Abstract

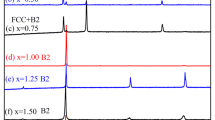

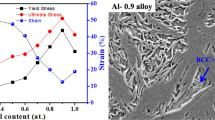

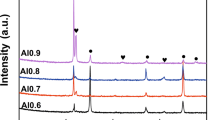

The phase constituents of AlxNi2−xCoCrFe (x = 0.25−1.75) alloys were thermodynamically calculated and experimentally investigated. The experimental results indicate that when 0.5 ≤ x < 1.0, the as-cast AlxNi2−xCoCrFe alloys consist of fcc + B2 phase, with the volume fraction of fcc phase decreasing as the Al content increases. When x ≥ 1.0, the as-cast alloys contain only the B2 phase. After 1000 °C annealing, large bcc blocks precipitate in the alloy Al1.25Cr0.75CoFeNi, with an increase Al content in the B2 phase. After 800 °C annealing, very fine B2 and or σ particles precipitated from the as-cast fcc phase when 0.5 ≤ x < 1.0, and Al-poor bcc phase precipitated from the as-cast B2 phase. Moreover, the hardness of the as-cast or 800 °C annealed AlxNi2−xCoCrFe alloys increased linearly with increasing Al content.

Similar content being viewed by others

References

Zhang G J, Tian Q W, Yin K X, Niu S Q, and Huang J C, Intermetallics 119 (2020) 106722. https://doi.org/10.1016/j.intermet.2020.106722

Meghwal A, Anupam A, and Luzin V, J Alloy Compd 854 (2021) 157140. https://doi.org/10.1016/j.jallcom.2020.157140

Wei Z, Wu Y, Hong S, Cheng J, and Zhu S, Surf Coat Tech 409 (2021) 126899. https://doi.org/10.1016/j.surfcoat.2021.126899

Wang W R, Wang W L, Wang S C, Tsai Y C, and Yeh J W, Intermetallics 26 (2012) 44. https://doi.org/10.1016/j.intermet.2012.03.005

Yen C C, Lu H N, Tsai M H, and Yen S K, Corros Sci 157 (2019) 462. https://doi.org/10.1016/j.corsci.2019.06.024

Chuang M H, Tsai M H, Wang W R, Lin S J, and Yeh J W, Acta Mater 59 (2011) 6308. https://doi.org/10.1016/j.actamat.2011.06.041

Chen Y, Ji Z, Hu M, Xu H, and Feng G, J Mater Res 112 (2021) 538. https://doi.org/10.1515/ijmr-2020-7953

Linden Y, Pinkas M, Munitz A, and Meshi L, Scr Mater 139 (2017) 49. https://doi.org/10.1016/j.scriptamat.2017.06.015

Meshi L, Linden Y, Munitz A, Salhov S, and Pinkas M, Mater Charact 148 (2019) 171. https://doi.org/10.1016/j.matchar.2018.12.010

Strumza E, and Hayun S, J Alloy Compd 856 (2021) 158220. https://doi.org/10.1016/j.jallcom.2020.158220

Lee K S, Kang J H, Lim K R, and Na Y S, Mater Charact 132 (2017) 162. https://doi.org/10.1016/j.matchar.2017.08.010

Zhou P F, Xiao D H, Wu Z, and Song M, Mater Res Express 6 (2019) 0865e7 https://doi.org/10.1088/2053-1591/ab2517

Wang Y P, Li B S, Ren M X, Yang C, and Fu H Z, Mater Sci Eng A 491 (2008) 154. https://doi.org/10.1016/j.msea.2008.01.064

Munitz A, Salhov S, Hayun S, and Frage N, J Alloy Compd 683 (2016) 221. https://doi.org/10.1016/j.jallcom.2016.05.034

Shivam V, Basu J, Pandey V K, Shadangi Y, and Mukhopadhyay N K, Adv Eng Mater 29 (2018) 2221. https://doi.org/10.1016/j.apt.2018.06.006

Shivam V, Sanjana V, and Mukhopadhyay N K, Trans Indian Inst Metal (2020). https://doi.org/10.1007/s12666-020-01892-1

Pradhan P, Shadangi Y, Shivam V, and Mukhopadhyay N K, J Alloy Compd 35 (2023) 168002. https://doi.org/10.1016/j.jallcom.2022.168002

Shivam V, Shadangi Y, Basu J, and Mukhopadhyay N K, J Alloy Compd 832 (2020) 154826. https://doi.org/10.1016/j.jallcom.2020.154826

Sourav A, Yebaji S, and Thangaraju S, Mater Sci Eng A 793 (2020) 139877. https://doi.org/10.1016/j.msea.2020.139877

Joseph J, Haghdadi N, Shamlaye K, Hodgson P, and Fabijanic D, Wear 428 (2019) 32. https://doi.org/10.1016/j.wear.2019.03.002

Rao J C, Diao H Y, Ocelík V, and De Hosson J T M, Acta Mater 131 (2017) 206. https://doi.org/10.1016/j.actamat.2017.03.066

Wang W-R, Wang W-L, and Yeh J-W, J Alloy Compd 589 (2014) 143. https://doi.org/10.1016/j.jallcom.2013.11.084

Huang L, Sun Y, Amar A, Wu C, and Li J, Vacuum 183 (2021) 109875. https://doi.org/10.1016/j.vacuum.2020.109875

Garlapati M M, Vaidya M, Karati A, Mishra S, and Murty B S, Adv Powder Technol 31 (2020) 1985. https://doi.org/10.1016/j.apt.2020.02.032

Shi Y, Mo J, Zhang F Y, Yang B, and Zhao Y, J Alloy Compd 844 (2020) 156014. https://doi.org/10.1016/j.jallcom.2020.156014

Shi Y, Collins L, Feng R, Zhang C, and Yang B, Corros Sci 133 (2018) 131. https://doi.org/10.1016/j.corsci.2018.01.030

Yang Y, Luo X, Ma T, Wen L, and Hu M, J Alloy Compd 864 (2021) 158717. https://doi.org/10.1016/j.jallcom.2021.158717

Yang Y C, Liu C, Lin C Y, and Xia Z, Scr Mater 178 (2020) 181. https://doi.org/10.1016/j.scriptamat.2019.11.016

Yang T, Xia S, Liu S, Wang C, and Wang Y, Mater Sci Eng A 648 (2015) 22. https://doi.org/10.1016/j.msea.2015.09.034

Qiu J, Xiao G, Jin T, Su B, and Ma S, Adv Mater Sci Eng 21 (2019) 1800744. https://doi.org/10.1002/adem.201800744

Muskeri S, Choudhuri D, Jannotti P A, Schuster B E, and Mukherjee S, Adv Mater Sci Eng 22 (2020) 2000124. https://doi.org/10.1002/adem.202000124

Li J, Yang H, Wang W Y, Kou H, and Wang J, Front Mater (2021). https://doi.org/10.3389/fmats.2020.585602

Kuczyk M, Kotte L, Kaspar J, Zimmermann M, and Leyens C, Front Mater (2020). https://doi.org/10.3389/fmats.2020.00242

John R, Karati A, Garlapati M M, Vaidya M, and Murty B S, J Mater Sci 54 (2019) 14588. https://doi.org/10.1007/s10853-019-03917-7

Hou J, Wang Z, Shi X, Wang Z, and Wu Y, J Mater Sci 55 (2020) 7894. https://doi.org/10.1007/s10853-020-04550-5

Wang X, Zhang Z, Wang Z, and Ren X, Mater 15 (2022) 1215.

Chen Q, Zhou K, Jiang L, Lu Y, and Li T, Arab J Sci Eng 40 (2015) 3657. https://doi.org/10.1007/s13369-015-1784-9

Mayahi R, J Alloy Compd 818 (2020) 152928. https://doi.org/10.1016/j.jallcom.2019.152928

Kaya F, Yetiş M, Selimoğlu G İ, and Derin B, Eng Sci Technol (2021). https://doi.org/10.1016/j.jestch.2021.05.007

Kang M, Lim K R, Won J W, and Na Y S, J Alloy Compd 769 (2018) 808. https://doi.org/10.1016/j.jallcom.2018.07.346

Ma L, Wang J, and Jin P, Mater Res Express 7 (2020) 016566. https://doi.org/10.1088/2053-1591/ab6580

Zhang L, and Zhang Y, Front Mater 7 (2020) 92. https://doi.org/10.3389/fmats.2020.00092

Qin G, Xue W, Fan C, Chen R, and Guo J, Mater Sci Eng A 710 (2018) 205. https://doi.org/10.1016/j.msea.2017.10.088

Li C, Li J C, Zhao M, and Jiang Q, J Alloy Compd 504 (2010) S515. https://doi.org/10.1016/j.jallcom.2010.03.111

Ma Y, Hao J, Wang Q, Zhang C, and Dong C, J Mater Sci 54 (2019) 8696. https://doi.org/10.1007/s10853-019-03459-y

Shadangi Y, Chattopadhyay K, and Mukhopadhyay N K, J Mater Res 38 (2023) 248. https://doi.org/10.1557/s43578-022-00866-x

Jain H, Shadangi Y, Chakravarty D, Dubey A K, and Mukhopadhyay N K, Mater Sci Eng A 856 (2022) 144029. https://doi.org/10.1016/j.msea.2022.144029

Lu Y, Dong Y, Guo S, Jiang L, and Li T, Sci Rep 4 (2014) 6200. https://doi.org/10.1038/srep06200

Wang L, Yao C, Shen J, Zhang Y, and Zhang G, Intermetallics 118 (2020) 106681. https://doi.org/10.1016/j.intermet.2019.106681

Gao X, Lu Y, Zhang B, Liang N, and Zhao Y, Acta Mater 141 (2017) 59. https://doi.org/10.1016/j.actamat.2017.07.041

Wani I S, Bhattacharjee T, Sheikh S, Bhattacharjee P P, and Tsuji N, Mater Sci Eng A 675 (2016) 99. https://doi.org/10.1016/j.msea.2016.08.048

Tang Z, Senkov O N, Parish C M, Zhang C, and Liaw P K, Mater Sci Eng A 647 (2015) 240. https://doi.org/10.1016/j.msea.2015.08.078

Muthupandi G, Lim K R, Na Y S, Park J, and Choi Y S, Sci Eng A 696 (2017) 154. https://doi.org/10.1016/j.msea.2017.04.045

Lim K R, Lee K S, Lee J S, Kim J Y, and Na Y S, J Alloy Compd 728 (2017) 1238. https://doi.org/10.1016/j.jallcom.2017.09.089

Zhang C, Zhang F, Diao H, Gao M C, and Liaw P K, Mater Des 109 (2016) 425. https://doi.org/10.1016/j.matdes.2016.07.073

Borkar T, Chaudhary V, Gwalani B, Choudhuri D, and Banerjee R, Adv Eng Mater 19 (2017) 1700048. https://doi.org/10.1002/adem.201700048

Sun Y, Wu C, Peng H, Liu Y, and Su X, J Phase Equilib Diff 40 (2019) 714. https://doi.org/10.1007/s11669-019-00761-9

Xiong W, Wu C J, Liu Y, Tu H P, and Su X P, J Phase Equilib Diff 42 (2021) 388. https://doi.org/10.1007/s11669-021-00890-0

Wang S, Zhao Y, Cheng P, Guo Q, and Hou H, Mater Res Express 6 (2020) 1265e2. https://doi.org/10.1088/2053-1591/ab3d86

Wu C, Wei X, Zhou C, Liu Y, and Su X, J Changzhou university (Natural Sci Edition) 33 (2021) 1.

Laplanche G, Berglund S, Reinhart C, Kostka A, Fox F, and George E P, Acta Mater 161 (2018) 338. https://doi.org/10.1016/j.actamat.2018.09.040

Zhu Z G, Ma K H, Yang X, and Shek C H, J Alloy Compd 695 (2017) 2945. https://doi.org/10.1016/j.jallcom.2016.11.376

Yamamoto Y, Brady M P, Santella M L, Bei H, and Pint B A, Mater Trans A 42 (2011) 931. https://doi.org/10.1007/s11661-010-0295-2

Shadangi Y, Shivam V, Chattopadhyay K, and Mukhopadhyay N K, J Manuf Mater Process 6 (2022) 60. https://doi.org/10.3390/jmmp6030060

Funding

The authors gratefully acknowledge the financial support from National Natural Science Foundation of China (Nos. 51971039 and 52271005) and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Contributions

All the authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest regarding this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, C., Ding, Z., Peng, H. et al. Microstructure Evolution and Microhardness of AlxNi2−xCoCrFe Alloys After Long-Time Annealing. Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-024-03311-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-024-03311-1