Abstract

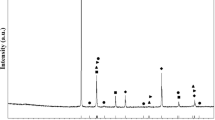

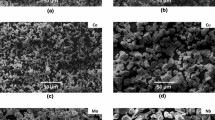

FeCoNi medium entropy alloy was mechanically alloyed at two angular velocities, i.e., 500 and 300 rpm, utilizing a high-energy planetary ball mill. The energy transfer criteria, phase, and microstructural evolution during the milling mechanism were described and analyzed by kinematics, X-ray diffraction, scanning electron microscope, and transmission electron microscopy. The results revealed that the total energy transferred during mechanical alloying was near ~ 4.635 times greater than FeCoNi-300 rpm. However, the structural analysis showed the γ-FCC phase in the case of FeCoNi-500 rpm and α-BCC + γ-FCC phases in case of FeCoNi-300 rpm. The magnetic properties were studied at 300 K and presented an excellent soft magnetic behavior with saturation magnetization of 124.86 emu/g and coercivity of 15.39 Oe in the case of FeCoNi-500 rpm. Furthermore, temperature-dependent magnetization measurements were also carried out and fitted with the modified Bloch model and Bloch and Curie–Weiss law-modified model. The results revealed that there is the existence of a significant ferromagnetic phase in the case of FeCoNi-300 rpm.

Similar content being viewed by others

References

Kustas A B, Susan D F, and Monson T, JOM 74 (2022) 1306–1328. https://doi.org/10.1007/S11837-021-05019-9/FIGURES/15

Subramanian A T S, Meenalochini P, Sathiya S S B, and Prakash G R, Mater Today Proc 45 (2021) 1591. https://doi.org/10.1016/J.MATPR.2020.08.389

The global soft magnetic materials market was valued at, (n.d.). https://www.globenewswire.com/news-release/2019/10/29/1937022/0/en/The-global-soft-magnetic-materials-market-was-valued-at-47-3-billion-in-2018-and-is-projected-to-reach-87-2-billion-by-2026-growing-at-a-CAGR-of-8-8-from-2019-to-2026.html (accessed October 31, 2021).

Mohapatra J, Xing M, Elkins J, and Liu J P, J Alloys Compd 824 (2020) 153874. https://doi.org/10.1016/J.JALLCOM.2020.153874

Betancourt-Cantera J A, Bolarín-Miró A M, Jesús FS-D, and Betancourt-Cantera L G, J Magn 25 (2020) 36. https://doi.org/10.4283/JMAG.2020.25.1.036

Ramos R, Valdez B, Nedev N, Curiel M, Perez O, and Salvador J, Instrum Sci Technol 49 (2021) 499. https://doi.org/10.1080/10739149.2021.1888115

Paganotti A, Bessa C V X, Ferreira L D R, Gama S, and Silva R A G, J Alloys Compd 811 (2019) 152029. https://doi.org/10.1016/J.JALLCOM.2019.152029

Li H, Wang A, Liu T, Chen P, He A, Li Q, Luan J, and Liu C T, Mater Today 42 (2021) 49. https://doi.org/10.1016/J.MATTOD.2020.09.030

Harrington K M, Miller E C, Frye A, and Stoyanov P, Wear 477 (2021) 203827. https://doi.org/10.1016/J.WEAR.2021.203827

Kalantari H, Zandrahimi M, Adeli M, and Ebrahimifar H, Intermetallics 150 (2022) 107694. https://doi.org/10.1016/J.INTERMET.2022.107694

Karati A, Manna J, Mishra S, and Murty B S, High Entropy Alloys (2020). https://doi.org/10.1201/9780367374426-18

Chaudhary V, Chaudhary R, Banerjee R, and Ramanujan R V, Mater Today (2021). https://doi.org/10.1016/J.MATTOD.2021.03.018

Zhou Y, Zhou D, Jin X, Zhang L, Du X, and Li B, Sci Rep 8 (2018) 1. https://doi.org/10.1038/s41598-018-19449-0

Yin F, Hu S, Xu R, Xiang S, Hua L, and Cheng G J, Mater Sci Eng A 823 (2021) 141631. https://doi.org/10.1016/J.MSEA.2021.141631

Pikula T, Oleszak D, Pekała M, and Jartych E, J Magn Magn Mater 320 (2008) 413. https://doi.org/10.1016/j.jmmm.2007.06.020

Pikula T, Nukleonika 58 (2013) 153.

Jayaraman T V, Rathi A, and Thotakura G V, Intermetallics 113 (2019) 106583. https://doi.org/10.1016/j.intermet.2019.106583

Thotakura G V, Rathi A, and Jayaraman T V, Appl Phys A Mater Sci Process 125 (2019) 235. https://doi.org/10.1007/s00339-019-2535-7

Jayaraman T V, Rathi A, and Thotakura G V, Intermetallics 119 (2020) 106715. https://doi.org/10.1016/j.intermet.2020.106715

Daly R, Khitouni N, Escoda M L, Isern N L, Juan Jose S M, Greneche J M, and Khitouni M, Arab J Sci Eng 46 (2021) 5633. https://doi.org/10.1007/S13369-020-05166-2/FIGURES/10

Betancourt-Cantera L G, Sánchez-De Jesús F, Bolarín-Miró A M, Gallegos-Melgar A, Mayen J, and Betancourt-Cantera J A, J Mater Res Technol 9 (2020) 14969. https://doi.org/10.1016/J.JMRT.2020.10.068

Jayaraman T V, Thotakura G V, and Rathi A, J Magn Magn Mater 489 (2019) 165466. https://doi.org/10.1016/j.jmmm.2019.165466

Rathi A, Meka V M, and Jayaraman T V, J Magn Magn Mater 469 (2019) 467. https://doi.org/10.1016/j.jmmm.2018.09.002

Prasad N K, and Kumar V, J Mater Sci Mater Electron 26 (2015) 10109. https://doi.org/10.1007/s10854-015-3695-7

Burgio N, Iasonna A, Magini M, Martelli S, and Padella F, Il Nuovo Cimento D 13 (1991) 459. https://doi.org/10.1007/BF02452130

Abdellaoui M, and Gaffet E, Acta Metallurgica et Materialia 43 (1995) 1087. https://doi.org/10.1016/0956-7151(95)92625-7

Meng Q, Guo S, Zhao X, and Veintemillas-Verdaguer S, J Alloys Compd 580 (2013) 187–190. https://doi.org/10.1016/J.JALLCOM.2013.05.115

Shewmon P, Diffusion in Solids, 2nd edn. Springer, Berlin (2016). https://doi.org/10.1007/978-3-319-48206-4

Chen Y L, Hu Y H, Hsieh C A, Yeh J W, and Chen S K, J Alloys Comps 481 (2009) 768. https://doi.org/10.1016/j.jallcom.2009.03.087

Zarezadeh Mehrizi M, and Beygi R, J Adv Mater Process (J Mater Sci) (2017). www.SID.ir (accessed May 24, 2021).

Sahu P, Samal S, and Kumar V, Materialia 18 (2021) 101133. https://doi.org/10.1016/j.mtla.2021.101133

Murty B S, Mohan Rao M, and Ranganathan S, Acta Metallurgica et Materialia 43 (1995) 2443. https://doi.org/10.1016/0956-7151(94)00402-1

Joardar J, Pabi S K, and Murty B S, J Alloys Compd 429 (2007) 204. https://doi.org/10.1016/j.jallcom.2006.04.045

Bhatt J, and Murty B S, J Alloys Compd 459 (2008) 135. https://doi.org/10.1016/j.jallcom.2007.04.242

Salemi F, Abbasi M H, and Karimzadeh F, J Alloys Compd 685 (2016) 278. https://doi.org/10.1016/j.jallcom.2016.05.274

Dastanpoor E, and Enayati M H, Indian J Eng Mater Sci (IJEMS) 22 (2015) 521. http://hdl.handle.net/123456789/33434

Nelson J B, and Riley D P, Proc Phys Soc 57 (1945) 160. https://doi.org/10.1088/0959-5309/57/3/302

Williamson G K, and Hall W H, Acta Metallurgica. 1 (1953) 22. https://doi.org/10.1016/0001-6160(53)90006-6

Suryanarayana C, Al-Joubori A A, and Wang Z, Met Mater Int (2021). https://doi.org/10.1007/S12540-021-00998-5

Aghamiri S M S, Oono N, Ukai S, Kasada R, Noto H, Hishinuma Y, and Muroga T, Nucl Mater Energy 15 (2018) 17. https://doi.org/10.1016/j.nme.2018.05.019

Kulkarni R, Murty B S, and Srinivas V, J Alloys Compd 746 (2018) 194. https://doi.org/10.1016/J.JALLCOM.2018.02.275

Mishra R K, Kumari P, Gupta A K, and Shahi R R, J Alloys Compd 889 (2021) 161773. https://doi.org/10.1016/J.JALLCOM.2021.161773

Kang T, Wu S, Wang M, Wang J, Fan X, and Lu Y, Appl Phys A 127 (2021) 1. https://doi.org/10.1007/S00339-021-04988-7

Mishra R K, Shahi R R, Singh A R, and Sahay P P, Emergent Mater 3 (2020) 655. https://doi.org/10.1007/s42247-020-00110-4

Li P, Wang A, and Liu C T, Intermetallics 87 (2017) 21. https://doi.org/10.1016/j.intermet.2017.04.007

Herzer G, IEEE Trans Magn 26 (1990) 1397. https://doi.org/10.1109/20.104389

Sahu P, Bagri A S, Anoop M D, Kumar M, and Kumar V, Silicon 12 (2020) 893. https://doi.org/10.1007/s12633-019-00182-w

Alijani F, Reihanian M, and Gheisari K, J Alloys Compd 773 (2019) 623–630. https://doi.org/10.1016/j.jallcom.2018.09.204

Chaudhary V, Chaudhary R, Banerjee R, and Ramanujan R V, Mater Today. 49 (2021) 231–252. https://doi.org/10.1016/J.MATTOD.2021.03.018

Li Z, Gu Y, Pan M, Wang C, Wu Z, Hou X, Tan X, and Xu H, J Alloys Compd 792 (2019) 215. https://doi.org/10.1016/j.jallcom.2019.03.411

Chaudhary V, Tan L P, Sharma V K, and Ramanujan R V, J Alloys Compd 869 (2021) 159318. https://doi.org/10.1016/j.jallcom.2021.159318

Prasad N K, and Kumar V, J Mater Sci Mater Electron 27 (2016) 10136. https://doi.org/10.1007/s10854-016-5090-4

Yakın A, Şimşek T, Avar B, Chattopadhyay A K, Özcan S, and Şimşek T, Appl Phys A 128 (2022) 1. https://doi.org/10.1007/S00339-022-05836-Y

Ghasemi A, Zamani K, Tavoosi M, and Gordani G R, J Supercond Novel Magn 33 (2020) 3189–3196. https://doi.org/10.1007/s10948-020-05579-y

Zhao R F, Ren B, Zhang G P, Liu Z X, and Zhang J, J Magn Magn Mater 468 (2018) 14. https://doi.org/10.1016/j.jmmm.2018.07.072

Mishra R K, and Shahi R, J Alloys Compd 821 (2020) 153534. https://doi.org/10.1016/j.jallcom.2019.153534

Duan Y, Wen X, Zhang B, Ma G, and Wang T, J Magn Magn Mater 497 (2020) 165947. https://doi.org/10.1016/j.jmmm.2019.165947

Liu X, Duan Y, Yang X, Huang L, Gao M, and Wang T, J Alloys Compd 872 (2021) 159602. https://doi.org/10.1016/J.JALLCOM.2021.159602

Yingzhe Z, Yudao C, Qingdong Q, and Wei L, J Magn Magn Mater 498 (2020) 166151. https://doi.org/10.1016/J.JMMM.2019.166151

Sahu P, Solanki S, Dewangan S, and Kumar V, J Mater Res 34 (2019) 829. https://doi.org/10.1557/jmr.2019.34

Khitouni N, Hammami B, Llorca-Isern N, Ben Mbarek W, Suñol J J, and Khitouni M, Materials 15 (2022) 6483. https://doi.org/10.3390/MA15186483

Yaykasli H, Avar B, Panigrahi M, Gogebakan M, and Eskalen H, Arab J Sci Eng (2022). https://doi.org/10.1007/S13369-022-07037-4/FIGURES/5

Aquino R, Depeyrot J, Sousa M H, Tourinho F A, Dubois E, and Perzynski R, Phys Rev B Condens Matter Mater Phys 72 (2005) 184435. https://doi.org/10.1103/PHYSREVB.72.184435/FIGURES/7/MEDIUM

Sharma V K, Najim M, Srivastava A K, and Varma G D, J Magn Magn Mater 324 (2012) 683. https://doi.org/10.1016/J.JMMM.2011.08.061

Acknowledgements

VK and PS would like to acknowledge the Institute Instrumentation Center (IIC), Roorkee, for the VSM facility. PS would like to thank the Indian government's Ministry of Human Resource Development (MHRD) for awarding a scholarship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sahu, P., Samal, S. & Kumar, V. Phase Evolution and Soft Magnetic Behavior of Mechanically Alloyed Fe–Co–Ni Medium Entropy Alloy at Different Disk Angular Velocity. Trans Indian Inst Met 76, 3065–3078 (2023). https://doi.org/10.1007/s12666-023-03035-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03035-8