Abstract

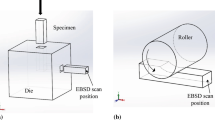

In this experimental study, a commercially available AA 6063 in the form of cold profile extruded and T6 heat treated was processed by Incremental Equal Angular Pressing (I-ECAP) through the BC route. I-ECAP deformation was applied at room temperature with a feeding rate of 0.1 mm/cycle. Afterward, the effect of I-ECAP on the microstructure and mechanical properties of AA 6063 was investigated in detail. The aim of this study was to investigate the possibilities to improve properties of semi-products of commercially available aluminum alloy, especially for industrial applications. According to the visible light microscope observations 4 passes of I-ECAP resulted in grain size reduction, which was 46%. The hardness and tensile test results showed that the I-ECAP process significantly increased mechanical properties of the billets. The hardness was 56% higher, and the mechanical strength was 37% higher than measured for the initial state. Moreover, the grain size distribution was more homogenous in the 4 I-ECAP passes processed samples than the initial state. According to these results, the I-ECAP method has potential in industrial usage for manufacturing ultrafine and fine-grain semi- and final products with superior mechanical properties.

Graphic abstract

Similar content being viewed by others

References

Valiev R Z, Estrin Y, Horita Z, Langdon T G, Zehetbauer M J and Zhu Y, JOM 68 (2006) 1216.

Zhu Y T and Langdon T G, JOM 56 (2004) 58.

Hansen N and Mehl R F, Metall Mater Trans A: Phys Metall Mater Sci 32 (2001) 2917.

Valiev R Z, and Langdon T G, Prog Mat Sci 51 (2006) 881.

Rezaei M R, Shabestari S G, and Razavi S H, Compos Interfaces 25 (2018) 669.

Mousavi S E, Naghshekesh N, Ahmadi F, Sadeghi B, and Cavaliere P, J Mater Sci Eng A 728 (2018) 231.

Khelfa T, Muñoz-Bolaños J A, Li F, Cabrera-Marrero J M, and Khitouni M, Met Mater Int 26 (2020), 1247.

Wang Y C, Afifi M A, Cheng X, Li S, and Langdon T G, Adv Eng Mater 22 (2020) 1.

Bulutsuz A G, Chrominski W and Huang Y, et al Adv. Eng. Mater., 22 (2020)

A.G. Bulutsuz, M.E. Yurci, N.M. Durakbaşa, Mater. Res. 21 (2018)

Rhee K Y, Han W Y, Park H J, and Kim S S, J Mater Sci Eng A 25 (2004) 70.

Bazarnik P, Huang Y, Lewandowska M, and Langdon T G, J Mater Sci Eng A 712 (2018) 513.

Pachla W, Kulczyk M, and Sus-Ryszkowska M, Mazur A, and Kurzydlowski K J, J Mater Process Technol 205 (2008) 173.

Zhilyaev A P, Langdon T G, Prog Mater Sci 53 (2008) 893.

Xu C,Horita Z, and Langdon T G, Acta Mater 55 (2007) 203.

Huang J Y, Zhu Y T, Jiang H, and Lowe T C, Acta Mater 49 (2001) 1497.

Raab G J, Valiev R Z, Lowe T C, and ZhuY T, J Mater Sci Eng A 382 (2004) 30.

Rajinikanth V, Arora G, Narasaiah N, and Venkateswarlu K, Mater Lett 62 (2008) 301.

Pandey S C, Joseph M A, Pradeep M S, Raghavendra K, Ranganath V R, Venkateswarlu K, and Langdon T G, J Mater Sci Eng A 62 (2012) 301.

Thangapandian N, Balasivanandha Prabu S, and Padmanabhan K A, J Mater Sci Eng A 649 (2016) 229.

Siddesha H S and Shantharaja M, JOM 65 (2013) 294.

Głuchowski W, Stobrawa J, Rdzawski Z, and Malec W, Mater Sci Forum 674 (2011) 177.

Gunderov D V, Polyakov A V, Semenova I P, Raab G I, Churakova A A, Gimaltdinova E I, Sabirov I, and Segurado J, Mate Sci Eng 562 (2013) 128.

Semenova I P, Polyakov A V, Raab G I, Lowe T C, and Valiev R Z, J Mater Sci 47 (2012) 7777.

Xu C, Schroeder S, Berbon P B, and Langdon T G, Acta Mater 58 (2010) 1379.

Lee J C, Seok H K, Han J H, and Chung Y H, Mater Res Bull 36 (2001) 997.

Rosochowski A, and Olejnik L, AIP Proceedings 907 (2007).

Rosochowski A, Olejnik L, and Richert M, Mater Sci Forum 584–586 (2008) 139.

Olejnik L, Rosochowski A, and Richert M, Mater Sci Forum 584-586 (2008).

Gzyl M, Rosochowski A, Boczkal S, and Olejnik L, J Mater Sci Eng A 638 (2015) 20.

Mohebbi M S, and Akbarzadeh A, J Mater Sci Eng A 528 (2010) 180.

Hohenwarter A, J Mater Sci Eng 626 (2015) 80.

Eskandarzade M, Masoumi A, Faraji G, Mohammadpour M, and Yan X S, J Alloys Compd 695 (2017)1539.

Frint P, Härtel M, Selbmann R, Dietrich D, Bergmann M, Lampke T, Landgrebe D, and Wagner M F X, J Met 8 (2018).

Takizawa Y, Sumikawa K, Watanabe K, Masuda T, Yumoto M, Kanai Y, Otagiri Y, and Horita Z, Metall Mater Trans A Phys Metall Mater Sci 49 (2018) 1830.

Shigeno E, Komatsu T, Sumikawa K, Masuda T, Takizawa Y, Yumoto M, Otagiri Y, and Z. Horita, Mater Trans 48 (2018) 1830.

Lipinska M, Chrominski W, Olejnik L, Golinski J, Rosochowski A, and Lewandowska M, Metall. Mater. Trans. A Phys Metall Mater Sci 48 (2017) 4871.

Olejnik L, Chrominski W, Rosochowski A, Lipinska M, and Lewandowska M, IOP Con Series: Mater Sci Eng (2014) 63.

Chrominski W, Olejnik L, Rosochowski A, Lewandowska M, J Mater Sci Eng A 636 (2015)172.

Chrominski W, Kulczyk M, Siwek M, and Lewandowska M, Mater Sci Forum 765 (2013) 388.

Majzoobi G H, Nemati J, Pipelzadeh M K, and Sulaiman S, Int J Adv Manuf Technol 84 (2016) 663.

Abd El Aal M I, and Sadawy M M, Trans. Nonferrous Met. Soc. China (English Edition), 25 (2015) 3865.

Faraji G, Roostae S, Seyyed Nosrati A, Kang J Y, and Kim H S, Metall Mater Trans A Phys Metall Mater Sci 46 (2015) 1805.

Samaee M, Najafi S, Eivani A R, Jafarian H R, and Zhou J, J Mater Sci Eng A 669 (2016) 350.

Das M, Das G, Ghosh M, Wegner M, Rajnikant V, Ghosh Chowdhury S, and Pal T K, J Mater Sci Eng A 558 (2012) 525.

Bagherzadeh S, Abrinia K, Liu Y, and Han Q, Int J Adv Manuf Technol 88 (2017) 229.

Edwards G A, Stiller K, Dunlop G L, and Couper M J, Acta Mater 46 (1998) 3893.

Marioara C D, Andersen S J, Jansen J, and Zandbergen H W, Acta Mater. 49 (2001) 321.

Najafi S, Eivani A R, Samaee M, et al. Mater Charact 136 (2018) 60.

Gzyl M, Rosochowski A, and Boczkal S, et al, Adv Eng Mater 18 (2016).

Qarni M J, Sivaswamy G, Rosochowski V, and Boczkal S, Mater Design 122 (2017) 385.

Lapovok R, Loader C, Torre F H D, and Semiatin S L, J Mater Sci Eng A 425 (2006) 36.

Acknowledgement

This research was supported by TEM Technical Electrical Materials Industry and Trade Inc. Company and by The Scientific and Technological Research Council of Turkey (No. 216M037).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Günay Bulutsuz, A., Chrominski, W. Incremental Severe Plastic Deformation Effect on Mechanical and Microstructural Characteristics of AA6063. Trans Indian Inst Met 74, 69–77 (2021). https://doi.org/10.1007/s12666-020-02122-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02122-4