Abstract

The influence of temperature between 283 K and 328 K on hydrogen electrosorption into Pd-Ru alloys in the bulk composition range 87–100% at. Pd was studied voltammetrically and chronoamperometrically in 0.5 M H2SO4 solution. The maximum alloy ability to absorb hydrogen decreases with increasing temperature. The extent of hydrogen absorption/desorption hysteresis is slightly reduced with increasing temperature and markedly reduced with increasing Ru bulk content. Both increasing temperature and Ru bulk content results not only in a decrease in the thermodynamic stability of the hydride phase but also in an improvement in the kinetics of hydrogen electrosorption. Pd-Ru alloys containing more than ca. 97% at. Pd absorb more hydrogen than pure Pd, while further Ru additive results in a significant deterioration of the alloy ability to absorb hydrogen. The data on the influence of temperature and alloy bulk composition on the processes of hydrogen electrosorption in Pd binary alloys with Ru, Rh, Pt, and Au have been compared.

ᅟ

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In the whole group of Pd binary alloys, which are known as good catalysts and hydrogen absorbers [1,2,3,4,5,6], two systems deserve a special attention, namely Pd-Rh and Pd-Ru alloys. These systems are exceptional, because for certain composition ranges, the maximum amounts of absorbed hydrogen are greater than in the case of pure Pd [1,2,3,4,5,6,7,8,9,10,11,12,13,14], while other Pd alloys in their full composition range are always characterized by a weaker maximum ability to absorb hydrogen [1,2,3,4,5,6, 15,16,17,18,19]. In most Pd alloys, the gaps in the Pd d-band are filled by the electrons originating from the alloying metal, and therefore, less electronic states remain free for the electrons to be accepted from absorbing hydrogen, which leads to a deterioration of the absorption capacity [16]. Only for Pd-Rh and Pd-Ru alloys containing small amounts of Rh or Ru in the bulk, the number of gaps in the Pd d-band below the Fermi level is greater, which is manifested by an enhanced ability to absorb hydrogen [1,2,3,4,5,6,7,8,9,10,11,12,13,14].

The Pd-Rh system has been relatively well investigated, especially in recent years, and many of its electrochemical properties are now known, including those concerning hydrogen absorption phenomenon [7,8,9,10]. Also, the influence of surface poisons, like the products of CO2 and CO electrosorption, on the electrochemical processes of hydrogen adsorption, absorption, and desorption on/in/from Rh-containing Pd alloys was thoroughly examined in our laboratory [20,21,22].

Pd-Ru alloys, however, have rarely been studied [23,24,25,26,27], and just a few reports exist on hydrogen electrosorption in those materials [12,13,14, 28]. In order to fill this lack of scientific knowledge, we started in our laboratory a systematic examination of the electrochemistry of Pd-Ru alloys obtained as thin electrodeposits, i.e., limited volume electrodes (LVE) [12,13,14, 28].

In earlier papers devoted to the Pd-Ru system, we reported on the details of electrode preparation and characterization [28], hydrogen absorption in these alloys at room temperature [12, 13], and determination of the thermodynamic functions of the hydride phase formation [14]. Following our studies on the influence of temperature on the process of hydrogen electrosorption into Pd binary alloys with other noble metals (Au, Pt, and Rh), described in a series of articles [10, 29,30,31], we report here on the effect of temperature on the amount of hydrogen electrosorbed by Pd-Ru of various bulk compositions. We present the influence of temperature and alloy composition on the potential of the voltammetric peak due to electrosorbed hydrogen oxidation (EpHox), the potentials of the α → β and β-α phase transitions (Eα-β and Eβ-α), and the extent of absorption/desorption hysteresis. We also compare data for the Pd-Ru system with our earlier results obtained for other Pd-noble metal systems [8,9,10, 12,13,14, 29,30,31,32].

Experimental

Hydrogen absorption in Pd-Ru alloys was performed under voltammetric and chronoamperometric conditions from 0.5 M H2SO4 in the temperature range 283–328 K. Analytical grade reagents (POCh, Poland) and purified water (applying Hydrolab and Millipore systems) were used for the preparation of solutions. In order to avoid the interference with dissolved oxygen, the electrolyte was deoxygenated by Ar (99.999%) for 20 min prior to the experiments, while during the experiments, Ar was continuously passing above the solution level.

Three-electrode system was applied with a Hg│Hg2SO4│0.5 M H2SO4 and a Pt gauze as the reference and auxiliary electrode, respectively. All potentials are expressed in the RHE scale according to the calculations described earlier [10]. A CH Instrument potentiostat (model 604) was used for the experiment performance, data acquisition, and their further treatment. The whole electrochemical cell was maintained in a given, constant temperature, controlled by a thermostat (Lauda RE 306, Germany).

Pd or Pd-Ru layers (thickness ca. 1.0 μm, i.e., LVE) electroplated on a gold wire (99.99%, 0.5-mm diameter) served as working electrodes. The alloys were prepared by a potentiostatic electrodeposition from baths obtained by mixing in various proportions the aqueous solutions of PdCl2, RuCl3, and HCl. As we reported earlier [28], lower deposition potential resulted in higher Ru bulk concentration in the alloys. In order to determine Pd and Ru contents in the deposited alloys, the electrodes were analyzed by atomic emission spectroscopy after the electrochemical measurements.

We used the same procedures of hydrogen electrosorption and the calculations of the amount of absorbed hydrogen as those described earlier [8,9,10, 12,13,14, 29,30,31,32].

Results and Discussion

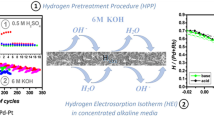

Typical cyclic voltammograms (0.01 V s−1, 298 K) for a Pd-Ru alloy (99.3% Pd in the bulk) and pure Pd in the potential region related to hydrogen electrosorption phenomena are shown in Fig. 1. The lines denoted with number (1) represent the voltammetric responses for fresh electrodes, i.e., just after their deposition. The lines denoted with (2) concern CVs for the same samples after the hydrogen pretreatment procedure involving several tens of repeated absorption/desorption cycles in the potential range between − 0.10 and 0.38 V at 298 K.

The comparison of cyclic voltammograms (scan rate 0.01 V s−1, 298 K) recorded for a pure Pd and a Pd-Ru alloy (99.3% Pd in the bulk): both for freshly deposited layer – lines 1 and after H treatment – lines 2 (several tens of repeated absorption/desorption cycles in the potential range between − 0.10 and 0.38 V at 298 K)

As for other Pd-based electrodeposits, the hydrogen pretreatment procedure leads to the improvement in kinetics of hydrogen electrosorption by Pd-Ru alloys, as compared with a freshly prepared electrode. Again, typically of a Pd alloy with another noble metal (e.g., Rh, Pt or Au), the course of a CV curve for a freshly deposited Pd-Ru alloy is more similar to the curve after the pretreatment procedure than in the case of pure Pd, where the CVs recorded at these two stages of treatment are markedly different regarding the shape, height, and potentials of the hydrogen-related current signals. The effect of hydrogen treatment was thoroughly discussed in our previous papers [10, 29, 30] and explained mainly by defect creation and relaxation of the misfit strain energy at the interface resulting from the metal interactions with hydrogen [33, 34]. A conclusion was drawn that the second noble metal, such as Ru, alloyed with Pd may accelerate the processes of phase transitions or surface kinetics of hydrogen electrosorption.

Since hydrogen pretreatment of fresh Pd-based electrodeposits is crucial to minimize the effects of further alloy aging during the hydrogen experiment proper, each alloy after its preparation was subjected to a series of voltammetric (0.01 V s−1) and chronoamperometric runs between − 0.10 and 0.50 V at 298 K, until a stable voltammogram was reached. Although the evolution of CV curves for hydrogen-treated Pd-Ru electrodes was not shown earlier, it should be stressed that the same procedure was applied in all our previous works devoted to hydrogen electrosorption in Pd-Ru alloys [12,13,14, 28].

CV curves (0.01 V s−1) obtained at temperature range 283–328 K in hydrogen electrosorption potential region for Pd and Pd-Ru alloys are presented in Fig. 2. For a detailed analysis of the nature of the hydrogen-related signals on CV curves recorded for Pd-based electrodes, we refer the reader to the literature [32]. Briefly, the large cathodic and anodic current peaks placed below ca 0.20 V correspond mainly to hydrogen absorption and its oxidative removal from the electrode bulk, while a pair of smaller peaks placed between 0.23 and 0.30 V (visible in Fig. 2b, c) originates mainly from surface processes of hydrogen adsorption/desorption.

One should note that two main factors influence the course of CVs in the hydrogen electrosorption potential region:

-

1.

Temperature

Temperature influences the shape, height, and potential of both the cathodic (hydrogen electrosorption) and anodic peaks (oxidation of electrosorbed hydrogen). Namely, with increasing temperature, these signals become sharper and the potential difference between anodic and cathodic peaks decreases. Such tendencies mirror a greater degree of the electrochemical reversibility of the processes of hydrogen sorption/desorption at higher temperatures. Thus, the processes of hydrogen uptake and removal into/from Pd-Ru alloys are accelerated as temperature rises.

Due to the fact that hydrogen electrosorption in Pd and its alloys is a multi-step process involving surface reaction, hydrogen transfer through the interface, its subsequent diffusion within metal bulk, and phase transitions between the phases of absorbed hydrogen, the exact result observed under given experimental conditions is the effect of the interplay between the influence of temperature, potential, and alloy composition on each of these steps. The point has been discussed in the literature [35, 36].

-

2.

Alloy bulk composition

For each temperature studied, the main anodic peaks due to oxidation of electrosorbed hydrogen are shifted into lower potentials as the amount of Ru in the alloy bulk increases, while the position of the cathodic peaks is only slightly dependent on alloy bulk composition. The latter signal disappears for the alloys relatively rich in Ru (see CVs for 86.9% Pd-Ru in Fig. 2). According to our earlier findings, when Ru bulk content in the Pd-Ru alloy exceeds ca. 7%, the β-phase of absorbed hydrogen is no longer formed and absorbed hydrogen exists only as a single α-phase [12,13,14].

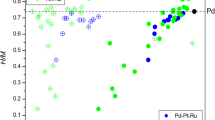

The effect of alloy bulk composition and temperature on the potential of the main anodic peak due to the oxidation of electrosorbed hydrogen (EpHox) is shown in Fig. 3. The negative shift of EpHox with increasing both bulk Ru content and temperature is similar to the trends observed for Pd alloys with other noble metals [9, 10, 29,30,31,32].

The detailed analysis of the influence of alloy bulk composition on the potentials of hydrogen-related signals for Pd alloys is presented elsewhere [32]. A comparison of that effect for various Pd alloys is presented in Table 1 and in Fig. 8 at the end of this paper. It should be stressed that hydrogen desorption from all the alloys studied is kinetically facilitated in comparison with the situation for pure Pd, even if the trends in the changes in the thermodynamic functions describing the processes of hydrogen absorption/desorption may be opposite for Pd alloys with various noble metals [29,30,31,32].

Figure 4 shows the influence of temperature on the maximum amount of electrosorbed hydrogen in Pd and Pd-Ru alloys of various bulk compositions. In all cases, the absorption capacity decreases with increasing temperature, as can be expected for an exothermic process [1, 36]. Similarly to the analogous dependence reported for the Pd-Rh system [10], for Pd-Ru alloys with different bulk compositions, different slopes of the H/M vs. T relationships are observed. The changes in these slopes with the amount of Ru in the alloy bulk can be attributed to the following factors, which are interrelated:

-

1.

The values of enthalpy of hydride formation (more precisely, determined from van’t Hoff plots as the enthalpy of the phase transition, ΔHα-β) in Pd-Ru alloys change with alloy bulk composition, which affects the temperature effect on hydrogen absorption capacity for a given alloy composition [14]. However, since ΔHα-β becomes less and less negative (i.e., the process of the β-phase formation becomes less exothermic) with the increase in Ru bulk content, the greater effect of temperature on the maximum H/M ratio (i.e., higher slopes of the lines in Fig. 4) for Pd-Ru alloys than for pure Pd cannot alone be explained by those monotonic changes in ΔHα-β.

-

2.

The influence of temperature and alloy composition on the position of the H/M vs. potential curve on the potential axis (see then Fig. 5) and on the width of the two-phase region in the Pd-Ru-H system [13] has a significant impact on the amount of hydrogen electrosorbed at a given potential at different temperatures [13, 32]. When temperature is low, hydrogen can be absorbed in the β-phase at sufficiently low potentials, while for the same alloy at elevated temperature, pure β-phase is no longer formed and absorbed hydrogen exists as a mixture of the α- and β-phases or as the α-phase only. Thus, at different temperatures, the maximum hydrogen absorption capacity of a given alloy may be related to different phases of absorbed hydrogen, whose hydrogen capacities are markedly different. Moreover, one should also remember that when the effect of temperature concerns the single α-phase, the values of enthalpy of that phase formation is different from ΔHα-β considered above and the effect on H/M vs. T dependence originating from enthalpy changes with temperature may here be different than that for the β-phase.

The effect of electrode potential, temperature, and alloy bulk composition on the amount of electrosorbed hydrogen is shown in Fig. 5. The experimental procedures and data treatment were described in our previous papers [8,9,10, 12,13,14, 29,30,31,32], where also the detailed analysis of this kind of plots was presented.

Influence of electrosorption potential and temperature on the amount of hydrogen electrosorbed in Pd and Pd-Ru alloys. a 100% Pd. b 99.3% Pd-Ru. c 96.1% Pd-Ru. d 93.7% Pd-Ru. Absorption course (solid symbol and solid lines); desorption course (from chronoamperometric data) (open symbols and dashed lines)

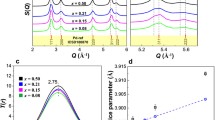

Here, one should pay attention to the region with a sharp increase in the hydrogen absorption capacity, corresponding to the α → β and β → α phase transitions during absorption and desorption, respectively. The potentials of the phase transitions (Eα-β, Eβ-α) are shifted negatively with increasing temperature. This trend is well visible in Fig. 6, where the values of Eα-β and Eβ-α are recalculated into the Gibbs free energy of the hydride phase formation/decomposition (in fact, the respective functions of phase transitions, ΔGα-β and ΔGβ-α). With increasing temperature, the values of ΔGα-β become less negative and the values of ΔGβ-α become less positive, which means that at elevated temperatures, the β-phase becomes thermodynamically less stable. More information of the thermodynamics of hydrogen absorption in Pd-Ru and other alloys was given in our recent papers [14, 37].

Influence of temperature on the values of Gibbs free energy of the β-phase formation and decomposition (ΔGα-β and ΔGβ-α) in Pd and Pd-Ru alloys of different bulk compositions. Absorption course (solid symbol and solid lines); desorption course (from chronoamperometric data) (open symbols and dashed lines)

A decrease in the absolute values of both ΔGα-β and ΔGβ-α is also observed with an increase in Ru bulk content in Pd-Ru alloys. This effect originates from the crystal lattice contraction after Pd alloying with Ru (geometric effect) [28]. On the other hand, the electronic effect, concerning an increase in the number of gaps in the Pd d-band around and below Pd Fermi level, is responsible for a higher hydrogen absorption capacity of Pd-Ru alloys containing less than ca. 3% Ru in the bulk (with a sharp maximum of the H/M ratio for ca. 1% at. Ru), as compared with the capacity of pure Pd [16, 38, 39].

Figure 7 shows the influence of temperature and alloy bulk composition on the extent of the absorption/desorption hysteresis, i.e., the difference between Eα-β and Eβ-α [1]. The hysteresis strongly depends on Pd bulk content in Pd-rich Pd-Ru alloys and decreases from 16 mV for pure Pd to ca. 4 mV with Ru additive of only 4%. The remaining residual hysteresis for Pd-Ru alloys with higher amounts of Ru is likely to be an overestimation originating from difficulties in separation of the currents due to hydrogen electrosorption and evolution, which are more strongly overlapped for the alloys containing more Ru (see [6]).

The hysteresis decrease with increasing bulk amount of Ru is in line with the miscibility gap reduction in the Pd-Ru-hydrogen system reported earlier [13]. In the temperature range studied, the hysteresis very weakly depends on temperature; nevertheless, a small reduction of hysteresis is yet visible, which is again consistent with the fact that an increase in temperature makes the two-phase region in the Pd-metal-hydrogen system narrower [1].

In Table 1, we have compared our data on the influence of temperature and alloy bulk composition on the processes of hydrogen electrosorption in Pd binary alloys with Ru, Rh, Pt, and Au [8,9,10, 12,13,14, 29,30,31,32]. In particular, one should note that some aspects of the electrosorption processes are influenced qualitatively in the same manner by the increase in both temperature and second metal bulk content, namely the kinetics of absorbed hydrogen oxidation is facilitated, and the miscibility gap in the Pd-metal-hydrogen system as well as hysteresis is reduced.

However, Fig. 8 shows that from the quantitative point of view, the influence of alloy bulk composition on these parameters may be markedly different for various alloying metals. It is noteworthy that the additive of Ru has the strongest effect on the changes in EpHox, Eα-β and Eβ-α. Moreover, also in the case of the Pd-Ru system, the smallest Ru additive is needed for the miscibility gap to disappear and hysteresis to be reduced. This behavior indicates that the presence of even minor amounts of Ru markedly modifies the properties of Pd in the alloy of these metals. As we mentioned in our earlier reports [12,13,14], such a situation is probably due to a significant alteration of the alloy electronic structure. In the other Pd-based system exhibiting a similar behavior, i.e., Pd-Rh, the effect of the bulk content of the additive metal is not as strong and the alloy composition range corresponding to the enhanced ability to absorb hydrogen is broader (up to ca. 20% at. Rh), as compared to a very narrow range of compositions for Pd-Ru alloys (less than 3% at. Ru) absorbing more hydrogen than pure Pd.

a The values of a mean slope (expressed in mV per one atomic percent of bulk content of second metal additive) of the temperature dependence of the potentials of the main peak of electrosorbed hydrogen oxidation—EpHox (from cyclic voltammetric data: scan rate 0.01 V s−1, 298 K) and the α-β phase transition—Eα-β (from chronoamperometric data, 298 K), for various Pd-noble metal alloys. b The values of the limiting bulk content of second metal additive needed for the hysteresis reduction below 4 mV and the miscibility gap disappearance in various Pd-noble metal-hydrogen systems (from chronoamperometric data, 298 K)

The additive of any amounts of Pt to Pd leads to a deterioration of the maximum hydrogen absorption capacity and makes the β-phase thermodynamically less stable; however, it has the most favorable effect on hydrogen electrosorption kinetics and hysteresis reduction of all noble metals. On the other hand, the presence of Au in Pd alloys has usually the weakest effect on the above parameters from all types of the alloys studied here. Other comparisons between the behavior of Pd-noble metal alloys toward hydrogen were presented in other papers devoted to the thermodynamic functions of hydride formation/decomposition [14, 29, 30, 37], the nature of hydrogen-related electrochemical signals [32], and the properties of these materials as electrodes for electrochemical capacitors [40].

Conclusions

Increasing temperature in the range 283–328 K results in the following changes in hydrogen electrosorption properties of Pd-Ru alloys:

-

(a)

A decrease in the maximum ability to absorb hydrogen.

-

(b)

A decrease in the thermodynamic stability of the β-phase.

-

(c)

A slight reduction in the extent of absorption/desorption hysteresis and miscibility gap in the Pd-Ru-H system.

-

(d)

An acceleration of hydrogen electrosorption and desorption, leading to a greater degree of electrochemical reversibility of these processes.

For a given temperature, increasing Ru bulk content in Pd-Ru alloys results in:

-

(a)

An increase in the maximum ability to absorb hydrogen for Pd-Ru alloys containing in the bulk ca. 1% at. Ru, followed by a sharp deterioration of the absorption properties with a greater Ru additive (above 3% at.).

-

(b)

A decrease in the thermodynamic stability of the β-phase.

-

(c)

A significant decrease in the extent of absorption/desorption hysteresis, which becomes reduced to ca. 4 mV after the additive of ca. 4% Ru.

-

(d)

A complete disappearance of the two-phase region in the Pd-Ru-H system for Pd-Ru alloys containing more than ca. 7% Ru in the bulk.

-

(e)

An acceleration of hydrogen electrosorption and desorption, leading to a greater degree of electrochemical reversibility of these processes.

Among various Pd-binary alloys with noble metals studied in our laboratory, hydrogen electrosorption properties of the Pd-Ru system alter the most strongly with the variation of the second metal bulk content.

References

F.A. Lewis, The palladium/hydrogen system (Academic Press, New York, 1967)

G. Alefeld, J. Völkl (eds.), Hydrogen in metals (Springer-Verlag, Berlin, 1978)

G. Jerkiewicz, Prog. Surf. Sci. 57, 137 (1998)

G. Jerkiewicz, Electrocatalysis 1(4), 179 (2010)

A. Zalineeva, S. Baranton, C. Coutanceau, G. Jerkiewicz, Langmuir 31, 1605 (2015)

A. Zalineeva, S. Baranton, C. Coutanceau, G. Jerkiewicz, Sci. Adv. 3, e1600542 (2017)

N. Comisso, A. De Ninno, E. Del Giudice, G. Mengoli, P. Soldan, Electrochim. Acta 49, 1379 (2004)

A. Żurowski, M. Łukaszewski, A. Czerwiński, Electrochim. Acta 51, 3112 (2006)

U. Koss, M. Łukaszewski, K. Hubkowska, A. Czerwiński, J. Solid State Electrochem. 15, 2477 (2011)

U. Koss, K. Hubkowska, M. Łukaszewski, A. Czerwiński, Electrochim. Acta 107, 269 (2013)

Y. Sakamoto, Y. Haraguchi, M. Ura, F.L. Chen, Ber. Bunsenges. Phys. Chem. 98, 964 (1994)

K. Hubkowska, M. Łukaszewski, A. Czerwiński, Electrochem. Commun. 20, 175 (2012)

K. Hubkowska, U. Koss, M. Łukaszewski, A. Czerwiński, J. Electroanal. Chem. 704, 10 (2013)

K. Hubkowska, M. Łukaszewski, A. Czerwiński, Electrochem. Commun. 48, 40 (2014)

Y. Sakamoto, F.L. Chen, M. Ura, T.B. Flanagan, Ber. Bunsenges. Phys. Chem. 99, 807 (1995)

E. Wicke, K. Frölich, Z. Phys, Chem. N. F. 163, 35 (1989)

K. Kandasamy, F.A. Lewis, W.D. McFall, R.-A. McNicholl, Z. Phys, Chem. N. F. 163, 41 (1989)

F.A. Lewis, Plat. Met. Rev. 5, 21 (1961)

T.B. Flanagan, Y. Sakamoto, Plat. Met. Rev. 37, 26 (1993)

M. Łukaszewski, M. Grdeń, A. Czerwiński, J. Phys. Chem. Solids 65, 523 (2004)

M. Łukaszewski, M. Grdeń, A. Czerwiński, Anal. Lett. 37, 967 (2004)

M. Łukaszewski, M. Grdeń, A. Czerwiński, Electrochim. Acta. 49,3161 (2004)

L. Sun, D. Cao, G. Wang, J. Appl. Electrochem. 38, 1415 (2008)

J. Bagchi, S.K. Bhattacharya, Transit. Met. Chem. 32, 47 (2007)

Z. Bai, L. Yang, J. Zhang, L. Li, J. Lv, C. Hu, J. Zhou, Catal Commun. 11, 919 (2010)

P. Kędzierzawski, A. Mikołajczuk, A. Borodziński, B. Mierzwa, L. Stobiński, ECS Trans. 28, 23 (2010)

A.L. Cabrera, E. Morales-Leal, Catal. Lett. 30, 11 (1995)

K. Hubkowska, U. Koss, M. Łukaszewski, A. Czerwiński, Electrochim. Acta 132, 214 (2014)

K. Hubkowska, M. Łukaszewski, A. Czerwiński, Electrochim. Acta 56, 235 (2010)

K. Hubkowska, M. Łukaszewski, A. Czerwiński, Electrochim. Acta 56, 2344 (2011)

M. Łukaszewski, K. Hubkowska, A. Czerwiński, J. Electroanal. Chem. 651, 131 (2011)

M. Łukaszewski, K. Hubkowska, U. Koss, A. Czerwiński, Materials 6, 4817 (2013)

P. Millet, M. Srour, R. Faure, R. Durand, Electrochem. Commun. 3, 478 (2001)

K. Sakaki, T. Yamada, M. Mizuno, H. Araki, Y. Shirai, Mater. Trans. 43(11), 2652 (2002)

W.S. Zhang, X.W. Zhang, X.G. Zhao, J. Electroanal. Chem. 458, 107 (1998)

A. Czerwiński, I. Kiersztyn, M. Grdeń, J. Solid State Electroanal. 7, 321 (2003)

U. Koss, M. Łukaszewski, K. Hubkowska, A. Czerwiński, J. Electroanal. Chem. 756, 124 (2015)

K. Frölich, H.G. Severin, R. Hempelmann, E. Wicke, Z. Phys, Chem. N. F. 119, 33 (1980)

E. Wicke, J. Less-Common Met. 74, 185 (1980)

M. Łukaszewski, K. Hubkowska, U. Koss, A. Czerwiński, J. Solid State, Electrochem 16, 2533 (2012)

Funding

This work was financially supported by NCN (National Science Centre, Poland), grant no. 2011/01/N/ST4/02285 and grant no. 2015/17/ B/ST8/03377.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Hubkowska, K., Łukaszewski, M. & Czerwiński, A. Effect of Temperature, Electrode Potential, and Bulk Composition on Hydrogen Electrosorption into Palladium-Ruthenium Alloys—Comparative Study with Other Binary Systems. Electrocatalysis 9, 593–601 (2018). https://doi.org/10.1007/s12678-018-0458-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12678-018-0458-2