Abstract

On smallholder farms in Ethiopia, livestock manure and organic residues are traditionally removed from fields for construction, feed, and fuel purposes, while the remainder stays in the field as feed or fertilizer. Burning and removing organic matter without replacing it leads to valuable losses of on-farm nutrients and soil carbon, which could otherwise be used to fertilize crops. Instead, resources need to be used efficiently by reducing and recycling organic residues and forming a closed production system. Competition between applications can be eliminated by bio-methanation using a biodigester. There, organic residues are transformed to biogas utilized for light and cooking and bioslurry, a nutritious organic fertilizer and source of organic matter. Through capturing nutrients in agricultural by-products, nutrients become available to the food system again. Literature review has been supplemented with empirical evidence from a study carried out in the central Ethiopian Highlands on 47 smallholder farms, to provide a baseline for further improvements on the management of biogas technology. The study identifies a series of inadequate handling practices and thus a significant potential to optimize the farming system around a biodigester. It is recommended to include forage legumes in the farm system to enhance on-farm available nutrients that can be recycled through a biodigester. It is further necessary to involve the private sector in biodigester programs, to improve local availability of materials, which are suitable to the local culture and traditions. Space for knowledge exchange between farmers and advisors like demonstration farms can further improve bioslurry management. Although challenges remain, the integration of a biodigester should be encouraged as it fulfills the production of energy and a nutritious and economic fertilizer without additional resources, resulting in a win-win situation for the farmer.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With an increasing population and decreasing availability of agricultural land, pressure on resources required for crop production is growing (Rahmann et al. 2019). To cover food demand for the rising population with limited resources, organic matter residue losses should be avoided and biomass and its nutrients recycled (Smith et al. 2014). The current situation on smallholder farms in Ethiopia shows that valuable nutrients and organic matter are often lost from farms, as organic residues are removed for fuel, feed, and construction purposes which could otherwise be used to fertilize crops. As a result, soils are largely degraded and their organic matter content low (Hailu et al. 2015). To sustain soil productivity, accessible fertilizers to farmers are required (Rahmann et al. 2019). Although chemical fertilizers can be applied to replace nutrients removed from harvested crops, it is expensive to administer, requires fossil fuels, reduces the pH value in often already acidic soils, and is harmful to the environment, due to a lack of knowledge and adapted application technologies. As a consequence, the optimization of the endogenous potential of smallholder farms to recycle farm internal nutrients is a priority.

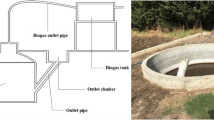

The competition between using organic resources for fuel or fertilizer can efficiently be eliminated by the implementation of a small-scale biodigester, which transforms organic matter to biogas utilized for light and cooking and bioslurry, a nutritious organic fertilizer and source of organic matter. As a biodigester uses on-farm resources to cover household energy and fertilizer demand, a biodigester contributes towards closing the farm nutrient cycle and thereby reducing demand for off-farm inputs (Fig. 1). If quality fertilizer like bioslurry is available, limited access, transportation barriers, and unaffordability to alternative industrial fertilizers would be less of a problem.

The main objective of this paper is to evaluate the performance of biodigesters and its impact on farm nutrient flows by analyzing the management of liquid bioslurry, bioslurry compost, and biogas. For that, we made a brief analysis to narrow down the key challenges and solutions of a biogas system. In this study, data from two different sources are used: literature and output of a survey conducted in the Arsi zone in the central Ethiopian Highlands. During this field study, 47 semi-structured interviews with farmers were carried out in late 2017.

Functioning of a household biodigester

Suitable substrates

During anaerobic digestion, organic matter is decomposed in an oxygen-deprived environment and converted to biogas and bioslurry (Vögeli et al. 2014). Suitable substrates can originate from a variety of organic sources, including animal manure, human feces, and crop residues. Each source yields different levels of biogas and quality of bioslurry, depending on carbon and nutrient contents (Smith et al. 2014). A common substrate used in Ethiopia is cow manure as it is abundantly available. Also, there is high potential to use other types of organic material like vegetable waste and manure from remaining livestock as a substrate. Such co-digestion of food waste with cow dung or substrate with a low carbon content can improve process stability and biogas production (Gashaw and Teshita 2014).

Human feces enter a biodigester through a connected latrine, allowing to produce energy and a fertilizer from an otherwise wasted resource. Compared with modern toilets, bio-latrines do not need water to flush and hence can be installed in water-scarce environments (Amruta and Sarah 2013). There are however risks associated with pathogens present in bioslurry originating from human excreta. While pathogens exponentially die-off with increasing temperatures, it is unlikely that pathogens are persistently removed (Avery et al. 2014; Bonten et al. 2014). In environments where the retention time is hard to control, it is not recommended to apply bioslurry to fresh crops like salads, but preferably to trees.

Products of anaerobic digestion

Biogas for energy

Biogas consists of methane (50–75%), carbon dioxide (25–50%), and, depending on the substrate, traces of water vapor, oxygen, and sulfur (Wellinger et al. 2013). The methane content in biogas is the most important, as at least 45% of methane is needed for biogas to be flammable (Deublein and Steinhauser 2011).

In Ethiopia, biogas is primarily used for light and cooking. Biogas lamps are particularly useful for households that have no or unreliable access to electricity or to alternative sources for light, like solar or kerosene lamps, as these often show greater light efficiency (Kossmann et al. 2011). The use of biogas for cooking can potentially replace the traditional fuel sources wood, manure, and charcoal, thereby supporting the circulation of on-farm nutrients, reduction of indoor smoke, and pressure on local forests. This potential can best be shown with a calculation. With a daily manure production of 10 kg per cow, 400 l of biogas can be produced (IRENA 2016; Kossmann et al. 1999). This is sufficient to use a household burner with an average gas consumption of 325 l/h for approximately 1 h or a biogas lamp with an average gas consumption of 135 l/h for approximately 3 h (Kossmann et al. 1999). With 1-kg firewood corresponding to 200 l of biogas, one cow can therefore replace 2 kg of firewood per day if all manure is collected and used as input for the biodigester (Kossmann et al. 2011). On a larger scale, replacing biomass based fuels with biogas for cooking reduces carbon dioxide emissions (Abadi et al. 2017). This permits countries to install biodigesters to help realize their climate goals.

Bioslurry for fertilizer use

Bioslurry is an organic fertilizer and has high potential to replenish and increase nutrients and organic matter contents in soils. Bioslurry contains a high content of nitrogen, potassium, and phosphorus and a wide range of other micro- and macro nutrients like calcium, magnesium, and iron, all of which are required for crop growth (De Groot and Bogdanski 2013). A typical bioslurry on smallholder farms consists of 93% water and 7% dry matter, of which 4.5% is organic and 2.5% inorganic matter (Warnars and Oppenoorth 2014). As carbon compounds like fats, proteins, and carbohydrates are broken down and released as biogas during anaerobic digestion, bioslurry has a higher ammonium to total nitrogen ratio, reduced carbon contents, a higher pH value, and a lower carbon to nitrogen ratio compared with its substrate (Table 1) (Bonten et al. 2014; De Groot and Bogdanski 2013). Depending on the substrate, between 10 and 70% of organic carbon is converted to biogas, while pH increases between 0.5 to 2 units (Bonten et al. 2014). Bonten et al. (2014) reported that between 10 and 33% of total nitrogen is converted to ammonium, describing the high impact anaerobic digestion has on the availability of nutrients directly available to plants. As stable compounds remaining in bioslurry after digestion continue to mineralize when applied to the field, nutrients are released throughout the growing season (Smith et al. 2014). As a result of these transformations, new forms of nutrients are introduced to the farm (Fulford 2015; Siegmeier et al. 2015).

Due to the conversion of volatile compounds to gas during anaerobic digestion, bioslurry contains stable organic matter, strengthening physical, chemical, and biological soil properties. Fulford (2015) describes that the left over, carbon-rich material is arranged in a lignin matrix. Lignin is a strong molecule that holds structures together in biomass. When bioslurry is added to soil, it forms the consistency of humus, acting as a sponge, “absorbing and retaining moisture and plant nutrients” in accessible distance from crops, thereby preventing nutrient leaching (Fulford 2015, p. 86). Through these characteristics, bioslurry can be applied to improve the soils nutrient and water holding capacity and soil structure (Warnars and Oppenoorth 2014). This is particularly beneficial for largely depleted soils, where bioslurry will support healthy root growth and access to directly available crop nutrients.

Studies have disputed the impact of bioslurry on yields compared with other fertilizers (De Groot and Bogdanski 2013). However, if the organic matter content is integrated into the assessment, both together have a high potential to efficiently support farm resilience against critical impacts of climate change like extreme weather events, fluctuating rainfall and dry periods. Bioslurry can furthermore be used to increase the soil pH, positively affecting nutrient availability and conditions required for crop growth.

To ease transportation of bioslurry and reduce nutrient losses during storage if not applied directly, liquid bioslurry is transformed to bioslurry compost (Bonten et al. 2014; Fulford 2015). To compost, organic dry materials like straw, grasses, or coffee husks are placed in the bioslurry pit in alternating layers with bioslurry (Fulford 2015). These materials are not used for biogas production directly, as they either have a high lignin content or can potentially block the inlet and outlet of the biodigester. Composting bioslurry with material with an absorption capacity reduces nitrogen losses through volatilization. Also, the decomposition of organic dry material can be accelerated due to microbes in the added bioslurry.

Methodology

Study area

The study took place in the Arsi zone, located in the Oromia region, about 160 km southeast from the capital Addis Ababa, Ethiopia. The farms visited are scattered around the administrative center of the Arsi zone, Asella, the central hub for the exchange of goods and services in the area. The Arsi zone is characterized by two wet seasons, a short rainy season between February and May and a longer rainy season between June and October, during which the main growing season occurs. The average annual rainfall is 900–1200 mm and mean annual temperature is 10–25 °C (Oromia Bureau of Finance and Economic Development 2011). The altitude of visited farms was measured using a GPS receiver and was found to be on average 2370 m.a.s.l, with the lowest point of 1863 m.a.s.l and the highest point of 2642 m.a.s.l.

The Arsi zone is dominated by a rainfed smallholder mixed farming system, with livestock and crop production. Most important crops cultivated are wheat (Triticum aestivum), barley (Hordeum vulgare), teff (Eragrostis tef), and faba bean (Vicia faba). Agriculture in the Arsi zone has high agricultural potential due to favorable climate and soil conditions but is limited by water logging, soil erosion, and depleting soils as organic matter is not returned to fields (Begna et al. 2015; Jutzi 1988; Woldeab 1988). Biodigesters have been introduced by GIZ and Welthungerhilfe to strengthen the integration of livestock and cropping systems and to provide an alternative fertilizer to the farm while covering household energy needs. The type of biodigester installed on farms was a fixed dome biodigester with a size of 6 m2 or 9 m2, depending on the number of cows owned. Also, one latrine was connected to the biodigester. Appliances used by farmers were a biogas lamp and a stove.

Sample size

Farm selection was based on farms with an already constructed biodigester and those that are accessible during the rainy season. At the point of study, 100 biodigesters were completed, from which 47 were analyzed. As this study was a follow-up of a pre-study carried out by GIZ, the same farmers were visited. The group of people interviewed was the household head of the farm.

Data collection and analysis

Farms were visited twice, once at the beginning of the rainy season and once towards the end of the rainy season, to enhance understanding of resource management throughout the season. The goal of the first visit was to test and ask preliminary questions, to make first field notes, and to get acquainted with the study area. During the second visit, data was collected using semi-structured interviews and field notes, taken during field observations and transect walks on each farm. The semi-structured interview was organized in different information categories: personal information, crop management, livestock husbandry, market, water access, biodigester management, and knowledge and training. The transect walk was based on a checklist, which covered key areas where resource management took place, like the homegarden, animal sheds, the biodigester, and composting areas. Numerical data was collected using local measuring devices. For example, to measure the daily amount of manure and water fed to the biodigester, the bucket size was documented. Observations were recorded using photographs. As interviews took place in Amharic and Oromo, an interpreter was used for translation into English.

Collected data was transferred to an Excel spreadsheet in the categories that guided the interview. For narrative data, a deductive coding method has been used, according to pre-defined thematic fields and subsequently descriptively analyzed. Numeric data was analyzed using univariate descriptive statistics.

Research approach

So far, efforts to improve agricultural production systems have focused on specific production units but failed to identify the interconnectedness between units (Amejo et al. 2018). Consequently, productivity and resource use efficiency in sub-Saharan countries remains low. To understand the integration of a biodigester in a farm and its complexity, this paper uses a systems approach. A systems approach allows to identify the multiple effects a biodigester has on farm nutrient flow and opportunities for better resource use efficiency.

Figure 2 shows a typical farm system in the Arsi zone with the crop livestock, household, and biodigester subsystem as production units. These units are integrated through the flow of resources, in which output from one unit becomes the input for another unit to facilitate nutrient recycling. The degree of integration is determined by the magnitude of resource flow and its management in the specific unit.

Analyzed farming systems are framed by social, economic, and ecological environments (Fig. 2). The environment includes subsystems a farmer cannot influence but has to be considered in the analysis as they influence the household decision-making. For example, access to spare parts of the biodigester is largely influenced by market availability and infrastructure. Inability to replace broken parts will consequently result in households to revert to using traditional fuel sources. Another example is soil and climate conditions, which determines suitable crops for the region.

Results and discussion

Socioeconomic characteristics of households

The variables that were expected to influence agricultural practices were analyzed and summarized in Table 2. Results indicate that average age of the household head was 48 years and thus part of the active workforce. The majority of them were fully engaged in agriculture with production mainly for subsistence needs, with some excess products sold on the market. Only a few household heads additionally had off-farm jobs. The majority of household heads were male, suggesting their influence on the household decision-making.

Overview of the predominant cropping system

Crop production systems in the Arsi zone were very diverse and showed a wide range of cultivated crops and arrangement of these (Table 3). Cultivation is differentiated by crops grown in the homegarden and on fields. A homegarden, found on 31 farms, is used to grow horticultural crops like maize, onions and grasses. Field crops are primarily grain crops like wheat, teff and barley. Results showed that of the 31 farms, only 16% grew a greater variety of crops in their homegarden (Picture 1), measured by growing more than 11 of the most stated dominant species by farmers. The study revealed a correlation between farm distance to the administrative center Asella and farm crop diversity; the further the farm from Asella, the smaller the crop diversity. This was explained by a lack access to infrastructure like roads, seeds, and extension services.

All farmers practiced some sort of crop rotation on their fields. The main type of crop rotation consisted of the two dominant regional crops, wheat and faba bean. This rotation, however, limits the positive impact a crop rotation is supposed to have on the accumulation of soil biomass and nutrients, as above ground biomass is removed for feed and food purposes. Consequently, a more sophisticated crop rotation aiming for all year soil cover and the use of forage leguminous species with high root biomass is recommended.

Intercropping was only practiced in the homegarden and ranged from integrating two species to a variety of species like vegetables, trees, and shrubs. One farmer intercropped maize with coffee, while another farmer combined maize, oranges, coffee herbs, alfalfa, and tree lucerne. Such a well-developed intercropping system uses resources efficiently including land and water, allowing to increase yields per unit area compared with growing a single crop. Particularly the integration of alfalfa and tree lucerne should be encouraged, as they are valuable feed sources due to their high protein content and good palatability. Improved feed will increase manure production and available nutrients that can potentially be recyclized through the biodigester.

Observations showed that grasses like desho grass were often planted as field boundaries and fed to livestock through the cut and carry system. Incorporating grasses in the cropping system is an efficient measure against soil erosion and can be used as mulch, as due to its rapid growth can be cut multiple times a year.

Farmers were able to quantify application rates of fertilizers only to field crops, as application to the homegarden was uncontrolled and arbitrarily during the growing season. To field crops, 62% of farmers applied inorganic fertilizers, 23% bioslurry and inorganic fertilizer, 10% bioslurry, and 5% apply no fertilizer. As the largest share of bioslurry was applied to the homegarden, farmers mentioned that production was insufficient to also apply to fields. Bioslurry was mainly applied to the homegarden because it was located near the biodigester, from which transportation is less time intensive. In the homegarden, bioslurry was either applied as a liquid to crops directly after it leaves the biodigester or transformed to bioslurry compost.

Despite the positive impact bioslurry has on soil structure and fertility, findings indicate that farmers were reluctant to apply bioslurry. This is because bioslurry was a newly introduced fertilizer in the region and farmers did not want to risk any crop failures. However, some farmers that applied bioslurry observed a positive impact on crops. Two farmers, for example, mentioned a stronger color of wheat leaves and a higher number of tillers compared with the previous year. Another five farmers were part of a field-testing carried out by a local organization, aiming to test the impact of bioslurry on crop growth. Results were promising, but to make reliable conclusions, data needs to be collected for a time period longer than 1 year. For further dissemination to be successful, it is therefore important for farmers to share experiences on the application of bioslurry.

Overview of livestock management

Key findings on livestock management are summarized in Table 4. On average, each farm owned 10.47 cows, which, as the key input for a biodigester, determines potential bioslurry and biogas production. It was found that despite manure being a good substrate, not all manure is used for the biodigester due to a tradeoff for fuel purposes. The drier manure found on the farm compound is used as cooking fuel to bake injera and bread. While similar quality manure is found on the communal grassland, manure is left there for convenience reasons. Manure found in the stable is used as a substrate for the biodigester, as it is the freshest and can easily be transformed to a homogeneous liquid. All farms mentioned that children and primarily women were responsible for manure collection and mixing it with water (Picture 2).

Nutrient contents of manure and hence nutrients that can be recycled through a biodigester are determined by feed intake. During the wet season, cows grazed on communal grassland or on grassland around the farm compound, a feed material with relatively low nutrient and protein content. Additional feed like straw and fresh maize stalks and on-farm grasses like desho grass (Pennisetum pedicellatum) was fed through the cut and carry system (Picture 3).

During the dry season, livestock were taken out to fields for the first 2 months to graze on the remaining plant residues. As grass was rare for the remaining 4 to 5 months, straw, grains, mill residues, and oil seeds cake were additionally fed. These enrich the nutrient content of manure, while the share of raw fiber is limited in such rations. In both the dry and wet season, livestock returned to the stable during the night. It is evident that given these feed rations and the dominant crop systems in the region, there is high potential to introduce quality feed sources like forage to increase animal productivity and on-farm nutrients.

Overview of the biodigester system

Substrates

An overview of substrates, the utilization of biogas, and management of bioslurry are presented in Table 5. A biodigester in the study region was fed with manure and human excreta. On average, 31 kg of manure mixed with water at a ratio of 50:50 was added daily (Picture 4). Most frequently, 20 kg of manure was added by 29.8% of farms and 40 kg also by 29.8%.

The latrine, through which human excrete enters the biodigester, was used by 76% of farms. 19% of households reported to not use the latrine due to an absent shed because of insufficient time to build it, but are planning to do so in the future (Picture 5). Another 4% revealed to own a modern toilet with access to the communal system on the farm and thus do not require the latrine.

Biogas utilization

Traditionally, households rely on charcoal, wood, and cow manure for cooking fuel. Cow manure is predominantly used, as it is available all year and is the most affordable. The alternative biogas stove that has been introduced on farms aims to reduce the use of these traditional fuel sources. The study revealed that the biogas stove overall received a positive feedback due to a shorter cooking time and reduced indoor smoke. Especially women, who do most of the cooking, appreciated the biogas stove, as reduced indoor smoking has a positive impact on health. Despite these benefits and 98% of farmers that use the biogas stove, findings revealed that food habits and cooking traditions leave farmers to further rely on traditional fuel sources. A primary shortcoming was that the installed biogas stove does not support making coffee and cooking the locally favored injera, a staple food based on teff grain (Eragrostis tef). To bake injera, a biogas base mitad is required, which is a plate-like structure able to uniformly distribute heat. There have been efforts to develop a mitad in both the private and public sector; however, manufacturing and distribution at country level is not yet available.

Estimating the biogas production per day through calculations suggests that, theoretically, there is sufficient biogas to cover biogas demand. With an average of approximately 10 cows per farm, a daily biogas production of 400 l per cow, and an average biogas consumption of 325 l/ h of the stove, a household can cook for 12 h per day (IRENA 2016; Kossmann et al. 1999). Even if only half the manure is fed into the biodigester, as largely manure from the stable is suitable, the biogas stove can be used for 6 h. Based on this calculation, biogas produced from two cows will most likely be insufficient to cover household energy demand.

The biogas lamp was used by 53% of farmers and received mixed responses. Forty-six percent revealed to not use the lamp due to access to electricity and only divert to use the biogas lamp in case of a power outage or an absent electrical light in a room. Another 11% of farmers preferred to use solar light, because its light is brighter than the biogas lamp. Further reasons are related to technical problems; 20% of farmers complained about a broken glass shade (Picture 6), while another 26% observed explosions as a result of too much pressure. In the case that the glass shade broke, farmers complained about the long replacing time, as materials are not locally available.

Bioslurry management

Field observations show that handling of bioslurry varied greatly between farms and is often inadequate (Pictures 7 and 8). Key problems with bioslurry management were the absence of a shed, impurities like plastic in the bioslurry pit, overflow of the bioslurry pit, and inadequate cover and storage of bioslurry compost. An absent shed and inadequate cover rises exposure of bioslurry to the sun, increasing nutrient losses through volatilization. Dried bioslurry as a result of overflow suggests poor management, in which the bioslurry is not transformed to bioslurry compost and thus not applied as a fertilizer. Not using the bioslurry means heavy on-farm nutrient losses as these cannot be further recycled.

Conclusion and recommendations

Arguments in favor of a biodigester are the various positive impacts it has for the farm through provision of energy, organic matter, and nutrient recycling to cover household energy demand to improve soil structure and crop growth. Although compared with other fertilizers the impact of bioslurry on yields is disputed, introducing bioslurry on farms in areas with limited access to synthetic fertilizers, bioslurry will improve the nutritional status of crops (De Groot and Bogdanski 2013; Rahmann et al. 2019; Smith et al. 2014). This study shows that the purpose of a biodigester is partly fulfilled and that there is high potential to optimize the approach as well as the whole farming system with support of biodigesters (Table 6).

One factor preventing nutrient cycling is insufficient production and inadequate management of bioslurry. Production is limited by biodigester size, labor, and manure collection, as suitable manure for the biodigester is predominantly from the stable. To increase bioslurry production, it is recommended to use other sources of organic material like vegetable residues and manure from remaining livestock like goats and sheep as a substrate. Inadequate management was observed by an absent shed to cover the bioslurry pit, cover of bioslurry compost, and overflow of the bioslurry pit suggesting that bioslurry is not applied as a fertilizer. These shortcomings increase the risk of nutrient losses from the farm system through volatilization. Interactive learning and experience exchange through a demonstration farm can train farmers to correctly manage bioslurry. As farmers are not docile acceptors of technologies, a higher participation can increase acceptance among farmers (Lightfoot et al. 1993).

Barriers to utilization of biogas for cooking or light are the absence of a mitad and broken glass shades farmers are often confronted with. From a systems perspective, an absent mitad will prevent a closed nutrient cycling as farmers further rely on traditional fuel sources like wood and manure. This demonstrates that the translation of cultural habits in technology is key to achieve its purpose. To overcome these problems, the private sector is encouraged to develop biogas appliances with materials available on the local market, also allowing technology to adapt to cultural customs. To facilitate private sector development, programs need to become decentralized with less public intervention (Kamp and Forn 2016). How far biogas for injera production has a future is however questioned, as farmers discussed a different taste compared with traditional fuel sources. Combined energy systems of biogas with alley cropping as a wood source are to be examined.

Low-quality feed, specifically the lack of protein, minimizes potential nutrients that can be recycled through a biodigester. Feed quality can be raised by adding forage legumes, shrubs, and hybrid grasses into the farm system. Adding forage legumes will initiate a positive feedback nutrient cycle in the whole farming system (Fig. 3), far beyond increasing nutrients. For the production of these crops, no additional land is required, as they can be incorporated into unused land like field margins and boundaries, into the homegarden, or into existing cropping systems through intercropping. These solutions maximize the flow of resources between production units and imitate the circular food chain model from the LandLessFood concept.

Small-scale biodigesters exist in different sizes and types, allowing customized installations and easy integration into farms. Programs like the National Biogas Program implemented in many East African countries often install a standard biodigester. To increase functionality and to avoid socioeconomic obstacles described by Abadi et al. (2017) and in this paper, further dissemination requires biogas programs to deviate from a standardized approach. Customizing materials, type and size of a biodigester to farm conditions will also remediate the often-presented financial obstacle to biodigester implementation. Also, alternative systems to installation may be considered. An example is the system developed by the social business (B) energy, offering an entrepreneurial approach to biodigester ownership (Pütz 2020).

Relevance of a small-scale biodigester for the LandLessFood concept

A biodigester offers a close link between crop production and the farm residue system through opening new pathways for nutrient circulation, fertilizer production, and organic food production. With the peak phosphate rate to be reached in the near future, land availability declining, and soils degrading, higher resource use efficiency through recycling of on-farm nutrients is crucial (Rahmann et al. 2019; Siegmeier et al. 2015). A challenge to implementing a small-scale biodigester in other parts of sub-Saharan Africa could possibly be limited availability and access to water, as an equal amount of water and substrate is required. Next to investing in water harvesting and storing methods, a potential water source is wastewater from production and processing facilities of the circular food chain model presented in the LandLessFood concept.

In the landless system model, a biodigester acts as a redistribution unit of resources through using residues of bioreactors, animals, and mushroom production and transforming it to household energy and a fertilizer. Through this transformation, nutrients become available to the food system again. With the ability of bioslurry to increase the buffer capacity of a farm through compensating decomposed organic matter and affiliated nutrients by crops, an agricultural system can be integrated into more harsh environments like areas with high temperatures and little rainfall which are so far excluded from the production system. If sufficient and nutritious rich bioslurry can be produced, agricultural systems can be reshaped to a resilient and stable system while providing new economic opportunities to the farmer.

Change history

13 November 2020

A Correction to this paper has been published: https://doi.org/10.1007/s13165-020-00332-0

References

Abadi N, Gebrehiwot K, Techane A, Nerea H (2017) Links between biogas technology adoption and health status of households in rural Tigray, orthern Ethiopia. Energy Policy 101:284–292. https://doi.org/10.1016/j.enpol.2016.11.015

Amejo AG, Gebere YM, Kassa H (2018) Integrating crop and livestock in smallholder production systems for food security and poverty reduction in sub-Saharan Africa. Afr J Agric Res 13(25):1272–1282. https://doi.org/10.5897/AJAR2018.13020

Amruta K, Sarah M (2013) Bio-latrines Retrieved from https://www.pseau.org/outils/ouvrages/practical_action_bio_latrines_2013.pdf

Avery L, Yongabi K, Tumwesige V, Strachan N, Goude JP (2014) Potential for pathogen reduction in anaerobic digestion and biogas generation in Sub-Saharan Africa 70. doi:https://doi.org/10.1016/j.biombioe.2014.01.053

Begna B, Yami M, Lemma E, Solomom T, Etana T (2015) Characterization of crop production and marketing to improve food security in Arsi zone, Ethiopia. Journal of Agricultural Extension and Rural Development 7(4):87–97. https://doi.org/10.5897/JAERD2014.0586

Bonten LTC, Zwart KB, Rietra RPJJ, Postma R, De Haas M, Nysingh S (2014) Bio-slurry as fertilizer: is bio-slurry from household digesters a better fertilizer than manure? A literature review. Alterra Wageningen University and Research Center

De Groot L, Bogdanski A (2013) Bioslurry= brown gold? FAO environment and natural resources management working paper 55

Deublein D, Steinhauser A (2011) Biogas from waste and renewable resources: an introduction. Wiley-VCH, Weinheim

Fulford D (2015) Small-scale, rural biogas programmes: a handbook. Bourton on Dunsmore, Rugby, Warwickshire, UK: Practical Action Publishing

Gashaw A, Teshita A (2014) Co-digestion of Ethiopian food waste with cow dung for biogas production. Int J Res, 1(7)

Hailu H, Mamo T, Keskinen R, Karltun E, Gebrekidan H, Bekele T (2015) Soil fertility status and wheat nutrient content in vertisol cropping systems of central highlands of Ethiopia. Agriculture & Food Security 4(1):1–10. https://doi.org/10.1186/s40066-015-0038-0

IRENA (2016) Measuring small-scale biogas capacity and production Retrieved from Abu Dhabi: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2016/IRENA_Statistics_Measuring_small-scale_biogas_2016.pdf

Jones J, Thornton O, Hansen J (1997) Opportunities for systems approaches at the farm scale. In P. Teng, M. Kropff, H. Berge, J. Dent, F. Lansigan, & H. Laar (Eds.), Applications of systems approaches at the farm and regional levels proceedings of the second international symposium on systems approaches for agricultural development, helt at IRRI, Los Baños, Philippines, 6-8 December 1995. Volume 1

Jutzi S (1988) Deep black clay soils (Vertisols): management options for the Ethiopian highlands. Mt Res Dev 8(2/3):153–156. https://doi.org/10.2307/3673442

Kamp LM, Forn EB (2016) Ethiopia′ s emerging domestic biogas sector: current status, bottlenecks and drivers. Renew Sust Energ Rev 60:475–488. https://doi.org/10.1016/j.rser.2016.01.068

Kossmann W, Pönitz U, Habermehl S, Hoerz T, Krämer P, Klingler B, . . . Euler H (1999) Biogas digest, Volume II–Biogas–Application and product development

Kossmann W, Pönitz U, Habermehl S, Hoerz T, Krämer P, Klingler B, . . . Euler H (2011) Biogas digest: volume I-biogas basics

Lightfoot C, Bimbao MAP, Dalsgaard JPT, Pullin RS (1993) Aquaculture and sustainability through integrated resources management. Outlook on Agriculture 22(3):143–150

Oromia Bureau of Finance and Economic Development (2011) Physical and socio economic profile of arsi zone and districts Retrieved from http://www.oromiabofed.gov.et/index.php?option=com_content&view=category&layout=blog&id=45&Itemid=62

Pütz K (2020) A social business- making biogas accessible Retrieved from http://www.be-nrg.com/bhome/

Rahmann G, Grimm D, Kuenz A, Hessel E (2019) Combining land-based organic and landless food production: a concept for a circular and sustainable food chain for Africa in 2100. Organic Agriculture, 1-13. doi:https://doi.org/10.1007/s13165-019-00247-5

Siegmeier T, Blumenstein B, Möller D (2015) Farm biogas production in organic agriculture: system implications. Agric Syst 139:196–209. https://doi.org/10.1016/j.agsy.2015.07.006

Smith J, Abegaz A, Matthews RB, Subedi M, Orskov ER, Tumwesige V, Smith P (2014) What is the potential for biogas digesters to improve soil fertility and crop production in sub-Saharan Africa? Biomass and Bioenergy 70:58–72. https://doi.org/10.1016/j.biombioe.2014.02.030

Vögeli Y, Lohri RC, Gallardo A, Diener S, Zurbrügg C (2014) Anaerobic digestion of biowaste in developing countries: Practical information and case studies retrieved from Dübendorf, Switzerland https://www.eawag.ch/fileadmin/Domain1/Abteilungen/sandec/publikationen/SWM/Anaerobic_Digestion/biowaste.pdf

Warnars L, Oppenoorth H (2014) Bioslurry: a supreme fertiliser A study on bioslurry results and uses. Paper presented at the practitioners’ track, IFOAM organic world congress 2014, ‘building organic bridges’, 13-15 Oct., Istanbul, Turkey

Wellinger A, Murphy JD, Baxter D (2013) The biogas handbook: science, production and applications. Woodhead Publishing, Woodhead

Woldeab A (1988) Physical properties of Ethiopian vertisols. Paper presented at the Management of Vertisols in sub-Saharan Africa conference, ILCA, Addis Ababa, Ethiopia

Funding

Open access funding provided by University of Natural Resources and Life Sciences Vienna (BOKU).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Schoeber, M., Rahmann, G. & Freyer, B. Small-scale biogas facilities to enhance nutrient flows in rural Africa—relevance, acceptance, and implementation challenges in Ethiopia. Org. Agr. 11, 231–244 (2021). https://doi.org/10.1007/s13165-020-00329-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13165-020-00329-9