Abstract

Supplementation of vitamin B2 (riboflavin) in poultry feeding is essential. For economic and environmental reasons, riboflavin is now produced biotechnologically, which, in most industrial production, is based on genetically modified organisms (GMOs). Due to legislation, organic animals must be fed with GMO-free feeds, which also applies to the production processes of vitamin additives in the feed. Therefore, the main objective of experiments in this paper is the screening of GMO-free wild-type yeast strains overproducing riboflavin as a starting point to develop GMO-free riboflavin production lines that ensure the continuous supply of riboflavin for organic livestock. A screening of wild-type, non-GMO microorganisms overproducing riboflavin was conducted. The wild-type yeast Meyerozyma guilliermondii DSM 11947 produced the highest riboflavin concentration in the screening procedure. In order to provide a feasible and affordable certified organic animal vitamin B2 supplement, the possibility of minimizing the expensive media component, yeast extract, was shown. This work shows the possibility of using a wild-type strain to achieve higher levels of riboflavin by means of bioprocess engineering and without metabolic engineering. A fermentation strategy at the laboratory scale is provided, where a yield of 30 mg riboflavin per g dry matter of yeast cells was achieved.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Riboflavin (vitamin B2) is a crystalline, odorless powder (Flores-Garcia 1992). The yellow-to-orange-yellow, bitter-tasting riboflavin is also approved as a food colorant in human nutrition and noted with the European approval number E 101 (Turck et al. 2017). It is water-soluble and an important cofactor of several enzymes in the metabolism of blood and liver (Northrop-Clewes and Thurnham 2012). Besides the production of erythrocytes, riboflavin is also essential in neurological processes, in particular in growing birds (Wyatt et al. 1973; NRC 1994; Pond et al. 1995; Wada et al. 1996; Cai et al. 2006). In poultry, deficiency may lead to disturbances of growth (in particular of the limbs), neuropathies, and impaired blood synthesis. Furthermore, inflammatory disturbances in epithelia, atrophy, and hyperkeratosis of the skin as well as deformations in neural tissues and impaired development of the embryo may occur due to riboflavin deficiency in poultry (Wyatt et al. 1973; NRC 1994; Scholtyssek 1987; Olkowski and Classen 1998; Roth-Maier and Kirchgessner 1997; Engelhardt 2010). This leads either to death or, in subclinical cases, to unspecific reductions in growth efficiency. Symptoms of riboflavin deficiency are thus of high relevance for animal welfare and productivity in poultry.

Natural sources of riboflavin include milk, eggs, yeast, cereals, meat, fatty fish, and green leafy vegetables (Zhang et al. 2021). Recommendations for riboflavin additions have never been established for organic poultry production, and conventional recommendation values are usually used for formulations. However, depending on feeding and feed components such as silages and access to fresh grass, intrinsic concentrations in the organic feed may be higher than in conventional feed, so required riboflavin additions may be lower (Witten and Aulrich 2018; Witten and Aulrich 2019).

New studies deal with experiments to find out a safe lower threshold level of riboflavin supplementation for laying hens fed on organic formulations (Lambertz et al. 2021a; Leiber et al. 2022). In the literature, it was found that no health or performance problems occurred in breeder hens or broiler chicks when 4.0 mg riboflavin per kg of organic feed was added, while lower supplementation of 2.5 mg per kg of feed resulted in lower weight gains, but without other riboflavin deficiency symptoms (Leiber et al. 2022). In further studies applicable only to organic winter feed, different levels of riboflavin (4.5, 3.0, or 1.5 mg GMO-free riboflavin per kg feed) were added to monitor performance, egg quality, and health traits of hens and to define a threshold at which deficiency is unlikely (Leiber et al. 2021). Here, feed consumption, laying performance, egg quality, riboflavin concentration in the yolk, and clinical health scores were evaluated. Based on these results, the addition of 3 mg riboflavin per kg feed appeared to be adequate for the health and performance of laying hen. Supplementation with only 1.5 mg per kg feed has been observed to result in some metabolic signs of deficiency (Leiber et al. 2021). Lambertz et al. studied the usability of the fermentation broth of the filamentous fungus Ashbya gossypii as an alternative source of feed material containing high native riboflavin content. It was shown that the native contents of 3.27 mg per kg DM were not sufficient to meet the riboflavin demand (Lambertz et al. 2021a).

In the past decades, expensive chemical synthesis was gradually replaced by the introduction of a number of biotechnological production processes (You et al. 2021). For economic and environmental reasons, riboflavin is now produced under in vitro conditions, which in most industrial production is based on genetically modified organisms (GMOs) since GMO-free processes are often less cost-efficient, resulting in significantly higher product costs to the end-users (Leiber et al. 2022). About 70% of the biotechnologically produced riboflavin is used as a feed additive and about 30% as a food additive and pharmaceutical applications (Schwechheimer et al. 2016; Revuelta et al. 2016; Burgess et al. 2009).

In organic farming, it is not allowed to use GMOs or products produced by GMOs (European Union 2018). This also applies to supplemented vitamins in the feed. The manufacturer of organic baker’s yeast (Agrano GmbH & Co. KG, Switzerland) is developing an alternative to GMO-yeast-based riboflavin: the product EcoVit R is made from the filamentous fungus Ashbya gossypii, which grows in a nutrient solution from organic ingredients. It can be used as a liquid or as a dry product (Agrano 2019). A non-GMO yeast-based riboflavin product is therefore available for the European feed market. Besides the price, there is uncertainty about its legal status. It is currently inconsistent between countries, whether EcoVit R is regarded as a feed material or a feed additive.

In contrast to many bacteria and yeasts (e.g., Candida famata, Clostridium acetobutylicum, Lactobacillus fermentum (You et al. 2021; Schwechheimer et al. 2016), and Ashbya gossypii (You et al. 2021; Wang et al. 2021; Revuelta et al. 2016; Burgess et al. 2009), higher eukaryotes (e.g. livestock) cannot synthesize riboflavin, and therefore, the supply of this vitamin is a dietary necessity. For the industrial riboflavin production three microorganisms, Ashbya gossypii, Bacillus subtilis, and Candida famata are exploited (Perkins et al. 1999; Schallmey et al. 2004; Stahmann et al. 2000; Wang et al. 2021; Zhang et al. 2021). Using metabolic engineering, the riboflavin titer of Ashbya gossypii was increased to more than 20 g/L using vegetable oils as carbon source and complex nitrogen sources like soy flour or corn steep liquor (Schwechheimer et al. 2016; Wang et al. 2021). An engineered Bacillus subtilis uses molasses and starch hydrolysates or thick juice as a carbon source as well as corn steep liquor and yeast extract as a nitrogen source. Final titers of more than 26 g/L riboflavin are achieved (Wang et al. 2021; Lee et al. 2004). A recombinant Candida famata strain is able to produce a final concentration of 16 g/L riboflavin (Dmytruk et al. 2014).

After screening GMO-free wild-type strains that overproduce riboflavin, the main objective of this study is to develop and optimize these GMO-free riboflavin production lines to ensure a continuous supply of riboflavin for organic livestock production.

Materials and methods

Microorganism

Phylogenetically close relatives of known naturally overproducing riboflavin yeast strains were ordered from culture collection (NRRL—Agricultural Research Service Culture Collection (Peoria, IL, USA); DSMZ—German Collection of Microorganisms and Cell Cultures (Braunschweig, Germany)). The inoculum was incubated at the propagation conditions recommended by the culture collections. Glycerol stock cultures were prepared for long-term storage.

Media composition and cultivation

The pre-cultures were performed in TYG-medium and contained 5 g/L yeast extract, 5 g/L tryptone/pepton from casein, 1 g/L K2HPO4, and 5 g/L glucose∙H2O. The pre-culture was inoculated with one inoculation loop from an agar plate and conducted in 300 mL shake flasks with three baffles and a filling volume of 90 mL at 150 rpm (50 mm shaking diameter) and 37 °C for approximately 6 h to reach an optical density of OD605nm 4–5.

Unless otherwise stated, the production media contained 70 g/L glucose∙H2O, 4 g/L yeast extract, 1 g/L urea, 1.2 g/L K2HPO4, 0.2 g/L KH2PO4, 1 g/L asparagine, 2 g/L glycine, 1 μg/L biotin, 0.4 mg/L thiamine, 1.23 g/L MgSO4∙7H2O, 0.32 g/L CaCl2∙2H2O, 50 mg/L H3BrO3, 5 mg/L K2Cr2O7, 17.5 mM ZnSO4∙7H2O, 0.2 mM CuSO4∙5H2O, 125 mM KI, 4.5 mM MnSO4∙H2O, and 2 mM NaMoO4∙2H2O. The media components were p.a. quality and purchased from Merck (Germany), Sigma-Aldrich (USA), or Roth (Germany). Stock solutions of all media components were prepared separately. The solutions were autoclaved for 20 min at 121 °C. The amino acid, vitamin, and trace element solutions were not autoclaved but sterile-filtered (Membrane filter, sterile, pore size 0.22 μm, Carl Roth GmbH + Co. KG, Germany).

Unless otherwise stated, experiments were performed in 100 mL shake flasks with two baffles and a filling volume of 30 mL production media at 150 rpm (50 mm shaking diameter) with 2% inoculum, incubated at 33 °C. Evaporation was compensated by adding sterile water at every sampling. Samples were taken regularly during cultivation. Cultivations were carried out minimum in duplicates.

The experiments in bioreactors were conducted in four parallel 1 L-bioreactors, equipped with one 6-bladed impeller (DASGIP GmbH, Jülich, Germany), 2% inoculum, and a working volume of 600 mL production medium. DASGIP Control software (DASGIP GmbH, Jülich, Germany) was used for the regulation of gassing, temperature, pH value, and stirring rate, as well as for recording the data. The pH regulation to pH 6.2 was carried out with a 4 M NaOH solution. Cultivations were carried out minimum in duplicates.

Analytical methods

High-performance liquid chromatography

To analyze the concentrations of the substrate glucose and organic acids, a high-performance liquid chromatography (HPLC) with a HPX-87H column at 40 °C and a refractive index detector and UV detector at 210 nm was used. A 5 mM H2SO4 solution at a flow rate of 0.6 mL/min was used as the mobile phase.

Regarding product analysis, the measurement of riboflavin was established. A HPLC system with an ODS—hypersil 120 A column at 40 °C (4.5 × 125 mm, 3 μm) and a Diode Array-Detector (DAD) at 270 nm was used. As the mobile phase, a gradient system with a flow rate of 1 mL/min was used (start with 100% mobile phase 1 (5% ACN with 50 mM KH2PO4), after 9 min 100% mobile phase 2 (20% ACN with 50 mM KH2PO4)).

Microscopy

The cells were examined using a phase-contrast microscope (Axioplan, Carl Zeiss AG, Jena, Germany) with the software Analysis Pro (Analysis 5.1, Olympus Soft Imaging Solutions GmbH, Münster, Germany).

Cell growth

Optical density measurement was carried out using a photometer T80 UV/VIS Spectrophotometer (PG Instruments Ltd., UK) to determine the extinction at a wavelength of 605 nm (OD605nm) with the software UVWin (UVWin 5 Software for UV-Visible Spectrophotometers, PG Instruments Ltd., UK).

Bio dry mass was determined gravimetrically. Samples were centrifuged at 20,800 × g for 10 min at 20 °C. The pellet was washed twice with deionized water and dried to constant weight at 105 °C for at least 48 h.

Results

Screening of overproducing riboflavin strains

To identify riboflavin overproducing GMO-free yeast strain, phylogenetically close relatives of known naturally overproducing riboflavin strains were ordered in strain collections, cultivated, and tested regarding riboflavin overproduction. Successful growth of the strains was achieved, and riboflavin production was detected in six cultures (Table 1). The wild-type yeast Meyerozyma guilliermondii DSM 11947 produced the highest riboflavin concentration with more than 20 mg/L.

The validation of the overproduction of riboflavin during the cultivation under non-optimized screening conditions was successful. Therefore, Meyerozyma guilliermondii DSM 11947 was chosen for further investigations in order to achieve a higher level of riboflavin, by means of bio-process engineering and without metabolic engineering.

Nutrient requirements of M. guilliermondii DSM 11947

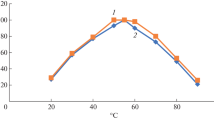

The nutrient requirements of the wild-type strain M. guilliermondii DSM 11947 and the scale up from shaking flasks to a 1 L-bioreactor were under investigation. Therefore, the yeast extract concentration was reduced from 4 (reference) to 2 g/L, 1 g/L as well as 0 g/L (Fig. 1). Equivalent to the fastest conversion to riboflavin, glucose was completely consumed within 3 days in the reference cultivation. In the variations with a lower concentration of yeast extract, glucose took longer to be utilized, and the production of riboflavin was significantly lower. At the end of the cultivation after 6 days, the highest riboflavin concentration with 34 mg/L was obtained with a reduced amount of 2 g/L yeast extract, compared to 23 mg/L riboflavin of the reference.

Since the production medium already contains another source of nitrogen (urea), which is much cheaper compared to yeast extract, the complete replacement of yeast extract by urea was tested. For this purpose, the urea concentration was increased and 0.5, 2, 5, and 10 g/L urea were tested. The nitrogen content of the reference (4 g/L yeast extract and 1 g/L urea) corresponds to a concentration of 1.97 g/L urea using urea as the sole nitrogen source. The complete omission of yeast extract led to a slowed riboflavin formation independent of the used urea concentration. The maximum productivity was lower, but after 14 days of cultivation, the same amount of riboflavin was produced (data not shown).

Since yeast extract is an important source for vitamins and amino acids, the influence of B vitamins and amino acids was under investigation in the following approaches. Here, a minimal supplemented medium with 1 g/L urea and 0 g/L yeast extract was used. In order to ensure a minimal supply for the strain and the riboflavin synthesis, the B vitamins and amino acids contained in 4 g/L yeast extract are added both as totally and individually. The results showed that the addition of the individual B vitamins is not essential for an overproduction of riboflavin in M. guilliermondii DSM 11947, because even without the addition of vitamins, the strain was able to form a similar quantity of riboflavin (data not shown).

To study the effect of amino acids, 3 solutions were prepared with respect to the heat resistance and solubility of the different amino acids. Amino acid mix 1 consists of alanine, glycine, valine, leucine, L-isoleucine, threonine, serine, proline, methionine, phenylalanine, lysine, histidine, and cysteine. Amino acid mix 2 consists of aspartic acid, glutamic acid, and asparagine. Amino acid mix 3 consists of tryptophan and tyrosine. The variations pointed out that amino acid mix 1 had a significantly steeper increase in riboflavin synthesis than the reference by the third day of cultivation. After 6 days of cultivation, the glucose was only depleted in the case of the reference and the approach with the addition of all 3 amino acid solutions. However, the highest riboflavin concentration was achieved with the addition of amino acid mix 3 with 14.5 mg/L, followed by the approach with amino acid mix 1 with 11.2 mg/L (data not shown).

Cultivation of M. guilliermondii DSM 11947 in 1 L-bioreactor

In order to make this process applicable for industrial production, a scale up, i.e., a gradual increase in scale, had to be conducted. Therefore, the transfer of the fermentation process from shaking flasks to a 1 L-bioreactor was investigated. Since air input plays a crucial role in aerobic processes such as this one, it must be controlled so that the yeast strain M. guilliermondii DSM 11947 is supplied with sufficient oxygen. In this process, the demand was regulated via a dissolved oxygen (DO) cascade (Table 2). To keep the process value at setpoint (10% and later 30%), the agitation speed and the oxygen concentration in the gas mix and the gas flow are altered in a cascaded manner. In all experiments, the gas flow rate stayed at 6 sL/h constant throughout the cultivation.

Consumption of glucose initiated growth of the culture, and after 1 day of cultivation, riboflavin production of M. guilliermondii DSM 11947 started (Fig. 2). In the following course, the strain entered the growth phase, with a steep increase to 26 mg/L in riboflavin production. Although complete consumption of glucose occurred after 3 days, a final riboflavin concentration of 42.4 mg/L was formed after 6.7 days.

Just a few hours after the start of the cultivation, the DO value dropped to the setpoint of 10%. For this purpose, the agitation speed N was first continuously increased from 300 rpm at the beginning. After reaching the maximum value of 800 rpm, the oxygen concentration was finally regulated to 100% in order to be able to cover the oxygen demand.

The results showed clearly that the scale-up into the 1 L-bioreactor in a batch mode is possible. In order to be able to generate higher riboflavin concentrations, the fed-batch mode was used (Fig. 3). The DO cascade was retained. In the form of solids, a feed of approximately 40–50 g/L glucose was added daily starting at the second day of fermentation. After 9.7 d of cultivation, a maximum riboflavin concentration of 170.2 mg/L was obtained; this was already achieved before the 6th day. The additional feeding resulted only in an increase in optical density but not in a further riboflavin formation.

Considering the cascaded DO control, the setpoint of 10% was not maintained even though the agitation speed and the oxygen concentration were adjusted to their maximum values at 800 rpm and 100%.

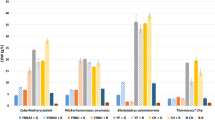

In order to ensure a sufficient supply of the oxygen demand of the culture, the influence of the maximum agitation speed was investigated (Fig. 4). For this purpose, the initial agitation speed was increased to 500 rpm, the aeration rate to 9 sL/h, and the DO setpoint to 30%. The DO cascade order was otherwise maintained. In addition, the glucose feed was reduced to 28 g/L for each feed. In terms of glucose consumption, the results showed clearly that the conversion was almost identical in the three approaches. Initially, glucose was converted slightly faster at the higher agitation speeds, but after a cultivation period of about 6 days, glucose is no longer completely metabolized at 900 and 1000 rpm. This is also displayed in riboflavin formation, where an increase in agitation speed resulted in a lower riboflavin concentration. After about 9 days, a maximum concentration of 317.6 mg/L was produced at a final agitation speed of 800 rpm (Fig. 5).

A previously performed correlation of optical density and cell dry weight established a linear relationship described by a regression line of y = 0.183 x. The coefficient of determination (R2) was given as 0.989. So that a product/biomass yield (YP/X) of 29.1 mgRiboflavin/gbio dry mass can be calculated for this process at a maximum agitation speed of 800 rpm (Fig. 5).

In addition, notwithstanding the agitation speed, cell growth in the form of optical density measurement (OD605nm) became stagnant from day 2 of fermentation, and a maximum value of about OD605nm = 50 (11 g/L bio dry mass) was obtained in all three approaches.

Discussion

For organic farming, non-GMO derivative riboflavin is required, and the only corresponding product on the market is more expensive than the conventional products (Leiber et al. 2022). Therefore, we performed the screening of wild-type, non-GMO microorganisms with an overproduction of riboflavin to show the possibility to build up a feasible and affordable certified organic animal vitamin B2 supplement. During that screening, the wild-type yeast Meyerozyma guilliermondii DSM 11947 produced the highest riboflavin concentration with more than 20 mg/L. Meyerozyma guilliermondii (former known as Pichia guilliermondii) is a yeast species widely distributed in the environment and the TRBA-460 (Technical Rules for Biological Agents) classify this species in risk group 1 and thus as an organism which is very unlikely to cause disease in humans. The first isolation took place in 1912 from the lungs of bronchomycosis patients (Kurtzman et al. 2010).

M. guilliermondii was of early biotechnological interest as a model organism of flavinogenic yeasts, to produce riboflavin, during cultivation in an iron-deficient medium (Tanner et al. 1945; Papon et al. 2013; Sibirny and Boretsky 2009). Although this phenomenon was first described in 1945, neither the physiological role nor the mechanisms of iron-dependent regulation of flavinogenesis are known. M. guilliermondii can be seen as the model organism for flavinogenic yeasts, due to the development of the methods for classic and molecular genetics of this species (Sibirny and Boretsky 2009).

The validation of the overproduction of riboflavin during the cultivation under non-optimized screening conditions was successful. Therefore, this strain was chosen for further investigations in order to achieve a higher level of riboflavin, by means of bio-process engineering and without metabolic engineering.

The nutrient requirements of the wild-type strain M. guilliermondii DSM 11947 and the scale up from shaking flasks to a 1 L-bioreactor were investigated. To make the process economical, it is important to eliminate expensive components during the cultivation process of the yeast. Besides the substrate, nutrient sources like yeast extract, with a price of 6–10 €/kg, cause the highest production costs (Klotz 2017). Thus, the focus here was primarily on yeast extract, which accounts for an enormous proportion of the media costs, but on the other hand, serves as an important source of nitrogen and nutrients like vitamins and trace elements (Sommer 1998). Therefore, the yeast extract concentration was reduced. Equivalent to the fastest conversion to riboflavin, glucose was completely consumed within 3 days in the reference cultivation. In the variations with a lower concentration of yeast extract (2 g/L, 1 g/L, and 0 g/L yeast extract), glucose took longer to be utilized, and the maximum riboflavin productivity was significantly lower. But in the end of the cultivation after 6 days, the highest riboflavin concentration of 34 mg/L was obtained with a reduced amount of 2 g/L yeast extract, compared to 23 mg/L of the reference with 4 g/L yeast extract. The energy was probably preferentially put into the formation of riboflavin. Thus, a reduction of the complex component is possible, but riboflavin formation is accelerated with higher yeast extract concentrations of up to 4 g/L. Since the production medium already contains another source of nitrogen (urea, with a price of 0.68–0.83 €/kg (urea 2022)), which in comparison to yeast extract is much cheaper, the complete replacement of yeast extract by urea was tested. The complete omission of yeast extract led to a slowed riboflavin formation independent of the used urea concentration. The maximum productivity was lower, but after 14 days of cultivation, the same amount of riboflavin was produced. Thus, it was shown that urea is suitable as a cheap substitute for yeast extract, but the variations and higher amounts of urea did not lead to any positive effect under these cultivation conditions. The influence of yeast extract and urea has not yet been clarified in this series of experiments. However, it has been shown that a constant nitrogen content does not lead to comparable productivities. The influence of iron is discussed in the literature, and the nitrogen sources used have different iron contents. The reason for the overproduction of riboflavin in iron deficiency in flavinogenic yeasts is not fully understood. It is thought that the excretion of riboflavin in iron deficiency plays a role in the non-enzymatic reduction of insoluble Fe3+ to the more accessible soluble Fe2+, thus providing cells with an additional source of iron (Papon et al. 2013). According to the literature, the overproduction of riboflavin by the yeast strains only occurs at very low iron concentrations (< 40 ppm) (Sibirny and Voronovsky 2009). The yeast extract used in these experiments, with 36.7 mg iron per∙kg yeast extract (Klotz 2017), calculated to the amount used, introduces a concentration of 146.8 μg/L into the medium. Since iron is a significant inhibitory factor in the production of riboflavin with M. guilliermondii DSM 11947, a positive effect on the final concentration of the vitamin should thus theoretically be perceptible in the absence of the yeast extract, provided that the alternative nitrogen sources are suitable for yeast growth (Papon et al. 2013). Furthermore, different concentrations of iron should be used in a series of experiments to observe their influence on biomass and riboflavin production. This is of interest because iron not only has an inhibitory effect on riboflavin production, but can also positively influence riboflavin production in certain concentration ranges according to findings from the literature (Tanner et al. 1945). Tanner et al. studied the effect of the iron concentration on the growth and riboflavin synthesis of Candida species. The results show that in an iron-free medium, both cell proliferation and riboflavin synthesis were retarded. However, the iron concentration required for maximum riboflavin formation was much lower than the concentration required for maximum growth. Although their experiments were conducted with a synthetic medium, it has been shown that various sugars and many organic and inorganic nitrogen compounds can be used in media for the production of riboflavin by Candida species if the iron content of the medium is properly adjusted (Tanner et al. 1945).

After the variation of the nitrogen source, the influence of the vitamins and amino acids content of the yeast extract was under investigation. The supplementation of B vitamins is not essential for an overproduction of riboflavin using M. guilliermondii DSM 11947, because even without the addition of vitamins, the strain was able to form riboflavin. In the case of the influence of amino acids, the situation was different. The supplementation of amino acid mix 1 showed a positive effect during the growing phase, whereas the addition of amino acid mix 3 yielded the highest riboflavin concentration. Further studies would be necessary to get more information regarding the nutrient requirement. According to the literature, the growth requirements for the riboflavin production using M. guilliermondii are similar to those of Lactobacillus casei, but M. guilliermondii has much simpler nutritional requirements (Papon et al. 2013).

The transfer of the fermentation process from shaking flasks to a 1 L-bioreactor was also conducted. It could be pointed out that the air supply, the dissolved oxygen content, as well as the feeding rate during a fed-batch cultivation mode play a crucial role during the cultivation of M. guilliermondii DSM 11947 to produce riboflavin. It is possible that the insufficient air/oxygen supply to the culture led to the stagnation of riboflavin synthesis. In addition, the high remaining glucose concentration in the medium, caused by the feeds, could also have been decisive. In order to increase the riboflavin formation and efficiently satisfy the oxygen demand of the culture, the influence of the maximum agitation speed was investigated and in addition, the glucose feed was reduced. Initially, glucose was converted slightly faster at the higher agitation speeds, but after a cultivation period of about 6 days, glucose is no longer completely metabolized at 900 and 1000 rpm. This is also displayed in riboflavin formation, where an increase in agitation speed resulted in a lower riboflavin concentration. After about 9 d, a maximum concentration of 317.6 mg/L riboflavin was produced at an agitation speed of 800 rpm. In addition, notwithstanding the agitation speed, cell growth in the form of optical density measurement (OD605nm) stagnated from day 2 of fermentation, and a maximum value of about OD605nm = 50 (11 g/L bio dry mass) was obtained in all three approaches.

According to the literature, the product EcoVit R is made from the filamentous fungus Ashbya gossypii (Agrano 2019). Lambertz et al. first conducted shake flask scale experiments for the formulation of a suitable cultivation medium. The raw materials organic cane sugar, organic potato protein, organic rice protein, organic sunflower oil, and yeast extract were identified as the most suitable raw materials for the cultivation of Ashbya gossypii and the production of riboflavin. Fermentations were carried out in the pilot plant and pilot fermenters using the formulated media composition. During fermentation, the bioreactors were aerated with sterile-filtered air and mixed with stirrers. The cultivation times were 48–120 h. On a pilot scale, riboflavin concentrations of 300–600 mg/kg could be achieved in the fermentation suspension. Furthermore, the process was also successfully transferred to a production scale (30,000 l), where concentrations of 500–600 mg/kg of riboflavin were produced (Lambertz et al. 2021b). The results provided here, using M. guilliermondii DSM 11947 in a 1 L-bioreactor yielded 30 mg riboflavin per g dry matter of yeast cells.

However, after this initial optimization of the wild-type strain M. guilliermondii DSM 11947, riboflavin production is lower than that of industrial genetically engineered producers based on the yeast C. famata, the bacterium B. subtilis and the filamentous fungus Ashbya gossypii (Wang et al. 2021). But in organic farming, it is not allowed to use GMOs or products produced by GMOs. In this work, a GMO-free wild-type strain was identified that could serve as a starting point for the development of GMO-free vitamin B2 production lines to ensure a continuous supply of organic livestock.

Conclusions

The identification of a GMO-free yeast strain overproducing riboflavin was achieved. In the shake flask scale, the replacement of yeast extract by using urea was successful, resulting in a lower productivity but reaching comparable amounts of riboflavin after 14 days of cultivation time. The riboflavin production was successfully transferred to the 1 L-bioreactor scale. Here, the most critical parameter seemed to be the supply of enough oxygen, combined with the right rpm range. So far, the highest titer of 317.6 mg/L riboflavin was achieved during a fed-batch cultivation after 9 days. In conclusion, a yield of 30 mg riboflavin per g dry matter of yeast cells was achieved.

Data availability

Not applicable

Code availability

Not applicable

References

Agrano (2019) https://www.biopress.de/de/inhalte/details/6902/agrano-bietet-vitamin-b2-ohne-gentechnik.html. Accessed 19 April 2022

Burgess CM, Smid EJ, van Sinderen D (2009) Bacterial vitamin B2, B11 and B12 overproduction: an overview. Int J Food Microbiol 133:1–7

Cai Z, Finnie JW, Blumbergs PC (2006) Avian riboflavin deficiency: an acquired tomaculous neuropathy. Vet Pathol 43:780–781

Dmytruk K, Lyzak O, Yatsyshyn V, Kluz M, Sibirny V, Puchalski C, Sibirny A (2014) Construction and fed-batch cultivation of Candida famata with enhanced riboflavin production. J Biotechnol 172:11–17

Engelhardt W (2010) Physiologie der Haustiere. Enke Verlag, Stuttgart

European Union (2018) Regulation (EU) 2018/848 of the European parliament and of the council of 30 May 2018 on organic production and labelling of organic products and repealing Council Regulation (EC) No 834/2007. Official J Eur Union 150:1–92

Flores-Garcia W (1992) Einfluss verschiedener B-Vitamine, speziell des Riboflavins, auf Reproduktionsmerkmale bei Legehennen. Dissertation,. Universität Hohenheim

Klotz S (2017) Biotechnisch erzeugte D-Milchsäure - Substitution von Hefeextrakt durch agrarische Rohstoffhydrolysate. Dissertation, University of Braunschweig

Kurtzman CP, Fell JW, Boekhout T (2010) The yeasts: a taxonomic study, 5th edn. Elsevier, Amsterdam, Oxford, pp 1–3

Lambertz C, Leopold J, Ammer S, Leiber F, Thesing B, Wild C, Damme K (2021a) Demand-oriented riboflavin supply of organic broiler using a feed material from fermentation of Ashbya gossypii. Animal 15(1):100003. https://doi.org/10.1016/j.animal.2020.100003

Lambertz C, Leopold J, Leiber F, Dumont L, Vogt-Kaute W, Damme K, Bellof G (2021b) Abschlussbericht zum Vorhaben “Demand-oriented nutrition of poultry-focus: new sources for riboflavin (vitamin B2)”; FKZ2811OE099 und FKZ 2815OE052, Laufzeit des Vorhabens: 01.01.2017 –31.03.2020. FiBL Deutschland e.V., Agrano GmbH & Co. KG, (2021) 145 p

Lee K, Park Y, Han J, Park J, Choi H (2004) Microorganism for producing riboflavin and method for producing riboflavin using the same. US2004/0110249A1; 10.06.2004

Leiber F, Amsler Z, Bieber A, Quander-Stoll N, Maurer V, Lambertz C, Früh B, Ayrle H (2022) Effects of riboflavin supplementation level on health, performance, and fertility of organic broiler parent stock and their chicks. Animal 16(1):100433. https://doi.org/10.1016/j.animal.2021.100433

Leiber F, Holinger M, Amsler Z, Maeschli A, Maurer V, Früh B, Lambertz C, Ayrle H (2021) Riboflavin for laying hens fed organic winter diets: effects of different supplementation rates on health, performance and egg quality. Biol Agric and Hortic 38:1–16. https://doi.org/10.1080/01448765.2021.1955005

Northrop-Clewes CA, Thurnham DI (2012) The discovery and characterization of riboflavin. Ann Nutr Metab 61(3):224–230. https://doi.org/10.1159/000343111

NRC (National Research Council) (1994) Nutrient requirements of poultry. The National Academies Press, Ninth Revised Edition, Washington, DC. https://doi.org/10.17226/2114

Olkowski AA, Classen HL (1998) The study of riboflavin requirements in broiler chickens. Int J Vit Nutr Res 68:316–327

Papon N, Savini V, Lanoue A, Simkin A, Crèche J, Giglioli-Guivarc’h N, Clastre M, Courdavault V, Sibirny A (2013) Candida guilliermondii: biotechnological applications, perspectives for biological control, emerging clinical importance and recent advances in genetics. Curr Genet 59:73–90. https://doi.org/10.1007/s00294-013-0391-0

Perkins JB, Sloma A, Hermann T, Theriault K, Zachgo E, Erdenberger T, Hannett N, Chatterjee NP, Williams V, Rufo GA, Hatch R, Pero J (1999) Genetic engineering of Bacillus subtilis for the commercial production of riboflavin. J Ind Microbiol Biot 22:8–18

Pond WG, Church DC, Pond KR (1995) Basic animal nutrition and feeding. CAB Publishing, Collingwood

Revuelta JL, Ledesma-Amaro R, Jiménez A (2016) Industrial production of vitamin b2 by microbial fermentation. In: Industrial Biotechnology of Vitamins, Biopigments, and Antioxidants. Wiley-VCH Verlag GmbH & Co. KGaA, pp 15–40

Roth-Maier DA, Kirchgessner M (1997) Untersuchungen zum Riboflavinbedarf von Mastküken. Arch Geflügelk 61:14–16

Schallmey M, Singh A, Ward OP (2004) Developments in the use of Bacillus species for industrial production. Can J Microbiol 50:1–17. https://doi.org/10.1139/w03-076

Scholtyssek S (1987) Geflügel. Ulmer Verlag Stuttgart

Schwechheimer SK, Park EY, Revuelta JL, Becker J, Wittmann C (2016) Biotechnology of riboflavin. Appl Microbiol Biot 100:2107–2119

Sibirny AA, Boretsky YR (2009) Yeast biotechnology: diversity and applications, Chapter VI: Pichia guilliermondii. In: Satyanarayana T, Kunze G (eds) Yeast Biotechnology: Diversity and Applications. Springer, Dordrecht. https://doi.org/10.1007/978-1-4020-8292-4_6

Sibirny AA, Voronovsky AY (2009) Candida famata (Debaryomyces hansenii). In: Satyanarayana T, Kunze G (eds) Yeast Biotechnology: Diversity and Applications. Springer, Dordrecht. https://doi.org/10.1007/978-1-4020-8292-4_5

Sommer R (1998) Yeast extracts: production, properties and components. Food Aust 50:181–183

Stahmann KP, Revuelta JL, Seulberger H (2000) Three biotechnical processes using Ashbya gossypii, Candida famata, or Bacillus subtilis compete with chemical riboflavin production. Appl Microbiol Biot 53:509–516

Tanner FW, Vojnovich C, van Lanen JM (1945) Riboflavin production by Candida species. Science (New York, N.Y.), 101(2616): 180–181. https://doi.org/10.1126/science.101.2616.180

Turck D, EFSA NDA Panel (EFSA Panel on Dietetic Products, Nutrition and Allergies), Bresson JL, Burlingame B, Dean T, Fairweather-Tait S, Heinonen M, Hirsch-Ernst KI, Mangelsdorf I, HJ MA, Naska A, Nowicka G, Pentieva K, Sanz Y, Siani A, Sjödin A, Stern M, Tomé D, Van Loveren H et al (2017) Dietary reference values for riboflavin. EFSA Journal 15(8):4919. https://doi.org/10.2903/j.efsa.2017.4919

Urea (2022) https://www.theglobaleconomy.com/world/urea_prices/. Accessed 19 April 2022

Wada Y, Kondo H, Itakura C (1996) Peripheral neuropathy of dietary riboflavin deficiency in racing pigeons. J Vet Sci 58:161–163

Wang Y, Liu L, Jin Z, Zhang D (2021) Microbial cell factories for green production of vitamins. Front Bioeng Biotechnol 9:661562. https://doi.org/10.3389/fbioe.2021.661562

Witten S, Aulrich K (2018) Effect of variety and environment on the amount of thiamine and riboflavin in cereals and grain legumes. Anim Feed Sci Technol 238:39–46. https://doi.org/10.1016/j.anifeedsci.2018.01.022

Witten S, Aulrich K (2019) Exemplary calculations of native thiamine (vitamin B1) and riboflavin (vitamin B2) contents in common cereal-based diets for monogastric animals. Org Agr 9:155–164. https://doi.org/10.1007/s13165-018-0219-9

Wyatt RD, Tung HT, Donaldson WE, Hamilton PB (1973) A new description of riboflavin deficiency syndrome in chickens. Poultry Science 52:237–244

You J, Pan X, Yang C, Du Y, Osire T, Yang T, Zhang X, Xu M, Xu G, Rao Z (2021) Microbial production of riboflavin: Biotechnological advances and perspectives. Metab Eng 68:46–58. https://doi.org/10.1016/j.ymben.2021.08.009

Zhang J-R, Ge Y-Y, Liu P-H, Wu D, Liu H, Li H-B, Corke H, Gan R-Y (2021) Biotechnological strategies of riboflavin biosynthesis in microbes. Engineering 12:115–127. https://doi.org/10.1016/j.eng.2021.03.018

Funding

Open Access funding enabled and organized by Projekt DEAL. The project received funding from the European Union’s Horizon 2020 research and innovation program under Grant Agreement No.773431 (Replacement of Contentious Inputs in Organic Farming Systems; RELACS). Open Access funding enabled and organized by Project DEAL.

Author information

Authors and Affiliations

Contributions

AK and SB designed the work and interpreted the results. SB and MT carried out the trials and the evaluation. AK and SB have created the figures and written the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable

Consent to participate

I consent.

Consent for publication

I consent.

Conflict of interest

The authors declare no competing interests.

Open access

This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution, and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kuenz, A., Tölle, M. & Bromann, S. Investigations on riboflavin production by wild-type yeast strain for supplementation of organic feed. Org. Agr. 13, 399–410 (2023). https://doi.org/10.1007/s13165-023-00435-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13165-023-00435-4