Abstract

Heat-induced physical changes of rocks, as would happen in fire accidents, have crucial importance in the long-term stability of underground openings such as tunnels or radioactive waste disposal chambers. The thermal behaviour of monzogranite from the Radioactive waste repository of Bátaapáti (Hungary) was studied in that context. Room temperature (22 °C) and a series of high temperature (250 °C, 375 °C, 500 °C, 625 °C, 750 °C) heat-treated samples were tested. P and S- ultrasound pulse velocity, bulk density, Duroskop rebound, uniaxial compressive strength, and modulus of elasticity were measured and compared, detecting temperature-related changes. Descriptive statistics and non-parametric Kruskal–Wallis and Median tests were carried out to analyze the heat-induced rock mechanical and mineralogical alteration processes. Based on these results using the data set of physical parameters, it is possible to predict the heating temperature of granitic rocks when the firing or heat stress conditions are unknown. Additionally, the data could be utilized for design and monitoring systems in underground repositories or tunnel systems constructed in granitic rock settings globally. The study demonstrated that significant alteration occurs above 500 °C; all studied rock-mechanical parameters decreased rapidly. These changes are linked to the thermal expansion, micro-cracking in micro-fabric, and volumetric increase and fragmentation of quartz inversion. Consequently, the propagation velocities of P- and S-waves also decreased significantly. Bulk density and Duroskop surface strength significantly decreased above 375 °C, while uniaxial compressive strength and modulus of elasticity dropped drastically at 750 °C after a linear decrease.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Radioactive repositories are crucial in the safety and long-term management of radioactive waste generated from various industrial, energetical, and research activities. The management of radioactive waste has been a subject of intense scientific and regulatory investigation for several decades (Neumann 1988). Radioactive materials can remain hazardous for thousands of years. They require careful planning and engineering to ensure that they are isolated from the biosphere and hydrosphere, as radioactive exposure could lead to severe health issues to humans. One of the severe health issues is caused by the fact that the flux of radioactive decay products can be released from the soil to air over long periods of time without proper isolation (Mudelsee et al. 2020).

Deep geological repositories involve waste placement in deep underground formations, typically in stable rock formations. This method to isolate and contain the radioactive waste takes advantage of the natural barriers provided by the geology of the site. Granitic rocks have emerged as a viable option for the long-term disposal of certain types of radioactive waste because they possess favourable geological characteristics that make them suitable for hosting radioactive repositories (Chapman and Hooper 2012; Gautam et al. 2019). One of the main advantages is their inherent stability and low permeability, which can help to limit the migration of radioactive materials. Several countries worldwide have implemented or are considering implementing radioactive repositories in granitic environments, such as India (Gautam et al. 2019), Japan (Kondo et al. 1981), Sweden, Finland (Pettersson and Loennerberg 2008), and Hungary (Deák et al. 2014, 2020, 2023; Somodi et al. 2018).

The long-term repository performance requires the intense study of rock physical properties of enclosing rock masses. It is essential to assess the geomechanical stability, the design and construction of the repository, to evaluate barrier performance, and to accurately characterize the geological formation. One of the most critical aspects of studying physical parameters is the loss of strength due to increased temperature in the geological environment (Gautam et al. 2019; Shang et al. 2019). Investigating heat-treatment-induced rock physical parameters in the context of radioactive repositories is crucial for assessing thermal behaviour, evaluating mechanical stability, analyzing mineralogical alterations, and conducting comprehensive long-term performance assessments of the geological environment (Vázquez et al. 2015; Chen et al. 2017). Increased temperatures in their geological settings, such as sudden fire events (Chakrabarti et al. 1996) or decay of high-level radioactive waste (Heierli and Genoni 2017), can elevate the temperature in the repository (from 100 to 700 °C). The surrounding rock formation acts as a natural thermal buffer and helps dissipate the heat generated in these scenarios; however, previous research demonstrated that temperature increases cause deterioration and loss of strength in the rock environment (Chakrabarti et al. 1996; Ozguven and Ozcelik 2013). The physical alteration of host rocks in these environments and the mineralogical processes accompanying these alterations under elevated temperatures are critical topics and must be studied.

Rock mechanical investigation of granitic rocks after heat treatment is well-studied. Non-destructive tests, such as ultrasound velocity (Fan et al. 2017; Shang et al. 2019), and destructive test methods as uniaxial compressive strength tests (Přikryl 2001; Shang et al. 2019; Zhu et al. 2021) have been previously investigated to a great extent. It has already been discovered that during heat-treatment, mineralogical transformations (Glover et al. 1995), micro-crack propagation (Freire-Lista et al. 2015, 2016), or crystal structure heterogeneity-related cracking processes (Guangsheng et al. 2022) cause mechanical deterioration in granitic rocks. Rock mechanical parameters of the Mórágy granite formation have been studied, testing and analyzing room temperature samples (Davarpanah et al. 2019, 2020; Deák et al. 2023). Moreover, rock physical changes induced by heat treatment have been studied to some extent (Török and Török 2015). Previous research on the present monzogranite found in this study has already been carried out, focusing on non-destructive rock mechanical (Németh and Török 2021a; Németh and Török 2021b, and optical and colour-image analysis studies (Németh et al. 2021).

This study aims to understand the physical changes of the rock that could occur in the granitic geological environment in response to elevated temperatures. In addition to understanding the direction and magnitude of the heat-induced rock physical changes and accompanying mineralogical processes, the main objective is to put them into a temperature framework, namely, to predict undetected temperatures measuring the physical properties of granitic rocks. It could also provide information for the design of disposal chambers and help develop a repository temperature monitoring system. The results could also be implemented in the case of other underground repositories or tunnel systems built in granitic rock environments worldwide.

2 Materials and methods

2.1 Materials

Low-and intermediate-level radioactive waste is disposed of in the National Radioactive Waste Storage Facility in Bátaapáti, South Hungary, in mountain Mecsek. The subsurface galleries are located at depths of 200–250 m. A 1.7 km-long tunnel leads to disposal chambers, where the radioactive waste is deposited. The host rock of the repository is the Mórágy Granite Formation, a Carboniferous intrusive crystalline body. The formation is slightly metamorphosed and comprises monzogranite, monzonite, and hybrid rock types. The current paper deals with the main lithotype, the monzogranite, which has been described as a prevailing lithology of the area (Balla and Gyalog 2009).

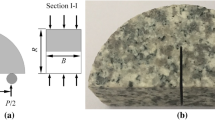

The rock type under examination is generally light grey to grey in colour but can also appear reddish brown to brownish grey when oxidized. It has a fine, medium, or coarse-grained texture with a slight directional pattern. This study focuses specifically on the porphyritic type of monzogranite, which is one of two subtypes. Porphyritic formations typically contain more quartz and less plagioclase than the other sub-group, and it is the prevailing lithology at the site. The presence of biotite, amphibole, quartz, and feldspars characterizes both sub-groups (Balla and Gyalog 2009). The most noticeable feature of these rock types is the pink-red, idiomorphic, or rounded hypidiomorphic microcline megacrysts, distinguishing the two sub-groups based on the amount of porphyries present. The feldspars in these rocks are often clay mineralized by surface weathering, and in weathering zones, chlorite, carbonate, clay mineralization, and limonitization are common (Peregi et al. 2009; Balla and Gyalog 2009; Istovics and Tóth 2016).

2.2 Sampling

The methodology of this study, from sample preparation to examination and interpretation, was carried out according to the workflow chart shown below (Fig. 1).

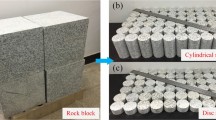

For the tests, cylindrical test specimens with a diameter of 4.7 cm and a height-diameter ratio of 2:1 were prepared with a rock-cutting saw with a diamond disc from a section of the pre-drilling materials from 95.72 to 110.65 m from pre-drilling of ID Bek-7 (Fig. 2). A total of 36 samples were taken, representing six different tests (heat treatment) groups of 6 samples per group.

The homogeneous and representative distribution of the samples in each group was inspected visually and by examining bulk density values of the samples before heat treatment. The standard deviation of bulk density values before heat treatment between the means of each sample group was only 2.6 kg/m3. This slight deviation can be neglected, therefore, the groups were classified as physically homogeneous and representatively distributed.

2.3 Laboratory testing

After sample preparation, the specimens were dried, measured, and subjected to non-destructive rock mechanical testing at room temperature. After preliminary testing, the monzogranite samples were heated (20 °C/min) and then thermally treated for 4 h in a Carbolite ABA 7/35 electric oven. Six different temperature (heat treatment) groups, each with 6 samples were tested. The temperatures are as follows: 22 °C (reference samples), 250 °C, 375 °C, 500 °C, 625 °C, and 750 °C, respectively. The samples were cooled uniformly at a slow rate (5 °C/min) to avoid cracking from rapid cooling. After slow cooling to room temperature, the samples were subjected to non-destructive and destructive tests.

Rock physical laboratory tests were carried out before and after the heat treatment of the samples. The non-destructive tests were bulk density measurement (according to EN 1936:2007), P- and S- wave velocity measurements (according to EN 14579:2005), and the Duroskop surface strength test (Török 2018). The destructive tests were uniaxial compressive strength Tests (according to EN 1926:2007) with an examination of elastic modulus (according to EN 14580:2005) (Fig. 3).

The results of these easily obtainable and fundamental rock physics tests serve as the primary input data for the geological engineering design of depositories and other structures, in rock physical modelling. These include tunnel design and monitoring, furthermore, it also provides information on the subject of international rock physical research (Török and Török 2015; Yang et al. 2017; Wang et al. 2020). For this reason, they have been selected in order to examine the material changes in these rocks caused by heat treatment.

Non-destructive tests such as P- and S-wave velocity and Duroskop rebound were carried out on each sample 6–12 times at each temperature, therefore, 36–72 times per heat-treated group for proper statistical interpretation. Bulk density and destructive test methods, such as the uniaxial compressive strength test with the elastic modulus test, were carried out once per sample because of the nature of the tests (Table 1).

2.4 Statistical data processing and evaluation

Statistical analysis of the rock physical tests and the evaluation of the results based on descriptive statistics and hypothesis testing were carried out to help interpret the results. Geomathematical tools have been used in many different fields of earth sciences, including managing large data sets in environmental science (Webster and Oliver 2007), climatic research (Costa and Soares 2009; Hatvani et al. 2020, 2021), ground and surface water analysis (Kovács et al. 2012b), geophysics (Bosch et al. 2010; Felgueiras 2012) and rock-physics (Rozgonyi-Boissinot et al. 2021), but it has been less commonly applied to characterize heat-related physical changes in rocks. The application of these methods is expected to assist in understanding the physical deterioration of the granitic rock environment and the radioactive waste repository with increasing temperature and explain the accompanying processes.

The data set of test results were processed, allowing comparisons between the different heat treatment groups. Although the number of cases is not equal between various tests, the same number of cases is found within the temperature groups of each test; therefore, a reliable comparison can be made.

After a review of the descriptive statistics (minimum, maximum, median, mean, standard deviation) for each sample sets that were treated at given temperatures, a Shapiro–Wilk normality test (Shapiro and Wilk 1965) was performed to see that each group of each test follows a normal distribution. If so (at α = 0.05), nonparametric statistical test methods are advised for further analyses.

To determine whether the data obtained from the heat treatment groups in each test method were statistically and significantly different from each other, non-parametric hypothesis tests were applied. First, the Kruskal–Wallis test, the examination of significant differences between the distributions of the different groups, and second, the median test, which is the examination of significant differences between the medians of the different groups, were applied. In both tests, the confidence interval was 95%, and the significance level of the hypothesis tests was chosen at α = 0.05. Suppose the p-value for comparing the groups is below the alpha level, i.e., p < 0.05. In that case, the relationship between the examined group is significantly different (i.e., a significant difference of pairs in distribution or median value). Similarly, if the significance level is greater than the alpha value, i.e., p > 0.05, then the relationship is, indeed, not significantly different (i.e., not significantly different group pairs in means of distribution or median value). In the following sections, as in the Results and Discussions parts, we will report the p levels between the examined heat treatment groups under study. This method allows the easy identification of significant relationships between pairs and also clarifies the strength of the relationships.

It is worth noting that the adjusted p-values in the tables have been corrected for multiple comparisons using a method called Bonferroni correction. This is important to reduce the likelihood of false positive results when multiple comparisons are made. The statistical hypothesis tests were then evaluated and interpreted. The evaluation examined whether the different heat treatment groups of each test were significantly different in terms of their distribution and/or median values. All the statistical analyses were made with IBM SPSS Statistics 27.

These statistical tests aim to see if the monzogranitic rock environment of the radioactive repository undergoes significant rock physics changes at the different temperature conditions we have defined. As the distribution and median values differ significantly between thermal treatment groups of the examined tests, an increase in temperature does indeed cause a change in the physical state of the host rock, making it essential to investigate further. A pairwise comparison of each group was carried out. Therefore, hypothesis testing can also determine which heat treatment groups do not differ significantly, i.e., no change occurs. Ultimately, it can be used to assess temperature boundaries where significant physical change occurs in each test.

3 Results

Descriptive statistics and normality tests were carried out for various properties of the Mórágy Granite Formation monzogranite samples subjected to different thermal treatments to investigate heat-related rock mechanical changes and mineralogical alteration processes. The properties examined include P-wave and S-wave velocities (in km/s), bulk density (in kg/m3), Duroskop value, uniaxial compressive strength (in MPa), and elastic modulus (in GPa).

3.1 Descriptive statistics of heat treated properties

Descriptive statistical results showed that increasing heat treatment temperature significantly decreased both P-wave and S-wave velocities (Table 2). P-wave velocity results at room temperature (22 °C) ranged from 4.65 to 6.10 km/s and decreased to 0.34 to 0.91 km/s at 750 °C. Similarly, the S-wave velocity decreased from a range of 2.86 to 3.53 km/s at 22 °C to a range of 0.22 to 0.47 km/s at 750 °C. The median and mean values of P-wave and S-wave velocities decreased as the temperature increased, indicating a consistent trend. However, if we examine the rate of decrease of the median and mean values between groups, we find that the rate of decrease of both P and S wave propagation velocities increases between 500 and 625 °C compared to the decreases between the previous and groups after. While between 22 and 500 °C the median value of the P-wave propagation velocity decreases by an average of 0.63 km/s and the mean by 0.65 km/s, between 500 and 625 °C the median is 1.93 and the mean is 1.95. Between 625 and 750 °C, the median decreases are 0.90 km/s, and the mean is 0.89 km/s.

The rate of decrease in S-wave propagation velocity between groups is similar. Between 22 and 500 °C, the decrease of the median is 0.31, and the mean is 0.30 km/s; then, between 500 and 625 °C, a decrease of 1.25 km/s median and 1.24 km/s mean value occurs. Between 625 and 750 °C, the median and mean values of S-wave propagation velocity decrease by 0.62 km/s. Regarding standard deviation, P- and S-wave velocity results decrease with increasing temperature, indicating that the effects become more homogeneous.

The bulk density of the monzogranite decreased significantly with increasing temperature. At 22 °C, the bulk density ranged from 2699.4 to 2763.2 kg/m3, decreasing to 2332.1 to 2583.5 kg/m3 at 750 °C. It can be stated that minimum and maximum values do not show a clear trend with temperature.

Mean and median values of bulk density also decreased with increasing temperature in absolute terms, with a decrease of 223 kg/m3 between the 22 and 750 °C group means. Median and mean values slightly increase from 250 to 375 °C as minimum and maximum values, then decrease at higher temperatures. Changes in bulk density values depend on changes in mass and volume. It can be stated that a steady and significant decrease in mass and a significant increase in volume from room temperature up to 750 °C occurs, with a slight decrease in volume from 250 to 375 °C temperatures (375 °C). Comparing the descriptive statistical, minimum, maximum, median, and mean values of the bulk density values, the change between 250 and 375 °C shows an increase (Table 3). Standard deviation values not decreasing uniformly as it decreases until 375 °C, then increases at 500 °C. At 625 °C, the most homogenous bulk density group of 4.5 kg/m3 appears, then at 750 °C, results increase to 106.1 kg/m3.

Duroskop results show a similar trend as bulk density values. Results tend to decrease (from 47 to 54) from 22 to 750 °C; however, they do not show a uniform trend with temperature increase. The minimum, maximum, median, mean, and standard deviation values slightly increase at 375 °C then decrease at higher temperatures. Standard deviation values are the highest at 5.74 at 750 °C.

The uniaxial compressive strength and elastic modulus of the monzogranite decrease significantly with increasing temperature. At 22 °C, the uniaxial compressive strength ranged from 91.7 to 134.8 MPa, while at 750 °C, it decreases to 9.7 to 61.5 MPa. The elastic modulus showed a similar trend, decreasing from 19.9 to 35.0 GPa at 22 °C to a range of 0.5 to 7.7 GPa at 750 °C. The mean and median values of uniaxial compressive strength and elastic modulus also decreased with increasing temperature, indicating a uniformly decreasing relationship between heat treatment and the examined mechanical properties of the monzogranite.

A Shapiro–Wilk test is a test of normality used to determine whether a given sample of data came from a normally distributed population. Out of all the heat-treatment group data of each test suggests that only the Uniaxial Compressive Strength and Elastic Modulus test group results are normally distributed (p < 0.05) (Table 2), while some of the thermal treatment groups, such as 250 °C of S-wave velocity, 22 and 375 °C of bulk density, and Duroskop values except 625 °C are not normally distributed.

3.2 Heat treatment induced distributional changes

The Kruskal–Wallis Test results are shown in Table 4, with the "Adj. Sig." column indicating the adjusted p-value for each pairwise comparison. The results of the Kruskal–Wallis test indicated significant differences between the six heat treatment groups concerning all six rock mechanical properties evaluated. For P-wave velocity and S-wave velocity distribution results, all the pairwise comparisons were significantly different at a significance level of 0.05. This suggests that heat treatment significantly affected the ultrasound propagation properties between all the thermal treatment groups.

Pairwise comparison of bulk density shows that between 22–375 °C and 250–500 °C heat treatment group pairs were found to be not significantly different at a significance level of 0.05. This indicates that bulk density values significantly change by heat treatment from 22 to 250 °C, from 250 to 375 °C and again from 375 to 500 °C; however, a slight increase and decrease in bulk density values occur between those temperatures. The decrease in density at 250 °C and the subsequent increase is to such an extent that the density distributions between 22 and 375 °C and between 250 and 500 °C are not significantly different (p = 1.00). Significant bulk density distribution change occurs after 500 °C due to heat treatment in the monzogranite samples.

Kruskal–Wallis pairwise comparisons of Duroskop surface strength values show that distributions between the 22–250 °C (p = 0.07), 22–375 °C (p = 1.00), 250–500 °C (p = 1.00) groups are not different significantly. The distribution of each of the other pairs can be considered significantly different (p = 0.00). A slight increase of Duroskop values at 375 °C causes the distributions not to be significantly different between some pairs of 22 °C, 250 °C, 375 °C and 500 °C (p > 0.05); however, a statistically significant difference between groups of 375 °C and 500 °C (p = 0.00) is shown. The significant Duroskop surface strength results occur above 500 °C (p = 0.00).

The pairwise comparisons for uniaxial compressive strength between the 22–250 °C (p = 1.00), 375–500 °C (p = 1.00), 375–625 °C (p = 0.41) and 500–625 °C (p = 1.00) heat treatment group pairs were found to be not significantly different. This indicates that the distributions between these four heat treatment group pairs are not that different and cannot be significantly distinguished using the Kruskal–Wallis Test criteria.

For elastic modulus, the pairwise comparisons between the 22 and 250 °C (p = 1.00), 250–375 °C (p = 0.52), and 375–500 °C (p = 0.14) heat treatment group pairs are not significantly different from each other. As can be inferred from the uniaxial compressive test results, the distribution of these groups overlaps and cannot be considered significantly different. However, groups above 500 °C also significantly differ from each other in their distributions with significance levels of p = 0.00 with the exclusion of 625–750 °C (p = 0.01).

3.3 Heat treatment induced changes of medians

The results of the independent-sample median test revealed statistically significant differences between the median values of the examined properties of the monzogranitic material at various temperature levels (Table 5). The analysis likely involved comparing the median values of each property at different temperature levels.

Comparing the median values between 22 and 750 °C for all properties showed statistically significant differences (p = 0.00). The same was observed for all other temperature comparisons, including 625–750 °C, 500–750 °C, 375–750 °C, and 250–750 °C (p = 0.00). The significant differences observed between these temperature levels suggest that the examined rock physical properties of the material are temperature dependent between those temperature scales.

In the comparison between 22 and 250 °C, Duroskop rebound values, Uniaxial Compressive Strength-, and elastic modulus values showed significantly not different median values (p = 1.00). These mechanical parameters, therefore, differ significantly in their median values only above 250 °C according to the median test criteria.

Median values of 22–375 °C of Bulk density and Duroskop, 250–500 °C pairs of bulk density, and 375 °C and 500 °C pairs of uniaxial compressive strength showed significantly not different median results (p = 1.00). It can be stated that between those temperature ranges, median results are not significantly different induced by heat treatment.

The median Test suggests that the change in physical parameters induced by heat treatment is prominent in Ultrasound propagation velocity between all temperature pairs; After 250 °C of Elastic modulus, After 375 °C of Duroskop surface strength, and after 500 °C of Bulk density and Uniaxial Compressive Strength.

4 Discussion

4.1 P- and S-wave velocity

P and S- ultrasound velocity results tend to decrease uniformly at increased temperatures; however, between 500 and 625 °C groups, there is almost a threefold decrease (1.93–1.95 km/s for P-wave velocity and 1.24–1.25 km/s for S-wave velocity) in ultrasound propagation velocities compared to between 22 and 500 °C mean decreases (0.63–0.65 km/s for P-wave velocity and 0.31–0.30 km/s for S-wave velocity). The decrease is also significant between 625 and 750 °C (0.90–0.95 km/s for P-wave velocity and 0.62 km/s for S-wave velocity), but the drop is not as large as between 500C and 625 °C. Statistical tools showed that all heat-treatment groups are significantly different in terms of distribution and median values (p = 0.00). Therefore according to the results, the heat-treatment series applied significantly changed the ultrasound propagation physical properties of the monzogranite between all examined temperature groups. Between room temperature and 250 °C, and then in steps of 125 °C up to 750 °C, the wave propagation velocity decreased continuously, although the change is more prominent between 500 and 625 °C and significant between 625 and 750 °C (Fig. 4).

Box-plot chart of P- (A) and S-wave velocity (B). The boxes indicate the interquartile intervals, while the two upright lines represent the minimum and maximum data, and the horizontal line inside the box represents the median value. All the temperature group median and distribution pairs are significantly different from each other according to Kruskal Wallis and Median Test (p < 0.05)

The decrease in wave propagation velocity is mainly associated with the development of cracks in the rocks (Fan et al. 2017; Siegesmund et al. 2018). Linear thermal expansion of minerals and different thermal expansion of the various rock-forming mineral cause microcracking (Fan et al. 2017); furthermore, mineral transformations which cause an increase in volume in the rock during heat treatment is a main microcracking factor (Singh et al. 2012; Fan et al. 2017; Siegesmund et al. 2018). The linear decrease of ultrasound velocity values in this study is mainly due to the previously mentioned thermal expansion factors. Thermal-induced mineralogical alteration processes between 500 and 625 °C entail a significant (2–3 times larger) decrease in P- and S- velocity values. This phenomenon was also recorded previously in terms of P-wave velocity in other studies (Wang et al. 2020). The rock-forming quartz mineral in the monzogranite is transformed from alpha-quartz to beta-quartz at 573 °C (quartz inversion), which causes an excess linear expansion of 0.45% in samples (Singh et al. 2012). This can be seen between the comparison of a 0.60% volumetric increase between the untreated and treated 500 °C samples and the significant 2.35% volumetric increase of the samples between untreated and 625 °C treated specimens. Previous studies showed that at high 750 °C temperature heat-treatment, the hereby examined monzogranite show macro-cracks, and fragmentation of the samples starts to develop (Németh et al. 2021). The volumetric increase between untreated and 750 °C treated samples is the most prominent of 8.35% of the volumetric examination.

This might explain why the ultrasound propagation velocity decreases significantly between 500 and 625 °C. Previous research has shown that this monzogranitic rock shows a yellowish-reddish discoloration at high temperatures, which becomes more pronounced above 625 °C (Németh et al. 2021). Whether the ultrasound propagation velocity shows a larger scale decrease between these temperature ranges remains to be investigated.

4.2 Bulk density

The bulk density of monzogranite decreases significantly due to heat treatment. However, statistical values do not show a clear trend with temperature. Descriptive statistical values of heat-treatment groups and also both Kruskal–Wallis and median test pairwise comparison results show that the bulk density values significantly change by heat treatment from 22 to 250 °C, from 250 to 375 °C, and again from 375 to 500 °C. However, a slight increase and decrease in bulk density values between those temperatures occur. This phenomenon can be explained by the slight volume decrease between 250 and 375 °C. The bulk density of the samples between 22 and 375 °C and between 250 and 500 °C are not significantly different (p = 1.00). A significant bulk density change occurs after 500 °C due to heat treatment in the monzogranite samples (Fig. 5A).

Box-plot chart of Bulk density (A) and Duroskop (B) results. The boxes indicate the interquartile intervals, while the two upright lines represent the minimum and maximum data, and the horizontal line inside the box represents the median value (Kovács et al. 2012a). The figure graphically shows the non-parametric independent sample hypothesis test results. Significantly not different pairs, according to Kruskal–Wallis Test pairwise comparison (p > 0.05), are connected via red line; significantly not different pairs, according to Median Test pairwise comparison (p > 0.05), are connected via blue lines. The pairs which are not connected are significantly different from each other according to Kruskal Wallis and Median Test (p < 0.05)

There are several reasons why the density values of samples at room temperature and 375 °C and samples heated between 250 and 500 °C are not significantly different and why there is an increase in bulk density between 250 and 375 °C. One reason may be that crystal water is being removed from the small pores and cracks that still contain water of crystallization at room temperature, thereby increasing the volume of the samples (decrease of bulk density) from room temperature to 250 °C. However, between 250 and 375 °C, microcracks close, volume decrease, and density increases. Microthermometric and fluid inclusion analysis of the Móragyi granite has been carried out previously, and the results suggest several fluid flow events and possible release scenarios until 290 °C (Poros et al. 2008; Szabó et al. 2008). It is possible that the significant decrease at 250 °C and the slight increase in density at 375 °C would not occur without the presence of crystal water in the rock and would only show a linear decreasing trend from 22 to 500 °C. Other studies have recorded a relative increase in bulk density values around 300 °C (Yang et al. 2017) and other strength (UCS) parameter increase between room temperature to 400 °C, which has been described as hardening and originated from water evaporation (Wang et al. 2020). Another possibility is that bulk density group anomaly could imply inner mineralogical (mineral distributional) or internal original fracture differentiation between sample groups.

Bulk density values tend to decrease significantly after 500 °C, as the processes discussed in the previous section. At 750 °C, the samples were cracked and fragmented, as was previously researched (Németh et al. 2021). Volume increase; therefore, a significant bulk density decrease is inevitable at this temperature range.

4.3 Duroskop surface strength

Results of Duroskop surface strength show a similar trend as bulk density results. Duroskop surface strength values show a decreasing trend with increasing temperature from 22 to 750 °C, with a slight increase at 375 °C in all descriptive statistical data. The Duroskop test measures the rebound strength at a point on the surface of the specimen, which is highly dependent on the surface quality. As the findings for bulk density are correct for the processes between room temperature and 375 °C, changes in bulk density may be related to crack opening and closing; this can directly affect the surface strength, i.e., the Duroskop rebound. The higher the cracked (fragmented) at a given surface, the lower the rebound energy (Török 2018). It, therefore, suggests that Duroskop values follow the heat-treatment-induced bulk density trends. The Kruskal–Wallis pairwise comparisons indicate that the distributions of Duroskop values are not significantly different between the 22–250 °C (p = 0.66), 22–375 °C, and 250–500 °C heat treatment group pairs (p = 1.00). The median test shows that the median values of the Duroskop rebound values between 22 and 250 °C and 22 °C and 375 °C are not significantly different (p = 1.00). However, the distribution of each of the other pairs are significantly different. The significant Duroskop surface strength results occur above 500 °C (p < 0.05) (Fig. 5B).

As a bulk density, the slight increase and decrease of values cause sample groups not directly related by temperature scale to give similar median and distribution group values. From 375 °C, as crack propagation and fragmentation develop, lower Duroskop values occur and show a significant decrease in surface strength values above 500 °C.

4.4 Uniaxial compressive strength

As the temperature increases, the uniaxial compressive strength mean and median values of the monzogranite decrease uniformly. The Kruskal–Wallis pairwise comparisons reveal that the distributions among the 375–625 °C (p = 0.41) and 22–250 °C, 375–500 °C, and 500–625 °C (p = 1.00) heat treatment groups do not differ significantly. The median test shows that values between 22 and 250 °C and 375 °C and 500 °C are not significantly different from each other in median values (p = 1.00) (Fig. 6/A).

Box-plot chart of uniaxial compressive strength (A) and elastic modulus (B) results. The boxes indicate the interquartile intervals, while the two upright lines represent the minimum and maximum data, and the horizontal line inside the box represents the median value (Kovács et al. 2012a). The figure graphically shows the non-parametric independent sample hypothesis test results. Significantly not different pairs, according to Kruskal–Wallis Test pairwise comparison (p > 0.05), are connected via red line; Significantly not different pairs, according to Median Test pairwise comparison (p > 0.05), are connected via blue lines. The pairs which are not connected are significantly different from each other according to Kruskal Wallis and Median Test (p < 0.05)

The change in uniaxial compressive strength in response to heat treatment in granites is a well-studied topic (Török and Török 2015; Yang et al. 2017; Wang et al. 2020). It is clearly shown in previous literature as well as here that the monzogranite specimens, through heat treatment, thermal expansion and relaxation, crack propagation, and finally fragmentation at high 750 °C, suffer internal strength loss and become weaker (Siegesmund et al. 2018). The individual heat treatment groups clearly show a linear trend in the decrease of compressive strength. However, the distributions of the heat treatment groups overlap in many cases, which the non-significant Kruskal–Wallis test pairwise comparisons show. Continuously decreasing strength parameters are observed in some studies (Török and Török 2015) as in the present paper; however, in other studies, there was a slight increase (hardening) up to 500 °C and then a significant decrease of UCS values (Yang et al. 2017; Wang et al. 2020). In our case, this phenomenon was mainly observed in bulk density and Duroskop values.

Hypothesis tests and descriptive statistical results also show that the median values and distributions of the uniaxial compressive strength values change significantly between 250 and 375 °C and between 625 and 750 °C (p = 0.00). Between 500 °C and 625 °C, a significant difference in median values occurs (p = 0.00); however, distributions overlap, therefore, are not significantly different from each other according to the Kruskal–Wallis test results (p = 1.00). Clarification of the processes between these temperature ranges, i.e., processes indicative of internal strength loss, could be coupled with mineralogical changes and internal cracking. It is worth noting that the loss of internal strength between 250 and 375 °C is not reflected in the loss of surface strength of Duroskop results. Above 625 °C, at 750 °C, the fragmentation of the samples due to a high volumetric increase of thermal expansion develops, which is reflected in the low internal strength values.

4.5 Elastic modulus

Elastic modulus results show a similar trend as Uniaxial Compressive strength results. The decreasing trend is uniform, and mean, and median values tend to decrease linearly. Both Kruskal–Wallis and Median test results show no statistically significant differences in elastic modulus values between 22 and 250 °C (p = 1.00); distributions according to the Kruskal–Wallis test are not significantly different between 250 and 375 °C (p = 0.52) and 375 °C and 500 °C (p = 0.14). Compared to the Duroskop surface strength, between 250 and 375 °C, there is also a significant difference in the median of the elastic modulus values (p = 0.00); however, no significant difference in the distribution of the two temperature pairs (p = 0.52). It is also worth noting that, however, Uniaxial compressive strength distribution results did not show a significantly different change between 500 and 625 °C; modulus of elasticity values did (p = 0.00). Therefore, the loss of elasticity is more prominent between 500 and 625 °C than the loss of internal strength (Fig. 6B).

After 500 °C, a significant elastic modulus decrease occurs in the samples. This fact is in good agreement with other international literature, where a significant decrease in elasticity values occurs between 400 and 600 °C, while results show stagnation before that temperature range (Wang et al. 2020). For elasticity values measured during heat treatment of other granites (Yang et al. 2017), a hardening (i.e., slightly increased elasticity values) was observed from room temperature to a maximum at 320 °C, followed by a significant decrease in the results. It can be stated that, although on a large scale, the heat-treatment-induced rock physics parameter changes show similarities, there are minor differences between granite types. The loss of elasticity in the Mórágy granite after 500 °C is prominent as the mineral alteration (quartz inversion) and thermal expansion-induced crack propagation develops. The significant rigidity of the samples at 625 °C and 750 °C is significant due to the fragmentation of the specimens.

5 Conclusions

P, and S- ultrasound velocity, bulk density, Duroskop surface strength, uniaxial compressive strength, and modulus of elasticity tests results show significant variations for samples of 22 °C and heat-treated samples of monzogranite 250 °C, 375 °C, 500 °C, 625 °C and 750 °C obtained from the geological environment of the Bátaapáti Radioactive waste repository, Hungary.

The following temperature framework and model for the temperature increase of the monzogranite can be established based on the results of the rock physics tests, statistical evaluation, and studied mineralogical processes:

-

From room temperature to 250 °C, cracks are initiated in the monzogranite, and further progradation of cracks occurs. Ultrasound velocity values and bulk density values decrease significantly. Duroskop, uniaxial compressive strength, and elastic modulus values decrease slightly.

-

Between 250 and 375 °C, a decrease in volume (relative bulk density increase) can be associated with crack closure after crystal water removal. The surface strength, i.e., the Duroskop rebound values, follows this significant trend. Ultrasound velocity values and UCS values decrease significantly.

-

Above 375 °C, until 500 °C as the temperature increases, the linear thermal expansion of the rock and the different thermal expansions of individual minerals lead to crack propagation. Rock physics values decrease, and UCS and Elastic modulus values decrease slightly.

-

Between 500° and 625°C, the inversion of quartz leads to excess linear expansion and the formation of larger cracks resulting in a highly significant drop in pulse velocities values. Due to quartz inversion-related processes, the bulk density, Duroskop, and elastic modulus values decrease significantly.

-

Temperature range between 625 and 750 °C is associated with macro-cracking and fragmentation. Drastic volume increase (density decrease), a decrease of elasticity, and internal and external strength decrease occur due to heavy deterioration of the monzogranite.

The evaluations show significant decreases in all studied rock-physical parameters above 500 °C. Between 500 and 625 °C, significant rock physical deterioration and mineralogical change occurs. Between 625 and 750 °C, the deterioration is drastic. With the data set of physical parameters, the results of our paper allow for predicting the heating temperature of the Bátaapáti monzogranitic rocks even when the firing or heat stress conditions are unknown. In case of designing in a monzogranite rock environment, temperatures after 500 °C should be avoided in the long term at all costs, as it drastically changes the rock physics and mineralogy of the host rock. It is recommended that this temperature framework range be taken into account when designing and building monitoring systems.

References

Balla, Z., Gyalog, L.A.: Mórágyi-Rög Északkeleti Részének Földtana. Magyarázó a Mórágyi-rög ÉK-i Részének Földtani Térkép sorozatához (1:10 000); (in Hungarian, translated title: Geology of the north-eastern part of the Mórágy Block: Explanatory notes to the geological map-series of the north-eastern part of the Mórágy Block (1:10 000)); Magyar Állami Földtani Intézet: Budapest, Hungary; vol. 15–17, pp. 58–69 (2009)

Bosch, M., Tapan, M., Ezequie, L.F.: Gonzalez Seismic inversion for reservoir properties combining statistical rock physics and geostatistics: a review. Geophysics 75, 75A165-75A176 (2010). https://doi.org/10.1190/1.3478209

Chakrabarti, B., Yates, T., Lewry, A.: Effect of fire damage on natural stonework in buildings. Constr. Build. Mater. 10, 539–544 (1996). https://doi.org/10.1016/0950-0618(95)00076-3

Chapman, N., Hooper, A.: The disposal of radioactive wastes underground. In: Proceedings of the geologists’ association, vol. 123, pp. 46–63 (2012). https://doi.org/10.1016/j.pgeola.2011.10.001

Chen, L., Wang, C.P., Liu, J.F., Li, Y., Liu, J., Wang, J.: Effects of temperature and stress on the time-dependent behavior of Beishan granite. Int. J. Rock Mech. Min. Sci. 93, 316–323 (2017). https://doi.org/10.1016/j.ijrmms.2016.11.007

Costa, A.C., Soares, A.: Homogenization of climate data: review and new perspectives using geostatistics. Math. Geosci. 41, 291–305 (2009). https://doi.org/10.1007/s11004-008-9203-3

Davarpanah, M., Somodi, G., Kovács, L., Vásárhelyi, B.: Complex analysis of uniaxial compressive tests of the Mórágy granitic rock formation (Hungary). Studia Geotech. Mech. 41(1), 21–32 (2019). https://doi.org/10.2478/sgem-2019-0010

Davarpanah, M., Somodi, G., Kovács, L.: Experimental determination of the mechanical properties and deformation constants of Mórágy granitic rock formation (Hungary). Geotech. Geol. Eng. 38, 3215–3229 (2020). https://doi.org/10.1007/s10706-020-01218-4

Deák, F., Kovács, L., Vásárhelyi, B.: Geotechnical rock mass documentation in the Bátaapáti radioactive waste repository. Cent. Eur. Geol. 57(2), 193–207 (2014)

Deák, F., Kovács, L., Mucsi, P., Máthé, Z.: Microscopic identification of progressive fracturing in granite under triaxial and uniaxial stress conditions from Bátaapáti Radwaste repository. Period. Polytech. Civ. Eng. 64(1), 231–240 (2020). https://doi.org/10.3311/PPci.15287

Deák, F., Perras, M.A., Szűcs, I., Török, Á.: Back-analysis of rock mass strength at a radioactive waste disposal site using acoustic emission monitoring data and 3D numerical modelling. Energies 16, 4686 (2023). https://doi.org/10.3390/en16124686

EN 14580:2005 Natural stone test methods - Determination of static elastic modulus (2005)

EN 1926:2006 Natural stone test methods - Determination of uniaxial compressive strength (2007)

EN 14579:2005 Natural Stone Test Methods-Determination of Sound Speed Propagation (2005).

EN 1936:2006 Natural Stone Test Methods. Determination of Real Density and Apparent Density, and of Total and Open Porosity (2007).

Fan, L.F., Wu, Z.J., Wan, Z., Gao, J.W.: Experimental investigation of thermal effects on the dynamic behavior of granite. Appl. Therm. Eng. 125, 94–103 (2017). https://doi.org/10.1016/j.applthermaleng.2017.07.007

Felgueiras, M.M.: Explaining the seismic moment of large earthquakes by heavy and extremely heavy-tailed models. Int. J. Geomath. 3, 209–222 (2012). https://doi.org/10.1007/s13137-012-0042-5

Freire-Lista, D., Gomez-Villalba, L., Fort, R.: Microcracking of granite feldspar during artificial thermal processes. Period. Min. 84, 519–537 (2015). https://doi.org/10.2451/2015PM0029

Freire-Lista, D.M., Fort, R., Varas-Muriel, M.J.: Thermal stress-induced microcracking in building granite. Eng. Geol. 206, 83–93 (2016). https://doi.org/10.1016/j.enggeo.2016.03.005

Gautam, P.K., Verma, A.K., Singh, T.N., Hu, W., Singh, K.H.: Experimental investigations on the thermal properties of Jalore granitic rocks for nuclear waste repository. Thermochim. Acta 681, 178381 (2019). https://doi.org/10.1016/j.tca.2019.178381

Glover, P.W.J., Baud, P., Darot, M., Meredith, P.G., Boon, S.A., LeRavalec, M., Zoussi, S., Reuschlé, T.: α/β phase transition in quartz monitored using acoustic emissions. Geophys. J. Int. 120(3), 775–782 (1995). https://doi.org/10.1111/j.1365-246X.1995.tb01852.x

Guangsheng, D., Shijiang, C., Xiaoyi, C., Zheng, J.: Temperature damage regularity of granite based on micro-inhomogeneity. Front. Earth Sci. (2022). https://doi.org/10.3389/feart.2022.981754

Hatvani, I., Erdélyi, D., Vreča, P., Kern, Z.: Analysis of the spatial distribution of stable oxygen and hydrogen isotopes in precipitation across the Iberian Peninsula. Water 12, 481 (2020). https://doi.org/10.3390/w12020481

Hatvani, I., Szatmári, G., Kern, Z., Erdélyi, D., Vreča, P., Kanduč, T., Czuppon, Gy., Lojen, S., Kohán, B.: Geostatistical evaluation of the design of the precipitation stable isotope monitoring network for Slovenia and Hungary. Environ. Int. 146, 106263 (2021). https://doi.org/10.1016/j.envint.2020.106263

Heierli, J., Genoni, O.: The role of temperature in the safety case for high-level radioactive waste disposal: a comparison of design concepts. Geosciences 7, 42 (2017). https://doi.org/10.3390/geosciences7020042

Istovics, K., Tóth, M.T.: Fracture network modeling around the Radioactive Waste Repository in Bátaapáti, based on BN2-1 pre-boring. In: Török, Á., Görög, P., Vásárhelyi, B. (eds.) Mérnökgeológia-Kőzetmechanika, pp. 119–128. Budapest, Hantken Kiadó (2016)

Kondo, S., Tokushita, T., Hwang, M.J., Murano, T.: Risk analysis of high-level radioactive waste disposal into granite formation. Nuclear Energy Agency of the OECD (NEA): OECD (1981)

Kovács, J., Tanos, P., Korponai, J., Székely, I.K., Gondár, K., Gondár-Sőregi, K., Hatvani, I.G.: Analysis of water quality data for scientists. In: Voudouris, K., Voutsa, D. (eds.) Water Quality Monitoring and Assessment, pp. 65–94. InTech, London (2012a). https://doi.org/10.5772/32173

Kovács, J., Korponai, J., Székely, I., Hatvani, I.: Introducing sampling frequency estimation using variograms in water research with the example of nutrient loads in the Kis-Balaton Water Protection System (W Hungary). Ecol. Eng. 42, 237–243 (2012b). https://doi.org/10.1016/j.ecoleng.2012.02.004

Mudelsee, M., Albert, J., Sirocko, F.: Weather control in radon flux time series from Schleswig-Holstein, Germany. Int. J. Geomath. 11, 23 (2020). https://doi.org/10.1007/s13137-020-00156-w

Németh, A., Török, Á.: Heat-related changes of density, P-wave velocity, and surface hardness of granite, periodica polytechnica. Civ. Eng. (2021b). https://doi.org/10.3311/PPci.18705

Németh, A., Antal, Á., Török, Á.: physical alteration and color change of granite subjected to high temperature. Appl. Sci. 11, 8792 (2021). https://doi.org/10.3390/app11198792

Németh, A., Török, Á: Thermal shock-induced physical changes of granitic rocks of a radioactive waste disposal site. In: IOP Conference Series: Earth and Environmental Science, Volume 833, Mechanics and Rock Engineering, from Theory to Practice 2021a, Turin, Italy Eurock, vol. 833, p. 012035 (2021a). https://doi.org/10.1088/1755-1315/833/1/012035

Neumann, P.A.: The geological disposal of nuclear waste. J. Environ. Radioact. 6, 92–94 (1988). https://doi.org/10.1016/0265-931X(88)90071-9

Ozguven, A., Ozcelik, Y.: Investigation of some property changes of natural building stones exposed to fire and high heat. Constr. Build. Mater. 38, 813–821 (2013). https://doi.org/10.1016/j.conbuildmat.2012.09.072

Peregi, Z., Gulácsi, Z.: Mórágyi Gránit Formáció, alsó-karbon. (in Hungarian, translated title: Mórágy Granite Formation, Lower Carboniferous). In Geology of the North-Eastern Part of the Mórágy Block: Explanatory Notes to the Geological Map-Series of the North-Eastern Part of the Mórágy Block (1:10 000); Balla, Z., Gyalog, L., Eds.; Magyar Állami Földtani Intézet: Budapest, Hungary, Chapter 3.1.1.3, pp. 338–359 (2009)

Pettersson, S., Loennerberg, B.: Final repository for spent nuclear fuel in granite—the KBS-3V concept in Sweden and Finland. Proceedings of the international technical conference on the practical aspects of deep geological disposal of radioactive waste, p. 346. Ceske vysoke uceni technicke, Fakulta stavebni, Czech Republic (2008)

Poros, Z.S., Molnár, F., Koroknai, B., Lespinasse, M., Maros, G.Y., Benkó, Z.S.: Application of studies on fluid inclusion planes and fracture systems in the reconstruction of the fracturing history of granitoid rocks III: results of studies in drillcores from the radioactive waste depository site at Bátaapáti (Üveghuta). Bull. Hung. Geol. Soc. 138, 361–382 (2008)

Přikryl, R.: Some microstructural aspects of strength variation in rocks. Int. J. Rock Mech. Min. Sci. 38, 671–682 (2001). https://doi.org/10.1016/S1365-1609(01)00031-4

Rozgonyi-Boissinot, N., Buocz, I., Hatvani, I.G., Török, Á.: Shear strength testing of consolidated claystones: breakpoint detection of shear stress versus shear displacement curves, a statistical approach. Int. J. Geomath. 12, 1 (2021). https://doi.org/10.1007/s13137-020-00168-6

Shang, X., Zhang, Z., Xu, X., Liu, T., Xing, Y.: Mineral composition, pore structure, and mechanical characteristics of pyroxene granite exposed to heat treatments. Minerals 9, 553 (2019). https://doi.org/10.3390/min9090553

Shapiro, S.S., Wilk, M.B.: An analysis of variance test for normality (complete samples). Biometrika 52(3–4), 591–611 (1965). https://doi.org/10.1093/biomet/52.3-4.591

Siegesmund, S., Sousa, L., Knell, C.: Thermal expansion of granitoids. Environ. Earth Sci. (2018). https://doi.org/10.1007/s12665-017-7119-2

Singh, V., Tathavadkar, V., Denys, B.M., Venugopal, R.: Application of quartz inversion phenomenon in mineral processing—a case study of siliceous manganese ores. Min. Eng. 32, 8–11 (2012). https://doi.org/10.1016/j.mineng.2012.03.010

Somodi, G., Krupa, Á., Kovács, L., Vásárhelyi, B.: Comparison of different calculation methods of Geological Strength Index (GSI) in a specific underground construction site. Eng. Geol. 243, 50–58 (2018). https://doi.org/10.1016/j.enggeo.2018.06.010

Szabó, B., Benkó, Z.S., Molnár, F.: The application of studies on fluid inclusion planes and fracture systems in the reconstruction of fracturing history of granitoid rocks II. Fracture systems of the Mórágy Granite. Bull. Hung. Geol. Soc. 138, 193–227 (2008)

Török, A., Török, Á.: The effect of temperature on the strength of two different granites. Cent. Eur. Geol. 58, 356–369 (2015). https://doi.org/10.1556/24.58.2015.4.5

Török, Á.: Non-destructive surface strength test—duroskop a forgotten tool; comparison to schmidt hammer rebound values of rocks. In Proceedings of the IAEG/AEG Annual Meeting, San Francisco, CA, USA, 17–21 September 2018; vol.6, pp. 129–135. (2018). https://doi.org/10.1007/978-3-319-93142-5_18

Vázquez, P., Shushakova, V., Gómez-Heras, M.: Influence of mineralogy on granite decay induced by temperature increase: experimental observations and stress simulation. Eng. Geol. 189, 58–67 (2015). https://doi.org/10.1016/j.enggeo.2015.01.026

Wang, F., Frühwirt, T., Konietzky, H.: Influence of repeated heating on physical-mechanical properties and damage evolution of granite. Int. J. Rock Mech. Min. Sci. 136, 104514 (2020). https://doi.org/10.1016/j.ijrmms.2020.104514

Webster R., Oliver M.A.: Geostatistics for Environmental Scientists, Wiley, Chichester, 336p (ISBN: 978-0-470-02858-2) (2007).

Yang, S., Ranjith, P., Jing, H., Tian, W., Ju, Y.: An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high-temperature treatments. Geothermics 65, 180–197 (2017). https://doi.org/10.1016/j.geothermics.2016.09.008

Zhu, Z., Ranjith, P.G., Tian, H., Jiang, G., Dou, B., Mei, G.: Relationships between P-wave velocity and mechanical properties of granite after exposure to different cyclic heating and water-cooling treatments. Renew. Energy 168, 375–392 (2021). https://doi.org/10.1016/j.renene.2020.12.048

Acknowledgements

We would like to thank the employees of RHK Kft. for offering a collection of samples and related documents for this and further research. We would like to thank the Department of Highway and Railway Engineering for using their electric oven and, last but not least, István G. Hatvani for his insights and assistance in the preparation and statistical examination. The support of the New National Excellence Programme 2022 (ÚNKP-22-3-II-BME-40) scholarship is acknowledged. The research was also partly funded by project no. TKP-6-6/PALY-2021 with the support provided by the Ministry of Culture and Innovation of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021-NVA funding scheme.

Funding

Open access funding provided by Budapest University of Technology and Economics.

Author information

Authors and Affiliations

Contributions

AN and ÁT designed the experiments, and AN carried them out. AN created the statistical dataset and tests and made the statistical interpretation—AN prepared the manuscript with contributions of ÁT. We applied the SDC approach for the sequence of authors.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Németh, A., Török, Á. Statistical analysis of heat-induced rock physics and mineralogical alteration processes of monzogranite samples from Bátaapáti, Hungary. Int J Geomath 14, 23 (2023). https://doi.org/10.1007/s13137-023-00234-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13137-023-00234-9