Abstract

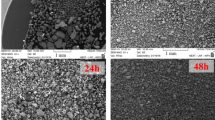

The addition of minor fractions of grain refiners commonly improves the mechanical properties of TiAl intermetallic alloys. In this study, Ti-36 wt.% Al powders were consolidated using a field-assisted sintering technique without adding grain refiners. Various temperatures (650–1300 °C) and pressures (14–50 MPa) were used to elucidate the structure–property relationship. An intermetallic of 99.9% relative density with a corresponding microhardness value of 327 ± 6 HV0.5 was achieved for alloys sintered at 1300 °C and 16 MPa. Alloys sintered at 1100 °C displayed a microstructure consisting of citrus Ti-rich grains, while a duplex microstructure consisting of γ-TiAl + α2-Ti3Al lamellae, and γ-TiAl phases were observed at 1300 °C.

Similar content being viewed by others

References

Williams J C, and Boyer R R, Metals 10 (2020) 705.

Leyens C, and Peters M, Titanium and Titanium Alloys: Fundamentals and Applications, Wiley, Weinheim (2006).

Musi M, Galy B, Monchoux J-P, Couret A, Clemens H, and Mayer S, Scripta Materialia 206 (2022) 114233.

Mishin Y, and Herzig C, Acta Materialia 48 (2000) 589.

Appel F, Clemens H, and Fischer F, Prog. Mater. Sci. 81 (2016) 55.

Ai T, Yu N, Feng X, Xie N, Li W, and Xia P, Metals Mater. Int. 21 (2015) 179.

Aldoshan A A, Spark Plasma Sintering of Titanium Aluminide Intermetallics and Its Composites, Oklahoma State University, Stillwater (2012).

Choudhuri D, Gwalani B, Gorsse S, Komarasamy M, Mantri S A, Srinivasan S G, Mishra R S, and Banerjee R, Acta Materialia 165 (2019) 420.

Brotzu A, Felli F, and Pilone D, Intermetallics 54 (2014) 176.

Um T-Y, Abe T, and Sumi S, J. Mater. Synth. Process. 7 (1999) 303.

Wu X, Intermetallics 14 (2006) 1114.

Al-Dabbagh J B, Rozman M T, Mahadzir I, Siti Aisyah H, Int. J. Nanoelectronics and Materials 8 (2015) 23.

Saheb N, Iqbal Z, Khalil A, Hakeem A S, Al Aqeeli N, Laoui T, Al-Qutub A, Kirchner R, J. Nanomater. 2012 (2012) 18.

Vanmeensel K, Laptev A, Hennicke J, Vleugels J, and Van der Biest O, Acta Materialia 53 (2005) 4379.

Skiba T, Haušild P, Karlík M, Vanmeensel K, and Vleugels J, Intermetallics 18 (2010) 1410.

Munir Z, Anselmi-Tamburini U, and Ohyanagi M, J. Mater. Sci. 41 (2006) 763.

Wu J, Zhang H, Zhang Y, and Wang X, Mater. Design 41 (2012) 344.

Yang F, Kong F, Chen Y, and Xiao S, J. Alloys Compd. 496 (2010) 462.

Shen Z, Johnsson M, Zhao Z, and Nygren M, Spark plasma sintering of alumina. Journal of the American Ceramic Society 85 (2002) 1921.

Cha S I, Hong S H, and Kim B K, Mater. Sci. Eng. A 351 (2003) 31.

Mei B, and Miyamoto Y, Metall. Mater. Trans. A 32 (2001) 843.

Lagos M, and Agote I, Intermetallics 36 (2013) 51.

German R M, Sintering Theory and Practice, Wiley-Interscience, 1st Edition, Weinheim (1996), p 568.

Kang S L, Liquid Phase Sintering, Sintering of Advanced Materials, Elsevier, Amsterdam (2010), p 110.

Nonaka K, Tanosaki K, Fujita M, Chiba A, Kawabata T, and Izumi O, Mater. Trans. JIM 33 (1992) 802.

Kasahara K, Hashimoto K, Doi H, and Tsujimoto T, Jpn. Inst. Metals J. 51 (1987) 278.

Ishiyama S, Buchkremer H P, and Stöver D, Mater. Trans. 43 (2002) 2331.

Mwamba L, Cornish L, and Van Der Lingen E, J. South. Afr. Inst. Min. Metall. 112 (2012) 517.

McCullough C, Valencia I J, Levi C G, and Mehtabian R, Acta Metals 41 (1989) 1321.

Huy T D, Fujiwara H, Yoshida R, and Miyamoto H, Mater. Trans. 55 (2014) 1091.

Cui N, Wang X-P, Kong F-T, Chen Y-Y, and Zhou H-T, Rare Metals 35 (2016) 42.

Acknowledgements

The authors would like to gratefully acknowledge the UNESCO-ANSTI/DAAD In-Region fellowship, South African Department of Science and Technology (DST)—National Research Foundation (NRF), and Tshwane University of Technology (TUT) for the financial support to carry out this research. The assistance received from the Institute for NanoEngineering Research (INER) in TUT for conducting this research is hereby acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nsiah-Baafi, E., Andrews, A., Ramakokovhu, M.M. et al. Field-Assisted Sintering on Microstructural Evolution and Properties of TiAl Intermetallic Alloys. Trans Indian Inst Met 76, 2625–2633 (2023). https://doi.org/10.1007/s12666-023-02948-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-02948-8