Abstract

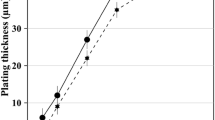

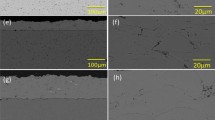

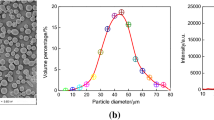

Influence of dilution on high-temperature–high-vacuum-friction behaviour of Ni-Cr-B-Si coating made on AISI 316L (N) stainless steel using plasma transferred arc welding process is studied. Two coatings with different dilution levels are made by using two different welding currents. With increase in dilution (Ni/Fe change from 4.4 to 2.5 and hardness from 46 ± 3 to 30 ± 5 RC), microstructure changed from hypereutectic to eutectic with variations in the distribution of borides and carbides as well as their relative contents. Sliding wear tests were conducted for coatings using SiC ball as the counterbody, at 823 K under vacuum of 10–5 mbar. Friction coefficient increased from 0.17 ± 0.04 to 0.42 ± 0.12 with increase in dilution, with the change of wear coefficient from 0.60 × 10−14 to 0.92 × 10−14 (m3/Nm). Results revealed the dependence of friction on dilution, the effect of which influences the nature of the triboinduced film which in turn controls wear.

Similar content being viewed by others

Data Availability

Data used to support the findings of this study are available in the supplementary data file.

References

Fernández-García M, Wang X, Belver C, Iglesias-Juez A, Hanson J C, and Rodriguez J A, Chem Mater 17 (2005) 4181. https://doi.org/10.1021/cm050265i

Miguel J M, Guilemany J M, and Vizcaino S, Tribol Int 36 (2003) 181. https://doi.org/10.1016/S0301-679X(02)00144-5

Kim S J, and Kim J K, J Nucl Mater 288 (2001) 163. https://doi.org/10.1016/S0022-3115(00)00711-X

Hemmati I, Ocelík V, and De Hosson J T M, WIT Trans Eng Sci 71 (2011) 287. https://doi.org/10.2495/SECM110251

Kumar H, Ramakrishnan V, Albert S K, Bhaduri A K, and Ray K K, J Nucl Mater 484 (2017) 141. https://doi.org/10.1016/j.jnucmat.2016.11.032

Parmar R S, Welding Engineering and Technology, Khanna Publishers (2003).

Bhaduri A K, Indira R, Albert S K, Rao B P S, Jain S C, and Asokkumar S, J Nucl Mater 334 (2004) 109. https://doi.org/10.1016/j.jnucmat.2004.05.005

Das C R, Albert S K, Bhaduri A K, Sudha C, and Terrance A L E, (2005). https://doi.org/10.1179/174329405X40867

Chakraborty G, Kumar N, Das C R, Albert S K, Bhaduri A K, Dash S, and Tyagi A K, Surf Coatings Technol 244 (2014) 180. https://doi.org/10.1016/j.surfcoat.2014.02.013

Chakraborty G, Rani R, Ramaseshan R, Arvinth Davinci M, Das C R, Mathews T, and Albert S K, Tribol Trans 64 (2021) 658. https://doi.org/10.1080/10402004.2021.1896059

Balaguru S, and Gupta M, J Mater Res Technol 10 (2021) 1210. https://doi.org/10.1016/j.jmrt.2020.12.026

Ramasubbu V, Chakraborty G, Albert S K, and Bhaduri A K, Mater Sci Technol 27 (2011) 573. https://doi.org/10.1179/026708309X12526555493431

Kesavan D, and Kamaraj M, Wear 272 (2011) 7. https://doi.org/10.1016/j.wear.2011.05.041

Gnanasekaran S, Padmanaban G, Balasubramanian V, Kumar H, and Albert S K, J Manuf Eng 12 (2017) 208. https://smenec.org/index.php/1/article/view/148

Hutchings I M, Tribology: Friction and Wear of Engineering Materials, (1992). https://www.elsevier.com/books/tribology/hutchings/978-0-08-100910-9

Gahr K H Z, Tribol Ser 10 (1987) 132. https://doi.org/10.1016/S0167-8922(08)70723-5

Stachowiak G W, and Batchelor A W, Engineering Tribology, Third, Butterworth-Heinemann, (2005). https://www.elsevier.com/books/engineering-tribology/stachowiak/978-0-7506-7836-0

Takadoum J, Materials and Surface Engineering in Tribology, Wiley-ISTE, (2008). https://www.wiley.com/en-us/Materials+and+Surface+Engineering+in+Tribology-p-9781848210677

Kumar N, Das C R, Dash S, Tyagi A K, Bhaduri A K, and Raj B, Tribol Trans 54 (2011) 62. https://doi.org/10.1080/10402004.2010.518342

Kumar H, Ramakrishnan V, Albert S K, Bhaduri A K, and Ray K K, J Nucl Mater 495 (2017) 43137. https://doi.org/10.1016/j.jnucmat.2017.08.036

Acknowledgements

Authors are thankful to colleagues of IGCAR for their help in carrying out experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Tom Mathews and S. K. Albert: Indira Gandhi Centre for Atomic Research, Kalpakkam (Retired).

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sreevidya, N., Rani, R., Das, C.R. et al. Effect of Dilution on High-Temperature and High-Vacuum Tribological Behaviour of Ni-Cr-B-Si Hardfaced Coating. Trans Indian Inst Met 76, 3127–3136 (2023). https://doi.org/10.1007/s12666-023-02963-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-02963-9