Abstract

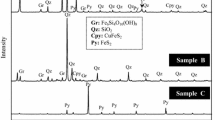

Being the most abundant copper sulfidic mineral, chalcopyrite (CuFeS2) is refractory to conventional hydrometallurgical methods, the result of which is incomplete or inefficient dissolution of copper. The complete dissolution in the presence of silver (Ag) catalyst was proved under optimized operating settings. The catalytic yield reached its highest value (97.18% conversion of CuFeS2 within 8 h) at 75 °C, potential control at 500–600 mV vs. standard hydrogen electrode (SHE), and solid percentage of 10% (w/v). The fresh and converted CuFeS2 samples were analyzed using chemical, mineralogical, and SEM–EDS techniques. These results indicated that the negative effect of the passive layer containing secondary precipitates (jarosite, sulfur, metal-deficient sulfide layer) formed on CuFeS2 can be completely controlled by providing optimal catalytic circumstances. Under these conditions, SEM images showed that chemical agents could have full access to the surface of CuFeS2 particles to completely convert. Leaching in sulfate media was one of the important advantages that these optimal conditions had for achieving nearly 100% recovery. As such, there are no concerns about chloride corrosion or related economic considerations. On the other hand, this leaching environment is completely compatible with the current operational solvent extraction and industrial electrowinning processes in the complex site, which can be considered as another important benefits of this optimized process. In terms of mechanisms, by analyzing SEM images of chalcopyrite samples before and after leaching, it was found that in addition to porosity created by silver ions at the surface for electron transfer, diffusion and formation of silver and silver sulfide itself was the main factor in increasing the electron flow capability of the chalcopyrite. Despite the passivation layer, this point was identified as the most important reason for increasing copper recovery and dissolution.

Graphical Abstract

Similar content being viewed by others

References

Moravvej Z et al (2021) The effect of radio-waves irradiation on copper-ore leaching. Hydrometallurgy 201:105584

Vakylabad AB (2011) A comparison of bioleaching ability of mesophilic and moderately thermophilic culture on copper bioleaching from flotation concentrate and smelter dust. Int J Miner Process 101(1–4):94–99

Vakylabad AB et al (2012) Bio-processing of copper from combined smelter dust and flotation concentrate: a comparative study on the stirred tank and airlift reactors. J Hazard Mater 241:197–206

Asgari K et al (2021) Effect of externally adding pyrite and electrical current on galvanic leaching of chalcopyrite concentrate. Physicochem Prob Mineral Process 57

Vakylabad AB et al (2011) Tank bioleaching of copper from combined flotation concentrate and smelter dust. Int Biodeterior Biodegradation 65(8):1208–1214

Vakylabad AB et al (2016) Optimization of staged bioleaching of low-grade chalcopyrite ore in the presence and absence of chloride in the irrigating lixiviant: ANFIS simulation. Bioprocess Biosyst Eng 39(7):1081–1104

Behrad Vakylabad A, Manafi Z (2020) Bioleaching operations of the low-grade chalcopyrite ore in the chloride conditions using adapted Indigenous microorganisms. J Microb World 12(4):328–342

Vakylabad AB et al (2016) A procedure for processing of pregnant leach solution (PLS) produced from a chalcopyrite-ore bio-heap: CuO Nano-powder fabrication. Hydrometallurgy 163:24–32

Moravvej Z, Mohebbi A, Daneshpajouh S (2018) The microwave irradiation effect on copper leaching from sulfide/oxide ores. Mater Manuf Processes 33(1):1–6

Thao NTP et al (2020) Redox potential-dependent chalcopyrite leaching in acidic ferric chloride solutions: Leaching experiments. Hydrometallurgy 194:105299

Kartal M et al (2020) Enhancing chalcopyrite leaching by tetrachloroethylene-assisted removal of sulphur passivation and the mechanism of jarosite formation. Hydrometallurgy 191:105192

Baláž P, Achimovičová M (2006) Mechano-chemical leaching in hydrometallurgy of complex sulphides. Hydrometallurgy 84(1–2):60–68

Nicolle M et al (2015) Leaching of copper sulphides. In: Copper Cobalt Africa, incorporating the 8th Southern African Base Metals Conference

Vakylabad AB (2021) Treatment of highly concentrated formaldehyde effluent using adsorption and ultrasonic dissociation on mesoporous copper iodide (CuI) nano-powder. J Environ Manag 285:112085

Córdoba E et al (2008) Leaching of chalcopyrite with ferric ion. Part I: General aspects. Hydrometallurgy 93(3–4):81–87

Harmer SL et al (2006) The evolution of surface layers formed during chalcopyrite leaching. Geochim Cosmochim Acta 70(17):4392–4402

Wang S (2005) Copper leaching from chalcopyrite concentrates. Jom 57(7):48–51

Alimohammadi O (2020) Effective removal of Cd (II) and Pb (II) from aqueous solution by synthesized palladium nanoparticles using spent PdCl2 catalyst: experimental design and optimization. Adv J Chem-Sect A 3(3):289–300

Parra-Cabrera C et al (2018) 3D printing in chemical engineering and catalytic technology: structured catalysts, mixers and reactors. Chem Soc Rev 47(1):209–230

Sun D et al (2020) Rational design of Ag-based catalysts for the electrochemical CO2 reduction to CO: a review. Chemsuschem 13(1):39–58

Rase HF (2019) Handbook of commercial catalysts: heterogeneous catalysts. CRC press

Opoku E (2020) Progress on homogeneous ruthenium complexes for water oxidation catalysis: experimental and computational insights. J Chem Rev 2(4):211–227

Nakhaei A, Davoodnia A, Nakhaei H (2019) (NH4) 42 [MoVI72MoV60O372 (CH3COO) 30 (H2O) 72] as a heterogeneous reusable catalyst for organic reactions: mini-review. J Chem Rev 1(2):139–153

Kazemi F, Abedi MR, Ebrahimi M (2021) Photodegradation of tramadol using α-Fe2O3 nanoparticles/12-tungstosilicic acid as an efficient photocatalyst in water sample employing box-behnken design. Chem Methodol 5(6):522–533

Hiroyoshi N et al (2002) A new reaction model for the catalytic effect of silver ions on chalcopyrite leaching in sulfuric acid solutions. Hydrometallurgy 63(3):257–267

Romero R et al (2003) Copper recovery from chalcopyrite concentrates by the BRISA process. Hydrometallurgy 70(1–3):205–215

Moravvej Z, Tabrizi FF, Rahimpour M (2021) Vapor phase conversion of furfural to valuable biofuel and chemicals over alumina-supported catalysts: screening catalysts. Topics Catal 1–14

Vakylabad AB, Nazari S, Darezereshki E (2022) Bioleaching of copper from chalcopyrite ore at higher NaCl concentrations. Minerals Eng 175:107281

Nazari G, Dixon D, Dreisinger D (2012) The mechanism of chalcopyrite leaching in the presence of silver-enhanced pyrite in the Galvanox™ process. Hydrometallurgy 113:122–130

Koleini SJ, Aghazadeh V, Sandström Å (2011) Acidic sulphate leaching of chalcopyrite concentrates in presence of pyrite. Miner Eng 24(5):381–386

Price D, Warren G (1986) The influence of silver ion on the electrochemical response of chalcopyrite and other mineral sulfide electrodes in sulfuric acid. Hydrometallurgy 15(3):303–324

Wang J et al (2021) In-situ probing of electrochemical dissolution and surface properties of chalcopyrite with implications for the dissolution kinetics and passivation mechanism. J Colloid Interface Sci 584:103–113

Liao R et al (2020) XRD and synchrotron-based XRD study of chalcopyrite leaching catalyzed by silver ions. in TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings. Springer

Yang B et al (2020) Catalytic effect of silver on copper release from chalcopyrite mediated by Acidithiobacillus ferrooxidans. J Hazard Mater 392:122290

Liao R et al (2021) Combined effect of silver ion and pyrite on AMD formation generated by chalcopyrite bio-dissolution. Chemosphere 279:130516

Barton IF, Hiskey JB (2021) Chalcopyrite leaching in novel lixiviants. Hydrometallurgy 105775

Zhang H et al (2021) Enhancement mechanism of polyoxyethylene nonyl phenyl ether on the bioleaching of chalcopyrite. Minerals Eng 173:107237

Phuong Thao NT et al (2020) Redox potential-dependent chalcopyrite leaching in acidic ferric chloride solutions: leaching experiments. Hydrometallurgy 194:105299

Córdoba E et al (2008) Leaching of chalcopyrite with ferric ion. Part III: effect of redox potential on the silver-catalyzed process. Hydrometallurgy 93(34):97–105

Sokić M et al (2019) Kinetics of chalcopyrite leaching by hydrogen peroxide in sulfuric acid. Metals 9(11):1173

Ruiz-Sánchez Á, Lapidus GT (2017) Study of chalcopyrite leaching from a copper concentrate with hydrogen peroxide in aqueous ethylene glycol media. Hydrometallurgy 169:192–200

Sokić MD, Marković B, Živković D (2009) Kinetics of chalcopyrite leaching by sodium nitrate in sulphuric acid. Hydrometallurgy 95(3–4):273–279

Hernández P et al (2020) Caliche and seawater, sources of nitrate and chloride ions to chalcopyrite leaching in acid media. Metals 10(4):551

Hernández PC et al (2018) Leaching of chalcopyrite in acidified nitrate using seawater-based media. Minerals 8(6):238

Laidler KJ (1984) The development of the Arrhenius equation. J Chem Educ 61(6):494

Galwey AK, Brown ME (2002) Application of the Arrhenius equation to solid state kinetics: can this be justified? Thermochim Acta 386(1):91–98

Arrhenius S (1889) Über die Dissociationswärme und den Einfluss der Temperatur auf den Dissociationsgrad der Elektrolyte. Z Phys Chem 4(1):96–116

Logan S (1982) The origin and status of the Arrhenius equation. J Chem Educ 59(4):279

Klauber C (2008) A critical review of the surface chemistry of acidic ferric sulphate dissolution of chalcopyrite with regards to hindered dissolution. Int J Miner Process 86(1–4):1–17

Brümmer G, Barrow N, Fischer L (2013) Effect of porosity of goethite on the sorption of six heavy metal ions. Eur J Soil Sci 64(6):805–813

Peters E (1976) Direct leaching of sulfides: chemistry and applications. Metall Trans B 7(4):505–517

Ghahremaninezhad A et al (2015) A model for silver ion catalysis of chalcopyrite (CuFeS2) dissolution. Hydrometallurgy 155:95–104

Lai L et al (2021) Critical review of natural iron-based minerals used as heterogeneous catalysts in peroxide activation processes: Characteristics, applications and mechanisms. J Hazard Mater 125809

Fullston D, Fornasiero D, Ralston J (1999) Zeta potential study of the oxidation of copper sulfide minerals. Colloids Surf, A 146(1–3):113–121

Millero FJ et al (1989) Oxidation of hydrogen sulfide with hydrogen peroxide in natural waters. Environ Sci Technol 23(2):209–213

Antonijević M, Janković Z, Dimitrijević M (2004) Kinetics of chalcopyrite dissolution by hydrogen peroxide in sulphuric acid. Hydrometallurgy 71(3–4):329–334

Acknowledgements

The authors acknowledge the financial support of the National Iranian Copper Industries Company (NICICo.), Grant No. (1002).

Author information

Authors and Affiliations

Contributions

LZ: conceptualization, methodology, writing—original draft. ABV: conceptualization, data curation, writing—review and editing. MEM: conceptualization, supervision, methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zand, L., Vakylabad, A.B. & Masoumi, M.E. Homogeneous Catalytic Dissolution of Recalcitrant Chalcopyrite (CuFeS2). Top Catal (2022). https://doi.org/10.1007/s11244-022-01565-x

Accepted:

Published:

DOI: https://doi.org/10.1007/s11244-022-01565-x