Abstract

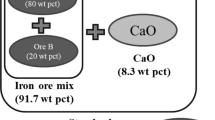

Iron-bearing by-products are rich in iron and carbon and are often reused in the iron ore sintering process. However, there are fewer studies on the effect of them on sintering flue gas pollutants. Four kinds of iron-bearing by-products were chosen to investigate the effect of them on the emission of SO2 and NOx and sinter quality through sinter-pot test. The results showed that all iron-bearing by-products promoted the emission of SO2, while steel slag tailings and mill scale inhibited the emission of NOx, and blast furnace dust and the sintering ESP dust promoted the emission of NOx. The main cause of blast furnace dust and the sintering ESP dust promoted the emission of SO2 and NOx was the residual unburned coke particles in them. The main cause of steel slag tailings and mill scale promoting the emission of SO2 and inhibiting the emission of NOx was the abundant iron oxides and calcium ferrite. In addition, the effect of them on sinter quality was slight. For reducing the emission of sintering flue gas pollutants, the addition ratio of blast furnace dust, steel slag tailings and mill scale should be controlled to be 1–3%, 3–4% and 2–5%, respectively. The sintering ESP dust from the 3rd electric field should not be added to raw materials, and the addition ratio of the dust from the 1st electric field and the 2nd electric field should be controlled to be 2–3%.

Similar content being viewed by others

References

Dusgupta R, and Reddy P S R, T Indian I Metals63 (2010) 859.

Jiang X, Han H L, Duan X G, and Hao Z Z, Sci Technol Rev29 (2011) 52 (in Chinese).

Wang N, Wang W, and Liu P Q, Meishan Technol1 (2016) 41 (in Chinese).

Meng F, Liu Q C, Zhu G T, Ren S, Zhu B H, Lan Y P, Liu G Q, and Niu D L, J Cent South Univ (Sci Technol)48 (2017) 31 (in Chinese).

Umadevi T, Brahmacharyulu A, Kathik P, Mahapatra P C, Prabhu M, and Ranjan M, Ironmak Steelmak39 (2012) 222.

Lanzerstorfer C, Bamberger-Strassmayr B, and Pilz K, ISIJ Int55 (2015) 758.

Gan M, Ji Z Y, Fan X H, Chen X L, Zhou Y, Wang G J, Tian Y, and Jiang T, J Hazard Mater353 (2018) 381.

Huang C J, Wang S J, Wu F, Zhu P, Zhou Z H, and Yi J M, Energ Source35 (2013) 1891.

Wu F, Wang S J, Zhang G, Zhu P, Wang Z Y, Chen S T, and Zhou Z, J Energy Inst87 (2014) 134.

Yu Z Y, Fan X H, Gan M, and Chen X L, J Iron Steel Res Int24 (2017) 1184.

Umadevi T, Karthik P, Mahapatra P C, Prabhu M, and Ranjan M, Ironmak Steelmak39 (2012) 180.

Mochόn J, Cores A, Ruiabustinza Í, Verdeja L F, Robla J I, and Garcia-Carcedo F, Dyna81 (2014) 168.

Huang W Q, Hu Q C, Hu B S, and Wang N, Min Metall26 (2017) 46 (in Chinese).

Nie H Y, and Li H P, Meishan Technol1 (2016) 57 (in Chinese).

EI-Hussiny N A, and Shalabi M E H, Sci Sinter42 (2010) 269.

Meng F, Liu Q C, Zhu G T, Ren S, Zhu B H, Lan Y P, Liu G Q, and Niu D L, J Central South Univ (Sci Technol)48 (2017) 31 (in Chinese).

Shatokha V I, Gogenko O O, and Kripak S M, Resour Conserv Recy55 (2011) 435.

Acknowledgements

This work was supported by the National Key Research and Development Program of China under Grant Nos. 2017YFB0603800 and 2017YFB0603802; National Natural Science Foundation of China under Grant No. 51234003.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qie, J.M., Zhang, C.X., Shangguan, F.Q. et al. Effect of Iron-Bearing By-products on the Emission of SO2 and NOx in the Iron Ore Sintering Process. Trans Indian Inst Met 73, 35–45 (2020). https://doi.org/10.1007/s12666-019-01801-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01801-1