Abstract

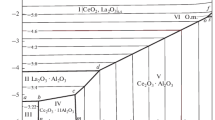

Deoxidation of liquid steel involves consumption of high energy materials like ferro alloys and generation of deoxidation products which could be entrapped into liquid steel as non-metallic inclusions. The present investigation is focused on deoxidation of liquid steel, considering mainly aluminium and silicon as deoxidizer. A simple and realistic mathematical model of deoxidation of liquid steel has been developed based on the thermodynamic principles and material balance approach for day to day industrial practice. One of the main aims of the theoretical study was to predict the amount of deoxidizers required for a given steel composition. A methodology has also been developed to predict the stability of different oxides expected to be present in liquid steel after deoxidation. Model predictions have been compared with the industrial data as well as results obtained from commercial thermodynamic software package FactSage 6.4, simulated under identical conditions. Model predictions are in reasonable agreement with the ferro alloy consumption in industrial steelmaking processes.

Similar content being viewed by others

References

Ren Y, Zhang L, and LI S, ISIJ Int 54 (2014) 2772.

Yu J Y, Kang Y, and Sohn I, Metall Mater Trans B 45 (2014) 113.

Yan P, Huang S, Pandelaers L, Van Dyck J, Guo M, and Blanpain B, Metall Mater Trans B 45 (2013) 1105.

Park J S, and Park J H, Metall Mater Trans B 45B (2014) 953.

Deng Z Y, and Zhu M Y, ISIJ Int 53 (2014) 1498.

Marie-Aline, Formation and Morphology of non-Metallic Inclusions in Aluminium Killed Steels, PhD Thesis, Université Catholique de Louvain, Belgium (2009).

Reis B H, Bielefeldt W V, and Vilela A C F, ISIJ Int 54 (2014) 1584.

Zaitsev A I, Rodionova I G, Shaposhnikov N G, Zemlyanko O A, and Karamisheva N A, J Phys Conf Ser 98 (2008) 1.

Mapelli C, Steel Res Int 77 (2006) 462.

Kobayashl S, ISIJ Int 42 (1999) 664.

Zhang X, Roelofs H, Lemgen S, Urlau U, and Subramanian S V, Steel Res Int 75 (2004) 314.

Doostmohammadi H, A Study of Slag/Metal Equilibrium and Inclusion Characteristics during Ladle Treatment and after Ingot Casting, PhD Thesis, KTH Royal Institute of Technology (2009).

Prasad A D, and Sankaranarayanan S R, J Min Metall B 48 (2012) 37.

Dekkers R, Chapter 5 Deoxidation in Low Carbon Steel Killed with Aluminium, PhD Thesis, Katholieke Universiteit Leuven (2002).

Björklund J, Thermodynamic Aspects on Inclusion Composition and Oxygen Activity during Ladle Treatment, Doctoral Thesis, KTH Royal Institute of Technology (2008).

Oeters F, Metallurgy of Steelmaking, English edition, STAHL EISEN (1994) 1. English edition.

Gosh A, Secondary Steelmaking: Principles and Applications, CRC Press, Boca Raton (2001).

Ohta H, and Suito H, Metall Mater Trans B 29 (1998) 119.

Jung I H, Decterov S A, and Pelton A D, Metall Mater Trans B 35 (2004) 493.

Adolf Z, Husar I, Suchánek P, Mater Tehnol 42 (2007) 185.

Mattias Ek, Know the Unknown: How carry-over Slag Varies and How it Impacts on the Processing and Product Quality in Metals Production, Personal Communication, Metsol AB Technical Report (2013).

Alexis J, Andersson M, Björkvall J, Sichen D, Sandberg A, Optimization of Secondary Metallurgy with Respect to Non: Metallic Inclusions, Technical Report, Jernkontoret (2011).

Smirnov A N, Pismarev K E, Kuberskiy S V, Metall Min Ind (2010) 3.

Venkatesan J, Ashok K, Venkatakrishnan P G, in proceedings of International Conference on Science and Technology of Iron and Steelmaking (2013).

Ashok K, Theoretical and Experimental Investigation on Deoxidation of Liquid Steel, M.Tech Thesis, AcSIR (2014).

Pretorius E B, and Marr R, Unpublished research (www.etech.lwbref.com).

Kiessling R, and Lang N, Non-Metallic Inclusions in Steel, The Metal Society publications, London (1968).

Fruehan R J, Ladle Metallurgy Principles and Practices, UMI Publication, Warrendale (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ashok, K., Mandal, G.K. & Bandyopadhyay, D. Theoretical Investigation on Deoxidation of Liquid Steel for Fe–Al–Si–O System. Trans Indian Inst Met 68 (Suppl 1), 9–18 (2015). https://doi.org/10.1007/s12666-015-0574-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0574-0