Abstract

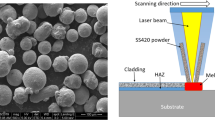

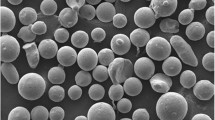

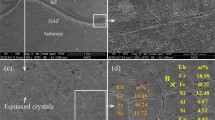

AISI type 316L stainless steel (SS) is used in the manufacturing of components that works in severe aggressive environments. These environments include petrochemical equipments, heat exchangers, power plants, waste water treatments, etc. After prolonged exposure in these environments, corrosion will initiate in these components. The aim of this study is to strengthen the anti-corrosion property of AISI type 316L SS by coating the Stellite 6 alloy via laser cladding. The cladded microstructure was analysed by the optical and FE-SEM micrographs along with the EDS spectra. The nanoindentation was made in the substrate and cladded region to compare the hardness property. In a three-electrode setup, the anti-corrosion behaviour of both AISI type 316L SS and Stellite 6 clad samples was evaluated at 0, 42 and 70 h, followed by the investigation of the corroded morphology and surface roughness (Ra). The results showed that the cladded region contains the Co-rich dendritic structure along with Cr-rich carbides decorated in the dendritic boundaries. These Cr-rich carbides were responsible for enhancing the hardness in the cladded layer. The corrosion test proved the existence of better passive (oxide) film on the cladded samples that provided significant resistance towards corrosion than the AISI type 316L SS samples. Further, the EIS analysis confirmed that the laser cladding of Stellite 6 seems to provide greater Rp values than the AISI type 316L SS. Notably, 70 h clad sample exhibited maximum corrosion resistance in terms of EIS, Tafel and surface roughness.

Similar content being viewed by others

Data availability

The experimental datasets obtained from this research work and then the analysed results during the current study are available from the corresponding author on reasonable request.

References

Painkra T K, Naik K S, Nishad R K, Sen P K, and Bohidar S K, Int J Innov Res Sci Technol 1 (2014) 93.

Talha M, Behera C K, and Sinha O P, Mater Sci Eng C 33 (2013) 3563.

Voronenko B I, Metal Sci Heat Treat 39 (1997) 428.

Baddoo N R J Constr Steel Res 64 (2008) 1199.

Shih C C, Shih C M, Su Y Y, Su L H, Chang M S, and Lin S J, Corros Sci 46 (2004) 427.

Matula M, Hyspecka L, Svoboda M, Vodarek V, Dagbert C, Galland J, Stonawska Z, and Tuma L, Materials Charact 46 (2001) 203.

Cai B, Liu Y, Tian X, Wang F, Li H, and Ji R, Corros Sci 52 (2010) 3235.

Hägg M S, Localised Corrosion and Atmospheric Corrosion of Stainless Steels (Doctoral dissertation, KTH).

Dearnley P A, and Aldrich-Smith G, Wear 256 (2004) 491.

Lee S J, and Lai J J, J Mater Process Technol 140 (2003) 206.

Zhu L, Xue P, Lan Q, Meng G, Ren Y, Yang Z, Xu P, and Liu Z, Opt Laser Technol 138 (2021) 106915.

Jeyaprakash N, Yang C H, and Tseng S P, Int J Adv Manuf Technol 106 (2020) 2347.

Jeyaprakash N, and Yang C H, Mater Manuf Process 35 (2020) 1383.

Birol Y, Wear 269 (2010) 664.

Romo S A, Santa J F, Giraldo J E, and Toro A, Tribol Int 47 (2012) 16.

Ferozhkhan M M, Kumar K G, and Ravibharath R, Arab J Sci Eng 42 (2017) 2067.

Mirshekari G R, Daee S, Bonabi S F, Tavakoli M R, Shafyei A, and Safaei M, Surf Interfaces 9 (2017) 79.

Shahroozi A, Afsari A, Khakan B, and Khalifeh A R, Surf Coat Technol 350 (2018) 648.

Chi H, Pans M A, Bai M, Sun C, Hussain T, Sun W, Yao Y, Lyu J, and Liu H, Fuel 288 (2021)119607.

Sassatelli P, Bolelli G, Gualtieri M L, Heinonen E, Honkanen M, Lusvarghi L, Manfredini T, Rigon R, and Vippola M, Surf Coat Technol 338 (2018) 45.

Brownlie F, Anene C, Hodgkiess T, Pearson A, and Galloway A M, Wear 404 (2018) 71.

Ding Y P, Liu R, Wang L, Li J H, and Yao J H, Prot Metals Phys Chem Surf 56 (2020) 392.

Wu T, Shi W, Xie L, Gong M, Huang J, Xie Y, and He K, Materials 15 (2022) 3952.

Sun S, Brandt M, Harris J, and Durandet Y, Surf Coat Technol 201 (2006) 998.

Liu Y, Ding Y, Yang L, Sun R, Zhang T, and Yang X, J Manuf Process 66 (2021) 341.

Singh S, Goyal D K, Kumar P, and Bansal A, Mater Res Exp 7 (2020) 012007.

Jeyaprakash N, Yang C H, and Sivasankaran S, Mater Manuf Process 35 (2020) 142.

Natarajan J, Yang C H, and Karuppasamy S S, Materials 14 (2021) 6183.

Luo F, Cockburn A, Lupoi R, Sparkes M, and O'Neill W, Surf Coat Technol 212 (2012) 119.

Shin J C, Doh J M, Yoon J K, Lee D Y, and Kim J S, Surf Coat Technol 166 (2003) 117.

Jeshvaghani R A, Shamanian M, and Jaberzadeh M, Mater Des 32 (2011) 2028.

Singh R, Kumar D, Mishra S K, and Tiwari S K, Surf Coat Technol 251 (2014) 87.

Gholipour A, Shamanian M, and Ashrafizadeh F, J Alloys Compnd 509 (2011) 4905.

Li Z, Cui Y, Wang J, Liu C, Wang J, Xu T, Lu T, Zhang H, Lu J, Ma S, and Fan H, Metals 9 (2019) 474.

Motallebzadeh A, Atar E, and Cimenoglu H, Manuf Sci Technol 3 (2015) 224.

Karuppasamy S S, Jeyaprakash N, and Yang CH, Arab J Sci Eng 6 (2022) 1.

Zhu Y Z, Yin Z M, and Hao T E, Trans Nonferrous Metals Soc China 17 (1) 35.

Kosaka T, Suzuki S, Inoue H, Saito M, Waseda Y, and Matsubara E, Appl Surf Sci 103 (1996) 55.

Li K, Li Y, Huang X, Gibson D, Zheng Y, Liu J, Sun L, and Fu Y Q, Appl Surf Sci 414 (2017) 63.

Malayoglu U, Neville A, Beamson G, Mater Sci Eng A 393 (2005) 91.

Wang L, and Li D Y. Wear 255 (2003) 535.

Jeyaprakash N, Yang C H, and Karuppasamy S S. Surf Rev Lett (2022).

Hong M S, Park Y, Kim J G, and Kim K, Effect of Incorporating MoS2 in Organic Coatings on the Corrosion Resistance of 316L Stainless Steel in a 3.5% NaCl Solution. InCORROSION 2019 OnePetro (2019).

Kamburova K, Boshkova N, Tabakova N, Boshkov N, and Radeva T, Colloids Surf A Physicochem Eng Asp 592 (2020) 124546

Hady H, Hammood A S, and Thair L, Mater Today Proc 42 (2021) 2326.

Toloei A, Stoilov V, and Northwood D, The Relationship Between Surface Roughness and Corrosion. InASME International Mechanical Engineering Congress and Exposition 2013 Nov 15 (Vol. 56192, p. V02BT02A054). American Society of Mechanical Engineers.

Acknowledgements

The authors like to acknowledge the Ministry of Science and Technology, Taiwan, for providing the funds for the successful completion of this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jeyaprakash, N., Yang, CH., Karuppasamy, S.S. et al. Stellite 6 Cladding on AISI Type 316L Stainless Steel: Microstructure, Nanohardness and Corrosion Resistance. Trans Indian Inst Met 76, 491–503 (2023). https://doi.org/10.1007/s12666-022-02731-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02731-1