Abstract

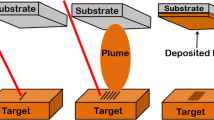

The present study reports the systematic study on the effect of film thickness on the optical and electrical properties of transparent tetragonal (α) WO3 phase, synthesized using pulsed laser deposition. The WO3 films of various thicknesses 250 ± 4 (S1), 350 ± 2 (S2), 750 ± 5 (S3) and 1150 ± 4 (S4) nm were obtained by varying the deposition time 8, 15, 30 and 60 min, respectively. The films were post-annealed at 500 °C for 1 h in the open atmosphere and extensively characterized using X-ray diffraction (XRD), atomic force microscopy (AFM), Raman spectroscopy, UV–Vis–NIR spectrophotometer and four-probe resistivity. The Rietveld analysis of XRD pattern revealed the presence of mixed orthorhombic and tetragonal crystalline phases in the S1 (250 ± 4 nm) film. A pure tetragonal crystalline phase of WO3 was observed in rest of the films. The Raman spectroscopic study also revealed the high-temperature WO3 phase formation. The grain size and surface roughness obtained from the AFM micrographs varied from 10 to 50 nm and 9.1 to 10.9 nm, respectively. The optical band gaps were found to decrease as 3.47, 3.28, 3.08 and 3.06 eV with the increase in the film thickness S1, S2, S3 and S4, respectively. The resistivity of the films was found to increase with an increase in film thickness. However, the decrease in the resistivity with an increase in the temperature revealed the semiconducting behavior of all the films. The activation energy was found to increase with the increase in the thickness of α-WO3 film.

Similar content being viewed by others

References

Castro-Hurtado I, Tavera T, Yurrita P, Pérez N, Rodriguez A, Mandayo G G, Castaño E, Appl Surf Sci 276 (2013) 229.

Sivakumar R, Gopalakrishnan R, Jayachandran M, Sanjeeviraja C, Opt Mater 29 (2007) 679.

Malin B J, Gustavo B, Iryna V, Clas P, Hans A, Gunnar A N, Lars Ö, J Phys Condens Matter 25 (2013) 205502.

Zou Y S, Zhang Y C, Lou D, Wang H P, Gu L, Dong Y H, Dou K, Song X F, Zeng H B, J Alloys Compd 583 (2014) 465.

Niklasson G A, Granqvist C G, J Mater Chem 17 (2007) 127.

Yang C, Chen J-F, Zeng X, Cheng D, Cao D, Ind Eng Chem Res 53 (2014)17981.

Tahir M B, Nabi G, Rafique M, Khalid N R, Int J Environ Sci Technol 14 (2017) 2519.

Su P-G, Peng Y-T, Sens Actuators B 193 (2014) 637.

Woodward P M, Sleight A W, Vogt T, J Solid State Chem 131 (1997) 9.

Righettoni M, Pratsinis S E, Mater Res Bull 59 (2014) 199.

Boulova M, Lucazeau G, J Solid State Chem 167 (2002) 425.

Ponzoni A, Comini E, Ferroni M, Sberveglieri G, Thin Solid Films 490 (2005) 81.

Panda A K, Singh A, Thirumurugesan R, Kuppusami P, Mohandas E, J Instrum 10 (2015) 09014.

Badilescu S, Ashrit P V, Solid State Ion 158 (2003) 187.

Sobia A, Christopher S B, Simon C N, Ivan P P, Meas Sci Technol 19 (2008) 025203.

Guojia F, Zuli L, Yao K L, J Phys D 34 (2001)2260.

Yamamoto S, Inouye A, Yoshikawa M, Nucl Instrum Methods Phys Res B 266 (2008) 802.

Stankova N E, Atanasov P A, Stanimirova T J, Dikovska A O, Eason R W, Appl Surf Sci 247 (2005) 401.

Ramana C V, Utsunomiya S, Ewing R C, Julien C M, Becker U, J Phys Chem B 110 (2006) 10430.

Fumiaki M, Eiichi H, Tomoaki I, Kenji E, Raj Kumar T, Jpn J Appl Phys 41 (2002) 5372.

Mitsugi F, Hiraiwa E, Ikegami T, Ebihara K, Surf. Coat. Technol. 169–170 (2003) 553.

Zhao Y, Feng Z-C, Liang Y, Sens. Actuators, B 66 (2000) 171.

Smits F M. Bell Labs Tech J 37 (1958) 711.

Rietveld H, Acta Crystallogr 22 (1967) 151.

Rietveld H, J Appl Crystallogr 2 (1969) 65.

Lutterotti L, Scardi P, J Appl Cryst 23 (1990) 246.

Kubo T, Nishikitani Y, J Electrochem Soc 145 (1998)1729.

Shigesato Y, Murayama A, Kamimori T, Matsuhiro K, Appl Surf Sci 33–34 (1988) 804.

Wu W, Yu Q, Lian J, Bao J, Liu Z, Pei S-S, J Cryst Growth 312 (2010) 3147.

Weckhuysen B M, Schoonheydt R A, Catal Today 49 (1999) 441.

Dhonge B P, Mathews T, Sundari S T, Thinaharan C, Kamruddin M, Dash S, Tyagi A K, Appl Surf Sci 258 (2011) 1091.

Ekimov A I, Efros A L, Onushchenko A A, Solid State Commun 56 (1985) 921.

Aguir K, Lemire C, Lollman D B B, Sens Actuators B 84 (2002) 1.

Kaneko H, Miyake K, Teramoto Y, J Appl Phys 53 (1982) 3070.

Acknowledgements

The authors thank Dr. S. Raju, Head PMD/MCG/IGCAR, and Dr. Saroja Saibaba, Associate Director MCG/IGCAR, for their constant encouragement and motivation during the project. Experimental support rendered by Ms. M. Jyothi and Dr. Niranjan Kumar (SND/MSG/IGCAR) is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dhonge, B.P., Singh, A., Panda, A.K. et al. Synthesis of α-WO3 Thin Film Using Pulsed Laser Deposition: Influence of Thickness on Optical and Electrical Properties. Trans Indian Inst Met 72, 733–740 (2019). https://doi.org/10.1007/s12666-018-1525-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1525-3