Abstract

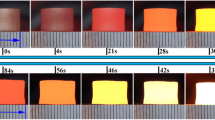

Al-Ti based porous materials were successfully synthesized via a combination process of evaporation and hot pressing, utilizing zinc powder as space holder, from Al-25at. % Ti element powders. The phase composition, porous structure, expansion behavior, and porosity were investigated under various evaporation times. Dominant phase Al3Ti exhibited cubic or long strip microstructures with the action of zinc, and the diffraction peaks continuously enhanced with the extension of evaporation time. The results illustrated that porous Al3Ti intermetallic compounds with open porosity of 66.9% could be prepared by adding 20vol. % zinc powder, while volume expansion was only 16.4%. It was confirmed that two types of pore structure could be observed, including large pores and small pores. Furthermore, the processed porous materials presented a uniform, labyrinth-like network structure.

Similar content being viewed by others

References

Yamanoglu R, Bahador A, and Kondoh K, Trans. Indian Inst. Met 74 (2021) 2555.

Shi Q, Qin B, Feng P, Ran H, and Ge Y, RSC Adv 5 (2015) 46339.

He Y H, Jiang Y, Xu N P, Zou J, and Liaw P K, Adv. Mater 19 (2007) 2102.

Ma J, Niu L B, Wu H, Gao C, and An Y J, J. Cent. South Univ. (Engl. Ed.) 27 (2020) 3594.

Chen M R, Jiang Y, He Y H, Lin L W, and Liu C T, J. Alloys Compd 521 (2012) 12.

Mishra D D, Makkar P, Rath P K, Dabhade V V, and Agarwala R C, Trans. Indian Inst. Met 70 (2017) 175.

Yang F, Zhang L, Lin J, Liang Y, and Liu Z K, Intermetallics 33 (2013) 2.

Wang Y H, Lin J P, He Y H, Wang Y L, and Chen G L, J. Alloys Compd 456 (2008) 297.

Sienkiewicz J, Kuroda S, Molak R M, Murakami H, and Kurzydlowski K J, Intermetallics 49 (2014) 57.

Novoselova T, Celotto S, Morgan R, Fox P, and O’Neill W, J. Alloys Compd 436 (2007) 69.

Jakubowicz J, Adamek G, and Dewidar M, J. Porous Mater 20 (2013) 1137.

Esen Z, and Bor S, Scr. Mater 56 (2007) 341.

Arakawa Y, Kobashi M, and Kanetake N, Intermetallics 41 (2013) 22.

Jiao X, Wang X, Kang X, Feng P, and Akhtar F, Mater. Lett 181 (2016) 261.

Jiao X, Feng P, Liu Y, Cai X, and Czujko T, J. Mater. Res 33 (2018) 2680.

Kumar R M, and Golla B R, Indian Inst. Met 74 (2021) 2379.

Xie B, Fan Y Z, Mu T Z, and Deng B, Mater. Sci. Eng. A 708 (2017) 419.

Hosseini S A, Yazdani-Rad R, Kazemzadeh A, and Alizadeh M, J. Mater. Eng. Perform 23 (2014) 799.

Wang J F, Gao H Y, Jiang Y, Yang J S and Jia Y H, Powder Metallurgy Materials Science and Engineering (in Chinese).

Ye B, and Dunand D C, Mater. Sci. Eng. A 528 (2010) 691.

Xu G, Li J, Cui H, He Q, and Zhan X, Ceram. Int. 41 (2015) 7042.

Wang Z, Jiao X, Feng P, Wang X, and Akhtar F, Intermetallics 68 (2016) 95.

Ma J, Niu L B, Yan Y T, Gao C, and Wang X G, J. Cent. South Univ. (Engl. Ed.) 27 (2020) 762.

Du H, Liu X W, Li J, Tao P, and Fan Z T, Mater. Manuf. Processes 31 (2016) 725.

Jiao X, Wang X, Kang X, Feng P, and Akhtar F, Mater. Manuf. Processes 32 (2017) 489.

Gao H, He Y, Shen P, Zou J, and Liu C T, Intermetallics 17 (2009) 1041.

Feng P Z, Su J, Zhou Y G, Wang J Z, and Wang X H, Rare Met. Mater. Eng (in Chinese).

Barlow I C, Jones H, and Rainforth W M, Acta Mater. 49 (2001) 1209.

Zhang Q, Xiao B L, Wang D, and Ma Z Y, Mater. Chem. Phys. 130 (2011) 1109.

Liang Y, Yang F, Zhang L, Lin J, and Liu Z K, Intermetallics 44 (2014) 1.

Jafari R, and Eghbali B, Trans. Indian Inst. Met 71 (2018) 2269.

Jiao X, Wang X, Feng P, Liu Y, and Akhtar F, Acta Metall. Sin. (Engl. Lett.) 31 (2018) 440.

Suzuki A, Kosugi N, Takata N, and Kobashi M, Mater. Sci. Eng. A 77 (2020) 139000.

Acknowledgements

This work was supported by the joint fund project of Clean Energy Innovation Research Institute of Chinese Academy of Sciences and Yulin University (Grant. YLU-DNL Fund 2021004) and the project (2018JQ5087) of Natural Science Basic Research Plan of Shaanxi Province in China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

An, YJ., Niu, LB., Hu, YY. et al. Study on Processing of Porous Al-Ti Materials with Zinc Powder as Space Holder. Trans Indian Inst Met 76, 2651–2657 (2023). https://doi.org/10.1007/s12666-023-02927-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-02927-z