Abstract

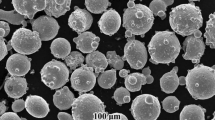

In this current work, 06Cr15Ni4CuMo steel fabricated using selective laser melting (SLM) in additive manufacturing, studied the tribological properties by dry wear test, and then, the results were compared with wrought SS410 martensitic stainless steel tested under similar conditions. The wear test was accomplished at three different loads 10, 20, and 30N at constant speed and time to quantify the wear volume and the values obtained were higher for the increased load to 30N. The wear loss and the wear rate at the load of 30N were found to be 3.42 mm3 and 0.0073 mm3/m for the 06Cr15Ni4CuMo sample and 0.65 mm3 and 0.00069 mm3/m for the SS410 sample. The wear mechanism was observed to be abrasive and ploughing through scanning electron microscopy. Topographic analysis in three dimensions was carried out by using the white light interferometer.

Similar content being viewed by others

Data Availability

Data may be shared by first author upon reasonable request.

References

Qin H, Xu R, Lan P, Wang J, and Lu W, Metals. 10 (2020) 304. https://doi.org/10.3390/met10030304

Zhu Y, Zou J, and Yang H-Y, Appl Phys & Eng 19 (2018) 95. https://doi.org/10.1631/jzus.A1700328

Sander J, Hufenbach J, Giebeler L, Bleckmann M, Eckert J, and Kühn U, Scripta Materialia. 126 (2017) 41. https://doi.org/10.1016/j.scriptamat.2016.07.029

Sun Y, and Moroz A, J Mater Eng Perform 23 (2014) 518. https://doi.org/10.1007/s11665-013-0784-8

Upadhyay R K, Wear. 458 (2020) 203437. https://doi.org/10.1016/j.wear.2020.203437

Kong D, Dong C, Ni X, and Li X, NPJ Mater Degrad 3 (2019) 34.

Vignal V, Voltz C, Thiébaut S, Demésy M, Heintz O, and Guerraz S, J Mater Eng Perform 30 (2021) 5050.

Yap C Y, Chua C, Dong Z, Liu Z, Zhang D, Loh L E, and Sing S L, Appl Phy Rev. 2 (2015) 041101.

Li C, Fu C H, Guo Y B, and Fang F Z, Proc Manuf 1 (2015) 355. https://doi.org/10.1016/j.promfg.2015.09.042

Krishna Pradeep G V, J Mater Eng Perform 31 (2022) 1009. https://doi.org/10.1007/s11665-021-06278-y

Fayazfar H, Salarian M, Rogalsky A, Sarker D, Russo P, Paserin V, and Toyserkani E, Microstruct Mech Prop Mater Des 144 (2018) 98.

Dalmau A, Rmili W, Joly D, and Igual-Muñoz A, Tribol Lett 56 (2014) 517. https://doi.org/10.1007/s11249-014-0429-6

Nayebi B, Najafi H, and Farnia A, J. Mech. Sci. Technol. 35 (2021) 1–8. https://doi.org/10.1007/s12206-021-0912-6

Krishna Pradeep G V, Duraiselvam M, Prasad K S, and Mohammad A, Trans Indian Inst Met (2020). https://doi.org/10.1007/s12666-020-01950-8

Rajan R K, Kumar H, Albert S K, and Vijayaram T R, Appl. Mech. Mater. 2 (2014) 20.

Dalmau A, Richard C, and Igual-Muñoz A, Tribol. Int. 121 (2018) 167–179. https://doi.org/10.1016/j.tribont.2018.01.036

Prabakaran V, Sivakumaran I, and Palimar S P, Appl Phys A 122 (2016) 468. https://doi.org/10.1007/s00339-016-9980-3

Rodríguez-Bravoa G A, Vite-Torresa M, and Godínez-Salcedo J G, Tribol Ind 3 (2019) 394. https://doi.org/10.24874/ti.2019.41.03.09

Vijayasarathi P, Suresh Prabhu P, and Rajaram G, World Engg Appl Sci J 7 (2), (2016) 85. https://doi.org/10.5829/idosi.weasj.2016.7.2.22602

Zhao Y, Meng W, Wang P, Chuanbin D, and Wang X, Materials 15 () 3234. https://doi.org/10.3390/ma15093234

Vivek Gaurav K, and Sankaranarayanan S R, J Mater Eng Perform (2021). https://doi.org/10.1007/s11665-021-06304-z

Maya J, Sivaprasad K, Kumar G V S, Baitimerov R, Lykov P, and Prashanth K G, Metals 12 (2022) 1303. https://doi.org/10.3390/met12081303

Author information

Authors and Affiliations

Contributions

KSP contributed to Conceptualization, Supervising, Analyzes, Verification, Paper correction, Funding acquirement. JM contributed to Formulation, Methodology, Investigation, Drafting. BRS contributed to Supervising, Analyzes, Verification, Paper correction. KGP contributed to Analyzes, Verification, Paper correction and Funding acquirement. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maya, J., Sivaprasad, K., Ravisankar, B. et al. Wear Behavior of Selective Laser Melted 06Cr15Ni4CuMo Steel. Trans Indian Inst Met (2024). https://doi.org/10.1007/s12666-023-03216-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-023-03216-5