Abstract

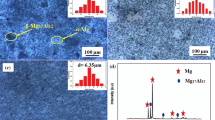

The purpose of this study is to investigate the changes in the microstructure of 5083-H116 alloys under different annealing temperatures and sensitization treatments. The properties of both annealed and sensitized samples were analyzed using various techniques, including tensile testing, scanning electron microscopy, and optical microscopy. The susceptibility of the alloy to intergranular corrosion (IGC) and stress corrosion cracking (SCC) was evaluated using the nitric acid mass loss test (ASTM G67 NAMLT) and the slow strain rate test, respectively. The results indicate that annealing temperatures below 200 °C and above 300 °C resulted in high susceptibility to IGC and SCC due to the continuous precipitation of β-phase (Mg2Al3) along the grain boundaries. In contrast, annealing in the temperature range of 200–250 °C led to the formation of discontinuous β-phase precipitates at the grain boundaries, resulting in high resistance to IGC and SCC.

Similar content being viewed by others

References

Golumbfskie W J, Tran K T, Noland J M, Park R, Stiles D J, Grogan G, and Wong C, Corrosion 72 (2016) 314. https://doi.org/10.5006/1916

Wahid M A, Siddiquee A N, and Khan Z A, Mar Syst Ocean Technol 15 (2019) 70. https://doi.org/10.1007/s40868-019-00069-w

Zhang R, Knight S P, Holtz R L, Goswami R, Davies C H J, and Birbilis N, Corrosion 72 (2016) 144. https://doi.org/10.5006/1787

Crane C B, and Gangloff R P, Corrosion 72 (2016) 221. https://doi.org/10.5006/1766

Goswami R, Spanos G, Pao P S, and Holtz R L, Mater Sci Eng A 527 (2010) 1089. https://doi.org/10.1016/j.msea.2009.10.007

Chen R Y, Chu H Y, Lai C C, and Wu C-T, Proc Inst Mech Eng Part L J Mater Des Appl 229 (2015) 339. https://doi.org/10.1177/1464420713512249

Seifi M, Ghamarian I, Samimi P, Collins P C, Holroyd N J H, and Lewandowski J J, Corros Sci 138 (2018) 219. https://doi.org/10.1016/j.corsci.2018.03.027

Schrock D J, and Locke J S, Corrosion 76 (2020) 63. https://doi.org/10.5006/3366

Mills R J, Lattimer B Y, Case S W, and Mouritz A P, Corros Sci 143 (2018) 1. https://doi.org/10.1016/j.corsci.2018.07.036

Seifi M, Holroyd N H, and Lewandowski J J, Corrosion 72 (2016) 264. https://doi.org/10.5006/1949

Li Z, Yi D, Tan C, and Wang B, J Alloys Compd 817 (2020) 152690. https://doi.org/10.1016/j.jallcom.2019.152690

McMahon M E, Haines R L, Steiner P J, Schulte J M, Fakler S E, and Burns J T, Corros Sci 169 (2020) 108618. https://doi.org/10.1016/j.corsci.2020.108618

Gao J, and Quesnel D J, Metall Mater Trans A 42 (2011) 356. https://doi.org/10.1007/s11661-010-0375-3

Searles J L, Gouma P I, and Buchheit R G, Metall Mater Trans A 32 (2001) 2859. https://doi.org/10.1007/s11661-001-1036-3

Goswami R, Spanos G, Pao P S, and Holtz R L, Metall Mater Trans A 42 (2011) 348. https://doi.org/10.1007/s11661-010-0262-y

Xue D, Wei W, Shi W, Zhou X R, Qi J T, Wen S P, Wu X L, Gao K Y, Xiong X Y, and Huang H, Mater Today Commun 35 (2023) 106177. https://doi.org/10.1016/j.mtcomm.2023.106177

Guo C, Chen Y, Zhang H, Ji H, Wu Z, Liu X, and Nagaumi H, J Alloys Compd 939 (2023) 168770. https://doi.org/10.1016/j.jallcom.2022.163714

ASTM B928/B928M-09, Standard Specification for High Magnesium Aluminium-Alloy Sheet and Plate for Marine Service, ASTM International, West Conshohocken (2009).

Oguocha I N A, Adigun O J, and Yannacopoulos S, J Mater Sci 43 (2008) 4208. https://doi.org/10.1007/s10853-008-2606-1

Holtz R L, Pao P S, Bayles R A, Longazel T M, and Goswami R, Metall Mater Trans A 43 (2012) 2839. https://doi.org/10.1007/s11661-011-0866-x

American Society for Testing, Materials, Standard Test Method for Determining the Susceptibility to Intergranular Corrosion of 5XXX Series Aluminum Alloys by Mass Loss After Exposure to Nitric Acid (NAMLT Test), ASTM International (2004).

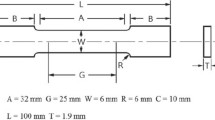

ASTM, 557-Standard Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products (2010).

ASTM, ASTM G129- Standard Practice for Slow Strain Rate Testing to Evaluate the Susceptibility of Metallic Materials to Environmentally Assisted Cracking (2004).

Popovic M, and Romhanji E, J Mater Process Technol 125–126 (2002) 275. https://doi.org/10.1016/S0924-0136(02)00398-9

Yen C H, Wu C T, Chen Y H, and Lee S L, J Mater Res 31 (2016) 1163. https://doi.org/10.1557/jmr.2016.120

ASTM, E112-Standard Test Methods for Determining Average Grain Size (2012).

McMahon M E, Steiner P J, Lass A B, and Burns J T, Corrosion 73 (2017) 347. https://doi.org/10.5006/2317

Jin Q I N, and Zhi L I, YI D, and Bin W. Trans Nonferrous Met Soc China 32 (2022) 765. https://doi.org/10.1016/S1003-6326(22)65831-X

Tan L, and Allen T R, Corros Sci 52 (2010) 548. https://doi.org/10.1016/j.corsci.2009.10.013

Yukawa H, Murata Y, Morinaga M, Takahashi Y, and Yoshida H, Acta Metall Mater 43 (1995) 681. https://doi.org/10.1016/0956-7151(94)00266-K

Popović M, and Romhanji E, Mater Sci Eng A 492 (2008) 460. https://doi.org/10.1016/j.msea.2008.04.001

Gao W, Gu Y, Chen L, Liang H, Wang D, Seifi M, and Lewandowski J J, J Mater Res Technol 25 (2023) 681. https://doi.org/10.1016/j.jmrt.2023.05.255

Xu W, Xin Y C, Zhang B, and Li X Y, Acta Mater 225 (2022) 117607. https://doi.org/10.1016/j.vacuum.2020.109299

Acknowledgements

The authors would like to extend their thanks to the National Science and Technology Council of the Republic of China under Grant no. NSTC 112-2221-E-992-088. The advice and financial support of NSTC are greatly acknowledged.

Funding

This work was funded by Ministry of Science and Technology, Taiwan (Grant No. NSTC 112-2221-E-992-088).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hwang, YM., Lu, CY. & Chen, RY. Influence of Microstructural Changes on Intergranular Corrosion and Stress Corrosion Cracking of 5083-H116 Alloys. Trans Indian Inst Met 77, 667–676 (2024). https://doi.org/10.1007/s12666-023-03157-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03157-z