Abstract

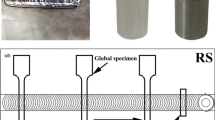

In the present study, structural steel plates of thickness 3 mm were welded using friction stir welding with the help of a tungsten carbide tool using welding speed of 20 mm/min and tool rotation speed of 508 rpm. The friction stir weld joints were characterized in respect of microstructure, hardness and tensile properties. The stir zone of the weld revealed the refined grain structure of ferrite, fine pearlite and martensite were also confirmed by XRD. Further, the hardness distribution of the weld joint exhibited higher hardness at the weld nugget than base metal and heat affected zone. The weld sample exhibited higher strength and lower ductility than the base metal. The tensile properties of the all weld samples taken from longitudinal direction were better than those taken from transverse direction. Influence of post weld heat treatment of FSW joints of steel on microstructure and mechanical properties was also investigated.

Similar content being viewed by others

References

Sharma C, Dwivedi D K, and Kumar P, Mater Des 36 (2012) 379.

Arora S K, Panday S, Schaper M, and Kumar R, Int J Adv Manuf Technol 50 (2010) 941.

Jagadeesha C B, Mater Sci Eng A 616 (2014) 55.

Wei S, Hao C, and Chen J, Mater Sci Eng A 452–453 (2007) 170.

Singh R K R, Sharma C, Dwivedi D K, Mehta N K, and Kumar P, Mater Des 32 (2011) 682.

Liu X, Lan S, and Ni J, Mater Des 59 (2014) 50.

Mishra R S, and Ma Z Y, Mater Sci Eng 50 (2005) 1.

Jafarzadegan M, Abdollah-zadeh A, Feng A H, Saeid T, Shen J, and Assadi H, J Mater Sci Technol 29 (2013) 367.

Cho H H, and Han H N, Mater Sci Eng A 528 (2011) 2889.

Meshram S D, Reddy G M, and Pandey S, Mater Des 49 (2013) 58.

Lienert T J, Stellwag W L, Grimmett B B, and Warke R W, Am Wel Soc (2013) 1.

Lakshminarayanan A K, Balasubramanian V, and Salahuddin M, J Iron Steel Res Int 17 (2010) 68.

ASTM International standard E-8. Standard test methods for tension testing of metallic materials.

Peelamedu R D, Roy R, and Agrawal D K, Mater Lett 55 (2002) 234.

Kou S, Welding Metallurgy, Wiley, New Jersey (2003) p 343.

Gong Y L, Wen C E, Li Y C, Wu X X, Cheng L P, Han X C, and Zhu X K, Mater Sci Eng A 569 (2013) 144.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, G., Dwivedi, D.K. Structure and Properties of Friction Stir Weld Joints of Structural Steel. Trans Indian Inst Met 70, 201–208 (2017). https://doi.org/10.1007/s12666-016-0876-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0876-x