Abstract

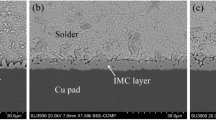

The microstructure and shear property of Cu/Sn–xZn/Cu (x = 0, 2, 5, 9, 30, 70 wt.%) composite solder joints fabricated by transient liquid phase (TLP) bonding were investigated. The results showed that the appropriate amount of Zn particles inhibited Cu6(Sn, Zn)5 phase formation at the Cu/solder interface. The Zn particles can improve the interface IMC morphology of composite solder joints, the interface IMC thickness of Cu/Sn–30Zn/Cu solder joint is only 3.89 μm, and the excessive (30–70 wt.%) Zn particles are harmful to the composite solder joints. Doping 2–9 wt.% Zn particles can improve the shear strength. The maximum shear strength value of the Cu/Sn–9Zn/Cu composite solder joint reaches 14.18 MPa. The fracture mechanism is mainly ductile brittle mixed fracture, which occurs near the Interface reaction zone.

Similar content being viewed by others

References

Shao H K, Wu A P, Bao Y D, Zhao Y, Zou G S, and Liu L, Mater. Character. 469 (2018) 144.

Dele-Afolabi T T, Azmah Hanim M A, Norkhairunnisa M, Yusoff H M, and Suraya M T, J. Alloys Compds. 368 (2015) 649.

Kannojia H K, and Dixit P, J. Mater. Res.-Mater. Electron. 6742 (2021) 32.

Zhang L, Liu Z, Chen S, Wang Y, Long W, Guo Y, Wang S, Ye G, and Liu W, J. Alloys Compds. 980 (2018) 750.

Zhu Z X, Li C C, Liao L L, Liu C K, and Kao C R, J. Alloys Compd. 340 (2016) 671.

Ide E, Angata S, Hirose A, and Kobayashi K F, Acta Mater. 2385 (2005) 53.

Liu H, Wang K, Aasmundtveit K E, and Hoivik N, J. Electron. Mater. 2453 (2012) 41.

Han X, Li X, and Yao P, Soldering Surface Mount Technol. 79 (2021) 34.

Zhang L, and Zhong S J, Front. Mater. 645782 (2021) 8.

Zhang F W, Liu J, Yang F B, Hu Q, He H J, and Xu J, Chin. J. Rare Met. 619 (2005) 29.

Shi Y P, Xue S B, Wang J X, and Gu R H, Weld. Joining. 14 (2007) 4.

Wei J M, Wei G Q, Kang Y Q, and Liu L, Spec. Cast. Nonferrous Alloys. 11 (2019) 39.

Wu Y, Wei X Q, Zhou L, and Zhou Z G, Mater. Rev. 6 (2005) 19.

Shao H K, Wu A P, Bao Y D, and Zhao Y, Mater. Sci. Eng. A. 221 (2017) 680.

Hang C J, Tian Y H, Zhang R, and Yang D S, J Mater Sci Mater Electron 3905 (2013) 24.

Li Q Q, Chan Y C, Zhang K L, and Yung K C, Microelectron Eng. 52 (2014) 122.

Wang Y W, Yang T L, Wu J Y, and Kao C R, J Alloys Compd. 570 (2018) 750.

Shao H K, Wu A P, Bao Y D, and Zhao Y, J Mater Sci. 3508 (2017) 52.

Chu K, Sohn Y, and Moon C, Scripta Materialia. 113 (2015) 109.

Bosco N S, and Zok F W, Acta Materialia. 2019 (2005) 53.

Liu X D, He S L, and Nishikawa H S, Scripta Materialia. 101 (2016) 110.

Liu B L, Tian Y H, Feng J Y, and Wang C X, J Mater Sci 1943 (2017) 52.

Nguyen V L, Kim S H, Jeong J W, Lim T S, Yang D Y, Kim K B, Kim Y J, Lee J H, Kim Y J, and Yang S, Electron. Mater. Lett. 420 (2017) 13.

Mao J, Yang W C, Song Q Q, Lv Y, Jiang S W, Li Y T, and Zhan Y Z, J Mater Res-Mater Electron 10843 (2021) 32.

Wang F J, Zhou L L, Wang X J, and He P, J Alloys Compd 639 (2016) 688.

Yang L, Xu Y, Zhang Y C, Lu K J, Qiao J, Yang Y, Feng X, and Gao H M, J Mater Sci: Mater Electron 8387 (2021) 32.

Yang L, Zhu L, Zhang Y C, Zhou S Y, Xiong Y F, and Wu P C, Mater Res Exp 026304 (2018) 5.

Paul A, Ghosh C, and Boettinger W J, Metall Mater Trans A 952 (2011) 42.

Ladani L, Int J High Speed Electron Syst 1550006 (2015) 24.

Frederikse H P R, Fields R J, and Feldman A, J Appl Phys 2879 (1992) 72.

Yu C, Yang Y, Wang K, Xu J J, Chen J M, and Lu H, J Mater Sci: Mater Electron 124 (2012) 23.

Acknowledgements

This research was financially supported by by the National Natural Science Foundation of China (Grant nos. 51865006 and 52165068), Guangxi Natural Science Foundation Project (Grant No. 2020GXNSFAA297004) and Middle-aged and Young Teachers' Basic Ability Promotion Project of Guangxi (Grant No. 2021KY0787).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Z., Wang, X.Y., Yang, L. et al. Microstructure and Shear properties of Sn–xZn Transient Liquid Phase Bonding in 3D-Chip Stacking Packaging. Trans Indian Inst Met 76, 2757–2763 (2023). https://doi.org/10.1007/s12666-022-02866-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02866-1