Abstract

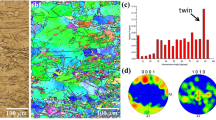

In this paper, the influence of process parameters on microstructural characteristics & mechanical properties of AZ80A Mg alloy during friction stir welding (FSW) are investigated in a detailed manner. The tensile fracture surfaces obtained from successfully fabricated joints are subjected to tensile tests and microstructural investigations were done using scanning electron microscope. From the experimental results, the joints produced under a 5 kN axial force value at 1000 rpm and at a feed rate of 1.5 mm/min were found to exhibit superior mechanical properties and metallurgically defect free weldments when compared with other joints. The chemical compositions of these defect free joints were analyzed using energy dispersive spectrometry. Moreover, ideal level of heat generation, uniform flow of the plasticized material and formation of fine grain structure with uniform distribution in the FSW zone were found to be the main reasons for these superior mechanical properties and flawless joints.

Similar content being viewed by others

References

Friedrich H and Schumann S, J Mater Process Technol 117 (2001) 276.

Lee W B, Kim M J W, Yeon Y M and Jung S B, J Mater Trans 44 (2003) 917.

Fechner D, Blawert C, Hort N, Dieringa H and Kainer K U, Mater Sci Eng A 576 (2013) 222.

Razal Rose A, Manisekar K, Balasubramanian V and Rajakumar S, Mater Des 37 (2012) 334.

Sevvel P and Jaiganesh V, Appl Mech Mater 594 (2014) 312.

Feng A H and Ma Z Y, Scripta Mater 56 (2007) 397.

Bozzi S, Helbert-Etter A L, Baudin T, Klosek V, Kerbiguet J G and Criqui B, J Mater Process Technol 210 (2010) 1429.

Liu H J, Hou J C and Guo H, Mater Des 50 (2013) 872.

Jaiganesh V and Sevvel P, Adv Mater Res 985 (2014) 604.

Torres M, Effect of process parameters on temperature distribution, microstructure, and mechanical properties of self-reacting friction stir welding aluminum alloy 6061-T651, The University of Texas, El Paso (2011).

Yuana W, Mishra R S, Webb S, Chen Y L, Carlson B and Herling D R, J Mater Process Technol 211 (2011) 972.

Firouzdor V and Kou A, J Metall Mater Trans A 41 (2010) 2914.

Acknowledgments

The authors gratefully thank the Management and Mechanical Engg Dept., S.A Engineering College, Chennai, India for providing the welding equipment facilities. The authors wish to express thanks to All India Council for Technical Education (AICTE) Govt. of INDIA, funded project (Grant No. 8023/RID/RPS/037/2011-12) for sponsoring FSW machine.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jaiganesh, V., Sevvel, P. Effect of Process Parameters on the Microstructural Characteristics and Mechanical Properties of AZ80A Mg Alloy During Friction Stir Welding. Trans Indian Inst Met 68 (Suppl 1), 99–104 (2015). https://doi.org/10.1007/s12666-015-0620-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0620-y