Abstract

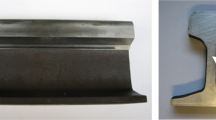

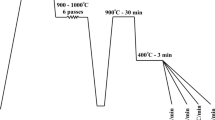

Carbide-free bainitic steels are known for their very high strength because of their fine nanoscale hard bainitic ferrite and inter-layer ductile retained austenite. The mechanical properties of these steels are influenced by the size, fraction, and morphology of constituent bainite and retained austenite phases. Prior austenite microstructure plays an important role in determining the morphology and volume fraction of bainite and retained austenite resulting from the austempering treatment. In the present study, mechanical properties of two high-carbon, high-silicon, carbide-free bainitic steels with and without niobium addition austenitized at three different temperatures (900 °C, 970 °C, and 1050 °C) and austempered at 300 °C for 12 h are reported. Both the steels show a decrease in total elongation and Charpy V-notch impact toughness with increasing austenitization temperature. Niobium addition significantly refines the prior austenitic grain size at any given austenitization temperature, which improves total elongation and Charpy V-notch impact toughness.

Similar content being viewed by others

References

Bhadeshia H K D H, Mater Sci Forum 500 (2005) 63.

Caballero F G, Bhadeshia H K D H, Mawella K J A, Jones D G, and Brown P, Mater Sci Technol 18 (2002) 279. https://doi.org/10.1179/026708301225000725

Bhadeshia H K D H, Proc R Soc A Math Phys Eng Sci 466 (2010) 3.

Peet M J, Fielding L C D, Hamedany A A, Rawson M, Hill P, and Bhadeshia H K D H, Mater Sci Technol 33 (2017) 1171. https://doi.org/10.1080/02670836.2016.1271522

Tsai Y T, Chang H T, Huang B M, Huang C Y, and Yang J R, Mater Charact 107 (2015) 63. https://doi.org/10.1016/j.matchar.2015.06.037

Wu B B, Wang X L, Wang Z Q, Zhao J X, Jin Y H, Wang C S, Shang C J, and Misra R D, Mater Sci Eng A 745 (2019) 126.

Zhang C, Wang Q, Ren J, Li R, Wang M, Zhang F, and Sun K, Mater Sci Eng A 534 (2012) 339.

Chunfang W, Maoqiu W, Jie S H I, Weijun H U I, and Han D, J Mater Sci Technol 23 (2007) 659.

Gwon H, Kim J-K, Shin S, Cho L, and De Cooman B C, Mater Sci Eng A 696 (2017) 416.

Shams N, Mater Sci Technol 1 (1985) 950.

Hu F, Hodgson P D, and Wu K M, Mater Lett 122 (2014) 240.

Zhao J, Li J, Ji H, and Wang T, Materials 10 (2017) 874.

Chhajed B, Mishra K, Singh K, and Singh A, Mater Charact 192 (2022) 112214. https://doi.org/10.1016/J.MATCHAR.2022.112214

de Andrés C G, Caballero F G, Capdevila C, and San Martın D, Mater Charact 49 (2002) 121.

De Andres C G, Bartolomé M J, Capdevila C, San Martın D, Caballero F G, and López V, Mater Charact 46 (2001) 389.

Ogino Y, Tanida H, Kitaura M, and Adachi A, Tetsu-to-Hagané 57 (1971) 533.

Speer J G, and Hansen S S, Metall Trans A 20 (1989) 25. https://doi.org/10.1007/BF02647491

Garcia-Mateo C, Caballero F G, Miller M K, and Jiménez J A, J Mater Sci 47 (2012) 1004.

Singh S B, and Bhadeshia H K D H, Mater Sci Eng A 245 (1998) 72. https://doi.org/10.1016/S0921-5093(97)00701-6

Wang Z, Wu Q, Zhou W, He F, Yu C, Lin D, Wang J, and Liu C T, Scr Mater 162 (2019) 468. https://doi.org/10.1016/j.scriptamat.2018.12.022

Lee S J, and Lee Y K, Scr Mater 52 (2005) 973. https://doi.org/10.1016/j.scriptamat.2005.01.028

Peet M, and Bhadeshia H K D, Phase Transformations and Complex Properties Group, Department of Materials Science and Metallurgy, University of Cambridge, Cambridge, UK.

Peet M, Babu S S, Miller M K, and Bhadeshia H, Scr Mater 50 (2004) 1277.

Caballero F G, Garcia-Mateo C, Santofimia M J, Miller M K, and García de Andrés C, Acta Mater 57 (2009) 8. https://doi.org/10.1016/j.actamat.2008.08.041

Yang H S, and Bhadeshia H K D H, Scr Mater 60 (2009) 493. https://doi.org/10.1016/j.scriptamat.2008.11.043

Van Der Zwaag S, Zhao L, Kruijver S O, and Sietsma J, ISIJ Int 42 (2002) 1565.

Garcia-Mateo C, Caballero F G, Chao J, Capdevila C, and Garcia De Andres C, J Mater Sci 44 (2009) 4617. https://doi.org/10.1007/s10853-009-3704-4

Xiong X C, Chen B, Huang M X, Wang J F, and Wang L, Scr Mater 68 (2013) 321. https://doi.org/10.1016/j.scriptamat.2012.11.003

Ryu J H, Kim D I, Kim H S, Bhadeshia H K D H, and Suh D W, Scr Mater 63 (2010) 297. https://doi.org/10.1016/j.scriptamat.2010.04.020

Li X, Lu G, Wang Q, Zhao J, Xie Z, Misra R D K, and Shang C, Metals 12 (2021) 28.

Lan H F, Du L X, Li Q, Qiu C L, Li J P, and Misra R D K, J Alloys Compd 710 (2017) 702.

Acknowledgements

The authors would like to thank Director, DMRL for granting permission to publish this paper. The authors wish to thank DRDO for funding this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest with any third party with respect to the content of this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Senthil, P.P., Singh, E., Sukumar, G. et al. Influence of Austenitization Temperature on Tensile Properties and Impact Toughness of Niobium Micro-alloyed Carbide-Free Bainitic Steel. Trans Indian Inst Met 77, 543–552 (2024). https://doi.org/10.1007/s12666-023-03115-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03115-9