Abstract

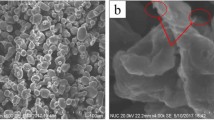

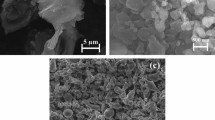

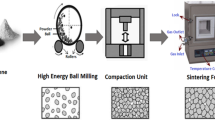

The present work investigates the tribological properties and microstructures of tungsten carbide (WC: 0–30 wt%) and few-layer graphene (FLG: 0.1–0.5 wt%)-reinforced aluminum matrix composites fabricated via the powder metallurgy route. The tribological and mechanical behavior of the produced samples were investigated by the pin-on-disk wear testing machine, micro-Vickers hardness test unit, and compressive test machine. Based on the test results, Al-30 wt%WC-0.3 wt% FLG composite exhibited maximum density (3.35 ± 0.01 g/cm3), hardness (98 ± 1.5 HV), compressive strength (189 ± 4 MPa), and lowest mass loss (0.9 mg), wear rate (1.1 × 10–4 mm3/(Nm)), coefficient of friction (0.14). Compared to pure aluminum, the hardness, compressive strength, wear rate, and friction coefficient of Al-30%WC-0.3%FLG was improved by ~ 250%, ~ 77%, 428%, and ~ 77%, respectively. After 0.3 wt% FLG content, the tribological and mechanical properties were decreased due to the agglomerated graphene nanoplatelets from the scanning electron microscope image of the Al-30%WC-0.5%FLG composite.

Similar content being viewed by others

References

Han W H, Li P, Liu N, Chen C G, Dong S P, Guo Z M, Yang F, Sui Y L, and Volinsky A A, J Cent South Univ 29 (2022) 871. https://doi.org/10.1007/s11771-022-4962-4

Kumar P S, Sachit T S, Mohan N, and Akshay P M, Mater Today Proc 44 (2021) 566. https://doi.org/10.1016/j.matpr.2020.10.351

Chak V, Chattopadhyay H, and Dora T L, Mater Manuf Process 36 (2021) 1219. https://doi.org/10.1080/10426914.2021.1914845

Ravikumar K, Kiran K, and Sreebalaji V S, Measurement 102 (2017) 142. https://doi.org/10.1016/j.measurement.2017.01.045

Rajesh D, Anand P, Lenin N, Raja V K B, Palanikumar K, and Balaji V, Mater Today Proc 46 (2021) 3618. https://doi.org/10.1016/j.matpr.2021.01.634

Patel S K, Singh V P, Kumar D, Roy B S, and Kuriachen B, Mater Sci Eng B 276 (2022) 1. https://doi.org/10.1016/j.mseb.2021.115476

Kalaiyarasan A, Sundaram S, Gunesekaran K, and Bensam R, Ind Lub Tribol 73 (2021) 980. https://doi.org/10.1108/ILT-05-2021-0191

Han T, Li J, Zhao N, and He C, Carbon 159 (2020) 311. https://doi.org/10.1016/j.carbon.2019.12.029

Shao P, Chen G, Ju B, Yang W, Zhang Q, Wang Z, Tan X, Pei Y, Zhong S, and Hussain M, Carbon 162 (2020) 455. https://doi.org/10.1016/j.carbon.2020.02.080

Xu Z Y, Li C J, Wang Z, Fang D, Gao P, Tao J M, Yi J H, and Eckert J, Mater Sci Eng A 796 (2020) 1. https://doi.org/10.1016/j.msea.2020.140067

Zhang C, Yin J, Yao D, Zuo K, Xia Y, Liang H, and Zeng Y, Compos Part A Appl Sci Manuf 102 (2017) 145. https://doi.org/10.1016/j.compositesa.2017.07.025

Şenel M C, and Gürbüz M, Duzce J Sci Technol 8 (2020) 1864. https://doi.org/10.29130/dubited.683876

Şenel M C, and Üstün M, Arab J Sci Eng 47 (2022) 9253. https://doi.org/10.1007/s13369-022-06661-4

Sagadevan S, Das I, Singh P, and Podder J, J Mater Sci Mater El 28 (2017) 1136. https://doi.org/10.1007/s10854-016-5638-3

Azar H M, Sadri B, Nemati A, Angizi S, Shaeri M H, Minarik P, Vesely J, and Djavanroodi F, Nanomaterials 9 (2019) 1. https://doi.org/10.3390/nano9081070

Şenel M C, and Gürbüz M, B Mater Sci 43 (2020) 1. https://doi.org/10.1007/s12034-020-02124-4

Tabandeh-Khorshid M, Kumar A, Omrani E, Kim C, and Rohatgi P, Compos Part B Eng 183 (2020) 1. https://doi.org/10.1016/j.compositesb.2019.107664

Palei B B, Dash T, and Biswal S K, J Mater Sci 57 (2022) 8544. https://doi.org/10.1007/s10853-022-07043-9

Ahmad S I, Hamoudi H, Abdala A, Ghouri Z K, and Youssef K M, Rev Adv Mater Sci 59 (2020) 67. https://doi.org/10.1515/rams-2020-0007

Kumar H G P, and Xavior M A, T Indian I Metals 69 (2016) 415. https://doi.org/10.1007/s12666-015-0780-9

Şenel M C, and Üstün M, J Mater Eng Perform 32 (2023) 1248. https://doi.org/10.1007/s11665-022-07194-5

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Taşkin, A., Şenel, M.C. Tribological Properties and Microstructures of Tungsten Carbide and Few-Layer Graphene-Reinforced Aluminum-Based Composites. Trans Indian Inst Met 77, 445–456 (2024). https://doi.org/10.1007/s12666-023-03114-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03114-w