Abstract

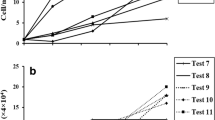

Consumption of zinc metal has been rapidly increased in the world. Zinc metal exists as oxide, sulfide, carbonate and silicate ores, among which zinc oxide ores have not been mined because it is very difficult to separate zinc from gangue or to concentrate using the conventional flotation processes. In the current study, a low-grade zinc oxide ore containing 5.9% Zn, 33.4% Fe and 13.7% Mn was selected to investigate direct leaching. Results of the direct leaching at conventional conditions showed that the Zn leaching efficiency was improved at high acidity, high temperature and grinding conditions and reached about 60% at temperature of 50 °C, d80 of 110 microns, leaching time of 120 min and sulfuric acid consumption of 3.3 kg/kg Zn. Results showed that between 20 and 30% of zinc is associated with other species containing manganese IV. In the reductive leaching experiments by using Na2SO3 as reductant, the maximum Zn and Mn leaching efficiencies are about 82.7% and 96.2%. Dissolving high manganese as impurity in the pregnant solution is a potential concern with the reductive leaching process that needs further investigation.

Similar content being viewed by others

References

Abkhoshk E, Jorjani E, Al-Harahsheh M S, Rashchi F, and Naazeri M, Hydrometallurgy 149 (2014) 153.

Antuñano N, Cambra J F, and Arias P L, Hydrometallurgy 161 (2016) 65.

Jia N, Wang H-G, Zhang M, and Guo M, Miner Process Extr Metall Rev 37 (2016) 418.

Yanbo S and Xin T, Procedia Environ Sci 31 (2016) 195.

Bulatovic: ‘13 - Flotation of Copper–Zinc Ores’ S M Handbook of Flotation Reagents, Amsterdam, Elsevier (2007), p. 295.

de Wet J R and Singleton J D, J South Afr Inst Min Metall 108 (2008) 253.

Moradkhani D, Khodakarami S B M, and Ataei I, Physicochem Problems Miner Process 50 (2014) 735.

Filippou D, Miner Process Extr Metall Rev 25 (2004) 205.

Martin D, Diaz G, García M A, and Sanchez F, J South Afr Inst Min Metall 102 (2002) 463.

Fuls H F and Petersen J, J South Afr Inst Min Metall 113 (2013) 00.

El Hazek M N, Lasheen T A, and Helal A S, Hydrometallurgy 84 (2006) 187.

Qin W-Q, Lan Z-Y, and Li W-Z, J Cent South Univ Technol 10 98.

Zhang Q B and Hua Y, Hydrometallurgy 99 (2009) 249.

Zhang W and Cheng C Y, Hydrometallurgy 89 (2007) 178.

Soltani F, Abdollahy M, Petersen J, Ram R, Becker M, Koleini S J, and Moradkhani D, Hydrometallurgy 177 (2018) 66.

Bera S, Prince A A M, Welmurugan S, Raghavan P S, Gopalan R, Panneerselvam G, and Narasimhan S V, J Mater Sci 36 (2001) 5379.

Su H, Wen Y, Wang F, Sun Y, and Tong Z, Hydrometallurgy, 93 (2008) 136.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soltani, F., Aram, R., Aazami, M. et al. Direct Leaching of Low-Grade Zinc Oxide Ore Containing High Amounts of Iron and Manganese. Trans Indian Inst Met 72, 1371–1380 (2019). https://doi.org/10.1007/s12666-019-01635-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01635-x