Abstract

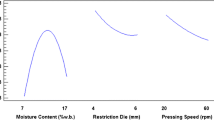

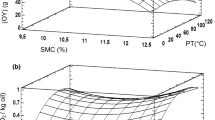

Screw pressing performance of whole and dehulled flaxseed at different seed moisture (6.4 to 11.1 % d.b.) and press head temperature (80–120 °C) was investigated. Oil recovery, residual oil, press rate and sediment content and some important physico-chemical characteristics were determined at six different levels (50, 60, 70, 80, 90 and 100 %) of dehulled flaxseed. Oil recovery decreased with increasing moisture content as well as press head temperature. Press rate was found maximum for 100 % dehulled flaxseed while minimum for 50 % dehulled flaxseed at 6.4 % moisture content. Colour of oil samples was found affected both with the level of dehulled flaxseed and press head temperature. Free fatty acids content of oil ranged from 1.07 % to 2.70 % and lower at 80 °C press head temperature. Oil and cake temperatures ranged from 53.10 °C to 65.95 °C and 69.15 to 103.75 °C, respectively. The α-linolenic acid content of different oil samples obtained at 80 °C was in the range of 53.34 ± 0.95 to 54.21 ± 1.04 %. In view of maximum oil recovery (82.9 % d.b.), lower FFA content, and oil and cake temperature, 7:3 ratio of dehulled and whole flaxseed having 6.4 % d.b. moisture content and 80 °C press head temperature may be considered for screw pressing of flaxseed.

Similar content being viewed by others

References

Ajibola OO, Okunade DA, Owolarafe OK (2002) Oil point pressure of soybean seed. J Food Process Eng 25:407–416

Adlercreutz H (2007) Lignans and human health. Crit Rev Clin Lab Sci 44(5):483–525

AOAC (2000) Official methods of analysis, 17th edn. Association of Official Analytical Chemists, Washington

Appleqvist LA (1968) Rapid methods of lipid extraction and fatty acid esters preparation for seed and leaf tissue with special remarks on preventing the accumulation of lipid contaminants. Ark Kenci 28:351–370

Bamgboye AI, Adejumo AOD (2007) Development of a sunflower oil expeller. Agric Eng Int CIGR E J 9:1–6

Bargale PC, Ford RJ, Sosulki FW, Wulfsohn D, Irudayaraj J (1999) Mechanical oil expression from extruded soybean samples. J Am Oil Chem Soc 76:223–229

Barnwal P, Singh KK, Mridula D, Kumar R, Rehal J (2010) Effect of moisture content and residence time on dehulling of flaxseed. J Food Sci Technol 47(6):662–667

Baryeh EA (2001) Effect of palm oil processing parameters on yield. J Food Eng 48:1–6

Bhatty RS (1995) Nutritional composition of whole flaxseed and flaxseed meal. In: Cunnane SC, Thompson LH (eds) Flaxseed in human nutrition. AOCS Press, Champaign, pp 22–45

Chakraverty A (1988) Post-harvest technology of cereals, pulses and oilseeds. Oxford and IBH publ Co Pvt Ltd, New Delhi

Clark WF, Muir AD, Westcott ND, Parbtani A (2000) A novel treatment for lupus nephritis: lignan precursor derived from flax. Lupus 9:429–436

Faborode MO, Favier JF (1996) Identification and significance of the oil-point in seed-oil expression. J Agr Eng Res 65:335–375

FAO Production Year book (2004) http://www.fao.org/ag/aga/agap/frg/AFRIS/DATA/508. htm accessed 31.03.04

Felycia ES, Budijanto GM, Prasetyo RI, Indraswati N (2008) Effects of pre-treatment condition on the yield and quality of Neem oil obtained by mechanical; pressing. ARPN J Eng Appl Sci 3(5):45–49

Fils JM (2000) The production of oils. In: Hamm W, Hamilton RJ (eds) Edible oil processing. Sheffield Academic Press, Sheffield, pp 47–78

Hernandez LF, Larsen AO, Lindstrom LI, Iriarte LB (2008) Physiological maturity in sunflower—correspondence between the quantitative and the visual definition. Proceedings of the 17th International Sunflower Conference Cordoba, June 8–12, Spain, p 337–340 (http://www.criba.edu.ar/morfologiavegetal/producfiles/ papers/17ISC-PhysMat.pdf)

Hoffmann G (1989) The chemistry and technology of edible oils and fats and their high-fat products. Academic, New York, pp 63–68

Kangas N, Niehaus M, Hall CA III (2006) Utilization of flaxseed gum in dairy foods. In: Proceedings of the 61st Flax Institute of the U.S. Carter JF (Ed.). North Dakota State University, Fargo, ND. p 205–212

Kettler DB (2001) Can manipulation of ratios of essential fatty acids shows the rapid rate of post menopausal bone loss? Alternative Med Rev 6(1):61–77

Khan LM, Hanna MA (1983) Expression of oil from oilseeds—a review. J Agr Eng Res 28:495–503

Mridula D, Singh KK, Barnwal P (2011a) Development of omega-3 rich energy bar with flaxseed. J Food Sci Tech. doi:10.1007/s13197-011-0425x

Mridula D, Daljeet K, Nagra SS, Barnwal P, Gurumayum S, Singh KK (2011b) Growth performance, carcass traits and meat quality in broilers, fed flaxseed meal. Asian Australas J Anim Sci 24(12):1729–1735

Mridula D, Barnwal P, Gurumayum S, Singh KK (2012) Effect of chemical pre-treatment on dehulling parameters of flaxseed (cv. Garima). J Food Sci Tech. doi:10.1007/s13197-012-0699-7

Nagaraj G (2009) Oilseeds-properties, processing, products and procedures. New India Publishing Agency, New Delhi

Panfilis FD, Toschi TG, Lercker G (1998) Quality control for cold-pressed oils. Informatics 9:212–221

Pohjanheimo TA, Hakala MA, Tahvonen RL, Salminen SJ, Kallio HP (2006) Flaxseed in breed making: effects on sensory quality, aging, and composition of bakery products. J Food Sci 71:S343–S348

Prasad K, Mantha SV, Muir AD, Westcott ND (1998) Reduction of hyper cholesterolemic atherosclerosis by CDC-flaxseed with very low alphalinolenic acid. Atherosclerosis 136:367–375

Ranganna S (2008) Hanbook of analysis and quality control for fruit and vegetable products 2nd edn. The MaGraw-Hill Publishing Company Limited, New Delhi

Reuber M (1992) New technologies for processing crambe abyssinica. M.S. Thesis, Iowa State University, Ames

Shukla VKS (2003) A designer oil for better health. Int New Fats Oils Relat Mater 14(6):340–341

Simopoulos AP (1999) Essential fatty acids in health and chronic disease. Am J Clin Nutr 70(3):560–569

Singh J, Bargale PC (1990) Mechanical expression of oil from linseed. J Oilseed Res 7:106–110

Singh J, Bargale PC (2000) Development of a small capacity double stage compression screw press oil expression. J Food Eng 43:75–82

Singh KK, Jhamb SA, Kumar R (2010) Effect of pretreatments on performance of screw pressing for flaxseed. J Food Process Eng. doi:10.1111/j.1745-4530.2010.00606.x

Singh KK, Mridula D, Rehal J, Barnwal P (2011a) Flaxseed: a potential source of food, feed and fibre. Crit Rev Food Sci Nutr 51:210–222

Singh KK, Mridula D, Barnwal P, Rehal J (2011b) Selected engineering and biochemical properties of 11 flaxseed varieties. Food Bioproc Technol. doi:10.1007/s11947-011-0607-6

Singh KK, Wiesenborn DP, Tostenson K, Kangas N (2002) Influence of moisture content and cooking on screw pressing of crambe seed. J Am Oil Chem Soc 79:165–170

Singh MS, Farsai A, Stewart LE, Douglass LW (1984) Development of mathematical models to predict sunflower oil expression. Trans ASAE 27:1190–1194

Spence JD, Thornton T, Muir AD, Westcott ND (2003) The effect of flax seed cultivars with differing content of alpha-linolenic acid and lignans on responses to mental stress. J Am Coll Nutr 22:494–501

Yoyock JY, Lombia G, Owonubi JJ (1988) Crop science and production in warm climates. General edition. Macmillan Intermediate Agricultural Series, London

Zhang W, Xu S, Wang Z, Yang R, Lu R (2009) Demucilaging and dehulling flaxseed with a wet process. LWT--Food Sci Technol 42:1193–1198

Zheng Y, Wiesnborn DP, Tostenson K, Kangas N (2003) Characterization of preparation parameters for improved screw pressing of crambe seed. Trans ASAE 45:1029–1035

Zheng Y, Wiesnborn DP, Tostenson K, Kangas N (2005) Energy analysis in the screw pressing of whole and dehulled flaxseed. J Food Eng 66(2):193–202

Acknowledgments

Financial assistance received from Department of Science and Technology (DST), Govt. of India, New Delhi, India for this study is duly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mridula, D., Barnwal, P. & Singh, K.K. Screw pressing performance of whole and dehulled flaxseed and some physico-chemical characteristics of flaxseed oil. J Food Sci Technol 52, 1498–1506 (2015). https://doi.org/10.1007/s13197-013-1132-6

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-013-1132-6