Abstract

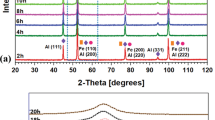

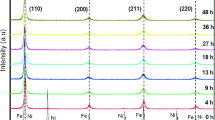

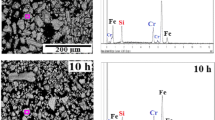

The mechanical alloying process has been used to synthesise the nanocrystalline Fe60Al35Mg5 (wt%) powders in a high-energy planetary ball-mill Retsch PM 400. The evolution structural, microstructural and magnetic properties of ball-milled powders at different milling times (t variation from 0 to 32 h) were investigated by X-ray diffraction using the MAUD program which is based on the Rietveld method and the vibrating sample magnetometer. The XRD results reveal the formation of a bcc-Fe (Al, Mg) solid solution after 8 h of milling possessing a lattice parameter of 0.2895 nm after 32 h of milling. It is also observed a refinement of the grain size, which reaches 18.75 nm, and an increase in the microstrain after 32 h of milling. Magnetic measurements of the milled Fe60Al35Mg5 (wt%) powder mixture exhibit a soft ferromagnetic character where the magnetic parameters are found to be very sensitive to the milling time mainly due to the particle size refinement as well as the formation of the solid solutions.

Similar content being viewed by others

References

Wederni A, Lachheb R, Suñol J J, Saurina J, Escoda L, and Khitouni M, Mater Charact 148 (2019) 272. https://doi.org/10.1016/j.matchar.2019.01.001

Zaharov Y A, Pugachev V M, Ovcharenko V I, Datiy K A, Popova A M, and Bogomyakov A S, Phys Status Solidi B 225 (2017) 1700175. https://doi.org/10.1002/pssb.201700175

Shokrollahi H, Mater Des 30 (2009) 3374. https://doi.org/10.1016/j.matdes.2009.03.035

Behvandi A, Shokrollahi H, Chitsazan B, and Ghaffari M, J Magn Magn Mater 322 (2010) 3932. https://doi.org/10.1016/j.jmmm.2010.08.025

Meka V M, Chirantana K, and Jayaraman T V, Powder Technol 332 (2018) 33. https://doi.org/10.1016/j.powtec.2018.03.038

Chen C W, J Appl Phys 32 (1961) 348S. https://doi.org/10.1063/1.2000465

Moumeni H, Alleg S, and Greneche J M, J Alloys Compd 386 (2005) 12. https://doi.org/10.1016/j.jallcom.2004.05.017

Ammouchi N, Otmani A, Bensebaa Z, Azzaza S, Bououdina M, Djekoun A, Bechiri L, and Greneche J M, J Supercond Nov Magn 28 (2015) 3651. https://doi.org/10.1007/s10948-015-3203-6

Bhoi B, Srinivas V, and Vidyadhar Singh J, Alloy Compd (2010). https://doi.org/10.1016/j.jallcom.2010.01.155

Avar B, and Ozcan S, J Alloy Compd (2015). https://doi.org/10.1016/j.jallcom.2015.07.268

Znaidi L, Mater Sci Eng B 174 (2010) 18. https://doi.org/10.1016/j.mseb.2010.07.001

Wu Q, Wongwiriyapan W, Park J H, Park S, Jung S J, Jeong T, Lee S, Lee Y H, and Song Y J, Curr Appl Phys 16 (2016) 1175. https://doi.org/10.1016/j.cap.2016.04.024

Hasnaouia N, Hafs A, Hafs T, and Bendjedaa F, J Alloys Compd 899 (2022) 163338. https://doi.org/10.1016/j.jallcom.2021.163338

Baker I, and Gaydosh D, Mater Sci Eng A 96 (1987) 147. https://doi.org/10.1016/0025-5416(87)90549-0

Zerniz N, Azzaza S, Chater R, Abbas H, Bououdina M and Bouchelaghem W, 100 (2015) 21. http://dx.doi.org/https://doi.org/10.1016/j.matchar.2014.12.010

Krifa M, Mhadhbi M, Escoda L, Güell J M, Suñol J J, Llorca-Isern N, Artieda-Guzmán C, and Khitouni M, J Alloy Compd 554 (2013) 51. https://doi.org/10.1016/j.jallcom.2012.11.131

Ibn Gharsallah H, Azabou M, Escoda L, Sunol J J, Lopez I, Llorca-Isern N, and Khitouni M, J. Alloy. Compd 729 (2017) 776e786. https://doi.org/10.1016/j.jallcom.2017.09.229

Lutterotti L, Laboratorio Scienza e Tecnologia dei Materiali, Universita di Torino, Corso (2000).

Young R A, and Wiles D B, J Appl Cryst 15 (1982) 430. https://doi.org/10.1107/S002188988201231X

Suryanarayana C, Prog Mater Sci 46 (2001) 1. https://doi.org/10.1016/S0079-6425(99)00010-9

Castex L, Lebrun J L, Maeder G, and Sprauel J M, Publs Scient Tech ENSAM 22 (1981) 51.

Chater R, Bououdina M, Chaanbi D, and Abbas H, J Solid State Chem 201 (2013) 317. https://doi.org/10.1016/j.jssc.2013.02.028

Boukherroub N, Guittoum A, Souami N, Akkouche K, and Boutarfaia S, EPJ Web Conf. 29 (2012) 00010. https://doi.org/10.1051/epjconf/20122900010

Hamlati Z, Guittoum A, Bergheul S, Souami N, Taibi K, and Azzaz M, J Mater Eng Perform 21 (2012) 1943. https://doi.org/10.1007/s11665-011-0095-x

Rajath Hegde M M, and Surendranathan A O, Powder Metall Met Ceram 48 (2009) 641. https://doi.org/10.1007/s11106-010-9181-0

Wederni A, Lachheb R, Suñolb J J, Saurina J, Escoda L, and Khitouni M, Mater Charact 148 (2019) 272. https://doi.org/10.1016/j.matchar.2019.01.001

Pękała M, Pękała K, Szydłowsk J, and Drozd V, J Magn Magn Mater 475 (2019) 189. https://doi.org/10.1016/j.jmmm.2018.11.069

Raanaei H, Eskandari H, and Mohammad-Hosseini V, J Magn Magn Mater 398 (2016) 190. https://doi.org/10.1016/j.jmmm.2015.09.031

Prasad N K, and Kumar V, J Mater Sci Mater Electron 26 (2015) 10109. https://doi.org/10.1007/s10854-015-3695-7

Hamzaoui R, and Elkedim O, J Alloys Compd 573 (2013) 157. https://doi.org/10.1016/j.jallcom.2013.03.183

Kuhrt C, and Schultz L, J Appl Phys 73 (1993) 6588. https://doi.org/10.1063/1.352573

Hamzaoui R, Elkedim O, Gaffet E, and Greneche J M, J Alloys Compd 417 (2006) 32. https://doi.org/10.1016/j.jallcom.2005.09.064

Acknowledgements

This work was supported by Algerian Directorate for Scientific Research and Technological Development (DGRSDT).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hafs, A., Hafs, T., Berdjane, D. et al. Investigating on Structural, Microstructural and Magnetic Properties of Nanocrystalline Fe60Al35Mg5 Alloy Synthesised by High-Energy Ball Milling. Trans Indian Inst Met 76, 3447–3454 (2023). https://doi.org/10.1007/s12666-023-03029-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03029-6