Abstract

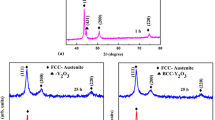

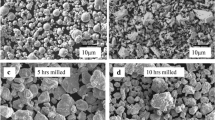

Composite powders of pre-alloyed 316 L austenitic stainless steel with yttria (Y2O3) powder in various compositions (0.3, 1.0, 1.5 and 2 wt%) were synthesized by mechanical alloying using a high energy ball mill. The 25-h milled powder has shown no changes other than exhibiting an austenite phase of FCC (a = 3.54 Å) structure. Milled powders were found to contain nano-yttria dispersed in the austenitic stainless steel matrix of nano-crystallite size and with high lattice strain. Milled powders were cold pressed and sintered at 1100 °C (1373 K) in a controlled atmosphere. It can be inferred that nano-yttria dispersion restricts grain growth of matrix even during conventional sintering. The present yittria dispersed austenitic alloy showed the low physical density and increase in compressive strength (194–374 MPa) and hardness (477–528 HV). The compressive strength and hardness enhancement can be attributed primarily to the dispersoids of nano-yttria in the austenitic matrix by dispersion strengthening/hardening mechanisms.

Similar content being viewed by others

References

Ukai T, Nishida S, Okuda T, and Yoshitake T, J Nucl Mater 263 (1998) 1745.

Raman L, Gothandapani K, and Murty B S, Def Sci J 66 (2016) 316.

El-genk M S, and Tournier J, J Nucl Mater 340 (2005) 93. https://doi.org/https://doi.org/10.1016/j.jnucmat.2004.10.118.

Yvon P, and Carré F, J Nucl Mater 385 (2009) 217. https://doi.org/https://doi.org/10.1016/j.jnucmat.2008.11.026.

Susila P, Sturm D, Heilmaier M, Murty B S, and Sarma V S, J Mater Sci 45 (2010) 4858. https://doi.org/https://doi.org/10.1007/s10853-010-4264-3.

Murty K L, and Charit I, J Nucl Mater 383 (2008) 189. https://doi.org/https://doi.org/10.1016/j.jnucmat.2008.08.044.

Veternikova J S, Degmova J, Pekarcikova M, Simko F, Petriska M, Skarba M, Mikula P, and Pupala M, Appl Surf Sci 387 (2016) 965. https://doi.org/https://doi.org/10.1016/j.apsusc.2016.06.151.

David C, Panigrahi B K, Balaji S, Balamurugan A K, Nair K G M, Amarendra G, and Sundar C S, J Nucl Mater 383 (2008) 132. https://doi.org/https://doi.org/10.1016/j.jnucmat.2008.08.049.

Ukai S, and Fujiwara M, J Nucl Mater 311 (2002) 749.

Ken H, Yao Z, Zhou Z, Wang M, Kaitasov O, and Daymond M R, J Nucl Mater 455 (2014) 242. https://doi.org/https://doi.org/10.1016/j.jnucmat.2014.06.024.

Seils S, Kauffmann A, Hinrichs F, Schliephake D, Boll T, and Heilmaier M, Mater Sci Eng A 786 (2020) 139452. https://doi.org/https://doi.org/10.1016/j.msea.2020.139452.

Masuda H, Tobe H, Sato E, Sugino Y, and Ukai S, Acta Mater 132 (2017) 245. https://doi.org/https://doi.org/10.1016/j.actamat.2017.04.047.

Klueh R L, Hashimoto N, Kenik E A, and Miyahara K, J Nucl Mater 311 (2008) 773.

Oka H, Watanabe M, Hashimoto N, Ohnuki S, and Yamashita S, J Nucl Mater 442 (2013) S164. https://doi.org/https://doi.org/10.1016/j.jnucmat.2013.04.073.

Oka K, Ohnuki S, Yamashita S, Akasaka N, Ohtsuka S, and Tanigawa H, Mater Trans 48 (2007) 2563. https://doi.org/https://doi.org/10.2320/matertrans.MD200715.

De Sanctis M, Fava A, Lovicu G, Montanari R, Richetta M, Testani C, and Varone A, Metals (Basel) 7 (2017) 1. https://doi.org/https://doi.org/10.3390/met7080283.

Meharwal A, Kumar M, Karak S K, Majumdar J D, and Manna I, Metall Mater Trans A 51 (2020) 5257. https://doi.org/https://doi.org/10.1007/s11661-020-05918-7.

Alamo M, Lambard A, Averty V, and Mathon X, J Nucl Mater 333 (2004) 333. https://doi.org/https://doi.org/10.1016/j.jnucmat.2004.05.004.

Li S, Zhou Z, Jang J, Wang M, Hu H, Sun H, and Zou L, J Nucl Mater 455 (2014) 194. https://doi.org/https://doi.org/10.1016/j.jnucmat.2014.05.061.

Ganesan D, Sellamuthu P, and Prashanth K G, J Manuf Mater Process 4 (2020) 93. doi:https://doi.org/10.3390/jmmp4030093.

Peng Y, Yu L, Liu Y, Ma Z, Li H, and Liu C, Mater Sci Eng A 767 (2019) 138419. https://doi.org/https://doi.org/10.1016/j.msea.2019.138419.

Shalchi B, Zahiri R, Zheng W, Guzonas D, Chmielus M, Chen W, and Li J, J Supercrit Fluids 119 (2017) 245. https://doi.org/https://doi.org/10.1016/j.supflu.2016.10.002.

Shivam V, Basu J, Pandey V K, Shadangi Y, and Mukhopadhyay N K, Adv Powder Technol 29 (2018) 2221. https://doi.org/https://doi.org/10.1016/j.apt.2018.06.006.

Suryanarayana C, Prog Mater Sci 46 (2001) 1. https://doi.org/https://doi.org/10.1016/S0079-6425(99)00010-9.

Shivam V, Shadangi Y, Basu J, and Mukhopadhyay N K, J Mater Res 35 (2019) 787. https://doi.org/https://doi.org/10.1557/jmr.2019.5.

Suryanarayana C, Ivanov E, and Boldyrev V, Mater Sci Eng A 304 (2001) 151. https://doi.org/https://doi.org/10.1016/S0921-5093(00)01465-9.

Shadangi Y, Sharma S, Shivam V, Basu J, Chattopadhyay K, Majumdar B, and Mukhopadhyay N K, J Alloys Compd 828 (2020) 154258. https://doi.org/https://doi.org/10.1016/j.jallcom.2020.154258.

Ali F, Scudino S, Liu G, Srivastava V C, Mukhopadhyay N K, Khoshkhoo M S, Prashanth K G, Uhlenwinkel V, Calin M, and Eckert J, J Alloys Compd 536 (2012) S130. https://doi.org/https://doi.org/10.1016/j.jallcom.2011.12.022.

Karak S K, Majumdar J D, Witczak Z, Lojkowski W, and Manna I, Mater Sci Eng A 580 (2013) 231. https://doi.org/https://doi.org/10.1016/j.msea.2013.04.085.

Boegelein T, Dryepondt S N, Pandey A, Dawson K, and Tatlock G J, Acta Mater 87 (2015) 201. https://doi.org/https://doi.org/10.1016/j.actamat.2014.12.047.

Hunt R M, Kramer K J, and El-dasher B, J Nucl Mater 464 (2015) 80. https://doi.org/https://doi.org/10.1016/j.jnucmat.2015.04.011.

Ghayoor M, Lee K, He Y, Chang C, Paul B K, and Pasebani S, Mater Sci Eng A 788 (2020) 139532. https://doi.org/https://doi.org/10.1016/j.msea.2020.139532.

Dai C, Schade C, Apelian D, and Lavernia E J, Metall Mater Trans B 49 (2018) 3043. https://doi.org/https://doi.org/10.1007/s11663-018-1429-y.

Klar P K, and Samal E, Powder Metallurgy Stainless Steels: Processing, Microstructures, and Properties, ASM International (2007) 1.

Okuda T, and Fujiwara M, J Mater Sci Lett 14 (1995) 1600. https://doi.org/https://doi.org/10.1007/BF00455428.

Wang M, Sun H, Zou L, Zhang G, Li S, and Zhou Z, Powder Technol 272 (2015) 309. https://doi.org/https://doi.org/10.1016/j.powtec.2014.12.008.

Kim I, and Choi B, Met Mater Int 8 (2002) 265.

Saber M, Xu W, Li L, Zhu Y, Koch C C, and Scattergood R O, J Nucl Mater 452 (2014) 223. https://doi.org/https://doi.org/10.1016/j.jnucmat.2014.05.014.

Murty B S, and Ranganathan S, Int Mater Rev 43 (1998) 101.

Benjamin J S, and Volin T E, Metall Trans 5 (1974) 1929.

Acknowledgements

The authors are thankful to Prof. R.K Mandal, Dr. Joysurya Basu, Mr Yagnesh Shadangi and Mr. Saptarshi Mukherjee for many stimulating discussions and their support. Authors are also grateful to the Advanced Research Centre for Iron and steel (ARCIS) of the Institute funded by the Steel Development Fund, Ministry of Steel, India. The authors would also like to acknowledge the DST-FIST funding for providing Electron microscopy facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Roy, T., Shivam, V., Chattopadhyay, K. et al. Microstructural Evolution and Mechanical Properties of Nano-Yttria Dispersed 316 L Austenitic Stainless Steel by Mechanical Alloying and Sintering. Trans Indian Inst Met 74, 2093–2104 (2021). https://doi.org/10.1007/s12666-021-02317-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02317-3