Abstract

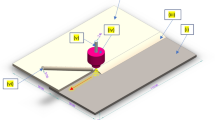

The emerging demand of light weight alloys and composites for the engineering and structural applications leads to explore the possibility to develop new techniques to achieve materials of high performance. In the present study, Al–B4C reinforced composite has been developed via semi solid technique. The influence of Boron carbide (B4C) content on the dry sliding wear characteristics of Al6061 matrix composites has been assessed using a pin-on-disc wear test. Wear rate was found to increase in ascending order with B4C particles content. On comparing the wear rate, it has been found that the wear resistance offered by coated B4C reinforced Al 6061 alloy matrix composites is higher than both base Al alloy and uncoated composites with incorporation of harder phase. This shows the good interfacial bonding of coated B4C and Al6061 alloy matrix phase.

Similar content being viewed by others

References

Mazahery A, and Shabani M O, Powder Tech 225 (2012) 101.

Shabani M O, and Mazahery A, Metall Mater Trans A 43 (2012) 2158.

Barati M, and Claytor G, J Mater Sci 39 (2007) 567.

Shabani M O, and Mazahery A, Trans Indian Inst Met 65 (2012) 77.

Pyzik A J, and Aksay I A, Processing of ceramic and metal matrix composites, In: Proceedings of the International Symposium on Advances in Processing of Ceramic and Metal Matrix Composites, New York, (1989), p 269.

Pyzik A J, and Beaman D R, J Am Ceram Soc 78 (1995) 305.

Rhee S K, J Am Ceram Soc 53 (1970) 386.

Mazahery A, Alizadeh M, and Shabani M O, Trans Indian Inst Met 65 (2012) 393.

Vugt L V, and Froyen L, J Mater Process Technol 104 (2000) 133.

Irons G A, and Owusu-Boahen K, Metall Mater Trans B 26 (1995) 980.

Gowri S, and Samuel F H, Metall Trans A 23 (1992) 3369.

Gupta M, Lu L, and Ang S E, J Mater Sci 32 (1997) 1261.

Karnezis P A, Durrant G, and Cantor B, Mater Charact 40 (1998) 97.

Mazahery A, and Shabani M O, Trans Indian Inst Met 65 (2012) 145.

Quaak C J, and Kool W H, Mater Sci Eng A 188 (1994) 277.

Shabani M O, and Mazahery A, Ceram Int 38 (2012) 4541.

Mazahery A, and Shabani M O, JOM 64 (2012) 323.

Leon C A, and Drew R L, J Mater Sci 35 (2000) 4763.

Davidson A M, and Regener D, Compos Sci Technol 60 (2000) 865.

Mazahery A, and Shabani M O, Compos Part B 43 (2012) 1302.

Fard R R, and Akhlaghi F, J Mater Process Technol 187–188 (2007) 433.

Shabani M O, and Mazahery A, Mater Tehnol 46 (2012) 109.

Moustafa S F, Badry S A, Sanad A M, and Kieback B, Wear 253 (2002) 699.

Zhan Y Z, and Zhang G, Mater Lett 57 (2003) 4583.

Mazahery A, and Shabani M O, Ceram Int 38 (2012) 4263.

McKimpson M G, and Scott T E, Mater Sci Eng 107 (1989) 93.

Ozdemir I, Cocen U, and Onel K, Compos Sci Technol 60 (2000) 411.

Mazahery A, and Shabani M O, J Mater Eng Perform 21 (2012) 247.

Shabani M O, and Mazahery A, JOM 63 (2011) 132.

Bauri R, and Surappa M K, J Mater Process Technol 209 (2009) 2077.

Petalas Y G, Antonopoulos C G, Bountis T C, and Vrahatis M N, Phys Lett 373 (2009) 334.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mazahery, A., Shabani, M.O. Ascending Order of Enhancement in Sliding Wear Behavior and Tensile Strength of the Compocast Aluminum Matrix Composites. Trans Indian Inst Met 66, 171–176 (2013). https://doi.org/10.1007/s12666-012-0238-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-012-0238-2