Abstract

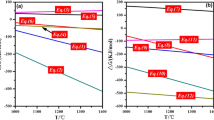

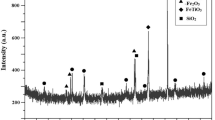

NO and SO2 are representative harmful gases generated in steel works, and iron ore sintering process accounts for more than 50 pct of total generation. The current study investigated the effects of adding CaO and FeO, which are the components contained in raw materials to sinter mix on the formation of NO and SO2. The addition of CaO to sinter mix promoted the formation of NO due to the catalytic effect of CaO. It also increased the conversion ratio of sulfur to SO2 by forming CaSO4 which then released SO2 as of 1200 °C. The addition of 5 wt pct of FeO significantly reduced the formation of NO and SO2, which could be believed that FeO reduced NO and SO2 by converting them to N2 and FeS, respectively. As the sources of CaO and FeO, calcined dolomite and mill scale with high potential for use in the steel industry were added to sinter mix to clarify their effects on the formation of NO and SO2. The addition of calcined dolomite increased the formation of NO more significantly due to the pores created by calcination and by the catalytic effects of CaO and MgO contained in calcined dolomite. The MgO in calcined dolomite also reacted with SO2 to form MgSO4 which was then thermally decomposed to release SO2 from 1000 °C. The added mill scale increased the formation of NO and SO2, which could be believed that the catalytic effect of Fe2O3 and Fe3O4 in mill scale on the formation of NO and SO2 might be more significant than the inhibiting effect of FeO on their formation.

Similar content being viewed by others

References

D. Fernandez-Gonzalez, I. Ruiz-Bustinza, J. Mochon, C. Gonzalez-Gasca, and L.F. Verdeja: Miner. Process. Extr. Metall. Rev., 2017, vol. 38, pp. 254–64.

M.S. Lee and S.C. Shim: ISIJ Int., 2004, vol. 44(3), pp. 470–75.

G. Li, C. Liu, M. Rao, Z. Fan, Z. You, Y. Zhang, and T. Jiang: ISIJ Int., 2014, vol. 54(1), pp. 37–42.

H. Yu, C. Zhang, and H. Wang: ISIJ Int., 2015, vol. 55(9), pp. 1876–81.

Y. Chen, Z. Guo, Z. Wang, and G. Feng: Int. J. Miner. Metall. Mater., 2009, vol. 16(2), pp. 143–48.

K. Katayama and S. Kasama: ISIJ Int., 2016, vol. 56(9), pp. 1563–69.

X. Gou, Y. Liu, S. Liu, Y. Cao, G. Li, and Q. Zhang: Fuel, 2020, vol. 270(117484), pp. 1–12.

H. Zhou, P. Ma, M. Zhou, Z. Lai, and M. Cheng: J. Energy Inst., 2019, vol. 92(5), pp. 1476–86.

J.M. Qie, C.X. Zhang, F.Q. Shangguan, X.P. Li, and J.C. Zhou: Trans. Indian Inst. Met., 2020, vol. 73, pp. 35–45.

Z. Ouyang, J. Zhu, Q. Lu, Y. Yao, and J. Liu: Fuel, 2014, vol. 120, pp. 116–21.

L. Tomas da Rocha, H. Kim, C. Lee, and S.M. Jung: Metall. Mater. Trans. B, 2020, vol. 51, pp. 2068–78.

L.N. Wu, Z.Y. Tian, W. Qin, X.Y. Hu, and C.Q. Dong: Proc. Combust. Inst., 2020, vol. 38(4), pp. 5355–62.

G.L. Wu, R.T. Guo, Y.Z. Liu, C.P. Duan, Y.F. Miao, J.W. Gu, and W.G. Pan: Chem. Pap., 2021, vol. 74, pp. 2495–501.

R.H. Borgwardt and K.R. Bruce: AIChE J., 1986, vol. 32(2), pp. 239–46.

G.A. Simons, A.R. Garman, and A.A. Boni: AIChE J., 1987, vol. 33(2), pp. 211–17.

M.J. Munoz-Guillena, A. Linares-Solano, and C. Salinas-Martinez de Lecea: Appl. Surf. Sci., 1994, vol. 81, pp. 409–15.

M.J. Munoz-Guillena, A. Linares-Solano, and C. Salinas-Martinez de Lecea: Appl. Surf. Sci., 1994, vol. 81, pp. 417–25.

K. Zhang, S. Yang, S. Liu, J. Shangguan, W. Du, Z. Wang, and Z. Chang: ACS Omega., 2020, vol. 5, pp. 3047–54.

E. Kasai, T. Sugiyama, and Y. Omori: Tetsu-to-Hagane, 1994, vol. 80(4), pp. 282–87.

E. Kasai and F. Saito: Kagaku Kogaku Ronbunshu, 1994, vol. 20(6), pp. 857–63.

S. Wu, T. Sugiyama, K. Morioka, E. Kasai, and Y. Omori: Tetsu-to-Hagane., 1994, vol. 8(4), pp. 276–81.

B.V. Reddy and S. N. Khanna: Phys. Rev. Lett., 2004, vol. 93(6), pp. 068301-1-4.

Z. G. Que, X. B. Ai and S.L. Wu: Int. J. Miner. Metall. Mater., 2020, pp. 1–23.

W. Mayangsari and A. B. Prasetyo: IOP Conf. Ser.: Mater. Sci. Eng., 2017, vol. 202 (012016), pp. 1–10.

S. Cho, L. Tomas da Rocha, B.J. Chung, and S.M. Jung: Metall. Mater. Trans. B, 2022, vol. 53B, pp. 84–95.

T. Umadevi, P. Karthik, P.C. Mahapatra, M. Prabhu, and M. Ranjan: Ironmak. Steelmak., 2012, vol. 39(3), pp. 180–89.

H. Qichen, W. Chunliang, S. Jianghuan, W. Na, and H. Binsheng: Int. J. Miner. Process. Extract. Metall., 2019, vol. 4(1), pp. 1–6.

L. Tomas da Rocha, B.J. Chung, and S.M. Jung: J. Sustain. Metall., 2021, vol. 7, pp. 377–90.

D.G. Gavin and M.A. Dorrington: Fuel., 1993, vol. 72, pp. 381–88.

Z. Zhao, W. Li, J. Qiu, X. Wang, and B. Li: Fuel., 2006, vol. 85, pp. 601–06.

Z. Zhao, W. Li, J. Qiu, and B. Li: Fuel., 2003, vol. 82, pp. 1839–44.

J. Wu, B. Wang, H.H. Lou, F. Yang, and F. Cheng: Asia-Pac. J. Chem. Eng., 2016, vol. 11, pp. 735–42.

W. Lv, X. Fan, X. Min, M. Gan, X. Chen, and Z. Ji: ISIJ Int., 2018, vol. 58(2), pp. 236–43.

R. Marouf, K.M. Khelifa, J. Schott, and A. Khelifa: Microporous Mesoporous Mater., 2009, vol. 122, pp. 99–104.

C. Chen, F. Chen, Z. Chen, Q. Chan, S. Kook, and G. Yeoh: J. Energy Inst., 2016, vol. 90(5), pp. 806–12.

J. Hammerschmidt and M. Wrobel: Sulphur and Sulphuric Acid Conference, The Southern African Institute of Mining and Metallurgy, 2009, vol. 87, pp. 87–100.

Y. Tardy and L. Gartner: Contrib. Mineral. Petrol., 1977, vol. 63, pp. 89–102.

M.N. Scheidema and P. Taskinen: Ind. Eng. Chem. Res., 2011, vol. 50, pp. 9550–56.

C. W. Bale, P. Chartrand, S. A. Degterov, G. Eriksson, K. Hack, R. Ben Mahfoun, J. Melancon, A. D. Pelton and S. Petersen: Calphad, 2002, vol. 26 (2), pp. 189–228.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 27, 2021; accepted March 15, 2022.

Rights and permissions

About this article

Cite this article

Cho, S., Tomas da Rocha, L., Chung, BJ. et al. Effects of Adding Calcined Dolomite and Mill Scale to Sinter Mix on the Formation of NO and SO2 in Iron Ore Sintering Process. Metall Mater Trans B 53, 1936–1947 (2022). https://doi.org/10.1007/s11663-022-02504-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02504-7