Abstract

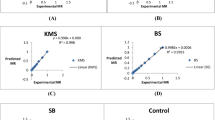

In this study, drying characteristics of pretreated and untreated pumpkin were examined in a hot-air dryer at air temperatures within a range of 40–80 °C and a constant air velocity of 1.5 m/s. The drying was observed to be in the falling-rate drying period and thus liquid diffusion is the main mechanism of moisture movement from the internal regions to the product surface. The experimental drying data for the pumpkin fruits were used to fit Exponential, General exponential, Logarithmic, Page, Midilli-Kucuk and Parabolic model and the statistical validity of models tested were determined by non-linear regression analysis. The Parabolic model had the highest R2 and lowest χ2 and RMSE values. This indicates that the Parabolic model is appropriate to describe the dehydration behavior for the pumpkin.

Similar content being viewed by others

Abbreviations

- a:

-

Drying constant

- b:

-

Drying constant

- c:

-

Drying constant

- DR:

-

Drying rate (g water/g dry matter*h)

- k:

-

Drying constant, 1/min

- Me :

-

Equilibrium moisture content (kg water/kg dry matter)

- Mi :

-

Initial moisture content (kg water/kg dry matter)

- MR :

-

Dimensionless moisture ratio

- MR exp,i :

-

Experimental dimensionless moisture ratio

- MR pre,i :

-

Predicted dimensionless moisture ratio

- Mt :

-

Moisture content at any time of drying (kg water/kg dry matter)

- Mt + dt :

-

Moisture content at t + dt (kg water/kg dry matter)

- N:

-

Number of observations

- n:

-

Drying constant, positive integer

- R2 :

-

Coefficient of determination

- t:

-

Time (min)

- W :

-

Amount of evaporated water (g)

- W0:

-

Initial weight of sample (g)

- W1:

-

Sample dry matter mass (g)

- z:

-

Number of constants

- χ2 :

-

Reduced chi-square

References

Akanbi CT, Adeyemi RS, Ojo A (2006) Drying characteristics and sorption isotherm of tomato slices. J Food Eng 73:141–146

Akpinar AK, Bicer Y (2008) Mathematical modelling of thin layer drying process of long green pepper in solar dryer and under open sun. Energy Conver Manag 49:1367–1375

Aliba I (2007) Microwave, air and combined microwave–air-drying parameters of pumpkin slices. LWT 40:1445–1451

AOAC (1990) Official methods of analysis, 15th edn. Association of Official Analytical Chemists, Arlington

Demir V, Gunhan T, Yagcioglu AK, Degirmencioglu A (2004) Mathematical modeling and the determination of some quality parameters of air-dried bay leaves. Biosys Eng 88(3):325–335

Doymaz I (2004a) Drying kinetics of white mulberry. J Food Eng 61(3):341–346

Doymaz I (2004b) Pretreatment effect on sun drying of mulberry fruit (Morus alba L.). J Food Eng 65(2):205–209

Doymaz I (2004c) Convective air drying characteristics of thin layer carrots. J Food Eng 61(3):359–364

Doymaz I (2007a) Air-drying characteristics of tomatoes. J Food Eng 78:1291–1297

Doymaz I (2007b) The kinetics of forced convective air-drying of pumpkin slices. J Food Eng 79:243–248

Doymaz I (2010) Effect of citric acid and blanching pre-treatments on drying and rehydration of Amasya red apples. Food Bioprod Proc 88(2–3):124–132

El-Beltagy A, Gamea GR, Amer Essa AH (2007) Solar drying characteristics of strawberry. J Food Eng 78:456–464

Gaston AL, Abalone RM, Giner SA, Bruce DM (2004) Effect of modelling assumptions on the effective water diffusivity in wheat. Biosys Eng 88(2):175–185

Goyal RK, Kingsly ARP, Manikantan MR, Ilyas SM (2006) Thin layer drying kinetics of raw mango slices. Biosys Eng 95(1):43–49

Goyal RK, Mujjeb O, Bhargava VK (2008) Mathematical modeling of thin layer drying kinetics of apple in tunnel dryer. Int J Food Eng 4(8):Article 8

Hii CL, Law CL, Cloke M, Suzannah S (2009) Thin layer drying kinetics of cocoa and dried product quality. Biosys Eng 102:153–161

Kingsly RP, Goyal RK, Manikantan MR, Ilyas SM (2007a) Effects of pretreatments and drying air temperature on drying behaviour of peach slice. Int J Food Sci Technol 42:65–69

Kingsly ARP, Singh R, Goyal RK, Singh DB (2007b) Thin-layer drying behaviour of organically produced tomato. Am J Food Technol 2:71–78

Kumar R, Jain S, Garg MK (2010) Drying behaviour of rapeseed under thin layer conditions. J Food Sci Technol 47(3):335–338

Lee JH, Kim HJ (2009) Vacuum drying kinetics of Asian white radish (Raphanus sativus L.) slices. LWT - Food Sci Technol 42:180–186

Midilli A, Kucuk H (2003) Mathematical modeling of thin layer drying of pistachio by using solar energy. Energy Conver Manag 44(7):1111–1122

Sacilik K (2007) Effect of drying methods on thin-layer drying characteristics of hull-less seed pumpkin (Cucurbita pepo L.). J Food Eng 79:23–30

Sacilik K, Elicin AK (2006) The thin layer drying characteristics of organic apple slices. J Food Eng 73:281–289

Sharma GP, Prasad S (2004) Effective moisture diffusivity of garlic cloves undergoing microwave convective drying. J Food Eng 65(4):609–617

Shittu TA, Raji AO (2008) Thin layer drying of African Breadfruit (Treculia africana) seeds: modeling and rehydration capacity. Food Bioprocess Technol: 1–8. doi:10.1007/s11947-008-0161-z

Simal S, Femenia A, Garau MC, Rossello C (2005) Use of exponential, page and diffusion models to simulate the drying kinetics of kiwi fruit. J Food Eng 66(3):323–328

Singh S, Sharma R, Bawa AS, Saxena DC (2008) Drying and rehydration characteristics of water chestnut (Trapa natans) as a function of drying air temperature. J Food Eng 87:213–221

Singh G, Arora S, Kumar S (2010) Effect of mechanical drying air conditions on quality of turmeric powder. J Food Sci Technol 47(3):347–350

Sobukola OP, Dairo OU, Odunewu AV (2008) Convective hot air drying of blanched yam slices. Int J Food Sci Technol 43:1233–1238

Sogi DS, Shivhare US, Garg SK, Bawa SA (2003) Water sorption isotherms and drying characteristics of tomato seeds. Biosys Eng 84(3):297–301

Tembo L, Chiteka ZA, Kadzere I, Akinnifesi FK, Tagwira F (2008) Blanching and drying period affect moisture loss and vitamin C content in Ziziphus mauritiana (Lamk.). Afric J Biotech 7:3100–3106

Togrul IT, Pehlivan D (2002) Mathematical modeling of solar drying of apricots in thin layers. J Food Eng 55:209–216

Togrul IT, Pehlivan D (2004) Modeling of thin layer drying kinetics of some fruits under open air sun drying process. J Food Eng 65(3):413–425

Tunde-Akintunde TY, Akintunde BO (1996) Post- harvest losses of food crops: sources and solutions. Proceedings of the Annual Conference of the Nigerian Society of Agricultural Engineers, Ile-Ife, Nigeria from November 19–22, 1996. Vol 18:258–261

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tunde-Akintunde, T.Y., Ogunlakin, G.O. Mathematical modeling of drying of pretreated and untreated pumpkin. J Food Sci Technol 50, 705–713 (2013). https://doi.org/10.1007/s13197-011-0392-2

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-011-0392-2