Abstract

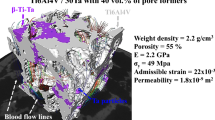

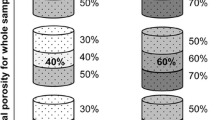

NiTi and Ti porous specimens with appropriate pore characteristics for biomedical applications are produced by space holder method. Porosities of the specimens linearly increase from 14 to 65 and 42 to 70% for the Ti and NiTi specimens, respectively, with the urea space holder. Mechanical properties such as stiffness, fracture strain, and strength of the porous NiTi and Ti are adjustable with pore characteristics. The apparent elasticity modulus of NiTi specimens decrease from 3.5 to 0.73 GPa as porosity increases. Since the initial linear part of the stress-strain curve consists of elastic behavior, formation of stress-induced martensite, deformation and/or detwinning of martensite variants, and plastic deformation, the unloading slope of stress-strain curves is a better approximation for the elasticity modulus of the NiTi porous specimens as it is proved by an isotropic cubic cell model. The unloading slope of the NiTi specimen with 61% porosity is 3.1 GPa, while the apparent elasticity or loading slope is 0.85 GPa. In comparison to Ti, the high, recoverable strain of NiTi improves capability of it as a good candidate for bone replacement. Moreover, in contrast to Ti specimens, hysteresis loops are clearly observed in the stress-strain curves of NiTi specimens.

Similar content being viewed by others

References

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, and H.N.G. Wadley, Metal Foams: A Design Guide, Elsevier, Burlington, 2000

A.G. Evans, J.W. Hutchinson, and M.F. Ashby, Multifunctionality Of Cellular Metal Systems, Prog. Mater. Sci., 1999, 43, p 22–171

A. Nouri, P.D. Hodgson, and C. Wen, Biomimetic Porous Titanium Scaffolds for Orthopedic and Dental Applications, A. Mukherjee, Ed., Biomimetics Learning from Nature, Chap. 21, InTech, Rijek, 2010

A. Bansiddhi, T.D. Sargeant, S.I. Stupp, and D.C. Dunand, Porous NiTi for Bone Implant: A Review, Acta Biomater., 2008, 4, p 773–782

M. Assad, F. Likibi, P. Jarzem, M.A. Leroux, C. Coillard, and C.H. Rivard, Porous nitinol vs. Titanium Intervertebral Fusion Implants: Computer Tomography, Radiological and Histological Study of Osseointegration Capacity, Materialwissenschaft und Werkstofftechnik, 2004, 35, p 219–223

S.K. Sadrnezhaad and S.A. Hosseini, Fabrication of Porous NiTi-Shape Memory Alloy Objects by Partially Hydride Titanium Powder for Biomedical Applications, Mater. Des., 2009, 30, p 4483–4487

C.L. Chu, C.Y. Chung, P.H. Lin, and S.D. Wang, Fabrication of Porous NiTi Shape Memory Alloy for Hard Tissue Implants by Combustion Synthesis, Mater. Sci. Eng. A, 2004, 366, p 114–119

C. Greiner, S.M. Oppenheimer, and D.C. Dunand, High Strength, Low Stiffness, Porous NiTi with Superelastic Properties, Acta Biomater., 2005, 1, p 705–716

Y. Zhao, M. Taya, Y. Kang, and A. Kawasaki, Compression Behavior of Porous NiTi Shape Memory Alloy, Acta Mater., 2005, 53, p 337–343

M. Kohl, M. Bram, P. Buchkremer, D. Stover, T. Habijan, and M. Koller, Production of Highly Porous Near-Net-Shape NiTi Components for Biomedical Applications, 2007 (Montreal), Metfoam Conference, Canada

I.V. Shishkovsky, L.T. Volova, M.V. Kuznetsov, Y.G. Morozov, and I.P. Parkin, Porous Biocompatible Implants and Tissue Scaffolds Synthesized By Selective Laser Sintering from Ti and NiTi, J. Mater. Chem., 2008, 18, p 1309–1317

A. Ghasemi, S.A. Hosseini, and S.K. Sadrnezhaad, Pore Control in SMA NiTi Scaffolds Via Space Holder Usage, Mater. Sci. Eng. C, 2012, 32, p 1266–1270

Z. Esen and Ş. Bor, Characterization of Ti-6Al-4V Alloy Foams Synthesized by Space Holder Technique, Mater. Sci. Eng. A, 2011, 528, p 3200–3209

M. Niinomi and M. Nakai, Titanium-Based Biomaterials for Preventing Stress Shielding Between Implant Devices and Bone, Int. J. Biomater., 2011, 1, p 1–10

V.E. Gjunter, P. Sysoliatin, and T. Temerkhamor, Superelastic Shape Memory Implants in Maxillofacial Surgery, Traumatology, Orthopaedics, and Neurosurgery, Tomsk University Publishing House, Russia, 1995, p 14–16

B.Y. Li, L.J. Rong, Y.Y. Li, and V.E. Gjunter, An Investigation of the Synthesis of Ti-50 At. Pct. Ni Alloys Through Combustion Synthesis and Conventional Powder Sintering, Metall. Mater. Trans. A, 2000, 31, p 1867–1871

M. Köhl, M. Bram, A. Moser, H.P. Buchkremer, T. Beck, and D. Stöver, Characterization of Porous, Net-Shaped NiTi Alloy Regarding Its Damping and Energy-Absorbing Capacity, Mater. Sci. Eng. A, 2011, 528, p 2454–2462

P. Suortt, Effects of Porosity and Surface Roughness on the x-ray Intensity Reflected from a Powder Specimen, J. Appl. Cryst., 1972, 5, p 325–331

S.A. Hosseini, S.K. Sadrnezhaad, and A. Ekrami, Phase Transformation Behavior of Porous NiTi Alloy Fabricated by Powder Metallurgical Method, Mater. Sci. Eng. C., 2009, 29, p 2203–2207

Y.B. Massalski, Ed., Binary Alloy Phase Diagrams, American Society for Metals, Metals Park, 1986

R.M. German, Powder Metallurgy Science, Metal Powder Industries Federation, Princeton, NJ, 1984

L.J. Gibson and M.F. Ashby, Cellular Solids: Structure and Properties, 2nd ed., Cambridge University Press, Cambridge, UK, 1997

Acknowledgments

The authors would like to thank Eng. Abedi and the staff from the School of Metallurgy and Material Engineering of the University of Tehran for their support in performing mechanical experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hosseini, S.A., Yazdani-Rad, R., Kazemzadeh, A. et al. A Comparative Study on the Mechanical Behavior of Porous Titanium and NiTi Produced by a Space Holder Technique. J. of Materi Eng and Perform 23, 799–808 (2014). https://doi.org/10.1007/s11665-013-0810-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0810-x