of analysis of AOAC international, 15th edn. AOAC International, Gaithersburg

Brochier B, Marczak LDF, Noreña CPZ (2015) Use of different kinds of solutes alternative to sucrose in osmotic dehydration of yacon. Braz Arch Biol Technol 58:34–40. doi:10.1590/s1516-8913201400035

de Gennaro S, Birch GG, Parke SA, Stancher B (2000) Studies on the physicochemical properties of inulin and inulin oligomers. Food Chem 68:179–183

Dermesonlouoglou EK, Giannakourou MC, Taoukis PS (2007) Kinetic modelling of the degradation of quality of osmo-dehydrofrozen tomatoes during storage. Food Chem 103:985–993. doi:10.1016/j.foodchem.2006.05.070

Derossi A, Severini C, Del Mastro A, De Pilli T (2015) Study and optimization of osmotic dehydration of cherry tomatoes in complex solution by response surface methodology and desirability approach. Food Sci Technol/Lebensm-Wiss Technol 60:641–648. doi:10.1016/j.lwt.2014.10.056

El-Aouar ÂA, PcM Azoubel, Barbosa JL, Xidieh Murr FE (2006) Influence of the osmotic agent on the osmotic dehydration of papaya (Carica papaya L.). J Food Eng 75:267–274. doi:10.1016/j.jfoodeng.2005.04.016

Falade KO, Igbeka JC, Ayanwuyi FA (2007) Kinetics of mass transfer, and colour changes during osmotic dehydration of watermelon. J Food Eng 80:979–985. doi:10.1016/j.jfoodeng.2006.06.033

Fernandes FAN, Rodrigues S, Gaspareto OCP, Oliveira EL (2006) Optimization of osmotic dehydration of papaya followed by air-drying. Food Res Int 39:492–498. doi:10.1016/j.foodres.2005.10.004

Garcia-Noguera J, Oliveira FIP, Weller CL, Rodrigues S, Fernandes FAN (2014) Effect of ultrasonic and osmotic dehydration pre-treatments on the colour of freeze dried strawberries. J Food Sci Technol 51:2222–2227. doi:10.1007/s13197-012-0724-x

Gonçalves EM, Pinheiro J, Abreu M, Brandão TRS, Silva CLM (2007) Modelling the kinetics of peroxidase inactivation, colour and texture changes of pumpkin (Cucurbita maxima L.) during blanching. J Food Eng 81:693–701. doi:10.1016/j.jfoodeng.2007.01.011

González E, Montenegro MA, Nazareno MA, López de Mishima BA (2001) Carotenoid composition and vitamin A value of an Argentinian squash (Cucurbita moschata). Arch Latinoam Nutr 51:395–399

Guiné RPF, Barroca MJ (2012) Effect of drying treatments on texture and color of vegetables (pumpkin and green pepper). Food Bioprod Process 90:58–63. doi:10.1016/j.fbp.2011.01.003

Heimbach J (2011) Determination of the GRAS status of the addition of oligofructose to Infant formula as a nutritional supplement. Prepared for Pfizer Nutrition and BENEO-Orafti and received by the division of Biotechnology and GRAS notice review. GRAS Monograph for Orafti®P95 Oligofructose in Infant Formula, Port Royal

İspir A, Toğrul İT (2009) Osmotic dehydration of apricot: kinetics and the effect of process parameters. Chem Eng Res Des 87:166–180. doi:10.1016/j.cherd.2008.07.011

Jacobo-Valenzuela N, Maróstica-Junior MR, Zazueta-Morales JdJ, Gallegos-Infante JA (2011) Physicochemical, technological properties, and health-benefits of Cucurbita moschata Duchense vs. Cehualca. Food Res Int 44:2587–2593. doi:10.1016/j.foodres.2011.04.039

Jain SK, Verma RC, Murdia LK, Jain HK, Sharma GP (2011) Optimization of process parameters for osmotic dehydration of papaya cubes. J Food Sci Technol 48:211–217. doi:10.1007/s13197-010-0161-7

Krokida MK, Oreopoulou V, Maroulis ZB, Marinos-Kouris D (2001) Colour changes during deep fat frying. J Food Eng 48:219–225

Lazarides HN, Gekas V, Mavroudis N (1997) Apparent mass diffusivities in fruit and vegetable tissues undergoing osmotic processing. J Food Eng 31:315–324

Lazou AE, Giannakourou MG, Lafka TI, Lazos ES (2016) Kinetic study of the osmotic pretreatment and quality evaluation of traditional greek candied pumpkin. Gavin J Food Nutr Sci 2016:28–36

Luchese CL, Gurak PD, Marczak LDF (2015) Osmotic dehydration of physalis (Physalis peruviana L.): evaluation of water loss and sucrose incorporation and the quantification of carotenoids. Food Sci Technol/Lebensm-Wiss Technol 63:1128–1136. doi:10.1016/j.lwt.2015.04.060

Matusek A, Czukor B, Merész P (2008) Comparison of sucrose and fructo-oligosaccharides as osmotic agents in apple. Innov Food Sci Emerg Technol 9:365–373. doi:10.1016/j.ifset.2007.10.003

Mayor L, Moreira R, Sereno AM (2011) Shrinkage, density, porosity and shape changes during dehydration of pumpkin (Cucurbita pepo L.) fruits. J Food Eng 103:29–37. doi:10.1016/j.jfoodeng.2010.08.031

Nambiar SS, Basu A, Shetty NP, Rastogi NK, Prapulla SG (2016) Infusion of fructooligosaccharide in Indian gooseberry (Emblica officinalis) fruit using osmotic treatment and its effect on the antioxidant activity of the fruit. J Food Eng 190:139–146. doi:10.1016/j.jfoodeng.2016.06.005

Nimmanpipug N, Therdthai N, Dhamvithee P (2013) Characterisation of osmotically dehydrated papaya with further hot air drying and microwave vacuum drying. Int J Food Sci Technol 48:1193–1200. doi:10.1111/ijfs.12075

Panagiotou N, Karathanos V, Maroulis Z (1998) Mass transfer modelling of the osmotic dehydration of some fruits. Int J Food Sci Technol 33:267–284

Rao VA (2001) The prebiotic properties of oligofructose at low intake levels. Nutr Res 21:843–848

Rastogi NK, Raghavarao KSMS (2004) Mass transfer during osmotic dehydration of pineapple: considering Fickian diffusion in cubical configuration. Food Sci Technol/Lebensm-Wiss Technol 37:43–47. doi:10.1016/s0023-6438(03)00131-2

Roberfroid MB (2000) Chicory fructooligosaccharides and the gastrointestinal tract. Nutr Res 16:677–679

Rubio-Arraez S, Capella JV, Ortolá MD, Castelló ML (2015a) Kinetics of osmotic dehydration of orange slices using healthy sweeteners. Int Food Res J 22:2162–2166

Rubio-Arraez S, Capella JV, Ortolá MD, Castelló ML (2015b) Modelling osmotic dehydration of lemon slices using new sweeteners. Int J Food Sci Tech 50:2046–2051. doi:10.1111/ijfs.12859

Vilela A, Sobreira C, Abraão AS, Lemos AM, Nunes FM (2016) Texture quality of candied fruits as influenced by osmotic dehydration agents. J Texture Stud 47:239–252. doi:10.1111/jtxs.12177

Warczok J, Gierszewska M, Kujawski W, Guell C (2007) Application of osmotic membrane distillation for reconcentration of sugar solutions from osmotic dehydration. Sep Purif Technol 57:425–429. doi:10.1016/j.seppur.2006.04.012

Yadav AK, Singh SV (2014) Osmotic dehydration of fruits and vegetables: a review. J Food Sci Technol 51:1654–1673. doi:10.1007/s13197-012-0659-2

Yadav BS, Yadav RB, Jatain M (2012) Optimization of osmotic dehydration conditions of peach slices in sucrose solution using response surface methodology. J Food Sci Technol 49:547–555. doi:10.1007/s13197-011-0298-z

Zhao J-H, Xiao H-W, Ding Y, Nie Y, Zhang Y, Zhu Z, Tang X-M (2017) Effect of osmotic dehydration pretreatment and glassy state storage on the quality attributes of frozen mangoes under long-term storage. J Food Sci Technol 54:1527–1537. doi:10.1007/s13197-017-2584-x

Acknowledgements

The authors wish to thank Prof. Evangelo S. Lazo for support and useful discussions.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Katsoufi, S., Lazou, A.E., Giannakourou, M.C. et al. Mass transfer kinetics and quality attributes of osmo-dehydrated candied pumpkins using nutritious sweeteners. J Food Sci Technol 54, 3338–3348 (2017). https://doi.org/10.1007/s13197-017-2786-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2786-2