Abstract

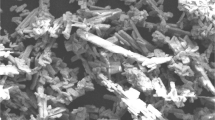

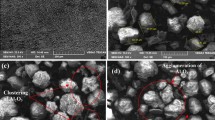

In this study, AA 7075 and its composites were developed using ex situ (stir casting) process for varying compositions 1–3 in weight fraction (wt%) of aluminosilicate (nanoclay) at an interval of 1 wt%. The developed alloy and its composites have undergone T6 heat treatment condition. As per the ASTM standard G99-95, tribological study of the developed alloy and its composites were performed using pin-on-disc equipment under ambient temperature. The composites with 1 and 2 wt% of nanoclay showed increase in wear resistance compared to matrix material with mild wear. Coefficient of friction (CoF) value increased by addition of nanoclay compared to matrix material, due to applied load and sliding speed. To understand the wear mechanism, worn specimen’s surface morphology were examined using field emission-scanning electron microscope (FE-SEM). Further addition of nanoclay above 2 wt% showed some severe wear, cluster formation and poor bonding of nanoclay into the matrix material. Hardness value increased at 1 and 2 wt% of nanoclay and decreased at 3 wt% due to the improper bonding with matrix material. Reinforcement of nanoclay particles with 1 and 2 wt% reduced the wear rate and improved the durability of the matrix material. AA7075 (T6) material showed that it has suffered from abrasive wear mechanism. Also, nanocomposites showed the oxidation and adhesive as a dominant wear mechanism.

Similar content being viewed by others

References

Mazahery A, and Shabani M O, JOM 64 (2012) 323.

Singh J, Friction 4 (2016) 191.

Das S, Das S, and Das K, Compos Sci Technol 67 (2007) 746.

Mondal D P, Das S, Jha A K, and Yegneswaran A H, Wear 223 (1998) 131.

Kumar P R S, Kumaran S, Rao T S, and Natarajan S, Mater Sci Eng A 527 (2010) 1501.

Borgonovo C, and Apelian D, Mater Sci Forum 678 (2011) 1.

Kumar S, and Balasubramanian V, Tribol Int 43 (2010) 414.

Ahmed A, Neely A J, Shankar K, Nolan P, Moricca S, and Eddowes T, Metall Mater Trans A 41 (2010) 1582.

Dursun T, and Soutis C, Mater Des 56 (2014) 862.

Miracle D B, Compos Sci Technol 65 (2005) 2526.

Rahimian M, Parvin N, and Ehsani N, Mater Des 32 (2011) 1031.

Sardar S, Karmakar S K, and Das D, Adv Mater Res 1042 (2014) 58.

Agbeleye A A, Esezobor D E, Balogun S A, Agunsoye J O, Solis J, and Neville A, J King Saud Univ Sci 32 (2020) 21.

Samuel Ratna Kumar P S, John Alexis S, Gautham Siddharth M, and Joses Jenish S, Int J Mech Prod Eng Res Dev 8 (2018) 783.

Esezobor D E, Obidiegwu E O, and Lawal G I, J Emerg Trends Eng Appl Sci 5 (2014) 305.

Rajesh S, Velmurugan C, Ebenezer Jacob Dhas D S, and Samuel Ratna Kumar P S, Mater Res Express 6 (2019) 1265b4.

Sahin Y, and Özdin K, Mater Des 29 (2008) 728.

Suresha B, Siddaramaiah, Kishore, Seetharamu S, and Kumaran P S, Wear 267 (2009) 1405.

Kumar A, Mahapatra M M, and Jha P K, Wear 306 (2013) 170.

Harsha A P, and Tewari U S, Polym Test 22 (2003) 403.

Pushkar J H A, Rakesh Kumar G, and Rajnesh T, Friction 5 (2017) 437.

Krishnakumar M, Mohnbabu A, and Saravanan R, Trans Indian Inst Met 72 (2019) 2395.

Samuel Ratna Kumar P S, Edwin Sudhagar P, John Alexis S, and Subramani M, Trans Indian Inst Met 72 (2019) 2449.

Dwiwedi S K, Srivastava A K, and Chopkar M K, Trans Indian Inst Met 72 (2019) 73.

Al-Qutub A M, Khalil A, Saheb N, and Hakeem A S, Wear 297 (2013) 752.

Jagannatham M, Senthil Saravanan M S, and Sivaprasad K, J Mater Eng Perform 27 (2018) 5675.

Sardar S, Karmakar S K, and Das D, Measurement 127 (2018) 42.

Ul Haq M I, and Anand A, Silicon 10 (2018) 1819.

Siva Sankara Raju R, Panigrahi M K, Ganguly R I, and Srinivasa Rao G, Tribol Int 129 (2019) 55.

Baradeswaran A, and Elaya Perumal A, Compos Part B 56 (2014) 464.

Sivasankaran S, Ramkumar K R, Al-Mufadi F A, and Irfan O M, Met Mater Int (2019), https://doi.org/10.1007/s12540-019-00543-5.

Kaushik N, and Singhal S, Mater Today Proc 5 (2018) 24147.

Lakshmikanthan A, Bontha S, Krishna M, Koppad P G, and Ramprabhu T, J Alloys Compd 786 (2019) 570.

Shyu R F, and Ho C T, J Mater Process Technol 171 (2006) 411.

Ramkumar K R, Sivasankaran S, Al-Mufadi F A, Siddharth S, and Raghu R, Arch Civ Mech Eng 19 (2019) 428.

Raoa V R, Ramanaiah N, and Sarcar M M M, J Mater Res Technol 5 (2016) 377.

Acknowledgements

The authors thank the University of Johannesburg, South Africa to carryout research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Samuel Ratna Kumar, P.S., Peter Madindwa, M. Investigation on Tribological Behaviour of Aluminosilicate Reinforced AA7075 Composites for Aviation Application. Trans Indian Inst Met 74, 79–88 (2021). https://doi.org/10.1007/s12666-020-02112-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02112-6