Abstract

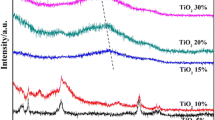

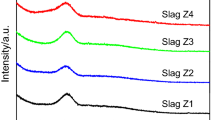

This manuscript expounds the crystallization behavior of CaO–SiO2–MgO–Al2O3 (CSMA) slags towards the smooth operation of the blast furnace, where a structure-oriented elucidation for viscous flow was highlighted for deeper understanding of the crystallization behavior. The CCT curves collected from confocal laser scanning microscopy showed that the initial crystallization temperatures decreased with lower CaO/SiO2 mass ratios, and the primary crystal phases transformed from a merwinite phase (Ca3MgSi2O8) with a stronger crystallization ability to a melilite solid solution (Ca2Al2SiO7–Ca2MgSi2O7) with a comparatively weaker crystallization ability, which correlates well with the variation of Mg/Al mole ratios in melilite and verifies the formation of Ca2MgSi2O7 as one of the main reasons for the poor fluidity of the slag. Furthermore, a higher viscosity was observed for modified slags with CaO/SiO2 mass ratios from 1.34 to 1.05, accompanied by the activation energy increased from 173.0 to 182.7 kJ/mol, which is consistent with the decreased NBO/Si value and the increased Q3/Q2 ratio detected by Raman spectra. The crystal phase with melting point higher than the discharged temperature and the enhanced degree of polymerization of the slag structure will lead to the poor fluidity of the slag, which should be emphasized in the actual modification of the blast furnace slag.

Similar content being viewed by others

References

Zhang X, Jiang T, Xue X, and Hu B, Steel Res. Int. 87 (2016) 87.

Jiao K, Fan X, Zhang J, Wang K, and Zhao Y, Ceram. Int. 44 (2018) 19981.

Chen M, Zhang D, Kou M, and Zhao B, ISIJ Int. 54 (2014) 2025.

Condo A F T, Allertz C, and Du S, Ironmak Steelmak 46 (2019) 207.

Jiang C, Li K, Zhang J, Qin Q, Liu Z, Sun M, Wang Z, Liang W, and Non-Cryst J, Solids 502 (2018) 76.

Jiao K, Zhang J, Chen C, Liu Z, and Jiang X, ISIJ Int. 57 (2017) 983.

Ma J, Fu G, Li W, and Zhu M, Int. J. Min. Met. Mater. 27 (2020) 310.

Hu X, Ren Z, Zhang G, Wang L, and Chou K, Int. J. Min. Met. Mater. 19 (2012) 1088.

Ta Y, Hoshino T, Tobo H, and Watanabe K, ISIJ Int. 59 (2019) 1917.

Kang Y, Liu C, Zhang Y, Xing H, Jiang M, and Non-Cryst J, Solids 500 (2018) 453.

Kashiwaya Y, Nakauchi T, Pham K S, Akiyama S, and Ishii K, ISIJ Int. 47 (2007) 44.

Wang Z, Sun Y, Sridhar S, Zhang M, Guo M, and Zhang Z, Metall. Mater. Trans. B 46 (2015) 537.

Liu Y, Lv X, Bai C, and Yu B, ISIJ Int. 54 (2014) 2154.

Sohn I, and Min D J, Steel Res. Int. 83 (2012) 611.

Wang Z, and Sohn I, Ceram. Int. 44 (2018) 19268.

Wang Z, and Sohn I, J. Am. Ceram. Soc. 102 (2019) 5632.

Lübeck A, Gastaldini A, Barin D, and Siqueira H, Cem. Concr. Compos. 34 (2012) 392.

Jiang C, Li K, Zhang J, Qin Q, Liu Z, Liang W, Sun M, and Wang Z, Metall. Mater. Trans. B 50 (2019) 367.

Kang Y, and Morita K, ISIJ Int. 46 (2006) 420.

Ohta H, and Suito H, Metall. Mater. Trans. B 29 (1998) 119.

Shi C, Yang X, Jiao J, Li C, and Guo H, ISIJ Int. 50 (2010) 1362.

Wang Z, Cai S, Zhang M, Guo M, and Zhang Z, Metall. Mater. Trans. B 48 (2017) 1139.

Zhang G, Chou K, and Mills K, ISIJ Int. 52 (2012) 355.

Wang Z, and Sohn I, J. Am. Ceram. Soc. 101 (2018) 4285.

George N C, Denault K A, and Seshadri R, Annu. Rev. Mater. Res. 43 (2013) 481.

Lejus A M, and Pelletier N, Opt. Mater. 6 (1996) 129.

Yao L, Ren S, Wang X, Liu Q, Dong L, Yang J, and Liu J, Steel Res. Int. 87 (2016) 241.

Kim H, Matsuura H, Tsukihashi F, Wang W, Min D J, and Sohn I, Metall. Mater. Trans. B 44 (2013) 5.

Wang W, Gao E, Zhou L, Zhang L, and Li H, J. Iron Steel Res. Int. 26 (2019) 355.

Sohn I, Wang W L, Matsuura H, Tsukihashi F, and Min D J, ISIJ Int. 52 (2012) 158.

Gao J, Wen G, Huang T, Tang P, Liu Q, and Non-Cryst J, Solids 435 (2016) 33.

Zheng K, Zhang Z, Liu L, and Wang X, Metall. Mater. Trans. B 45 (2014) 1389.

Yan Z, Lv X, Zhang J, Qin Y, and Bai C, Can. Metall. Q. 55 (2016) 186.

Feng C, Chu M, Tang J, Tang Y, and Liu Z, Steel Res. Int. 87 (2016) 1274.

Gao Y, Wang S, Hong C, Ma X, and Yang F, Int. J. Min. Metall. Mater. 21 (2014) 353.

Wang Z, Sun Y, Seetharaman S, Zhang M, and Zhang Z, Metall. Mater. Trans. B 48 (2017) 527.

Feng C, Tang J, Gao L, Liu Z, and Chu M, ISIJ Int. 59 (2019) 31.

Kim H, Kim W H, Sohn I, and Min D J, Steel Res. Int. 81 (2010) 261.

Kim G H, and Sohn I, Metall. Mater. Trans. B 45 (2014) 86.

Huang C, Behrman E, and Non-Cryst J, Solids 128 (1991) 310.

Mysen B O, Finger L W, Virgo D, and Seifert F A, Am. Mineral. 67 (1982) 686.

Park J H, Met. Mater. Int. 19 (2013) 577.

Acknowledgements

The authors sincerely thank the National Natural Science Foundation of China (Grant No. 52104295, the Young Elite Scientists Sponsorship Program by CAST (Grant No. 2021–2023QNRC001), the Fundamental Research Fund for Central Universities (Grant No. N2325020) and the Joint Funds of Natural Science Foundation of Liaoning Province (2023-MSBA-110).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, J., Cao, S. & Wang, Z. Elucidating the Crystallization Behavior of CaO–SiO2–MgO–Al2O3 Slags Towards the Smooth Operation of Blast Furnace. Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-024-03343-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-024-03343-7