Abstract

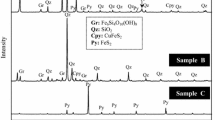

In this investigation, two ore bodies (silicate and carbonate), carefully sized, containing chalcopyrite (CuFeS2) were assessed for their Cu dissolution in acidic ferric sulfate (H2SO4-Fe2(SO4)3) at various pH (1.0, 1.5 and 1.8) and temperature (25 and 50 °C) under atmospheric pressure. Experiments were conducted with a size fraction of 53 + 38 for 12 h at a constant pulp density of 10% solids. The maximum Cu recovery of 70 and 58% was obtained in less than 2 h at pH 1.8 and 50 °C from silicate and carbonate chalcopyrite, respectively. The XRD analyses results of the residues indicated that copper dissolution from its CuFeS2 mineral proceeded through the formation of transient phases, dependent upon the media pH value. Cu2S was the major intermediate phase at pH1.0, while Cu5FeS4 was the major phase at both pH 1.5 and 1.8. It was further observed that mineralogical composition plays a vital role during Cu dissolution. The thermodynamic modeling predicted the sequential formation of CuFeS2 → Cu5FeS4 → Cu2S → CuS in which soluble intermediates were Cu5FeS4 and Cu2S, while CuS was identified as the end-transitory metastable, and main thermodynamically refractory phase, supporting its cumulating behavior throughout the dissolution. The obtained results suggest that the formation of CuS and excessive gypsum could contribute to the passive film formed during CuFeS2 leaching.

Similar content being viewed by others

References

US Congress O T A, Copper: Technology and Competitiveness, U.S. Gover., no. September. Washington, DC: (1988).

Nikoloski A N, and Malley G P O, Hydrometallurgy, 178, (2018) p.231.

De Koning A, Kleijn R, Huppes G, Sprecher B, Van Engelen G, and Tukker A, Resour Conserv Recycl, 129, (2018) p 202.

Lezak S, Cannon C, and Blank T K, Low-carbon metals for a low-carbon world: a new energy paradigm for mines, New York City (2019).

Karcz A P, Damø A J, Illerup J B, Rocks S, Dam-johansen K, and Chaiko D, J Mater Sci, 52, (2017) p 12044.

Peng J et al Chem Eng J, 397, (2020) p 1.

Norgate T, Jahanshahi S, Rankin W, Scientific T C, Elsevier, (2006) p 2.

Aydogan S, Chem Eng J, 123, (2006) p 65.

Tshilombo A F, Mechanism and kinetics of chalcopyrite passivation and depassivation during ferric and microbial leaching,” British Columbia (2004).

Watling H R, Hydrometallurgy, 140, (2013) p 163.

Dutrizac, Metall Trans B, 12, (1981) p 371.

Jorjani E, and Ghahreman A, Hydrometallurgy, 171, (2017) p 333.

Wermink W N, Versteeg G F, The Oxidation of Fe(II) in Acidic Sulfate Solutions with Air at Elevated Pressures. Part 1. Kinetics above 1 M H 2 SO 4,” no. Ii, (2017).

Sole M E S, King M J, Sole K C, and Davenport W G, Extractive Metallurgy of Copper, Fifth Edit. The Netherlands: Elsevier, (2011).

Stott M B, Watling H R, Franzmann P D, and Sutton D, Miner Eng, 13, (2000) p 1117.

Córdoba E M, Muñoz J A, Blázquez M L, González F, and Ballester A, Hydrometallurgy, 93, (2008) p 88.

Carneiro M F C, and Leão V A, Hydrometallurgy, 87, (2007) p 73.

Vilcáez J, Inoue C, Miner Eng, 22, (2009) p 951.

Klauber C, 86, (2008) p 1.

Hiroyoshi N, Miki H, Hirajima T, Tsunekawa M, Hydrometallurgy, 57, (2000) p 31.

Hiroyoshi N, Kuroiwa S, Miki H, Tsunekawa M, and Hirajima T, Hydrometallurgy, 87, (2007) p 1.

Sun X, Yuan W, Jin K, and Zhang Y, Minerals, 382, (2021) p 1.

Gallardo J T, Modeling chalcopyrite leaching kinetics, (2007).

Tanda B C, Eksteen J J, Oraby E A, and Connor G M O, Miner Eng, 135, (2019) p 118.

Dry M J, and Bryson A W, Hydrometallurgy, 21, (1988) p 59.

Warren G W, Wadsworth M E, and El-Raghy S M, Metallurgical Trans B13, (1982) p 571.

Muszer A, Wodka J, Chmielewski T, and S Matuska, Hydrometallurgy, 137, p 1

Majuste D, Chalcopyrite oxidation: Investigation of the electrochemical mechanism by applying ex situ and in situ synchrotron X-ray diffraction techniques and quantification of the galvanic effect of pyrite, (2011).

Kimball B E, Rimstidt J D, and Brantley S L, Appl Geochem, 25, (2010) p 972.

Tshilombo O M, and Ojumu T V, Adv Mater Res, 825, (2013) p 401.

Bai Y, Wang W, Zhao S, Lu D, Xie F, and Dreisinger D, Mineral Process Extractive Metallurgy Rev, (2021) p 1.

Dixon D G, Mayne D D, and Baxter K G, Can Metall Q, 47, (2008) p 327.

Simons K, Geogia, (2014).

Antonijevic G D, Bogdanovic M M, Investigation of the leaching of chalcopyritic ore in acidic solutions, 73, (2004) p 245.

Córdoba E M, Muñoz J A, Blázquez M L, González F, and Ballester A, Miner Eng 22 (2009) p 229.

Acero P, Cama P, Ayora J, Asta C, Geol Acta, 7, (2009) p 389.

Free M L, SME Annu Meet Exhib (2010) p 74.

Ntengwe F, Open Miner Process J, 3, (2010) p 60.

Koleini S M J, Jafarian M, Abdollahy M, and Aghazadeh V, Ind Eng Chem Res, 49, (2010) p 5997.

Saavedra A, García-Meza J V, Cortón E, and González I, Electrochim Acta, 265, (2018) p 569,

Lai J C-Y, Fundamental study of the controlled-potential leaching of chalcopyrite, (2003)

Acknowledgements

The authors are thankful the local South African mining company which participated in this research by providing the samples, the extraction metallurgy laboratory at the University of Johannesburg for equipment utilization, the North-West University and the University of South Africa for the support and promotion of this research.

Funding

This study was funded by the North-West University (IREA Account).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Author MM is indebted to funding through NSERC-DG, CFI, Public Works and Government Service Canada (formally Devco arm of ECBC), the Industrial Research Chair of Mine Water Management at CBU, ACOA and IRAP grants.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nyembwe, K.J., Fosso-Kankeu, E., Waanders, F. et al. Formation of Phase Transition During the Dissolution of Silicate and Carbonate Chalcopyrite in Acidic Ferric Sulfate. Trans Indian Inst Met 75, 1767–1779 (2022). https://doi.org/10.1007/s12666-022-02546-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02546-0