Abstract

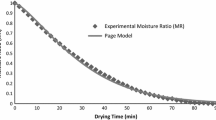

Infrared-vacuum dehydration characteristics of pumpkin (Cucurbita moschata) were evaluated in a combined dryer system. The effects of drying parameters, infrared radiation power (204–272 W), system pressure (5–15 kPa), slice thickness (5 and 7 mm) and time (0–220 min) on the drying kinetics and characteristics of pumpkin slices were investigated. The vacuum pressure, lamp power and slice had significant effect on the drying kinetics and various qualities of the dried pumpkin. Moisture ratios were fitted to 10 different mathematical equations using nonlinear regression analysis. The quadratic equation satisfactorily described the drying behavior of pumpkin slices with the highest r value and the lowest SE values. The effective moisture diffusivity increased with power and ranged between 0.71 and 2.86 × 10−9 m2/s. With increasing in infrared radiation power from 204 to 272 W, β–carotene content of dried pumpkins decreased from 30.04 to 24.55 mg/100 g. The rise in infrared power has a negative effect on the color changes (ΔE). The optimum condition was determined as power, 238W, pressure, 5 kPa and slice thickness, 5mm. These conditions resulted into dried pumpkin slices with maximum B-carotene retention.

Similar content being viewed by others

Abbreviations

- a :

-

Empirical coefficient

- D eff :

-

Effective diffusivity (m2/s)

- D 0 :

-

Pre-exponential factor (m2/s)

- L :

-

Half slab thickness of the slices (mm)

- K :

-

Slope

- k :

-

Drying rate constants in equations (1/s)

- MR :

-

Dimensionless moisture ratio

- M t :

-

Moisture content (kg water/kg dry matter)

- Me :

-

Equilibrium moisture content (kg water/kg dry matter)

- M 0 :

-

Initial moisture content (kg water/kg dry matter)

- N :

-

Number of observations

- n :

-

Number of constants

- r :

-

Correlation coefficient

- SE :

-

Standard error

- t :

-

Drying time (min)

- ΔE :

-

Color changes

References

Akpinar EK, Bicer Y (2005) Modelling of the drying of eggplants in thin‐layers. Int J Food Sci Technol 40(3):273–281

Alibas I (2007) Microwave, air and combined microwave–air-drying parameters of pumpkin slices. LWT–Food Sci Technol 40(8):1445–1451

AOAC (1995) Official methods of analysis, 16th edn. Association of Official Analytical Chemists, Washington DC

Arévalo-Pinedo A, Murr FEX (2007) Influence of pre-treatments on the drying kinetics during vacuum drying of carrot and pumpkin. J Food Eng 80(1):152–156

Bhat MA, Bhat A (2013) Study on physico-chemical characteristics of pumpkin blended cake. J Food Process Technol 4(9):4–9

Ceylan I, Aktaş M, Doğan H (2007) Mathematical modeling of drying characteristics of tropical fruits. Appl Therm Eng 27(11):1931–1936

Das S, Banerjee S (2015) Production of pumpkin powder and its utilization in bakery products development: a review. Int J Res Eng Technol 4(5):478–481

Doymaz I (2011) Drying of eggplant slices in thin layers at different air temperatures. J Food Process Preserv 35(2):280–289

Garcia CC, Mauro MA, Kimura M (2007) Kinetics of osmotic dehydration and air-drying of pumpkins (Cucurbita moschata). J Food Eng 82(3):284–291

Giri S, Prasad S (2007) Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng 78(2):512–521

Guiné RP, Barroca MJ (2012) Effect of drying treatments on texture and color of vegetables (pumpkin and green pepper). Food Bioprod Process 90(1):58–63

Horuz E, Maskan M (2015) Hot air and microwave drying of pomegranate (Punica granatum L.) arils. J Food Sci Technol 52(1):285–293

Lampinen MJ, Ojala KT, Koski E (1991) Modeling and measurements of infrared dryers for coated paper. Dry Technol 9(4):973–1017

Lozano J, Rotstein E, Urbicain M (1983) Shrinkage, porosity and bulk density of foodstuffs at changing moisture contents. J Food Sci 48(5):1497–1502

McLoughlin C, McMinn W, Magee T (2003) Microwave-vacuum drying of pharmaceutical powders. Dry Technol 21(9):1719–1733

Mihindukulasuriya SD, Jayasuriya HP (2015) Drying of chilli in a combined infrared and hot air rotary dryer. J Food Sci Technol 52(8):4895–4904

Mitra J, Shrivastava S, Rao P (2012) Onion dehydration: a review. J Food Sci Technol 49(3):267–277

Mongpraneet S, Abe T, Tsurusaki T (2002) Far infrared–vacuum and–convection drying of welsh onion. Trans ASAE 45(5):1529

Nawirska A, Figiel A, Kucharska AZ, Sokół-Łętowska A, Biesiada A (2009) Drying kinetics and quality parameters of pumpkin slices dehydrated using different methods. J Food Eng 94(1):14–20

Nimmol C (2010) Vacuum far-infrared drying of foods and agricultural materials. J King Mongkut’s Univ Technol North Bangkok 20:37–44

Nowak D, Lewicki PP (2004) Infrared drying of apple slices. Innov Food Sci Emerg 5(3):353–360

Potter N (1996) JH l-lotchkiss Food Science. CBS Publishers and Distributors, New Delhi. lndia

Rizvi SS (1986) Thermodynamic properties of foods in dehydration. Engineering properties of foods 133–214

Sacilik K (2007) Effect of drying methods on thin-layer drying characteristics of hull-less seed pumpkin (Cucurbita pepo L.). J Food Eng 79(1):23–30

Saengrayap R, Tansakul A, Mittal GS (2015) Effect of far-infrared radiation assisted microwave-vacuum drying on drying characteristics and quality of red chilli. J Food Sci Technol 52(5):2610–2621

Sakai N, Hanzawa T (1994) Applications and advances in far-infrared heating in Japan. Trends Food Sci Technol 5(11):357–362

Salehi F, Kashaninejad M (2014) Effect of different drying methods on rheological and textural properties of balangu seed Gum. Dry Technol 32(6):720–727

Salehi F, Kashaninejad M (2015) Effect of drying methods on rheological and textural properties, and color changes of wild sage seed gum. J Food Sci Technol 52(11):7361–7368

Salehi F, Kashaninejad M, Behshad V (2014) Effect of sugars and salts on rheological properties of Balangu seed (Lallemantia royleana) gum. Int J Biol Macromol 67:16–21

Salehi F, Kashaninejad M, Tadayyon A, Arabameri F (2015) Modeling of extraction process of crude polysaccharides from Basil seeds (Ocimum basilicum l.) as affected by process variables. J Food Sci Technol 52(8):5220–5227

Salehi F, Kashaninejad M, Akbari E, Sobhani SM, Asadi F (2016a) Potential of sponge cake making using infrared–Hot Air dried carrot. J Texture Stud 47(1):34–39

Salehi F, Kashaninejad M, Asadi F, Najafi A (2016b) Improvement of quality attributes of sponge cake using infrared dried button mushroom. J Food Sci Technol. 1–6. doi: 10.1007/s13197-015-2165-9.

Sandu C (1986) Infrared radiative drying in food engineering: a process analysis. Biotechnol Progr 2(3):109–119

Sojak M (1999) Modelling of the kinetics of pumpkin dehydration. Inz Rolnicza 2(8):87–94

Swasdisevi T, Devahastin S, Ngamchum R, Soponronnarit S (2007) Optimization of a drying process using infrared-vacuum drying of Cavendish banana slices. Optimization 29(3):810

Terazawa Y, Ito K, Masuda R, Yoshida K (2001) Changes in carbohydrate composition in pumpkins (Cucurbita maxima)(kabocha) during fruit growth. J Jpn Soc Hortic Sci 70(5):656–658

Therdthai N, Zhou W (2009) Characterization of microwave vacuum drying and hot air drying of mint leaves (Mentha cordifolia Opiz ex Fresen). J Food Eng 91(3):482–489

Toğrul H (2006) Suitable drying model for infrared drying of carrot. J Food Eng 77(3):610–619

Weinstein SJ, Vogt TM, Gerrior SA (2004) Healthy eating index scores are associated with blood nutrient concentrations in the third national health and nutrition examination survey. J Am Diet Assoc 104(4):576–584

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghaboos, S.H.H., Ardabili, S.M.S., Kashaninejad, M. et al. Combined infrared-vacuum drying of pumpkin slices. J Food Sci Technol 53, 2380–2388 (2016). https://doi.org/10.1007/s13197-016-2212-1

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2212-1