Abstract

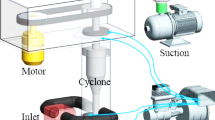

Classifiers have found wide applications in the mineral processing industry. In this study, a novel enhanced gravity closed spiral classifier is presented. This device uses induced centrifugal force to classify particles. A functional prototype of the separator was 3D printed to experimentally validate the concept. The performance characteristics of the classifier were established by conducting experiments under different process and design conditions. Silica slurries with particle loading of 5–15 wt% were used in this work as a model system. The particle size distribution analysis was performed using laser scattering particle size distribution analyser (LSPSDA). The effects of particle loading, velocity of feed stream, and number of turns of spiral were explored. The equipment could be used in many applications ranging from size (mass) classification to disposing of unwanted gangue.

Similar content being viewed by others

References

Lu L, Iron Ore: Mineralogy, Processing and Environmental Sustainability, Woodhead Publishing, Cambridge (2015).

Pradip, Int J Miner Met Mater Eng 59 (2006) 551.

Svarovsky L, Solid–Liquid Separation, Butterworth–Heinemann, Oxford (2000) p 1.

Davailles A, Climent E, and Bourgeois F, Sep Purif Technol 92 (2012) 152.

Banerjee C, Climent E, and Majumder A K, Chem Eng Sci 152 (2016) 724.

Reay D, Ramshaw C, and Harvey A, Process Intensification: Engineering for Efficiency, Sustainability and Flexibility, Butterworth–Heinemann, Oxford (2013).

Richards R G, Hunter D M, Gates P J, and Palmer M K, Miner Eng 13 (2000) 65.

Burt R O, and Mills C, Gravity Concentration Technology, Elsevier, Amsterdam (1984) p 226.

Kapur P C, and Meloy T P, Int J Miner Process 53 (1998) 15.

Kapur P C, and Meloy T P, Powder Technol 102 (1999) 244.

Bazin C, Sadeghi M, and Renaud M, Miner Eng 91 (2016) 74.

Doheim M A, Abdel Gawad A F, Mahran G M A, Abu Ali M H, and Rizk A M, Appl Math Model 37 (2013) 198.

Dixit P, Tiwari R, Mukherjee A K, and Banerjee P K, Powder Technol 275 (2015) 105.

Sadeghi M, Bazin C, and Renaud M, Int J Miner Process 153 (2016) 51.

Hseih K T, and Rajamani K, AIChE J 37 (1991) 735.

Hseih K T, and Rajamani K, Int J Miner Process 22 (1988) 223.

Vega-Garcia D, Brito-Parada P R, and Cilliers J J, Chem Eng J 350 (2018) 653.

Delgadillo J A, and Rajamani K R, Int J Miner Process 84 (2007) 252.

Yang Q, Wang H L, Liu Y, and Li Z, Sep Purif Technol 74 (2010) 271.

Ghodrat M, Kuang S B, Yu A B, Vince A, Barnett G D, and Barnett P J, Miner Eng 62 (2014) 74.

Vakamalla T R, Kumbhar K S, Gujjula R, and Mangadoddy N, Sep Purif Technol 138 (2014) 104.

Zhang C, Wei D, Cui B, Li T, and Luo N, Powder Technol 305 (2017) 156.

Hwang K J, and Chou S P, Sep Purif Technol 172 (2017) 76.

Vakamalla T R, and Mangadoddy N, Sep Purif Technol 176 (2017) 23.

Jain V, Rai B, Umesh V, Waghmare UV, Tammishetti V, and Pradip, Trans Indian Inst Met 66 (2013) 447.

Tammishetti V, Kumar D, Rai B, Pradip, Shukla V, Patra A S, Chakraborty D P, and Kumar A, Trans Indian Inst Met 70 (2017) 411.

Subramanian S, Pukkella A K, and Vysyaraju R, Indian Patent (Filed).

Pukkella A K, Vysyaraju R, and Subramanian S, AIChE J (2018) (under review).

Xu Y, Li Y, Zhang Y, Yang, and Wang H, Chem EngTechnol 39 (2016) 567.

Subramanian S, Tammishetti V, Rai B, and Pradip, Int J Miner Process 146 (2016) 1.

Narasimhan S, and Jordache C, Data Reconciliation and Gross Error Detection: An Intelligent Use of Process Data, Gulf Publishing Company, Houston (2000).

Plitt L R, and Kawatra S K, Int J Miner Process 5 (1979) 369.

AIChE Equipment Testing Procedure, Particle Size Classifiers, Wiley, Hoboken (1993).

Vakamalla T R, Koruprolu V B R, Arugonda R, and Mangadoddy N, Sep Purif Technol 175 (2017) 481.

Zhu G, and Liow J L, Chem Eng Sci 111 (2014) 94.

Bourgeois F, and Majumder A K, Powder Technol 237 (2013) 367.

Nageswararao K, Chem Eng J 80 (2000) 251.

Nageswararao K, and Karri B, Sep Purif Technol 158 (2016) 31.

Nageswararao K, and Medronho R A, Int J Miner Process 132 (2014) 43.

Acknowledgements

The authors deeply acknowledge the support of Mr. K. Ananth Krishnan, CTO, Tata Consultancy Services (TCS), in pursuing this research. The authors are grateful to Dr. Pradip, Dr. Beena Rai, and Dr. Venkataramana Runkana for their guidance and encouragement. We express our thanks to our laboratory assistants Mr. Yasin Shaikh, Mr. Sudam Konelu, and Mr. Rupesh Shinde.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The corrected separation efficiencies have been calculated using Eq. (7). The bypass parameter Bp is calculated as the minimum separation efficiency obtained in the experimentally observed efficiency curve. In most of the curves, the minimum efficiency due to the fish-hook behavior is observed to be near the particle size of ~ 20 μm. The D25c, D50c, and D75c are then calculated from the corrected separation efficiency curves. From Fig. 9, it is observed that corrected separation efficiency is stable for variation in particle loading of 5 to 15 wt%. From Figs. 10 and 11, it can be seen that the corrected separation efficiency curves are improving with increase in the feed velocity and the number of turns.

Rights and permissions

About this article

Cite this article

Vysyaraju, R., Pukkella, A.K. & Subramanian, S. Experimental Investigation of Novel Enhanced Gravity Closed Spiral Classifier. Trans Indian Inst Met 72, 2239–2248 (2019). https://doi.org/10.1007/s12666-019-01589-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01589-0